Professional Documents

Culture Documents

The Latest Quality Mantra " Total Productive Maintenance ": A Times of India Special Report by H.R.Gupta

Uploaded by

vishveshwarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Latest Quality Mantra " Total Productive Maintenance ": A Times of India Special Report by H.R.Gupta

Uploaded by

vishveshwarCopyright:

Available Formats

A TIMES OF INDIA SPECIAL REPORT By H.R.

Gupta

THE LATEST QUALITY MANTRA TOTAL PRODUCTIVE MAINTENANCE

(Courtesy : The Machinist)

n ancient times, the e

!i"e# a $a me % He &e!ie"e# in

s'(e nat' a! ()*e s an# 'se# t) *) shi( +)# *ith sta'nch $aith% One $ine m) nin,, (!ease# *ith his #e")ti)n, +)# a((ea e# an# as-e# the $a me t) see- an. &))n% The $a me t) see- an. &))n% The $a me as-e# +)# t) ma-e his hen !a. ,)!#en e,,s% /e it s) 'nti! .)' $ee# an# ca e $) the hen &.

.)' se!$ sai# +)# an# #isa((ea e#% The ()'!t . $a me &ecame ich "e . s))n% + ee# )"e t))- him% S))n he $)'n#, he &ecame !a0. an# c)'!# n)t atten# t) the hen% He hi e# (e)(!e t) #) the 1)& $) him% T 'e t) the &))n, the hen st)((e# !a.in, ,)!#en e,,s an# s))n #ie#%

The above tale is similar to our production facilities and equipment that exist in our industries. The attention we pay to goose laying golden eggs is dismal. A rough estimate shows that the Overall Equipment Effectiveness (O.E.E of plant and machinery in engineering industry is not more that !"# in India. O.E..E in Indian companies can be loosely divided as $%&'"# in an average industry( '"&"%# in well managed companies and )"# in world class companies. S'n#a am 2astene Limite#, a c)m(an. a(i#!. m)"in, t)*a #s &ec)min, *) !# c!ass, )(e ates at 345 O%E%E . *et us see how you can calculate the Overall Equipment Effectiveness of your equipment or the plant as a whole.

1/8

A TIMES OF INDIA SPECIAL REPORT By H.R.Gupta

THE LATEST QUALITY MANTRA TOTAL PRODUCTIVE MAINTENANCE

(Courtesy : The Machinist)

TPM E6CELLENCE A7ARD

S'n#a am 2astene s Lt#%, a TVS + )'( )$ C)m(an., has &een a*a #e# the ( esti,i)'s TPM E8ce!!ence A*a # &. the 9a(anese Instit'te )$ P!ant Maintenance :9IPM;% The a*a # has &een ,i"en t) S2L a$te a i,) )'s a'#its )$ its (!ants &. a'#it) s $) m 9IPM an# it *as ( esente# t) M % S' esh < ishna, Chai man = Mana,in, Di ect) , )n Oct)&e >? th @ ABBC at $'ncti)n he!# in T)-.), 9a(an% The 9IPM a*a # is ec),niti)n that S2L has m)"e# s'&stantia!!. #)*n the )a# t)*a #s c eatin, a c) () ate s.stem that ma8imi0es the e$$icienc. )$ its ( )#'cti)n s.stem% The 9a(anese instit'teDs TPM ( ), amme is a ten .ea (ac-a,e that &asica!!. attem(ts t) achie"e an# maintain 0e ) #e$ects, 0e ) acci#ents an# 0e ) $ai!' es in the enti e !i$e c.c!e )$ a ( )#'cti)n s.stem% It is a((!ica&!e t) a!! a eas )$ an ) ,ani0ati)n inc!'#in, ( )#'cti)n, a#minist ati)n an# #esi,n an# #e"e!)(ment% S2L -ic-e# )$$ the TPM ( ), amme in A','st ABBE an# )"e the (ast th ee .ea s ha# ma#e c)nsi#e a&!e ( ), ess in si,ni$icant!. & in,in, #)*n the n'm&e )$ & ea-#)*nDs, acci#ents, 1)& chan,e time, c'st)me c)m(!aints an# e"en the a#minist ati)nDs #)c'ment et ie"a! time% I$ the c)m(an. n)* ,)es )n t) c)m(!ete the ten .ea ( ), amme it *i!! &e e!i,i&!e t) &e ce ti$ie# as a *) !# c!ass c)m(an. &. 9OPM

Assume that you have equipment + A and you have bought it to run on two , shift basis. This equipment will be available for utili-ation in a year only for ."% out of /%% shifts planned for wor0 after reducing absenteeism of operator , !%#( brea0down and maintenance wor0 , !%#( on 1obs available on the machine , "# (2unday( holidays( bandhs and other disturbances excluded .Out of ."% shifts available( considering )% minutes stoppage of equipment per shift for lunch( tea( coffee and persona time( startup and closing time allowances for operator( we loose 3" shifts per year. The machine is actually available for production only for '/" shifts. Therefore( the utili-ation efficiency of the machine is '/"4/%%5%./%3 (/%.3# . Though the machine is available for utili-ation for '/" shifts( the output per shift from this machine may not be equal to its rated capacity per shift. This happens due to several reasons. 6e are not able to use cutting speeds and

2/8

A TIMES OF INDIA SPECIAL REPORT By H.R.Gupta

THE LATEST QUALITY MANTRA TOTAL PRODUCTIVE MAINTENANCE

(Courtesy : The Machinist)

feed as recommended by the machine tool manufacturer( we may have reduced parameters due to tool life or wor0piece accuracy requirements( the operator looses some time in searching for tools( 1igs and fixtures( setup time is longer than envisage etc. *et us say a part has a standard time of !%% hours. 7ue to all the above types of problems( it may actually ta0e !'% hours to produce this part. Therefore( the output efficiency of this equipment for '/" shifts( we receive output equivalent to output of $3% shifts ('/"x%.8/)

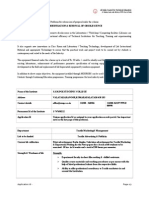

O"e a!! EF'i(ment E$$ecti"eness%

34%

18% 8% 8%

.#

4% 13% 11%

!. $. '. ..

2unday 4 9olidays , '.# :rea0down , 3# *unch( Tea 4 ;ofee , !!# <oor =uality *oss , .#

". /. 8. 3.

Absentism , 3# >o ?obs , .# Output Effiuciency *oss , !'# Actual Effective 6or0. , !3#

6e have yet to reach a stage of + @ight Airst Time B. Therefore( parts get re1ected during the stage of manufacturing as well as we some times salvage them through rewor0. A single machine may produce parts !%% per cent right first time but when this part goes to next operation to get re1ected( the wor0 done by the previous machine also goes waste. *et us say that on an average !%# of the wor0 done by a manufacturing shop is wasted in rewor0 and re1ections. Therefore( =uality Efficiency of the manufacturing plant would be %.)% ()%# . This means that though we produced output equivalent to $3% shifts( output equivalent to $"$./ shifts ($3x%.) was right first time and the balance time spent in rewor0 or re1ections. 6e spent in rewor0 or re1ections. 6e can now conclude by saying that the overall equipment is .$.!# ($"$./4/%% 5 %..$!# . If you consider the entire Indian engineering industry as a whole( overall utili-ation efficiency is not more than '"# (0eeping in view the underutili-ed equipment available in companies ( output efficiency not more than /%# and quality efficiency not more than 8%# resulting in Overall Equipment Effectiveness of !"#.

3/8

A TIMES OF INDIA SPECIAL REPORT By H.R.Gupta

THE LATEST QUALITY MANTRA TOTAL PRODUCTIVE MAINTENANCE

(Courtesy : The Machinist)

Imagine if the O.E.E of your plant was greater than 3"#. ;ould you reduce your manufacturing process cost by more than "%# besides reducing throughput&time( increased inventory turns( higher inflow of absolute profits through increased volumes of production and higher levels of adherence to committed delivery schedules and thereby increased customer satisfactionC DesC IsnEt it a gold mine at homeC. The Latest Q'a!it. Mant a G + Total <roductive Faintenance B (T<F is all about improving the Overall Equipment Effectiveness (O.E.E of your plant. Gnfortunately( a magic wand is not available in our hands that can change the situation in a 1iffy. 6e have to inculcate faith and devotion to the religion of T<F in achieving salvation from competitive pressures and move towards wor0 class manufacturing. Dou will have to practice and chant the mantra of O.E.E all the time. As you 0eep on crossing milestones on you 1ourney towards T<F( you will 0eep receiving rewards and benefits in the bottom line of the company. :ut how to beginC As n) sa!"ati)n is ()ssi&!e *ith)'t the he!( )$ a +URU , .)' *i!! nee# a Teache *h) can ,'i#e .)' )n .)' (ath )$ ( acticin, TPM% 9a(anese Instit'te )$ P!ant Maintenance :9IPM; introduced the concept of TOTAL PRODUCTIVE MAINTENANCE to the 6orld in early !)8%Es. T<F in In#ia is at a sta,e )$ in$anc.% Vi- am Cements( a #i"isi)n )$ + asim In#'st ies( *as the $i st C)m(an. in In#ia t) ecei"e /est TPM P!ant A*a # in ABBE an# S'n#a am 2astene s Limite#, the sec)n# c)m(an. in ABBC% :oth these companies have succeeded only because Fr. Aditya Hi0ram :irla and Fr. 2uresh Irishna chairman of respective companies spearheaded the program. Therefore( the chairman or the Fanaging 7irector will have to ma0e a public pronouncement of their + 2an0alp B (determination having adopted T<F as a religion for manufacturing management and personally lead this movement. :ut what does T<F meanC The ( ima . )&1ecti"e )$ TPM a e t)H C eate a mana,ement s.stem that (!ans, im(!ements, m)nit) s an# c)ntin')'s!. im( )"es :O%E%E; )$ the man'$act' in, $aci!itit.% C eate ( )cesses that can ass' e 0e ) #e$ects, 0e ) & ea-#)*ns, 0e ) acci#ents an# 0e ) !)sses% C eate t)ta! em(!).ee in")!"ement in achie"in, O%E%E% an# e!iminatin, *aste th )',h sma!! , )'( acti"ities% The implementation of T<F promoted by ?apanesse Institute of <lant Faintenance (?I<F is classified in eight categories.

O"e a!! EF'i(ment E$$ecti"eness%

OEE I Act'a! O(e atin, Time 6 Act'a! SPH ( )#'ce#

4/8

A TIMES OF INDIA SPECIAL REPORT By H.R.Gupta

THE LATEST QUALITY MANTRA TOTAL PRODUCTIVE MAINTENANCE

(Courtesy : The Machinist)

A"ai!a&!e Time 6 +))# P )#'cti)n T)ta! P )#'cti)n

The) etica! SPH A"!%

SPH I Stan#a # P )#'cti)n H)' s%

In#i"i#'a! Im( )"ementsHJ E"e . em(!).ee in the c)m(an. m'st &e ma#e a*a e )$ the a eas the c)nt i&'te t) !)sses an# h)* he can he!( e!iminate #e$ects $ )m his )*n *) - an# c)nt i&'te t) e#'cti)n )$ !)sses c)m(an. *i#e% This acti"it. (e tains t) t ainin, (e)(!e in im(!ementin,, s(ecia!!. the sta$$ an# sh)( s'(e "is) s )n h)* t) a## ess e!iminati)n )$ A4 a eas )$ ma1) !)sses that e8ist in an. man'$act' in, set G '(% An# a!s) ens' e 0e ) !)ss #'e t) eF'i(ment $ai!' e an# ( )#'ct #e$ect% PLANNED MAINTENANCEH J Sta$$, s'(e "is) s an# maintenance team nee# t) &e t aine# t) im( )"e F'a!it. )$ maintenance *) - )n the eF'i(ment that *i!! ens' e 0e ) & ea-#)*ns% This inc!'#e# #ata c)!!ecti)n, ana!.sis an# time!. c)!!ecti)n acti)ns an# time!. c)!!ecti)n acti)ns )$ ( e"enti)n )$ ec' ence% Ve . )$ten shi$t a an,ements a e ma#e t) -ee( the eF'i(ment '( #'e t) n)nJa"ai!a&i!it. )$ s(a e (a ts ) ina&i!it. t) #ia,n)se a (a tic'!a ( )&!em at that time% S'ch acti"ities c eate a (e manent #isa&i!it. in eF'i(ment an# se i)'s!. a$$ect the ca(a&i!it. )$ the eF'i(ment inc!'#in, t)ta! !i$e c.c!e )$ the asset% The (!anne# maintenance acti"it. sh)'!# ens' e time!. attenti)n t) a!! t.(es )$ e(ai s that *i!! a")i# ma1) & ea-#)*ns%

Mate ia! 2!)* S.stemHJ In an. man'$act' in, sh)(, !)catin, )$ t))!s, 1i,s an# $i8t' es an# )the han#t))!s ta-e s)me time )n!. &eca'se these ha"e n)t &een st) e# s.stematica!!. an# (e)(!e ha"e t) sea ch $) these t))!s% Q'ite )$ten, the eF'i e# t))! is n)t in st)c- *hen eF'i e#% /a!ancin, )$ !)a# )n machines is .et an)the ma1) iss'e% S)me machines a e )"e !)a#e# an# s)me *aitin, $) mate ia!% A!! this !ea#s t) !)ss t) ( )#'cti"e h)' s )$ the machine t))!% P ima . )&1ecti"e )$ mate ia! $!)* mana,ement sh)'!# &e t) ens' e 0e ) *aitin, time $) a!! t.(es )$ in('t mate ia! an# sh) test th )',h('t time

5/8

A TIMES OF INDIA SPECIAL REPORT By H.R.Gupta

THE LATEST QUALITY MANTRA TOTAL PRODUCTIVE MAINTENANCE

(Courtesy : The Machinist)

th )',h the chain )$ ( )cess% The e$) e, im(!ementin, acti"ities that can !ea# t) sh) tenin, the t ia! (e i)# $) ne* ( )#'cts ena&!in, hi,he a"ai!a&i!it. )$ eF'i(ment $) e,'!a ( )#'cti)n% In case )$ ne* eF'i(ment sh) ten #e"e!)(ment, #esi,n, an# man'$act' in, (e i)#s% Esta&!ish sh) test th )',h('t time )$ ( )#'cts% Im( )"e ( )cesses that can ass' e nea !. 0e ) sh) t sta t '( time )$ ne* eF'i(ment )n a i"a!% E#'cati)n an# T ainin,H J E#'cati)n an# T ainin, is the ( ime acti"it. t) ma-e the ( )cess s'ccee#% This inc!'#es t ainin, $) e"e . )ne in the c)m(an. sta tin, $ )m the ti( t) the !ast em(!).ee% S-i!! t ainin, $) )(e at) s an# maintenance team sta tin, $ )m &asic an# c)ntin')'s!. ,) )n t) im( )"e thei c) e c)m(etence in the tas- the. a e e8(ecte# t) (e $) m% A't)n)m)'s MaintenanceHJ The &asic ( emise )$ TPM !ies in the $act the machine )(e at) sh)'!# maintain the machine himse!$% It is s)methin, !i-e a ca # i"e% He is ta',ht the &asic s-i!! t) e(ai min) ( )&!ems in the ca s) that he is es()nsi&!e $) 0e ) & ea-#)*n )$ the ca )n the )a#% T) achie"e this ,)a!, he c!eans the ca e"e . #a., chec-s c itica! eF'i ements #ai!. an# see-s the he!( )$ e8te na! maintenance team at e(ai *) -sh)(s i$ he $in#s ma1) #e$ect% The e$) e the machine )(e at) s nee# t) &e t aine# t) 'n#e stan# thei machines *e!! an# he!# es()nsi&!e )"e a (e i)# )$ time $) thei machine '(time% The )!e )$ )(e at) , the e$) e, *)'!# inc!'#e c!eanin, the machine, #ai!. chec-J'( an# ana!.sisK ca .)'t sim(!e stan#a #i0e# maintenance *) -, a an,in, maintenance th )',h s(ecia!ists maintenance teamJ (e i)#ica!!. an# the e&. im( )"in, t)ta! !i$e c.c!e )$ the asset% The )!e )$ eF'i(ment &'i!#e nee#s t) &e e#e$ine# in te ms )$ his es()nsi&i!it. t)*a #s ma-in, his eF'i(ment $it $) TPM a((!icati)n the e&. ens' in, hi,h mean time &et*een $ai!' es :MT/2; an# sh) t mean time t) e(ai :MTTR;% Q'a!it. MaintenanceHJ Em(!).ees sh)'!# aim at Ri,ht 2i st Time the e&. Le ) G De$ect P )#'cti)n% T) achie"e this, it is necessa . that the sta$$ ec) #s act'a! #e$ects acc) #in, t) c)n$i me# stan#a #s an# ana!.ses the #ata t) e!ate #e$ects t) eF'i(ment ) ( )cess stan#a #s% C) ecti)n acti)ns sh)'!# &e im(!emente# th )',h <AILEN C )ss 2'ncti)na! Team, QC Ci c!e ) sma!! , )'( acti"ities% A#minist ati)n HJ

6/8

A TIMES OF INDIA SPECIAL REPORT By H.R.Gupta

THE LATEST QUALITY MANTRA TOTAL PRODUCTIVE MAINTENANCE

(Courtesy : The Machinist)

Man'$act' in, e8ce!!ence #i ect!. #e(en#s )n the )(e ati)na! e8ce!!ence )$ s'(() tin, #e(a tments G (!annin,, (' chasin,, 'ti!ities etc% Sta$$ $ )m these #e(a tments sh)'!# &e t aine# t) s'(() t ( )#'cti)n #e(a tments *ith , eat s(ee#, acc' ac. an# c)mm)n (' ()se% Sa$et., Sanitati)n an# En"i )nmentHJ The *) - en"i )nment sh)'!# &e $ ee $ )m is- )$ acci#ents% The e sh)'!# &e a#eF'ate s.stems in (!ace t) ana!.0e# an# maintain 0e ) acci#ent !e"e!s% C eat a hea!th. an# c!ean *) -in, site $) the em(!).ees% The <e. t) s'ccessH Em(!).ees a e the $)'n#ati)n )$ TPM ( ), am% The. sh)'!# c!ea !. 'n#e stan# thei chan,in, )!e% It is the es()nsi&i!it. )$ the t)( mana,ement t) c eate a#eF'ate !e"e!s )$ m)ti"ati)n am)n,st (e)(!e t) ( )acti"e!. ass'me )*ne shi( )$ the tas-% S'n#a am 2aste ne Limite# *h) ha"e s'ccee#e# #i# n)t ha"e a sin,!e inci#ence )$ *) - st)((a,e ) a sin,!e !iti,ati)n *ith em(!).ee 'ni)n in the (ast M> .ea s% The e$) e the ( ime )!e )$ t)( mana,ement *)'!# &e t) c eate an attit'#ina! chan,e am)n,st (e)(!e t) acce(t the tenets )$ TPM% The )&"i)'s!. *)'!# eF'i e a (a a#i,m shi$t in the min#s )$ t)( mana,ement t)*a #s em(!).ees an# thei t a#e 'ni)n acti"ities%

7hat can .)' achie"e th )',h TPMN Y)' can inc ease e$$ecti"e 'ti!i0ati)n )$ eF'i(ment '(t) CE5 )"e a (e i)# )$ th ee t) $i"e .ea s the e&. e#'cin, the eF'i ement )$ a##iti)na! es)' ces $) inc ease# ( )#'cti)n an# e#'cin, man'$act' in, c)sts )$ the ( )#'ct% Y)' *i!! & in, machine & ea-#*)n t) 0e ) &esi#es e#'ce# maintenance c)sts% Y)' *i!! inc ease in"ent) . t' ns th )',h s(ee#ie mate ia! $!)* an# achie"e 0e ) acci#ents% CON2EDERATION O2 INDIAN INDUSTRY HAS 9OINED HANDS 7ITH 9APANESE INSTITUE O2 PALNT MAINTENANCE :9IPM; AND STARTED A TPM CLU/ TO PORMOTE PROI2IERATION O2 TPM AMON+ST THEIR MEM/ERSHIP% THE PHILOSOPHY O2 TPM IS MORE IMPORTANT THAN ITS NAME% 7HAT IS A MUST IS THIS APPLICATION O2 ITS PHILOSOPHIES COMPANY 7IDE TO ACHIEVE A COMPETITIVE ADVANTA+E%

7/8

A TIMES OF INDIA SPECIAL REPORT By H.R.Gupta

THE LATEST QUALITY MANTRA TOTAL PRODUCTIVE MAINTENANCE

(Courtesy : The Machinist)

OOOOOOOOOOOOOOOOOOOOOOOOO6 OOOOOOOOOOOOOOOOOOOOOOOOOO

8/8

You might also like

- Divided States: Strategic Divisions in EU-Russia RelationsFrom EverandDivided States: Strategic Divisions in EU-Russia RelationsNo ratings yet

- Ilide - Info Ae Board Recalled Questions Part 1 in Farm Machinery and Allied Subjectspdf PRDocument5 pagesIlide - Info Ae Board Recalled Questions Part 1 in Farm Machinery and Allied Subjectspdf PRZeraul Jun Doydoy LuarezNo ratings yet

- Prolect Report of Material Management of Renusager Power Divison Hindalco Industries LTDDocument122 pagesProlect Report of Material Management of Renusager Power Divison Hindalco Industries LTDRahul RoyNo ratings yet

- Niloy Rajbangshi 04VWCM6054Document80 pagesNiloy Rajbangshi 04VWCM6054karthik79sNo ratings yet

- Government of India Ministry of RailwaysDocument10 pagesGovernment of India Ministry of Railwaysrdas1980No ratings yet

- Lesson Mechanalysis - The Key To Machinery ConditionDocument13 pagesLesson Mechanalysis - The Key To Machinery Conditionmister pogiNo ratings yet

- Indian-Manufacturing Overview and ProspectsDocument41 pagesIndian-Manufacturing Overview and ProspectsanubhaanandNo ratings yet

- Banquet Service ProceduresDocument24 pagesBanquet Service Proceduresmackybhoyamores100% (9)

- Industrial Engineering: DefinitionDocument11 pagesIndustrial Engineering: DefinitionK.s. RameshNo ratings yet

- Arning! A Arning! Arning! Arning! Rning! Arning! Arning! Arning! Arning! Arning!Document33 pagesArning! A Arning! Arning! Arning! Rning! Arning! Arning! Arning! Arning! Arning!Soporte Tecnico AutoMotrix100% (1)

- Quality Management in Service SystemsDocument0 pagesQuality Management in Service SystemsFlorin VladescuNo ratings yet

- PDF Sustainable DevelopmentDocument15 pagesPDF Sustainable Developmentaditya pariharNo ratings yet

- All India Council For Technical Education: Application Id - Page X/yDocument5 pagesAll India Council For Technical Education: Application Id - Page X/ysivapathasekaranNo ratings yet

- 5014 20432 Summer Project For MBADocument67 pages5014 20432 Summer Project For MBARaj SachinNo ratings yet

- Istanbul Technical University Maritime FacultyDocument4 pagesIstanbul Technical University Maritime FacultybobrekhirsiziNo ratings yet

- Comparison of Blast Furnace Parameters During Different Sinter PercentagesDocument54 pagesComparison of Blast Furnace Parameters During Different Sinter PercentageselangandhiNo ratings yet

- Sue Form C enDocument3 pagesSue Form C endermoscribdNo ratings yet

- Project Management Plan ExampleDocument32 pagesProject Management Plan ExampleStuart Alexander100% (2)

- Gap Control For Socket Weld Back Welded Threaded FittingsDocument12 pagesGap Control For Socket Weld Back Welded Threaded Fittingslaz_k100% (1)

- Mama's EGR Milk MoneyDocument33 pagesMama's EGR Milk MoneyGiapy Phuc Tran100% (13)

- Business Plan Model For StudentsDocument7 pagesBusiness Plan Model For StudentsprikinaNo ratings yet

- A Project Study Report On: P.L. Hyundai, JaipurDocument74 pagesA Project Study Report On: P.L. Hyundai, Jaipurrahulsogani123100% (1)

- Final Project Report VPNDocument96 pagesFinal Project Report VPNpmastjaatNo ratings yet

- Annexure-I List of Link Activities (2006-2007)Document12 pagesAnnexure-I List of Link Activities (2006-2007)rashidkingNo ratings yet

- GM 1927-35 Run at Rate Form - 121049 - 01032010151508Document3 pagesGM 1927-35 Run at Rate Form - 121049 - 01032010151508Jetesh Devgun100% (1)

- Layouts Oil and Gas Installations: Oil Industry Safety DirectorateDocument27 pagesLayouts Oil and Gas Installations: Oil Industry Safety DirectorateC.E. Ishmeet SinghNo ratings yet

- Equipment Performance 2005Document60 pagesEquipment Performance 2005Franz Theo KriboNo ratings yet

- Internship Report On Accounting System of RMG in Palmal Group of IndustriesDocument35 pagesInternship Report On Accounting System of RMG in Palmal Group of IndustriesOmaer Ahmed50% (2)

- Wages and Salary Fixation in Galaxy Toyota: A Research Project ReportDocument80 pagesWages and Salary Fixation in Galaxy Toyota: A Research Project ReportHimanshi MalikNo ratings yet

- JonyDocument90 pagesJonyNaMan SeThiNo ratings yet

- Automation, Prouction Systems and CIM MP GROOVER CHAPTER 3 SolutionDocument7 pagesAutomation, Prouction Systems and CIM MP GROOVER CHAPTER 3 SolutionMuhammad Adeel Ahsen100% (1)

- ERP Implementation at HCC Project ReportDocument85 pagesERP Implementation at HCC Project ReportTrader RedNo ratings yet

- Human Resource Department Public Relation OfficerDocument5 pagesHuman Resource Department Public Relation Officerpry_kumNo ratings yet

- Property Management SystemDocument45 pagesProperty Management SystemAlok RaiNo ratings yet

- Item P-209 Crushed Aggregate Base Course 133Document6 pagesItem P-209 Crushed Aggregate Base Course 133Jimmy LopezNo ratings yet

- Objective: Muhammad Bilal Aslam Electrical Engineer Abu Dhabi, UaeDocument4 pagesObjective: Muhammad Bilal Aslam Electrical Engineer Abu Dhabi, Uaeمھمد بلال اسلم عبدالعزیزNo ratings yet

- Bhel Bhopal Training ReportDocument26 pagesBhel Bhopal Training ReportHanish SinghalNo ratings yet

- Ultratech ProjectDocument48 pagesUltratech ProjectSubrat Swain100% (1)

- Letter On Safety OfficerDocument2 pagesLetter On Safety OfficerRaja RamNo ratings yet

- PROJECT Finance For Mba 4Document116 pagesPROJECT Finance For Mba 4Dhawal BhatiaNo ratings yet

- Date: No. of Pages: 1ss DistributionDocument2 pagesDate: No. of Pages: 1ss Distributionlucasferna123No ratings yet

- EOHSMS-02-C22 LOA Lifting SupervisorDocument3 pagesEOHSMS-02-C22 LOA Lifting SupervisorHassan Abdullah100% (1)

- Unit Ii Project Evaluation 9Document6 pagesUnit Ii Project Evaluation 9bhuvi2312No ratings yet

- Virendra Jha CVDocument7 pagesVirendra Jha CVvkjha2000No ratings yet

- Department of Business Administration: Ourse: Human Resource Management. OpicDocument8 pagesDepartment of Business Administration: Ourse: Human Resource Management. OpicMd HossainNo ratings yet

- REcommended Contents of A DPR-Version 3ADocument3 pagesREcommended Contents of A DPR-Version 3AVijay VaghelaNo ratings yet

- Infosys.110 Business Systems: Deliverable 2: Business Section 2014Document10 pagesInfosys.110 Business Systems: Deliverable 2: Business Section 2014Ellen Strange'No ratings yet

- Landscape Scope AustraliaDocument55 pagesLandscape Scope AustralianenaddimNo ratings yet

- Gaurav Dahiya 2K12/EL/034 2. Sanket Shokeen 2K12/CE/103 3. Vijay Kumar 2K12/CE/120Document6 pagesGaurav Dahiya 2K12/EL/034 2. Sanket Shokeen 2K12/CE/103 3. Vijay Kumar 2K12/CE/120Gaurav DahiyaNo ratings yet

- Lepanto Consolidated Mining Company vs. Ambanloc (June 29, 2010)Document5 pagesLepanto Consolidated Mining Company vs. Ambanloc (June 29, 2010)Vince LeidoNo ratings yet

- Hbs Centurybank Tentcost 30jan14Document8 pagesHbs Centurybank Tentcost 30jan14Amarendra K YadavNo ratings yet

- Auto Sem7 At2403nolDocument65 pagesAuto Sem7 At2403nolMatthew SmithNo ratings yet

- Epoxy Method 2Document11 pagesEpoxy Method 2abcd1860No ratings yet

- Heavy Equipment and LightDocument3 pagesHeavy Equipment and LighthermogenoalexNo ratings yet

- Lps NareshTGTYTG5ERGDocument39 pagesLps NareshTGTYTG5ERGSunil SheoranNo ratings yet

- Bhuvanan B.tech With ExpDocument3 pagesBhuvanan B.tech With Expvpn1987No ratings yet

- Project Management Case Study: The Custom Woodworking Company - Woody 2010 Project R. Max WidemanDocument9 pagesProject Management Case Study: The Custom Woodworking Company - Woody 2010 Project R. Max WidemantoaniltiwariNo ratings yet

- Idrumtech ManualDocument25 pagesIdrumtech ManualrenanzsNo ratings yet

- Ogn Ops Mech 031Document21 pagesOgn Ops Mech 031VIBHAV100% (1)

- Housekeeping Cleaning Equipments USED in HotelsDocument16 pagesHousekeeping Cleaning Equipments USED in HotelsmbakpithiNo ratings yet

- People v. SadiosaDocument3 pagesPeople v. SadiosaJoycee Armillo0% (1)

- Develop Business ModelDocument13 pagesDevelop Business Modelmarie joy ortizNo ratings yet

- Top Credit Rating Agencies of IndiaDocument14 pagesTop Credit Rating Agencies of IndiaAkhil GuptaNo ratings yet

- Tesco PLC Interim Slides 2021Document54 pagesTesco PLC Interim Slides 2021Anti VitaNo ratings yet

- Features of ICICI Pru Guaranteed Income For Tomorrow: What Are Benefits of This Policy?Document3 pagesFeatures of ICICI Pru Guaranteed Income For Tomorrow: What Are Benefits of This Policy?Meenu SinghNo ratings yet

- Design of Jigs and Fixtures 2 MarksDocument16 pagesDesign of Jigs and Fixtures 2 MarksParamasivam Veerappan100% (1)

- 5s Pillars of The Visual WorkplaceDocument35 pages5s Pillars of The Visual WorkplaceSaravana kumar NagarajanNo ratings yet

- Digital SelfDocument15 pagesDigital SelfArdeemay Pands100% (1)

- Hot Consolidation and Mechanical Properties of Nanocrystalline Equiatomic Alfeticrzncu High Entropy Alloy After Mechanical AlloyingDocument6 pagesHot Consolidation and Mechanical Properties of Nanocrystalline Equiatomic Alfeticrzncu High Entropy Alloy After Mechanical AlloyingBuluc GheorgheNo ratings yet

- CourseREG D49290GC10Document7 pagesCourseREG D49290GC10kulayarnieNo ratings yet

- VM1 PLWD r02x2-304Document241 pagesVM1 PLWD r02x2-304ag cnc & wedm machining shopNo ratings yet

- Treasurer's AffidavitDocument2 pagesTreasurer's Affidavityurets929100% (2)

- Company Name Industry Vertical Salutation First Name Designation AddressDocument14 pagesCompany Name Industry Vertical Salutation First Name Designation Addressinfo for businessNo ratings yet

- IRR Privacy Guidelines VER4.0 CleanDocument42 pagesIRR Privacy Guidelines VER4.0 CleanciryajamNo ratings yet

- Reflective Essay MKWDocument1 pageReflective Essay MKWnicholas aprilieNo ratings yet

- Ms Program Booklet 2023 24 Final UpdatedDocument21 pagesMs Program Booklet 2023 24 Final UpdatedCharles OnandoNo ratings yet

- ISO 9001-2015 Implementation PlanDocument19 pagesISO 9001-2015 Implementation PlanJustin RanjitNo ratings yet

- Unit-12 MCQDocument32 pagesUnit-12 MCQAlok p saxenaNo ratings yet

- Churros Marketing PlanDocument20 pagesChurros Marketing PlanViloria, Christine MicahNo ratings yet

- 3a Essential Oils and Oleoresins PDFDocument49 pages3a Essential Oils and Oleoresins PDFSravani reddyNo ratings yet

- Day1: - Foot Print of SAP: ECC vs. S/4HANADocument9 pagesDay1: - Foot Print of SAP: ECC vs. S/4HANALavlesh AggrawalNo ratings yet

- SBM ch-3 Brand - Resonance - and - Value - ChainDocument22 pagesSBM ch-3 Brand - Resonance - and - Value - ChainSana Ijaz100% (1)

- Boom and Bust?: A Political Economy Reading of India's Growth Experience, 1993-2013Document12 pagesBoom and Bust?: A Political Economy Reading of India's Growth Experience, 1993-2013ramitkatyalNo ratings yet

- JICRISD Digital Storytelling Lasem HeritageDocument16 pagesJICRISD Digital Storytelling Lasem HeritageIntan Putri CahyaniNo ratings yet

- A Presentation About Product Re-Brandinng: Meet Our TeamDocument14 pagesA Presentation About Product Re-Brandinng: Meet Our TeamTuhin SarwarNo ratings yet

- HSE InductionDocument8 pagesHSE InductionEsamKhalilAlQadi100% (1)

- Environmental CostingDocument4 pagesEnvironmental CostingAbdullah ChNo ratings yet

- Supply Chain Processes Analytics Exercise: Global Sourcing Decisions - Grainger: Reengineering The China/U.S Supply Chain Chapter 16 Case StudyDocument12 pagesSupply Chain Processes Analytics Exercise: Global Sourcing Decisions - Grainger: Reengineering The China/U.S Supply Chain Chapter 16 Case StudyTom TrageserNo ratings yet

- Guide To Implementing Iso 22000Document34 pagesGuide To Implementing Iso 22000getaneh abebeNo ratings yet

- Master Thesis Search Engine OptimizationDocument7 pagesMaster Thesis Search Engine Optimizationf60pk9dc100% (2)