Professional Documents

Culture Documents

Eight Reasons Why Special-Lite Doors Are Sustainable Brochure

Uploaded by

Special-Lite DoorsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eight Reasons Why Special-Lite Doors Are Sustainable Brochure

Uploaded by

Special-Lite DoorsCopyright:

Available Formats

SL55157_nspp.

qxd:Layout 1 11/20/08 9:41 AM Page 3

8 Reasons Why Special-Lite® Entrances

are the More Sustainable Choice

SL55157_nspp.qxd:Layout 1 11/20/08 9:41 AM Page 4

8 Reasons Why Special-Lite Entrances

are the More Sustainable Choice:

1 GREENGUARD Certification ensures better indoor air quality.

Special-Lite’s products were the first exterior entrance products to earn

GREENGUARD Certification, including the stringent Children & Schools Standard.

The GREENGUARD Environmental Institute (GEI) criteria are the toughest in the

industry, involving tests for formaldehyde, volatile organic compounds (VOCs),

phthalates and hundreds of other pollutant emissions using scientific environmental

chamber protocols. GREENGUARD Certification is your independent assurance

that no aspect of the materials we use or our method of construction will

compromise indoor air quality (IAQ).

Air Quality Sciences chamber testing

verifies that Special-Lite products meet

GREENGUARD Certification criteria.

2 Modern materials and durable

construction prolong service life.

Special-Lite doors are specially engineered and

manufactured to provide the longest possible service

life, even in the most abusive locations. Corrosion-

resistant materials and durable finishes ensure lasting

beauty with minimal maintenance, and deliver the

lowest lifecycle cost.

To prove their durability, we were the first to test our

FRP doors to the ANSI A250.4 standard to 25 million

open and close cycles, as well as to the NWWDA

T.M. 7-90 cycle-slam test through 5 million cycles.

In both cases, our SL-17 doors were still performing

beautifully and ready for more at the conclusion of

the testing. That’s why we confidently offer a limited

lifetime warranty on our flush doors, and a 10-year,

100% parts and labor warranty on all our other

entrance products.

The GREENGUARD INDOOR AIR QUALITY CERTIFIED Mark

is a registered certification mark used under license through

the GREENGUARD Environmental Institute. To view our

GREENGUARD certificate online, visit www.greenguard.org.

SL55157_nspp.qxd:Layout 1 11/20/08 9:41 AM Page 5

3 Lightweight doors extend the life of the entire entrance system.

Our design philosophy is unique in the industry. Contrary to conventional wisdom,

we make our heavy-duty doors lightweight and flexible, because less door mass

means less wear and tear on hardware and framing components, and flexibility

provides resiliency. This makes the entire entrance system last longer, which

conserves material, energy, and economic resources. And since our doors

weigh about half as much as hollow metal doors, less energy is required to

transport our doors to the job site as well.

chamber testing

4 Durable finishes reduce maintenance

costs and health risks.

Because Special-Lite products leave our factory pre-finished, they

e products meet don’t need to be painted at installation. The durability of our non-

ication criteria. corroding materials and factory finishes also eliminate the regular

refinishing required to delay the decay of hollow metal or wood

doors and frames. Not only are facility maintenance costs reduced,

but maintenance staff and building occupants are not exposed

to the airborne particulates, VOCs and irritating fumes

created by sanding and refinishing.

5 Easy cleaning with green cleaners

protects indoor air quality.

Routine cleaning and stain removal can be

a significant source of VOC emissions that

degrade IAQ. The durable, easy-care factory

finishes on Special-Lite doors not only stay new

looking for many years with only occasional

cleaning, but even tough stains like graffiti can

be removed using green cleaners, instead of

toxic solvents.

SL55157_nspp.qxd:Layout 1 11/20/08 9:41 AM Page 6

6 Better thermal performance helps reduce energy usage.

The thermal efficiency of the building envelope has never been

more important. Special-Lite flush doors can help reduce heating

and cooling loads by providing superior thermal performance

versus hollow metal doors. Compare our independent lab results

with those for hollow metal doors, if you can find any.

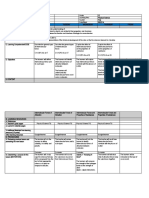

Thermal Properties:

Special-Lite FRP® Door Components, Panels, and Doors

U-value R-value CRF

Special-Lite FRP Door Components

®

1.5" Urethane foam only .11 9.1 88

1" FRP and urethane foam panel .23 4.3 81

1.75" FRP and urethane foam panel .10 10.0 87

Special-Lite FRP Door Assembly

®

.29 3.4 55

Tests conducted by Architectural Testing, Inc. Detailed test results are available on the Special-Lite

website, www.special-lite.com. For more complete recommendations on how to improve the thermal

performance of an entire exterior entrance, visit this page on the Special-Lite web site:

www.special-lite.com/thermal.

7 Aluminum is a sustainable material choice.

At Special-Lite, we manufacture our entrance products from aluminum because its unique

material properties make it a better choice than steel for exterior doors and framing. Its high

strength-to-weight ratio, natural corrosion resistance, excellent workability, and ability to

accept a wide range of finishes make it an excellent choice for architectural products.

Aluminum is also an excellent material choice for sustainable construction. It’s the most

abundant metallic element in the earth’s crust, and can be infinitely recycled without

degradation of properties. Aluminum’s high scrap value and well-established recycling

infrastructure make it the most frequently recycled metal, so much so that 73% of the

aluminum ever produced is still in use today.

8 All Special-Lite extrusions are made

from reprocessed aluminum

Special-Lite sources aluminum extrusions made from prime-

equivalent billet which is produced from 100% reprocessed 6063-T5

alloy recovered from industrial processes. The extrusions produced

from this prime-equivalent secondary billet are equal in all respects

to those made from virgin material, but have a smaller environmental

footprint. Aluminum recycling requires only 5% of the energy

necessary to produce virgin aluminum, so our use of post-industrial

reprocessed material helps to reduce the embodied energy inherent

in our family of entrance products.

SL55157_nspp.qxd:Layout 1 11/20/08 9:41 AM Page 1

Choose the Entrances with

More Life…For Better Quality of Life

SL55157_nspp.qxd:Layout 1 11/20/08 9:41 AM Page 2

Recycling our products

Our aluminum framing and monumental doors are easily dis-

assembled with hand tools and are fully recyclable after use.

The fiberglass reinforced polyester (FRP) face sheets, acrylic

modified polyester (AMP) face sheets, and urethane foam core

material in our flush doors are thermoset plastics and as such

are not recyclable. These materials are essentially inert, so

they can be safely disposed of at the end of their service life

without adverse impacts on water, soil, or air quality.

Improve Entrance Performance by Specifying

Special-Lite Doors, the Doors with More Life

Special-Lite pioneered the FRP door in 1981 to meet the

extreme demands of the school market, and we’ve been

making them the same way ever since because that’s what

works. Their extended service life, better thermal efficiency,

and reduced maintenance requirements help to conserve

material resources and energy, while contributing to the safety,

security, and well being of building users.

Contact your sales representative or Special-Lite for

more information, including detailed independent

lab test results, or visit www.special-lite.com.

Special-Lite, Inc.

P.O. Box 6, Decatur, MI 49045 Item #1122-R1

Ph: 800.821.6531 • Fx: 800.423.7610 • www.special-lite.com 10M 11/08 IW

You might also like

- Fire Rated Sandstone FRP Door BrochureDocument2 pagesFire Rated Sandstone FRP Door BrochureSpecial-Lite DoorsNo ratings yet

- Special-Lite AMP Flush Door BrochureDocument8 pagesSpecial-Lite AMP Flush Door BrochureSpecial-Lite DoorsNo ratings yet

- Special-Lite Monumental Door BrochureDocument4 pagesSpecial-Lite Monumental Door BrochureSpecial-Lite DoorsNo ratings yet

- Special-Lite FRP Flush Door Testing Summary BrochureDocument4 pagesSpecial-Lite FRP Flush Door Testing Summary BrochureSpecial-Lite DoorsNo ratings yet

- Special-Lite Retrofit Framing BrochureDocument4 pagesSpecial-Lite Retrofit Framing BrochureSpecial-Lite DoorsNo ratings yet

- Special-Lite Door Hurricane Rated Florida Approved Sales SheetDocument2 pagesSpecial-Lite Door Hurricane Rated Florida Approved Sales SheetSpecial-Lite DoorsNo ratings yet

- Special-Lite Fire-Rated FRP-Clad Fire Door Sales SheetDocument2 pagesSpecial-Lite Fire-Rated FRP-Clad Fire Door Sales SheetSpecial-Lite DoorsNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- GSTS Module-5Document14 pagesGSTS Module-5Poison PinkNo ratings yet

- Project ThesisDocument56 pagesProject ThesisHiren ThesiyaNo ratings yet

- Handbook - Calculations 5 PDFDocument1 pageHandbook - Calculations 5 PDFSmith SivaNo ratings yet

- 50031161662011fa PDFDocument88 pages50031161662011fa PDFAgung Pramu AjiNo ratings yet

- Rotary CoatingDocument5 pagesRotary Coatinggalati12345No ratings yet

- First Manganese (II) Bio-MOF: An Effective Heterogeneous Catalyst For Henry ReactionDocument9 pagesFirst Manganese (II) Bio-MOF: An Effective Heterogeneous Catalyst For Henry ReactionRahul palNo ratings yet

- Understanding Coating Weight Designations For Zinc-Based Coatings On Steel SheetDocument11 pagesUnderstanding Coating Weight Designations For Zinc-Based Coatings On Steel SheetkhurshedlakhoNo ratings yet

- Determination of Length Change of Concrete Due To Alkali-Silica ReactionDocument7 pagesDetermination of Length Change of Concrete Due To Alkali-Silica Reactioniipmnpti iipm100% (1)

- What Is Shell Mesh in HypermeshDocument1 pageWhat Is Shell Mesh in HypermeshRejita Pillai100% (1)

- Typical Cementitious Materials Caveats: Non-Shrink Grout Is A HydraulicDocument2 pagesTypical Cementitious Materials Caveats: Non-Shrink Grout Is A HydraulicEmdadul HuqNo ratings yet

- AAC Panel Is The Shortened Form of Autoclaved Aerated Concrete PanelDocument8 pagesAAC Panel Is The Shortened Form of Autoclaved Aerated Concrete PanelcesareNo ratings yet

- Nanostructures and NanomaterialsDocument2 pagesNanostructures and NanomaterialsSantosh MysoreNo ratings yet

- Metallurgy Theory PDFDocument13 pagesMetallurgy Theory PDFUtkarsh RaiNo ratings yet

- Industrial Slab Flooring ReportDocument31 pagesIndustrial Slab Flooring ReportChirag Chikmagalur VenkateshNo ratings yet

- Turbo S5 DR 46 TdsDocument2 pagesTurbo S5 DR 46 TdsFandemen AdintaNo ratings yet

- Liquid Metal Embrittlement (LME)Document13 pagesLiquid Metal Embrittlement (LME)a_omar_iitmNo ratings yet

- Soil Micronutrients FinalDocument56 pagesSoil Micronutrients Finalsundar100% (2)

- Weld Metal CertificateDocument1 pageWeld Metal CertificatePhương Do QuangNo ratings yet

- Physical Science DLP Q1W3Document7 pagesPhysical Science DLP Q1W3junar asentistaNo ratings yet

- G 94 - 05 (2014)Document31 pagesG 94 - 05 (2014)jose floresNo ratings yet

- Instrumen GCC PDFDocument10 pagesInstrumen GCC PDFSteven SantiagoNo ratings yet

- Timer PaperDocument5 pagesTimer Paperhajjiyare2016No ratings yet

- Indrakanty Surya ShashankDocument10 pagesIndrakanty Surya ShashankINDRAKANTY SURYA SHASHANKNo ratings yet

- H1 Atmospheric CorrosionDocument4 pagesH1 Atmospheric CorrosionJahnabi BasumataryNo ratings yet

- Pinnacle Flo, InC.Document16 pagesPinnacle Flo, InC.r_chulinNo ratings yet

- Atomic Absorption & EmissionDocument80 pagesAtomic Absorption & EmissionAkshay Patil100% (1)

- Ra6969 MH - Mavic BDocument68 pagesRa6969 MH - Mavic BVinz SelabeNo ratings yet

- Ha Coating On Ti 3.1Document9 pagesHa Coating On Ti 3.1Truong DucQuangNo ratings yet

- Technical Data Sheet Chryso RMC 5321 - 6146 - 3701Document1 pageTechnical Data Sheet Chryso RMC 5321 - 6146 - 3701ABHI MITRANo ratings yet

- Astm B 265-2010Document9 pagesAstm B 265-2010bryan wengNo ratings yet