Professional Documents

Culture Documents

Introduction To Advanced AMethods of Machining

Uploaded by

RAMAKANT RANAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Introduction To Advanced AMethods of Machining

Uploaded by

RAMAKANT RANACopyright:

Available Formats

R.K.

RANA [LECTURER]

M.Tech (P), B.Tech, LMIEI

YouTube.com/RamakantRana RamakantRana INTRODUCTION

Introduction:

Manufacturing processes can be broadly divided into two groups and they are primary manufacturing processes and secondary manufacturing processes. The former ones provide basic shape and size to the material as per designers requirement. Casting, forming, powder metallurgy are such processes to name a few. Secondary manufacturing processes provide the final shape and size with tighter control on dim dimension, ension, surface characteristics etc. Material removal processes are mainly the secondary manufacturing processes. Material removal processes once again can be divided into mainly two groups and they are Conventional Machining Processes and Non Non-Traditional Manufacturing Processes. Examples of conventional machining processes are turning, boring, milling, shaping, broaching, slotting, grinding etc. Similarly, Abrasive Jet Machining (AJM), Ultrasonic Machining (USM), Water Jet and Abrasive Water Jet Mach Machining (WJM and AWJM), Electro Electro-discharge discharge Machining (EDM) are some of the Non Traditional Machining (NTM) Processes. (ii) Classification of Non Traditional Machining Processes To classify Non Traditional Machining Processes (NTM), one needs to understand an and analyse the differences and similar characteristics between conventional machining processes and NTM processes. Conventional Machining Processes mostly remove material in the form of chips by applying forces on the work material with a wedge shaped cutt cutting ing tool that is harder than the work material under machining condition. Such forces induce plastic deformation within the work piece leading to shear deformation along the shear plane and chip formation. Fig. 9.1.1 depicts such chip formation by shear deformation formation in conventional machining.

Fig.1: Shear deformation in conventional machining leading to chip formation. Thus the major characteristics of conventional machining are:

www.CrazyProf.in

www.RamakantRana.blogspot.com

R.K. RANA [LECTURER]

M.Tech (P), B.Tech, LMIEI

YouTube.com/RamakantRana RamakantRana INTRODUCTION

Generally macroscopic chip formation by shear deformation Material removal takes place due to application tion of cutting forces energy domain can be classified as mechanical Cutting tool is harder than work piece at room temperature as well as under machining conditions Non Traditional Machining (NTM) Processes on the other hand are characterised as follows: Material removal may occur with chip formation or even no chip formation may take place. For example in AJM, chips are of microscopic size and in case of Electrochemical machining material removal occurs due to electrochemical dissolution at atomic level In NTM, there may not be a physical tool present. For example in laser jet machining, machining is carried out by laser beam. However in Electrochemical Machining there is a physical tool that is very much required for machining In NTM, the tool need not be harder than the work piece material. For example, in EDM, copper is used as the tool material to machine hardened steels. Mostly NTM processes do not necessarily use mechanical energy to provide material removal. They use different energy domains to pr provide ovide machining. For example, in USM, AJM, WJM mechanical energy is used to machine material, whereas in ECM electrochemical dissolution constitutes material removal. Thus classification of NTM processes is carried out depending on the nature of energy used for material removal. The broad classification is given as follows: o Mechanical Processes Abrasive Jet Machining (AJM) Ultrasonic Machining (USM) Water Jet Machining (WJM) Abrasive Water Jet Machining (AWJM) o Electrochemical Processes Electrochemical ectrochemical Machining (ECM) Electro Chemical Grinding (ECG) Electro Jet Drilling (EJD) o Electro-Thermal Thermal Processes Electro-discharge discharge machining (EDM) Laser Jet Machining (LJM) Electron Beam Machining (EBM) o Chemical Processes Chemical Milling (CHM) Photochemical Milling (PCM) etc.

www.CrazyProf.in

www.RamakantRana.blogspot.com

R.K. RANA [LECTURER]

M.Tech (P), B.Tech, LMIEI

YouTube.com/RamakantRana RamakantRana INTRODUCTION

Fig.2 Schematic representation of various metal cutting operations.

www.CrazyProf.in

www.RamakantRana.blogspot.com

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Engg Graphics 2 Edition PrefaceDocument16 pagesEngg Graphics 2 Edition PrefaceRAMAKANT RANANo ratings yet

- Engineering Drawing Lab ManualDocument52 pagesEngineering Drawing Lab ManualRAMAKANT RANA93% (15)

- SOME Write UPDocument3 pagesSOME Write UPRAMAKANT RANANo ratings yet

- Recent Advances in Mechanical Engineering RAME-2016 (Proceedings)Document768 pagesRecent Advances in Mechanical Engineering RAME-2016 (Proceedings)RAMAKANT RANA100% (4)

- EMM Lecture Unit VIDocument7 pagesEMM Lecture Unit VIRAMAKANT RANANo ratings yet

- Electrochemical Machining ECMDocument11 pagesElectrochemical Machining ECMRAMAKANT RANA100% (1)

- Electrochemical Machining (ECM)Document11 pagesElectrochemical Machining (ECM)RAMAKANT RANANo ratings yet

- Manufacturing Process SyllabusDocument4 pagesManufacturing Process SyllabusRAMAKANT RANANo ratings yet

- Mechatronics Lab ManualDocument32 pagesMechatronics Lab ManualRAMAKANT RANANo ratings yet

- Ultrasonic Machining (Usm)Document12 pagesUltrasonic Machining (Usm)RAMAKANT RANANo ratings yet

- CupolaDocument3 pagesCupolaRAMAKANT RANANo ratings yet

- Engineering Graphics Lab ManualDocument51 pagesEngineering Graphics Lab ManualRAMAKANT RANA63% (8)

- Course 17Document4 pagesCourse 17getprize4surveyNo ratings yet

- Robotics Practical FileDocument131 pagesRobotics Practical FileRAMAKANT RANANo ratings yet

- Laser Beam Machining (LBM)Document10 pagesLaser Beam Machining (LBM)RAMAKANT RANANo ratings yet

- Electrical Discharge MachiningDocument13 pagesElectrical Discharge MachiningRAMAKANT RANANo ratings yet

- Solutions To The Tutorial (No. 2) of Engineering Mechanics (First Semester) !Document4 pagesSolutions To The Tutorial (No. 2) of Engineering Mechanics (First Semester) !RAMAKANT RANANo ratings yet

- Presentation of Drilling Machine by Anil Dahiya SirDocument72 pagesPresentation of Drilling Machine by Anil Dahiya SirRAMAKANT RANA100% (1)

- Solutions To The Tutorial (No. 3) of Engineering Mechanics (First Semester) !Document5 pagesSolutions To The Tutorial (No. 3) of Engineering Mechanics (First Semester) !RAMAKANT RANANo ratings yet

- Tutorial No. 5Document1 pageTutorial No. 5RAMAKANT RANANo ratings yet

- Assignment Instrumentation V Sem EveningDocument5 pagesAssignment Instrumentation V Sem EveningRAMAKANT RANANo ratings yet

- Solutions To The Tutorial (No. 4) of Engineering Mechanics (First Semester) !Document3 pagesSolutions To The Tutorial (No. 4) of Engineering Mechanics (First Semester) !RAMAKANT RANANo ratings yet

- Tutorial No. 4Document2 pagesTutorial No. 4RAMAKANT RANANo ratings yet

- Tutorial No 1Document3 pagesTutorial No 1RAMAKANT RANANo ratings yet

- Engineering Graphics Viva QuestionsDocument1 pageEngineering Graphics Viva QuestionsRAMAKANT RANA75% (4)

- 2nd Sessional SyllabusDocument2 pages2nd Sessional SyllabusRAMAKANT RANANo ratings yet

- Engineering Graphics by RAMAKANT RANADocument1 pageEngineering Graphics by RAMAKANT RANARAMAKANT RANANo ratings yet

- Mecha Syllabus Point WiseDocument2 pagesMecha Syllabus Point WiseRAMAKANT RANANo ratings yet

- Mechanical SwitchesDocument1 pageMechanical SwitchesRAMAKANT RANANo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Reactor Modeling and Simulations in Synthesis Gas ProductionDocument39 pagesReactor Modeling and Simulations in Synthesis Gas ProductionSteven Sandoval100% (1)

- Itp For Main SteelaaaaaaDocument4 pagesItp For Main SteelaaaaaaaymanmalahNo ratings yet

- Types of Flame in Oxy-Acetylene WeldingDocument4 pagesTypes of Flame in Oxy-Acetylene WeldingChimwemwe KaongaNo ratings yet

- JIS G 3141 (2005) Cold-Reduced Carbon Steel Sheets and Strip (SPCC SPCD SPEC)Document15 pagesJIS G 3141 (2005) Cold-Reduced Carbon Steel Sheets and Strip (SPCC SPCD SPEC)Robert SumińskiNo ratings yet

- Ua Welding Continuity Form: Welder/Brazer Continuity InformationDocument1 pageUa Welding Continuity Form: Welder/Brazer Continuity InformationLalit Bom MallaNo ratings yet

- Refractory Installation Preparation Guidelines 2.1 Preparation Prior To The Refractory Installation in The Cement Rotary KilnDocument10 pagesRefractory Installation Preparation Guidelines 2.1 Preparation Prior To The Refractory Installation in The Cement Rotary KilnkING100% (1)

- Mechanical food processing equipment guideDocument3 pagesMechanical food processing equipment guideHamza HafeezNo ratings yet

- Bondhus CatalogDocument52 pagesBondhus CatalogCarbide Processors IncNo ratings yet

- Section - 079129 - Penetration SealsDocument6 pagesSection - 079129 - Penetration SealsBikash BhattaraiNo ratings yet

- Welding Procedure Specification Structural 3G PDFDocument3 pagesWelding Procedure Specification Structural 3G PDFsebincherianNo ratings yet

- Tabela de Peso Parafusos Sextavados A325Document5 pagesTabela de Peso Parafusos Sextavados A325w.araujo.xxxxNo ratings yet

- Make & Take: Rockler SeriesDocument3 pagesMake & Take: Rockler SeriescajemarNo ratings yet

- Drilling Jigs Italiana FerramentaDocument34 pagesDrilling Jigs Italiana FerramentaOliver Augusto Fuentes LópezNo ratings yet

- 178 - Norox TBPB DataDocument4 pages178 - Norox TBPB Datario mulyaNo ratings yet

- SKFP COEXTRUSION SOLUTIONS Jan 31 2022Document26 pagesSKFP COEXTRUSION SOLUTIONS Jan 31 2022李万福No ratings yet

- Versilon HP Pfa 400 High Purity TubingDocument2 pagesVersilon HP Pfa 400 High Purity TubingDHAVALNo ratings yet

- Piping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServiceDocument6 pagesPiping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServicePaulo GalvãoNo ratings yet

- Papermaking 2017Document7 pagesPapermaking 2017quizizz section4No ratings yet

- Interplus 356 PDFDocument4 pagesInterplus 356 PDFDamen JohnsonNo ratings yet

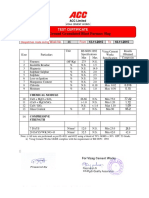

- Ground Granulated Blast Furnace Slag: Test CertificateDocument2 pagesGround Granulated Blast Furnace Slag: Test CertificatenoumanNo ratings yet

- Woodtech Pu ExteriorDocument2 pagesWoodtech Pu ExteriorSathish SathishNo ratings yet

- Ultra-high Strength Fastener GuideDocument4 pagesUltra-high Strength Fastener GuidemirosekNo ratings yet

- Common Laboratory TechniquesDocument16 pagesCommon Laboratory TechniquesNiki KevinNo ratings yet

- Hydrogen Embrittlement Relief I: en enDocument10 pagesHydrogen Embrittlement Relief I: en enCarmen HernandezNo ratings yet

- BMM3643 Manufacturing Process: 8.0 Materials Removal PROCESSES: MachiningDocument16 pagesBMM3643 Manufacturing Process: 8.0 Materials Removal PROCESSES: MachiningRima ChinnasamyNo ratings yet

- Workshop Manual Transporter 2016 23-29Document48 pagesWorkshop Manual Transporter 2016 23-29samueleNo ratings yet

- A350A350M-2018 Grade LF1, LF2, LF3, LF5, LF6, LF9, LF787Document6 pagesA350A350M-2018 Grade LF1, LF2, LF3, LF5, LF6, LF9, LF787Yilia WangNo ratings yet

- Design and Fabrication of Die for Metal Powder CompactionDocument69 pagesDesign and Fabrication of Die for Metal Powder CompactionMohit Assudani100% (2)

- 36NiCrMo16 PDFDocument2 pages36NiCrMo16 PDFAmy GriffinNo ratings yet

- PRO-76T Multifunction Drilling & Tapping MachineDocument4 pagesPRO-76T Multifunction Drilling & Tapping MachineBouraoui Ben AyedNo ratings yet