Professional Documents

Culture Documents

Aerospace Materials Guide

Uploaded by

snuffit11Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aerospace Materials Guide

Uploaded by

snuffit11Copyright:

Available Formats

Johann Maier GmbH & Co.

KG

Schockenriedstrae 38 70565 Stuttgart-Vaihingen

Typical aerospace-standard materials

Material No. 1.1174.4 1.1174.5 1.1174.6 Description Comparable to DIN Material Ck 35 1.1181 Rm [MPa] 540 - 690 580 - 730 620 - 770 A5 [%] 20 19 17

Unalloyed hardened and tempered steel with approx. 0,35 C

Special properties: not resistant to corrosion, weldable - but dependent on the process Application: components with average requirements on strength and toughness 1.4314.7 Stainless, austenitic steel 0,05C-18Cr-9Ni X5 CrNi 18 9 1.4301 860

*

10

*

Special Properties: weldable, resistant to erosive corrosion, intercrystalline and stress corrosion possible ( passivating ! ! ) Application: rustless components, fasteners and bolts with improved strength properties High-strength --1220 - 1400 10 precipitation-hardening 1. 4534.5 stainless 1400 - 1550 9 steel 1. 4534.6 0,04C-13Cr-8Ni1500 - 1650 9 2,2Mo-1Al Special Properties: resistant to corrosion and highly resistant to stress corrosion, highly strength up to elevated temperatures of 315C, weldable, perfect tensile strength and toughness - isotrope Application: highly strenght chassis components, fasteners, bolts 1.4544.7 Stainless, austenitic steel 0,05C-18Cr-10Ni-0,4Ti X10 CrNiTi 18 9 1.4541 600 35 1.4534.4

Special Properties: resistant to erosive and intercrystalline corrosion, weldable, scale resistant up to 850C Application: corrosion resistant, scale resistant components up to elevated temperatures of 850C

* semifinished product diameter 18 mm

Issue: October 2008

Page 1 of 6

Material No. 1.4548.4 1.4548.5 1.4548.6

Description

Comparable to DIN Material ---

Rm [MPa] 1070 1170 1310

A5 [%] 11 10 10

Stainless, austenitic steel 0,05C-16Cr-4Ni-4Cu

Special Properties: corrosion resistant, low tendency to distortion, appropriate for welding Application: components with high strength and high corrosion resistance up to 300C 1.4914.5 High-strength, hardened tempered stainless steel 0,15C-11Cr-0,7Mo0,4Nb-0,4V X19 CrMoVNb 11 1 1.4913 930 - 1080 10

Special Properties: heat resistant up to 600C, corrosion resistant if a fine grounded surface is available, nitrable but with lower corrosion resistant Application: components for aircraft engines, fasteners and bolts up to 600C 1.4939.5 1.4939.6 Heat-resisting hardened tempered steel 0,1C-12Cr-1,8Mo2,5Ni-0,3V --900 - 1100 1100 - 1300 14 10

Special Properties: weldable, corrosion resistant if a fine grounded surface is available Application: impeller components, fasteners, bolts, nuts up to approx. 550C 1.4943.4 Heat-resisting, precipitation-hardening steel 0,03C-25Ni-15Cr-1,8Ti --850 20

Special Properties: weldable, comparable with 1.4944 Application: weldable components for aircraft engines and gas turbines up to 700C 1.4944.4 1.4944.6 Heat-resisting, precipitation-hardening steel 0,06C-25Ni-15Cr2,1Ti-1,2Mo --960 1100 12 8

Special Properties: heat resistant and resistant to erosive corrosion up to approx. 725C (comparable to austenitic 18/8 CrNi-Steel), resistant to stress corrosion Application: gas turbine components, shafts, bolts, fasteners and nuts up to 700C, assembling with light metals possibel (expansion coefficient !)

Issue: October 2008 Page 2 of 6

Material No. 1.6604.4 1.6604.5 1.6604.6

Description

Comparable to DIN Material 30 CrNiMo 8 1.6580

Rm [MPa] 900 - 1100 1100 - 1300 1250 - 1450

A5 [%] 12 10 9

Low-alloyed hardened tempered steel 0,3C-2Cr-2Ni-0,4Mo

Special Properties: not weldable and not corrosion resistant, ductile Application: components with high requirements to strength and toughness up to 350C 1.7214.4 1.7214.5 Low-alloyed hardened tempered steel 0,25C-1Cr-0,2Mo 25 CrMo 4 1.7325 650 - 850 900 - 1100 15 12

Special Properties: weldable, not corrosion resistant Application: weldable components with improved strength up to approx.. 350C 1.7224.5 1.7224.6

**

Low-alloyed hardened tempered steel 0,35C-1Cr-0,2Mo

34 CrMo 4 1.7220

900 - 1100 1100 - 1300

12 10

Special Properties: not weldable and not corrosion resistant (cadmium plated !) Application: high strength fasteners, bolts and nuts up to a maximum of 200C 1.7734.4 1.7734.5 1.7734.6 Low-alloyed hardened tempered steel 0,15C-1,4Cr-0,9Mo0,25V 15 CrMoV 6 1.7262 700 980 - 1180 1080 - 1250 13 11 10

Special Properties: weldable, not corrosion resistant, improved high temperature strength and better tempering strength as the material 1.7214 Application: weldable components with high tempering strenght up to approx. 500C 1.7784.5 1.7784.6 High strength hardened tempered steel 0,4C-5Cr-1,3Mo-0,5V --1520 - 1670 1800 - 2000 9 7

Special Properties: highly temperature and highly strength up to approx. 500C, not corrosion resistant, low tendency to distortion, limited weldable, nitrable, scaling possible already at 500C Application: gas tanks, chassis components, fasteners and bolts with highly strenght requirements up to elevated temperatures of approx. 500C

** in the past the material-no. was 1.7220 ( with DIN standard material, with that reason its now 1.7224)

Issue: October 2008

Page 3 of 6

Material No. 1.8564.5 1.8564.6

Description

Comparable to DIN Material 31 CrMo 12

Rm [MPa] 950 - 1100 1050 - 1250

A5 [%] 13 10

Nitriding steel 0,3C-3Cr-0,4Mo

Special Properties: quench and tempering possible, nitrable, not corrosion resistant Application: components with high surface and core hardness and a good wear resistance up to 520C 2.4631.7 High strength precipitationhardening Nickel-Alloy 20Cr-2,3Ti-1,4Al-0,1C NiCr 20 TiAl Nimonic 80A 1000 20

Special Properties: high temperature strength and scale resistant up to 1000C, weldable, corrosion resistant, hot gas corrosion with S and Na compounds Application: turbine blades, turbine rings, turbine disks and fasteners up to elevated temperatures of 815C 2.4668.7 2.4668.9 High strength precipitationhardening Nickel-Alloy with approx. 19Cr-18Fe-5Nb3Mo-0,05C similar to Inconel 718 1270 1550 - 1750 11 8

Special Properties: high temperature strength, scale resistant and ductile up to approx. 700C, high resistant to oxidation and corrosion, stress corrosion resistant, weldable Application: fasteners, bolts, turbine and rocket components up to elevated temperatures of 700C 3.7164.1 3.7164.7 (+) Titanium-Alloy Ti-6Al-4V --900 1100

***

10 8

Special Properties: high ratio of strenght to weight, high fracture toughness, corrosion resistant, resistant to stress corrosion up to 300C, weldable, reaction with gases already at 200C possible attention: lost in ductility to improve the fretting and contact corrosion the anodic oxidation and thin film coating with lubricant on molybdenum disulphide will be helpful Application: turbine blades and discs, fasteners and bolts for the aircraft and space industry

*** semifinished product diameter 13 mm

Issue: October 2008

Page 4 of 6

Johann Maier GmbH & Co. KG

Schockenriedstrae 38 70565 Stuttgart-Vaihingen

Special alloys for high strength applications

Material No. MP 35 Description Comparable to DIN Material --Rm [MPa] 1800 - 2000 A5 [%] 8

++

Cobalt-based alloy mit 35Ni-20Cr-10Mo

Special Properties: highly strength up to 550C, ductile, corrosion and stress corrosion resistant, resistant to hydrogen embrittlement Application: highly strength fasteners and bolts 300 M High strength steel 0,4C-1,8Ni-0,9Cr-0,8Mn0,4Mo-0,1V-1,7Si --1900 7

Special Properties: highly strength and ductile, resistant to oxidation acid, not resistant to stress corrosion and hydrogen embrittlement Application: highly strength components for chassis, fasteners NC 310 similar to 300 M but more of approx. 1% Si and 0,1%V --2080 8

Special Properties: comparable to 300 M but a higher strength with a higher ductility Application: comparable to 300 M 30 NCD 16 Hardened tempered steel 0,3C-3,5Ni-1,2Cr-0,45Mo 1.6747 1080 - 1230 1220 - 1370

+++

10 8

Special Properties: highly strength and ductile, not corrosion resistant, high depth of hardness Application: components with high bending stress, impact stress and shock loading 35 NCD 16 Hardened tempered steel 0,35C-3,8Ni-1,7Cr-0,3Mo 1.6773 1080 - 1270 1230 - 1380

+++

10 8

Special Properties: comparable to 30 NCD 16 Application: highly stressed components with a extensive design and a high wear resistance

Issue: October 2008

Page 5 of 6

Johann Maier GmbH & Co. KG

Schockenriedstrae 38 70565 Stuttgart-Vaihingen

Material No. Marval X12H

Description

Rm [MPa] 1400 1520

A5 [%] 10 9

High-strength precipitation-hardening stainless steel

Special Properties: highly strength and ductile, corrosion resistant and highly resistant to stress corrosion Application: highly stressed components for chassis, fasteners , bolts and components for applications in the aerospace industry Ti Beta-C Ti-3Al-8V-6Cr-4Mo-4Zr Titanium near -Alloy c.d. 1400 1500 9 5

The mechanical properties have to be adjusted by the heat treatment and manufacturing process parameters and are only "provisional values". The effectively demands of mechanical properties at the finished components have to be clarified first. Special Properties: extremely light with a density from 4,82, high-strength and ductile compared to Ti 6 Al 4 V. Application: light and high strength fasteners and bolts with good processing and formability

++ measured with a A4 test sample according to AMS 5844 +++ a higher strength is possible, but with a lost in ductility

Remark: The specified mechanical values refer to semifinished rolled or pulled bars parallel to the axis. In the case of single values in the above tables these are represent minimum values. Furthermore the values are considered to semifinished products with a diameter up to 30 mm.

Issue: October 2008

Page 6 of 6

You might also like

- Manual Sierra BandaDocument62 pagesManual Sierra BandaElvis Luis Rivera Dueñas100% (1)

- WIKUS Band Saw BladesDocument64 pagesWIKUS Band Saw BladesRashedul HasanNo ratings yet

- Tig 4300i AC/DC DetailsDocument24 pagesTig 4300i AC/DC DetailsaswanthNo ratings yet

- 5 NuclitecDocument62 pages5 NuclitecArif KurniawanNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- Tabla Torqueo de PernosDocument1 pageTabla Torqueo de PernosErnesto LinaresNo ratings yet

- Manual Olimpus PDFDocument64 pagesManual Olimpus PDFmachine_toolsNo ratings yet

- Automatic CNC Drilling Line for Steel ProfilesDocument7 pagesAutomatic CNC Drilling Line for Steel ProfilesEugen CozianuNo ratings yet

- Survey Steel Grades MarkenübersichtDocument12 pagesSurvey Steel Grades MarkenübersichtLeandro AlmeidaNo ratings yet

- MIG/MAG Robot Hose Pack Parts ListDocument12 pagesMIG/MAG Robot Hose Pack Parts ListAdina Claudia BesliuNo ratings yet

- Understanding Crossed Roller Bearing Identification NumbersDocument16 pagesUnderstanding Crossed Roller Bearing Identification NumbersSandhya SankarNo ratings yet

- Tetrix 300 Acdc ManualDocument92 pagesTetrix 300 Acdc ManualnapalitoNo ratings yet

- H-1000-5021-06-B (E)Document53 pagesH-1000-5021-06-B (E)marioNo ratings yet

- RCEG-12 Assembly Drawings and SchematicsDocument121 pagesRCEG-12 Assembly Drawings and SchematicsEnrique Martinez RojasNo ratings yet

- SERVICE MANUAL - lg+LB1000ER PDFDocument43 pagesSERVICE MANUAL - lg+LB1000ER PDFPaulo LaraNo ratings yet

- 07387102Document455 pages07387102IvanNo ratings yet

- Bend TrainingDocument4 pagesBend TrainingbdaneshvarNo ratings yet

- Sandvik Versatile Tools 2018Document153 pagesSandvik Versatile Tools 2018jaajaNo ratings yet

- Cosmo New Mighty Super Oil SeriesDocument2 pagesCosmo New Mighty Super Oil SeriesluluNo ratings yet

- CNC Programming Examples Guide for S3000-S4000 SeriesDocument128 pagesCNC Programming Examples Guide for S3000-S4000 SeriesSQuestNo ratings yet

- Laser Cutting LVDDocument12 pagesLaser Cutting LVDPri HongNo ratings yet

- Welding ShopDocument10 pagesWelding ShopAsifJavedNo ratings yet

- Accu Fast IIDocument2 pagesAccu Fast IIVimal KumarNo ratings yet

- CZJ 2Document3 pagesCZJ 2onlyichwan wicaksonoNo ratings yet

- AMO Incremental Length Encoder CatalogDocument56 pagesAMO Incremental Length Encoder CatalogElectromateNo ratings yet

- TPSi OBUKADocument97 pagesTPSi OBUKASlavisaGNo ratings yet

- Samsung E1050 Service Manual Final AnyserviceDocument48 pagesSamsung E1050 Service Manual Final Anyserviceenya90100% (1)

- Quotation For Fiber Laser Cutting Machines 4 KW: NF - PRO 315 VentoDocument25 pagesQuotation For Fiber Laser Cutting Machines 4 KW: NF - PRO 315 VentobeemasundarNo ratings yet

- Leco Hard Testing 209Document8 pagesLeco Hard Testing 209Arun Sasi100% (1)

- GG 3903 01 enDocument1 pageGG 3903 01 enSamprit BasuNo ratings yet

- Ultrasonic Thickness Gauge ManualDocument13 pagesUltrasonic Thickness Gauge ManualMark K50% (2)

- Betriebsanleitung WT 035-03 Version 1.2 EngDocument16 pagesBetriebsanleitung WT 035-03 Version 1.2 EngGyörgy MurvaiNo ratings yet

- AMADA Katalog 2011 PDFDocument93 pagesAMADA Katalog 2011 PDFdejavu_45No ratings yet

- ARC Welding Application - E1102000124GB01Document116 pagesARC Welding Application - E1102000124GB01IsmaelNo ratings yet

- User's Manual of Haiwell PLC Digital ModuleDocument12 pagesUser's Manual of Haiwell PLC Digital ModuleEmmy-HaiwellNo ratings yet

- MIL-C-7438 Core Material Aluminum For Sandwich Construction Rev GDocument30 pagesMIL-C-7438 Core Material Aluminum For Sandwich Construction Rev GJayaram PothnisNo ratings yet

- HPR260XD Auto Gas - Instruction Manual 806350 Rev2 PDFDocument338 pagesHPR260XD Auto Gas - Instruction Manual 806350 Rev2 PDFIlian Avramov100% (1)

- Tig Up 293-403H AC DCDocument35 pagesTig Up 293-403H AC DCmagzigioNo ratings yet

- Dokumentation Energoutil 2015-35370 - enDocument37 pagesDokumentation Energoutil 2015-35370 - enbrctlnNo ratings yet

- TK102B English User ManualDocument10 pagesTK102B English User ManualIsyana Bundanya TakaZeera100% (3)

- DKC01.3 040 7 FW DKC01 Ecodrive Servo Drive Rexroth Manual PDFDocument346 pagesDKC01.3 040 7 FW DKC01 Ecodrive Servo Drive Rexroth Manual PDFZsolt PerecesNo ratings yet

- ZX3 ManualDocument76 pagesZX3 ManualhypoeNo ratings yet

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDocument2 pagesAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987No ratings yet

- f0211 300 NP FLG X FLG Data SheetDocument1 pagef0211 300 NP FLG X FLG Data SheetRay LujanNo ratings yet

- Manual TMEBDocument148 pagesManual TMEBwbello31No ratings yet

- 3RG6 Sonar-BERO Ultrasonic Proximity Switches: GeneralDocument22 pages3RG6 Sonar-BERO Ultrasonic Proximity Switches: Generalyouri59490No ratings yet

- Spare parts package options for EcoCwave machineDocument2 pagesSpare parts package options for EcoCwave machineVencislav VankovNo ratings yet

- Eurobond Standard E-CatalogueDocument28 pagesEurobond Standard E-CatalogueGowresankar ArNo ratings yet

- LG - LBUM7280BL Exploded ViewDocument55 pagesLG - LBUM7280BL Exploded ViewGuillermo HernandezNo ratings yet

- 3.1 EdmDocument60 pages3.1 EdmMohit KumarNo ratings yet

- IC-3005 Series DatasheetDocument2 pagesIC-3005 Series DatasheetNeneng SukriaNo ratings yet

- Schallater Gaas80 Gaa100 DownloadDocument4 pagesSchallater Gaas80 Gaa100 DownloadRakesh SrivastavaNo ratings yet

- Is5 Catalog PDFDocument24 pagesIs5 Catalog PDFTarmatNo ratings yet

- kFace-M882 Temperature Measurement Face Recognition TerminalDocument5 pageskFace-M882 Temperature Measurement Face Recognition Terminalibrahim ahmedNo ratings yet

- Tox PressotechnikDocument23 pagesTox PressotechnikCristobal Espinoza FloresNo ratings yet

- Industrial Theodolites & Total Stations Brochure en PDFDocument8 pagesIndustrial Theodolites & Total Stations Brochure en PDFGiora RozmarinNo ratings yet

- Aerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Document6 pagesAerospace Standard Materials - Mechanical Properties - Issue 12 - 2015Leandro González De CeccoNo ratings yet

- Material Specification Sheet Saarstahl - 36crnimo4Document1 pageMaterial Specification Sheet Saarstahl - 36crnimo4Anonymous rYZyQQot55No ratings yet

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDocument36 pagesRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456No ratings yet

- 4340Document1 page4340ralishNo ratings yet

- Merkel ZaptivkeDocument3 pagesMerkel Zaptivkesnuffit11No ratings yet

- Recommended Math/Stat Courses Bioe Graduate Committee/Michael SacksDocument1 pageRecommended Math/Stat Courses Bioe Graduate Committee/Michael Sackssnuffit11No ratings yet

- Us 8556209Document16 pagesUs 8556209snuffit11No ratings yet

- Modeling of Impact Dynamics of A Tennis Ball With A Flat SurfaceDocument182 pagesModeling of Impact Dynamics of A Tennis Ball With A Flat Surfacesnuffit11No ratings yet

- Modeling of Impact Dynamics of A Tennis Ball With A Flat SurfaceDocument182 pagesModeling of Impact Dynamics of A Tennis Ball With A Flat Surfacesnuffit11No ratings yet

- 11Document13 pages11snuffit11No ratings yet

- ISO and EN standards for securing cargo in vehicles and containersDocument35 pagesISO and EN standards for securing cargo in vehicles and containersMuharrem BeyogluNo ratings yet

- Pbat 10 eDocument16 pagesPbat 10 eapi-290101261No ratings yet

- AsaDocument35 pagesAsamarz95No ratings yet

- Rolls ModelsDocument186 pagesRolls ModelsapeirotanNo ratings yet

- BAWEJA Drying Shrinkage and CrackingDocument28 pagesBAWEJA Drying Shrinkage and CrackingMohammad IqbalNo ratings yet

- WIND LOADING ANALYSIS - Wall Components and Cladding: Input DataDocument15 pagesWIND LOADING ANALYSIS - Wall Components and Cladding: Input DataMartin VenichNo ratings yet

- Earth Ground Resistance Measurement GuideDocument5 pagesEarth Ground Resistance Measurement GuideRoopesh Kumar TirupathiNo ratings yet

- POWER JACK Report 35 PagesDocument35 pagesPOWER JACK Report 35 Pagesankush belkarNo ratings yet

- Sistem Narrowband Dan WidebandDocument4 pagesSistem Narrowband Dan Widebandarrizky ayu faradila purnamaNo ratings yet

- Modeling of The Evaporation and Condensation Phase Change Problems With FLUENTDocument17 pagesModeling of The Evaporation and Condensation Phase Change Problems With FLUENTRashed KaiserNo ratings yet

- Limit State DesignDocument12 pagesLimit State DesignEzhil KumarNo ratings yet

- Confirm Receipt TroubleshootingDocument1 pageConfirm Receipt TroubleshootingMahmoud Ibrahim ElatafawyNo ratings yet

- Gemology PDFDocument65 pagesGemology PDFNamwangala Rashid Natindu50% (2)

- Lecture 3Document43 pagesLecture 3InfragNo ratings yet

- Entropy Problems AnswersDocument6 pagesEntropy Problems AnswersTots HolaresNo ratings yet

- Strongroom&safes PDFDocument3 pagesStrongroom&safes PDFAlbertNo ratings yet

- Portal KombatDocument13 pagesPortal KombatspereiracunhaNo ratings yet

- DPWH Waterstop SpecificationDocument6 pagesDPWH Waterstop SpecificationFrancis DomingoNo ratings yet

- Ddrcs Unit 4Document22 pagesDdrcs Unit 4siva shanmukhaNo ratings yet

- Apr 88372Document2 pagesApr 88372N1234mNo ratings yet

- CSWA Simulasi Preparation Soal Dan JawabanDocument22 pagesCSWA Simulasi Preparation Soal Dan JawabanRirin ayu puspita40% (5)

- Cameleon OilerDocument48 pagesCameleon OilerKieran GabardNo ratings yet

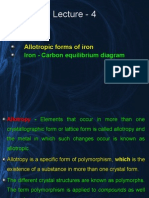

- FMP 221 Lecture 4Document22 pagesFMP 221 Lecture 4SarojKumarSinghNo ratings yet

- Tumble Dryer Instruction BookletDocument72 pagesTumble Dryer Instruction BookletElla MariaNo ratings yet

- Good Manual Xilinx-Fpga Fpga TimingDocument168 pagesGood Manual Xilinx-Fpga Fpga TimingChauHuynhNo ratings yet

- Final Cut Coach MC-6 Mid Term Exam QuestionsDocument10 pagesFinal Cut Coach MC-6 Mid Term Exam QuestionsVan CooperNo ratings yet

- REPORT On Power Line Carrier CommunicationDocument28 pagesREPORT On Power Line Carrier CommunicationAshish Jain100% (4)

- Kitchen Details by 0631 - DAGANTA PDFDocument1 pageKitchen Details by 0631 - DAGANTA PDFJay Carlo Daganta100% (1)

- How To Maintain Sf6 Circuit BreakerDocument6 pagesHow To Maintain Sf6 Circuit BreakerijsretNo ratings yet

- SQLite Database Connectivity in AndroidDocument7 pagesSQLite Database Connectivity in Androidz4pt3dNo ratings yet