Professional Documents

Culture Documents

Cerium Four and Three

Uploaded by

witkerzOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cerium Four and Three

Uploaded by

witkerzCopyright:

Available Formats

Geosystem Eng.

, 3(2), 81-83, (June 2000)

Preparation of Ceric Hydroxide through Transformation of Cerium Compounds

Jiang-Tao Jia1), Chun-Hua Yan1), Jong-Kee Oh2)*, Chang-Hong Kim2) and Chong-Hong Pyun2)

1)

State Key Laboratory of Rare Earth Materials Chemistry and Applications, Peking University, Beijing 100871, China 2) Korea Institute of Science and Technology, Seoul 130-650, Korea (Received January 28, 2000 ; Accepted May 12, 2000)

ABSTRACT : The light rare earths, particularly cerium compounds, are becoming more and more important recently. The preparation method of Ce(OH)4 xH2O through transformation between cerium compounds was investigated. The process is compared with the direct routine by reacting Ce(III) with sodium hydroxide and hydrogen peroxide as a oxidant. The results show that transformation process is a potential preparation technique to produce Ce(OH)4 xH2O with better physical properties. Key words : preparation, ceric hydroxide, transformation process, cerium compounds

INTRODUCTION

Rare earth elements play more and more important roles in materials science and technology recently. Because of their extraordinary characteristics in viewpoints of optics, electric and magnetic properties, rare earths have more advantages than other elements as functional materials. Scientists of American and Japanese regard them as the keys of the new material treasure house. Some of the developed countries even store rare earth resources as strategic materials for the coming 21st century. In fact, some novel rare earth materials came out and were industrialized and commercialized every five or ten years during the past several decades. And the cycling has been intending shorter and shorter over the last several decades. Cerium of an important light rare earths occupies nearly half of the rare earth composition in bastnasite and is particularly a unique element with oxidation number of III and IV. Its compounds are also extensively used in glasses, abrasives, decolorant, and solid electrolytes. As the requirements of environment protection, the exhausted gas from vehicles should be cleaned by catalysts made of cerium oxide. The cerium, an active component of the catalyst(Crucq A. et al.), is rapidly increasing in consumption, recently. Zhang H.J. reviewed on China Rare Earth Information that near half of the cerium production is consumed in this area in the United States during

the past few years. This demands to scale up the metallurgical processes of bastnasite. Nowadays, many kinds of cerium compounds have been produced. They are, for instance, CeO2, Ce(OH)4, Ce(SO4)2, Ce(NO3)4, Ce2(CO3)3, CeF3, CeCl3, Ce2(C2O4)3, CePO4, and a series of ammonium and sodium complex salts. CeO2 is the most popular compound among them for industrial uses. However, it is often difficult to be treated in most cases because the precursor of cerium is generally obtained as cerium dioxide which has low solubility in some mineral acids. CeF3, Ce2(C2O4)3 and CePO4 are also insoluble in mineral acid. CeCl3 has hygroscopic property and ceric chloride is unstable. The carbonate is available as a precursor on account of its high solubility in mineral acid. However, it has a drawback to emit much more volume of carbon dioxide gas during the leaching process. Ce(OH)4 is becoming more and more popular as a precursor recently, which is a primary product from the process of treating rare earth minerals in general.

EXPERIMENTAL

Reagents The sample and reagents used for the experiments are listed as follows : Cerous carbonate, CeO2 /REO 99%, TREO~ 50%, Zibo Rare Earth Plant, China; Sodium sulfate anhydrous, 98.5%, Extra pure, Kanto Chemical Co. Inc.; Sodium hydroxide, 96%, Guaranteed Reagent, Junsei Chemical Co., Ltd.; Hydrogen peroxide, ~35%, Extra pure, Junsei Chemical Co., Ltd. Preparations Cerium carbonate is dissolved into hydrochloric acid solution. The solution is treated with proper reactants as neutralizers like NaOH and KOH to produce ceric hydroxide, which is filtered and calcined at high temperature through drying to get the ceric oxide. First of all, 20.5 g Ce2(CO3)3 xH2O in a 200 ml beaker is pulped with 20 ml distilled water and 20 ml HCl(11.3 mol/L) is added to dissolve the cerium carbonate. The reaction is progressing very fast in the strong acid solution. The solution

81

82

Jiang-Tao Jia et al.

become clear when all the Ce2(CO3)3 xH2O is dissolved in hydrochloric acid. 20 g Na2SO4 is dissolved in distilled water and the solution is poured into the cerous solution. The white precipitate is washed and filtered. The precipitate is dissolved into 100 ml alkaline solution with 80 g NaOH per liter of distilled water. And then the slurry is treated by gradually adding 30 ml H2O2(30 wt.%), kept reaction for 4 hours and then heated for one hour to prepare the ceric hydroxide which is washed, filtered and calcined to transform it into ceric oxide.

RESULTS AND DISCUSSION

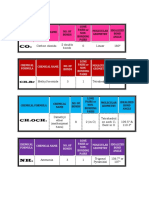

The solubility products of ceric hydroxide[Ce(OH)4] is much lower(about 10-40) than most other insoluble cerium salts. This makes it possible to prepare Ce(OH)4 xH2O by transformation from other salts. Ce2(CO3)3 and Ce (III) complex salts are rather popular species for preparation of Ce(OH)4 xH2O. When the cerrous carbonate is dissolved with hydrochloric acid by the reaction (1) over generation of carbon dioxide. Ce2(CO3)3 xH2O + 6HCl = 2CeCl3 + 3CO2 + (3+ x)H2O (White powder) (1) Cerous solution is treated with sodium sulfate to precipitate the white powder of NaCe(SO4)2 nH2O like equation (2). The slurry is settled after heating and stirring for about 10 minutes and decanted to remove the upper clear solution. The condensed cerous sulfate slurry is washed with warm water. The cerium can be recoverd with high efficiency, because the solubility of such complex salt is quite low in excessive sodium sulfate solution. The dried product is identified to be NaCeSO4 by XRD, as shown in Fig. 1. CeCl3 + 2Na2SO4 + nH2O = NaCe(SO4)2 nH2O (White) + 3NaCl (2)

into alkaline solution, where cerous ion is partially oxidized by the air to show the gray color. Hydrogen peroxide reacts with sodium cerous sulfate into hydroperoxyl ceric hydroxide with dark brown as shown in equation (3). The product is identified to be amorphous as shown in Fig. 2, which is partially converted into ceric hydroxide on drying. The slurry containing dark brown precipitate of Ce(OH)3 OOH is kept reation for 4 hours and then heated for about half an hour to transform the cerous compound into bright yellow precipitate of ceric hydroxide as shown in equation (4). The ceric hydroxide can be confirmed to be Ce(OH)4 2H2O by XRD as shown in Fig. 3. 2NaCe(SO4)2 nH2O+6NaOH+3H2O2 = 2Ce(OH)3 OOH + 4Na2SO4 + 2(n+1)H2O (Dark brown) 2Ce(OH)3 OOH = 2Ce(OH)4 +O2 (Yellow)

(3) (4)

The recovered ceric hydroxide through thoroughly washing is calcined to produce the ceric oxide, which has the proper size and better filtrability. Besides the way of transformation described as above,

The white precipitate of NaCe(SO4)2 nH2O is pulped

Fig. 2. XRD pattern of Ce(OH)3 OOH xH2O as intermediate product.

Fig. 1. Crystal of NaCeSO4 to be produced by reaction (2).

Fig. 3. Crystallinity of ceric hydroxide as Ce(OH)4 2H2O produced.

Preparation of Ceric Hydroxide through Transformation of Cerium Compounds

83

Ce(OH)4 xH2O can be directly prepared by reacting Ce(III) salts simultaneously with sodium hydroxide and hydrogen peroxide. Predetermined amount of Ce2(CO3)3 xH2O is made paste with water and dissolved in hydrochloric acid thoroughly. And then the residue is filtered out as insoluble impurities. The excessive amount of H2O2 poured into the filtrate in order to convert cerous to ceric ion and NaOH solution is dropped slowly. The dark brown precipitate appears according to equation (5). When the color changes to yellow on boiling, the precipite is filtered with washing to get the final product of ceric hydroxide. 2CeCl3 +6NaOH+3H2O2 = 2Ce(OH)3 OOH (Dark brown) + 2H2O +6NaCl (5)

Ni, J. Z. and Hong, G. Y., 1998, Progress on novel rare earth materials and flow sheets, Science Press, Beijing. Crucq A., 1991, Catalysis and automotive pollution control II: proceedings of the Second International Symposium (CAPoC 2), Brussels, Belgium, September 10-13, 1990, Elsevier, Amsterdam ; New York. Zhang H.J., 1999, Review and prospect on Rare Earth Market, China Rare Earth Information Center, Baotou. th Susan B., 1996, The Merck Index, 12 , Merck & Co. Inc.:Whitehouse Station, NJ, p1483.

Compared the two ways of preparation of ceric oxide, although the former process has more steps than the latter, Ce(OH)4 xH2O produced by the former method is more convenient to be rinsed and filtered than that obtained by the latter. So transformation process makes it quite easier to treat the product and to lessen the moisture content of the product.

Jiang-Tao Jia, received his B.S.(1991) in Chemistry and Ph.D. (1998) in Rare Earth Separation Chemistry from Peking University, China. He is currently postdoctoral researcher of Peking University and a visiting scientist in KIST, Korea. His main research interests are rare earth separation chemistry and engineering.

CONCLUSION

In order to make use of rare earths in functional materials conveniently, the preparation of Ce(OH)4 xH2O is investigated and reviewed through transformation process and direct precipitation. Compared with direct precipitation method of reacting Ce3+ with base after oxidation of cerous ion with hydrogen peroxide, complex salt of NaCe(SO4)2 is better to make Ce(OH)4 xH2O with better physical properties. The precipitates obtained by transformation is more convenient for washing and filtering the product. This process could be available in the industrialization for preparation of ceric oxide.

Chun-Hua Yan, received his B.S.(1982) in Chemistry, M.S.(1985), and Ph.D.(1988) in Inorganic Chemistry from Peking University, China. He is currently a professor of Chemistry in Peking University and a commissioner in ChinaKorea Advanced Materials Cooperation Center. His main interests are rare earth separation and materials chemistry. Jong Kee Oh, received his B.S.(1969) in the Mining Engineering Dept. and Ph.D.(1986) in Rare Earth Separation by Solvent Extraction from Seoul National University. He is currently principal researcher of Metal Processing Research Center at KIST and has mainly interests in recovery of metals from primary and/or secondary resources and hydrometallurgy.(ohjoko@kist.re.kr) Chang-Hong Kim, received his B.S. in Chemical Science from Seoul National Univeristy and Ph.D.(1979) in Chemistry from KAIS. He is currently principal researcher at KIST and has specialty in Solid Chemistry and preparation of luminescence materials. Also He takes charge of Korea-China New Material Corporation Center as Chief. Chong-Hong Pyun, received his B.S. in Chemical Science from Seoul National University and Ph.D.(1985) in Electrochemistry from New Mexico University. He is currently principal researcher at KIST and has specialty in characterization of luminescence materials and electrochemistry.

REFERENCES

Xu, G. X., 1995, Rare Earths, 2 try Press, Beijing, Vol. 1.

nd

Ed., Metallurgical Indus-

Jianf-Tao Jia

Chun-Hun Yan

Jong Kee Oh

Chang-Hong Kim

Chong-Hong Pyun

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Will KitDocument9 pagesWill KitwitkerzNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Liquid LiquidDocument20 pagesLiquid LiquidjoiyyaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Physics Grade 10Document228 pagesPhysics Grade 10Jan92% (26)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Physics Grade 10Document228 pagesPhysics Grade 10Jan92% (26)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Excel Sheet For Mass Balance CalcsDocument13 pagesExcel Sheet For Mass Balance Calcswitkerz100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- DC Arc Smelting - Conroast SAIMM 2004Document4 pagesDC Arc Smelting - Conroast SAIMM 2004witkerzNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Flotation - Release AnalysisDocument35 pagesFlotation - Release AnalysiswitkerzNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Ce ModifierDocument9 pagesCe ModifierwitkerzNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Thorium RecoveryDocument45 pagesThorium Recoverywitkerz50% (2)

- An Overview of Optimizing Strategies For Flotation BanksDocument14 pagesAn Overview of Optimizing Strategies For Flotation BankswitkerzNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Table of RadionuclidesDocument8 pagesTable of RadionuclidesMariana VillagomezNo ratings yet

- Excel Sheet For Mass Balance CalcsDocument13 pagesExcel Sheet For Mass Balance Calcswitkerz100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Energey Balance - HandoutDocument37 pagesEnergey Balance - HandoutwitkerzNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Evaporation Figures Jan Feb Mar Apr May June Rainfall (MM) 2.3 3.3 7.1 9.6 19.3 26 A-Pan Evaporation (MM) 328.6 271.6 254.2 177 130.2 108Document2 pagesEvaporation Figures Jan Feb Mar Apr May June Rainfall (MM) 2.3 3.3 7.1 9.6 19.3 26 A-Pan Evaporation (MM) 328.6 271.6 254.2 177 130.2 108witkerzNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Optimizing SAG Mill Product Size in SAG and Ball Mill CircuitsDocument6 pagesOptimizing SAG Mill Product Size in SAG and Ball Mill CircuitsAgie FernandezNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- SX - Bateman Case Study of 3 Different SX Circuits Cobalt and Nickel SeparationDocument13 pagesSX - Bateman Case Study of 3 Different SX Circuits Cobalt and Nickel SeparationwitkerzNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Flot and Gravity SeparationDocument24 pagesFlot and Gravity SeparationwitkerzNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Mass Transfer OperationDocument22 pagesMass Transfer Operationneerajtrip123No ratings yet

- Grinding Control Strategy On TheDocument4 pagesGrinding Control Strategy On ThedaniaticoNo ratings yet

- Solution Colligative PropertiesDocument10 pagesSolution Colligative PropertieswitkerzNo ratings yet

- ICP AnalysisDocument9 pagesICP AnalysiswitkerzNo ratings yet

- Atmospheric Pressure and the Hydrostatic EquationDocument76 pagesAtmospheric Pressure and the Hydrostatic EquationSathiyaseelan RengarajuNo ratings yet

- Solution Colligative PropertiesDocument10 pagesSolution Colligative PropertieswitkerzNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Free Air DeliveryDocument6 pagesFree Air DeliveryParmasamy SubramaniNo ratings yet

- Penetration Theory 1Document29 pagesPenetration Theory 1witkerzNo ratings yet

- Davis Magnetic Tube SeparatorDocument3 pagesDavis Magnetic Tube SeparatorwitkerzNo ratings yet

- Penetration Theory 1Document29 pagesPenetration Theory 1witkerzNo ratings yet

- Flotation Release AnalysisDocument12 pagesFlotation Release AnalysiswitkerzNo ratings yet

- Davis Magnetic Tube SeparatorDocument3 pagesDavis Magnetic Tube SeparatorwitkerzNo ratings yet

- Enzyme Part 1-5 Vikneswaran 260110132004Document7 pagesEnzyme Part 1-5 Vikneswaran 260110132004Vikneswaran VîçkýNo ratings yet

- Test 1 September 2020 SemesterDocument3 pagesTest 1 September 2020 SemesterAhmed AlwaqediNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Chapter 23 Dark Matter, Dark Energy, and The Fate of The UniverseDocument21 pagesChapter 23 Dark Matter, Dark Energy, and The Fate of The UniverseEdwin ChuenNo ratings yet

- B.Pharm Organic Chemistry Exam Questions on Resonance, Haworth Synthesis, Friedal-Crafts ReactionsDocument4 pagesB.Pharm Organic Chemistry Exam Questions on Resonance, Haworth Synthesis, Friedal-Crafts ReactionsSachu SachusNo ratings yet

- The Electro-Gravitational Chemistry in Structural Biology: Ratan Kumar SarkarDocument4 pagesThe Electro-Gravitational Chemistry in Structural Biology: Ratan Kumar SarkarBiochem M. JulyNo ratings yet

- Gel Filtration ColumnDocument2 pagesGel Filtration ColumnkostrenarijekaNo ratings yet

- Molecular Geometry ChartDocument3 pagesMolecular Geometry ChartJoyci CauilanNo ratings yet

- Materials Challenges in Hydrogen-Fuelled Gas TurbinesDocument27 pagesMaterials Challenges in Hydrogen-Fuelled Gas TurbinesSaiful ShokriNo ratings yet

- PhotosynthesisDocument35 pagesPhotosynthesisChristopher MullenNo ratings yet

- Vit CFD Modeling Final ReportDocument16 pagesVit CFD Modeling Final Reportrajeshps07No ratings yet

- Chapter 21 Cutting Tools: MET 33800 Manufacturing ProcessesDocument25 pagesChapter 21 Cutting Tools: MET 33800 Manufacturing ProcessesAlissa Saphira PutriNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Preview: Lesson Starter Objectives Branches of Chemistry Top Eight Chemicals Made in The United StatesDocument10 pagesPreview: Lesson Starter Objectives Branches of Chemistry Top Eight Chemicals Made in The United StatesJudy Ann CastorNo ratings yet

- Engineering Chemistry Module 1: An IntroductionDocument35 pagesEngineering Chemistry Module 1: An IntroductionAudrey MendozaNo ratings yet

- Benzaldehyde CAS No 100-52-7: Material Safety Data Sheet Sds/MsdsDocument7 pagesBenzaldehyde CAS No 100-52-7: Material Safety Data Sheet Sds/MsdsJuanDavidPBNo ratings yet

- Passivation GMPDocument51 pagesPassivation GMPAlexander AvdeiNo ratings yet

- KIMIA ANALISIS Teknik Kimia 2019Document4 pagesKIMIA ANALISIS Teknik Kimia 2019Imam FauziNo ratings yet

- أنتاج ثالثة 3Document6 pagesأنتاج ثالثة 3snariaNo ratings yet

- NSSC Process Optimization: Ii. Spent Liquors: AbstractDocument8 pagesNSSC Process Optimization: Ii. Spent Liquors: AbstractKarteek KandalaNo ratings yet

- Measuring Mechanical Work PaymentsDocument7 pagesMeasuring Mechanical Work PaymentsSteven JosephNo ratings yet

- Determination of Total, Temporary and Permanent Hardness in Water Sample Using EDTA MethodDocument8 pagesDetermination of Total, Temporary and Permanent Hardness in Water Sample Using EDTA MethodNaresh kumarNo ratings yet

- Prof. Ghana Shankara Girija Prasad's Physics AssignmentDocument20 pagesProf. Ghana Shankara Girija Prasad's Physics AssignmentkiranknNo ratings yet

- Journal of Alloys and Compounds: SciencedirectDocument7 pagesJournal of Alloys and Compounds: SciencedirectVatra ReksaNo ratings yet

- TDS R 996 en 1Document1 pageTDS R 996 en 1Osmar ContrerasNo ratings yet

- Subject Catagories ETDE PDFDocument67 pagesSubject Catagories ETDE PDFmartinimartiiniNo ratings yet

- Important JEE Main Physics PYQs 2002-20 @JEEAdvanced - 202Document84 pagesImportant JEE Main Physics PYQs 2002-20 @JEEAdvanced - 202Shradha ReddyNo ratings yet

- 3 - Introduction - Physical Geology Practice 2020Document24 pages3 - Introduction - Physical Geology Practice 2020William LimNo ratings yet

- 2 Vol 12 Issue 11 November 2021 IJPSR RE 4230Document8 pages2 Vol 12 Issue 11 November 2021 IJPSR RE 4230Steven M.Farm.,aptNo ratings yet

- Sample Emc2Document6 pagesSample Emc2Prajwal DasNo ratings yet

- Effect of Sugar on Light RotationDocument6 pagesEffect of Sugar on Light Rotationhaden tetwNo ratings yet

- SARA PEREZ TRUJILLO - Molecules and Bonds 7BDocument4 pagesSARA PEREZ TRUJILLO - Molecules and Bonds 7BApuestas JulanoNo ratings yet

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (14)

- Napoleon's Buttons: 17 Molecules That Changed HistoryFrom EverandNapoleon's Buttons: 17 Molecules That Changed HistoryRating: 4 out of 5 stars4/5 (25)

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)