Professional Documents

Culture Documents

Mechanical Nonlin 13.0 WS 09A Diagnostics

Uploaded by

Shaheen S. RatnaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Nonlin 13.0 WS 09A Diagnostics

Uploaded by

Shaheen S. RatnaniCopyright:

Available Formats

Customer Training Material

W k h 9A Workshop Contact Diagnostics g

ANSYS Mechanical Structural Nonlinearities

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved. Release 13.0 December 2010

WS9A-1

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Goal

Customer Training Material

Diagnose convergence trouble with surface body contact model

Model Description

3D Spring plate Surface Body 3D Rigid Target Body Linear steel material Meshed with 3D SHELL elements Spring Fixed support at one end, A Rigid Body displaced into Spring 19mm

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-2

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Steps to Follow:

Restore Archive browse for file W9a-diagnostics.wbpz

Customer Training Material

Save as

File name: W9a-diagnostics Save as type: Workbench Project Files (*.wbpj) ( .wbpj)

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-3

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

The project Schematic should look like the picture to the right.

From this Schematic, , you y can see that the Engineering (material) Data and Geometry have already been defined (green check marks). It remains to set up and run the FE model in M h i l Mechanical Highlight the Engineering Data Cell and open by clicking on the Right Mouse Button (RMB)=>Edit to verify the linear material properties. Verify y that the units are in Metric(Tonne,mm,..) ( , , ) system. If not, fix this by clicking on Utility Menu=>Units=>Metric(Tonne, mm,..)

Customer Training Material

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-4

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Return to Project Schematic

Utility Menu > Return to Project

Customer Training Material

D Double bl click li k on the th Model M d l Cell C ll to t open the th FE Model M d l (Mechanical (M h i l Session) (or RMB=>Edit)

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-5

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Unit > Metric (mm,kg,N,s,mV,mA)

Customer Training Material

Once inside the Mechanical application, verify the working unit system The spring assembly is already set up with frictionless contact pairs, a fixed boundary condition and a displacement load on the rigid component. component Highlight the entities beneath each folder to become familiar with the model and to confirm that it is properly supported and loaded and ready to solve.

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-6

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

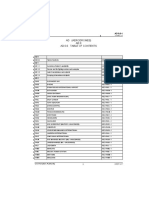

Confirm the Analysis Settings Specifications as shown:

Customer Training Material

Run the Solution Solution

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-7

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

The model solves without error.

Customer Training Material

After solution run is complete, highlight the Solution Information folder and scroll to near the bottom of the output.

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-8

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Review the Total Deformation results.

Customer Training Material

Something is wrong. The contact relationship between the two parts has obviously failed.

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-9

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Customer Training Material

With 25 initial substeps and Auto Time Stepping turned On, the contact should have engaged. In an effort to determine the problem, we will evaluate what the initial condition of the contact pairs are. Highlight the Connections Folder: RMB> Insert> Contact Tool

Highlight the Contact Tool: RMB>Initial Information>Generate Initial Contact Results. This will run a partial solve to establish initial contact parameters (i,e. Initial status, gap, penetration, etc).

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-10

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Review the Initial Contact Information. Note the following:

The two active pairs both have an initial status of Far Open Both B th pairs i have h a pinball i b ll radius di of f 4mm. 4 Is I 4mm 4 enough? h?

Customer Training Material

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-11

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Customer Training Material

By studying a profile of the undeformed geometry we can see that the initial gap is less then 1.50mm. Hence, the Pinball Radius of 4mm should be sufficient for this contact pair to be in an initial status of near-open.

Rigid Target Spring

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-12

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Customer Training Material

Hi Highlight hli ht the th contact t t region i representing ti the th contact t t between b t the th spring i and target.

In order for contact to work properly, the contact element normals must be facing the target g element normals. Recall that surface bodies are meshed with shell elements that have a top and a bottom face. The reason this contact pair is not working is because the contact normals are on the wrong side of the surface body with normals that face away from the target target. This needs to be reversed reversed.

Target element normal direction Contact element normal direction

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-13

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Customer Training Material

From the details window of the contact region, switch the contact shell face from Bottom to Top . The red color highlighting the contact side should switch.

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-14

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Highlight the Solution Information Branch

Set Newton-Raphson Residuals = 3 This will save force imbalance data for the last 3 3 Newton Newton-Raphson Raphson iterations. iterations This is especially helpful information for troubleshooting troubling contact convergence problems.

Customer Training Material

Rerun the solution

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-15

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Customer Training Material

From the Solution Information Branch, the contact is now engaging, but the solution fails to converge after several iterations.

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-16

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Customer Training Material

These first two converged substeps likely represent the trivial solutions that occur as the small gap between the two parts is being closed and no contact has been made yet. This first Thi fi t spike ik in i the th Newton-Raphson N t R h residual id l (measure ( of imbalance) likely occurs at the point when contact first engages. From there on out, the solution struggles and fails after two bisections and many y iterations to find a balance.

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-17

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Customer Training Material

A plot of Newton-Raphson Residual (measure of force imbalance in the model) confirms that the point where contact is engaged is the source of the highest imbalance .

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-18

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Highlight both Contact Regions and change the contact specifications in the details window.

Customer Training Material

Augmented Lagrange is recommended for general contact Reducing the contact stiffness factor will reduce the calculated force generated at the contact surface and thereby reduce the imbalance

Re-run the solution

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-19

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

The solution now converges very nicely with no bisections

Customer Training Material

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-20

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Review R i th Total the T t l Deformation D f ti results. lt

Customer Training Material

Although this solution is now converged, notice the excessive penetration. This is because, by default the shell contact detection points are at the midplane of the shells.

This can be remedied by adding a command object to the contact elements with the following command: KEYOPT,cid,11,1 (refer to Element manual documentation on CONTA174 and the KEYOPT command) This command will include an adjustment for the shell thickness.

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-21

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

EXTRA CREDIT !! Highlight each Contact Region and d RMB > I Insert t > Commands C d

Inside the command object and type the command as shown

Customer Training Material

* * Refer to Element Reference documentation on CONTA174 along with Command Manual documentation on KEYOPT

Re-run the solution

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-22

Release 13.0 December 2010

ANSYS Mechanical Structural Nonlinearities

Workshop 9A: Diagnostics

Review the Total Deformation results as before.

Shell thickness is now properly accounted for.

Customer Training Material

ANSYS, Inc. Proprietary 2010 ANSYS, Inc. All rights reserved.

WS9A-23

Release 13.0 December 2010

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Working With Panels - HM-1020: Exercise Step 1: in The Translate Panel, Select Nodes From The Graphics AreaDocument6 pagesWorking With Panels - HM-1020: Exercise Step 1: in The Translate Panel, Select Nodes From The Graphics AreaShaheen S. RatnaniNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Design of Members: Rui SimõesDocument53 pagesDesign of Members: Rui SimõesciposNo ratings yet

- CAD Help Center - Step by Step Guide To Install and Configure HyperWorks On Windows XP, Vista & 7 (32 & 64 Bit)Document7 pagesCAD Help Center - Step by Step Guide To Install and Configure HyperWorks On Windows XP, Vista & 7 (32 & 64 Bit)Shaheen S. RatnaniNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Axial Fans: Noise Prediction: Th. CarolusDocument13 pagesAxial Fans: Noise Prediction: Th. CarolusShaheen S. RatnaniNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- HM Tut 1030Document8 pagesHM Tut 1030Shaheen S. RatnaniNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Is 1363 Black Hexagon Bolts, Nuts, Lock Nuts and Hexagon ScrewsDocument16 pagesIs 1363 Black Hexagon Bolts, Nuts, Lock Nuts and Hexagon ScrewsprashantlingayatNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 37 43Document7 pages37 43Shaheen S. RatnaniNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Page Menu: Geom 1D 2D 3D Analysis Tool PostDocument1 pagePage Menu: Geom 1D 2D 3D Analysis Tool PostShaheen S. RatnaniNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Exercise 1: Opening and Saving FilesDocument5 pagesExercise 1: Opening and Saving FilesShaheen S. RatnaniNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Arabic Letters PDFDocument2 pagesArabic Letters PDFjunkyjunk4495No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- PVNewsletter March2014Document20 pagesPVNewsletter March2014Shaheen S. RatnaniNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Prod Docu 14.0 Ans AdvDocument380 pagesProd Docu 14.0 Ans AdvShaheen S. RatnaniNo ratings yet

- Getting Started With Hypermesh - Hm-1000: Title BarDocument3 pagesGetting Started With Hypermesh - Hm-1000: Title BarShaheen S. RatnaniNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Lecture 1.0Document29 pagesLecture 1.0Shaheen S. RatnaniNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Mech Dynamics 14.5 WS08C TransientDocument14 pagesMech Dynamics 14.5 WS08C TransientShaheen S. RatnaniNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hy-Andritz Centrifugal Pump IsoDocument6 pagesHy-Andritz Centrifugal Pump IsoShaheen S. RatnaniNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- PVNewsletter March2014Document20 pagesPVNewsletter March2014Shaheen S. RatnaniNo ratings yet

- MetalDocument32 pagesMetalShaheen S. RatnaniNo ratings yet

- Full Text 01Document48 pagesFull Text 01GicuNo ratings yet

- 152012.B OptiFloDocument36 pages152012.B OptiFloShaheen S. RatnaniNo ratings yet

- Mech Dynamics 14.5 WS08C TransientDocument14 pagesMech Dynamics 14.5 WS08C TransientShaheen S. RatnaniNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mechanical Nonlin 13.0 WS 05A PlasticityDocument26 pagesMechanical Nonlin 13.0 WS 05A PlasticityShaheen S. RatnaniNo ratings yet

- Mech Dynamics 14.5 WS01 IntroDocument19 pagesMech Dynamics 14.5 WS01 IntroShaheen S. RatnaniNo ratings yet

- Cheats TorchlightDocument7 pagesCheats TorchlightShaheen S. RatnaniNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Mech Dynamics 14.5 WS08B TransientDocument22 pagesMech Dynamics 14.5 WS08B TransientShaheen S. RatnaniNo ratings yet

- Mechanical Nonlin 13.0 WS 05B Localized YieldingDocument16 pagesMechanical Nonlin 13.0 WS 05B Localized YieldingShaheen S. RatnaniNo ratings yet

- Chapter 4 3D Solid Modeling 1Document18 pagesChapter 4 3D Solid Modeling 1Shaheen S. RatnaniNo ratings yet

- Mechanical-Nonlin 13.0 Ch00 IntroDocument5 pagesMechanical-Nonlin 13.0 Ch00 IntroShaheen S. RatnaniNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Mechanical-Nonlin 13.0 Ch02 ProcedureDocument38 pagesMechanical-Nonlin 13.0 Ch02 ProcedureShaheen S. RatnaniNo ratings yet

- Mechanical-Nonlin 13.0 Ch01 OverviewDocument17 pagesMechanical-Nonlin 13.0 Ch01 OverviewShaheen S. Ratnani100% (1)

- Referencing Using The Documentary-Note (Oxford) System, Deakin UniversityDocument9 pagesReferencing Using The Documentary-Note (Oxford) System, Deakin UniversityjengadjNo ratings yet

- ANSI - Ahri Standard 550-590 (I-P) With Addendum 3Document109 pagesANSI - Ahri Standard 550-590 (I-P) With Addendum 3Afzal KhanNo ratings yet

- A4000 Installation ManualDocument10 pagesA4000 Installation ManualMuti FutiNo ratings yet

- Business - 29 Aug 2014Document146 pagesBusiness - 29 Aug 2014Iftikhar AhmedNo ratings yet

- Influence of Nano - Sized Powder Content On Physical Properties of Waste Acid Refractory BrickDocument19 pagesInfluence of Nano - Sized Powder Content On Physical Properties of Waste Acid Refractory BrickamnajamNo ratings yet

- ANDROID Workshop MaheshDocument72 pagesANDROID Workshop MaheshPradeepCool100% (2)

- 2014 Rude Customer ServiceDocument3 pages2014 Rude Customer ServiceCaptain WalkerNo ratings yet

- 5400 Replace BBU BlockDocument15 pages5400 Replace BBU BlockAhmed HaggarNo ratings yet

- Grill Size CalculationDocument2 pagesGrill Size CalculationSiva SankarNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- GSM Underlaid Overlaid Frequency Allocation and ConfigurationDocument3 pagesGSM Underlaid Overlaid Frequency Allocation and ConfigurationrajNo ratings yet

- Self Priming Water Lifting Booster PumpDocument2 pagesSelf Priming Water Lifting Booster PumpzhelipumpNo ratings yet

- Mazda rx7Document3 pagesMazda rx7Jon WestNo ratings yet

- P40 Series: Technical SpecificationDocument2 pagesP40 Series: Technical SpecificationHarry HonchoNo ratings yet

- Bibliography of A Series of Publications On Ecology, Environment, Biology. Selected. Http://ru - Scribd.com/doc/238214870Document279 pagesBibliography of A Series of Publications On Ecology, Environment, Biology. Selected. Http://ru - Scribd.com/doc/238214870Sergei OstroumovNo ratings yet

- Aerodromes PDFDocument522 pagesAerodromes PDFaditya100% (1)

- SOP For Handling of Rejected Raw MaterialDocument6 pagesSOP For Handling of Rejected Raw Materialanoushia alviNo ratings yet

- HP77 Pg84 CouperDocument4 pagesHP77 Pg84 CouperSharjeel NazirNo ratings yet

- Scope of The WorkDocument5 pagesScope of The Worklogu RRNo ratings yet

- Move All Database Objects From One Tablespace To AnotherDocument2 pagesMove All Database Objects From One Tablespace To AnotherJabras GuppiesNo ratings yet

- Functional Buttons and Auto Power Off: International Electrical SymbolsDocument2 pagesFunctional Buttons and Auto Power Off: International Electrical SymbolsVentas SA TabNo ratings yet

- Doctrine Cheat SheetDocument1 pageDoctrine Cheat Sheetfreebolik86% (7)

- Oracle Fusion Financials Set Up Journal ApprovalsDocument64 pagesOracle Fusion Financials Set Up Journal Approvalssohaibmuzaffar0070% (3)

- Compair Fluid Force 4000 IndonesiaDocument3 pagesCompair Fluid Force 4000 Indonesiaindolube75% (4)

- How Bangalore Gets ElectricityDocument1 pageHow Bangalore Gets ElectricityNabeel AhmedNo ratings yet

- MS150093 01e PDFDocument181 pagesMS150093 01e PDFAntonio MartinNo ratings yet

- Proses Manufaktur: Machining Operation and Machine ToolsDocument34 pagesProses Manufaktur: Machining Operation and Machine ToolsLyndaNo ratings yet

- Conversion of Solar Energy Into Electrical Energy Class 12th ProjectDocument17 pagesConversion of Solar Energy Into Electrical Energy Class 12th ProjectVAIS100% (3)

- Cs2000 Universal Translations3006a 50 SGDocument508 pagesCs2000 Universal Translations3006a 50 SGAleksandr BashmakovNo ratings yet

- Kstar Inverosores DatasheetDocument1 pageKstar Inverosores DatasheetJosueLopesFariasNo ratings yet

- Id Based Multicast Secret-Key Management Scheme (SKMS) in ManetsDocument10 pagesId Based Multicast Secret-Key Management Scheme (SKMS) in ManetsSandhya RaniNo ratings yet