Professional Documents

Culture Documents

Scotle IR6000 V3 Manual

Uploaded by

Sharon TaylorCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scotle IR6000 V3 Manual

Uploaded by

Sharon TaylorCopyright:

Available Formats

Scotle Technology Group Ltd

Scotle IR6000 V3

BGA Rework Station User Manual

1

www.scotle.com

Scotle Technology Group Ltd

Scotle IR6000 V3

IR6000 BGA rework stations features

IR6000 BGA Rework Station is designed to meet the ever-changing demands

of todays fast BGA Rework manufacturing environments . Have the following characteristics:

1 IR6000 Excellent quality - CE certificated 2 IR6000 Larger Pre-heating area 21cmx21cm 3 IR6000 Air Protection Switch- More safer 4 IR6000 Detachable K

type thermocouple

5 IR6000 Taiwan FOTEK SSR inside 6 IR6000 Rework station for laptop motherboards, desktop computer motherboards,

server boards, industrial computer boards, all kinds of game boards, communications equipment motherboards, LCD TVs and other large circuit board BGA rework. 7IR6000 Innovative designs .An effective solution to general of infrared rework station vulnerable to the impact of air flow. Will lead an inaccurate of temperature control. Maximum temperature up to 400 C. Can easily deal with lead-free soldering rework. 8 IR6000 can set up 8 rising temperature segments and 8 constant temperature segments to control. It can save 10 groups of temperature curves at one time. 9 IR6000 can be connected to a computer to be controlled more conveniently with a built-in PC RS232 serial port and proprietary Software attached to it. programmable 10 IR6000 can easily rework the variety of CPU's seat, all kinds of shielding enclosures, replacement of various components slotCan easily deal with lead-free soldering rework 11 IR6000 sensitive temperature measurement sensor to obtain an accurate and instantaneous temperature reading and monitoring 12 IR6000 BGA rework station the technology of closed-loop temperature control ensures accurate temperature process and even heat distribution. 13 IR6000 Machine overall system integration Design, Rework station more integrated workbench area occupied by smaller, Didn't mixed and disorderly of cables. 14 IR6000 Linear guide type Bracket for BGA Reworkscan be locking adjusted by rotating the handle, Can be very easily fixed PCB board, effectively prevent the deformation of PCB board. 2

www.scotle.com

Scotle Technology Group Ltd

Safety Instructions

Electrical safety �

Make sure the supply power voltage accord with the standards---220V-250V/50hz alternating current before installing.

To avoid possible electric shock caused serious damage, please disconnect the power cord from the outlet temporary before moving machines.

If the machine damages, please contact us for maintenance. If the damage caused by the users when they dismantle or repair independently, they should take on the loss by themselves.

Operating safety � Please carefully read the relevant information provided by the manual before starting using this product. � Make sure the power cord has been properly connected properly before using the products. � Installed the equipment in stable work platform to use, where the air mobility should be small as possible. Avoid it closing to air conditioners, fans and the other outlet. � � � In case of electrical short-circuit, avoid the products contacting with water. Forbid using this equipment in flammable and explosive substances. The operators hands or other parts of the body should maintain a safe distance from the heater. Forbid touching the heater to avoid scalding. � If you have any technical questions or suggestions in the course of using this product, please contact with our technology department., We will try our best to solve.

www.scotle.com

Scotle Technology Group Ltd

Environmental requirements of operation and conservation 1. Operation environment of products � Operation temperature:15 ~ 45 � Operation humidity:5% to 95%, non-condensing � Products should be kept in the air mobility of a smaller environment under the welding operation. 2. Conservation environment of products � Storage temperature:-20 ~ 70 � Storage humidity: 5% to 95%, non-condensing

www.scotle.com

Scotle Technology Group Ltd

Scotle

BGA Rework Station

The parameters of

Basic Parameters

Heating Dimension Weight IR6000 V3

BGA Rework Station

IR

L 475mmW480mmH420 mm 16kg

Total weight Electrical Parameters

Power Upper Heating Size of Upper heating Consumption of upper heating Bottom Heating Size of Bottom heating

About 17 kg, vary with the differen need of the users

220V AC IR 80mm80 mm 450W IR 210 mmx 210 mm

Consumption of Bottom heating 1800W

Total

power

2400W

Temperature Control

Independent temperature control, high-precision closed-loop Control mode of Upper control, precision 0.5%, Alarm Independent temperature control, high-precision closed-loop Control mode of Bottom control, precision 0.5%, NO Alarm

Rework Function Suit for welding, remove or repair packaged devices SMD such as BGA,PBGA,CSP,multi-layer substratesEMI metallic shield product and solder/lead free Rework

www.scotle.com

Scotle Technology Group Ltd

welding

Size of applicable chips Size of applicable PCB 70mm70 mm 400mm305 mm

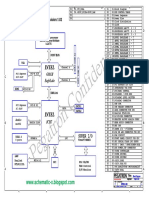

Hardware description

IR6000 V3 BGA Rework Station is composed of upper part of Heating Components /

Bottom Preheat Module / Bracket / Temperature Control Parts! Temperature control Table is control the upper and lower heating, Can Simultaneously heated or first preheat, then the upper part of heating.

1. Highly Sensitive K-temperature sensor 2. PCB Table 3. Power Switch 4. Upper Heater 5. X-Y Lifting Regulator 6. LED Auxiliary Lighting 7. Bottom Heater (Pre-Heater)

6

www.scotle.com

Scotle Technology Group Ltd

8. Lighting Switch 9. Upper fan Switch 10. Start Switch 11. Stop Switch 12. Upper Programmable Temperature Control pc410 13. Bottom Temperature Control CH6

Self-help Install

PCB Table 1.

Installation side support.

2.

Installation Slip.

3.

Installation side support.

www.scotle.com

Scotle Technology Group Ltd

Upper Heater

www.scotle.com

Scotle Technology Group Ltd

Cable connector

Temperature sensor

www.scotle.com

Scotle Technology Group Ltd

Installation of RS232 communication interface

Both suitable for Desktop & Laptop

Interface for desktop

transfer cable for laptop

Programmer/Controller General Description

The programmable controller contains an in-built setpoint generator in addition to the controller function. This setpoint generator can produce a temperature/time profile with 16 segments (09). When the program is running, the current setpoint from the setpoint generator is fed to the control algorithm. The current setpoint is continuously shown on the lower display.

10

www.scotle.com

Scotle Technology Group Ltd

The sixteen segments are defined in the order: Ramp 1, Dwell period 1, Ramp 2, Dwell period 2..., and are executed in succession.

S.N.

Item

Functions

Parameters setting key (Up key) Increase value (Down key) Decrease value Selects the program pattern number Starts/hold the program, changes the mode from fixed value control to program control

Program parameters setup Changes the indication on SV/MV/TIME display Output indicator Indicates the step number of program (Program monitor indicator) During program control, / is lit when the PV is rising During program control, - is lit when the PV is constant During program control, \ is lit when the PV is falling (Pattern number display) Indicates the pattern number 09 (Program control runing indicator) The LED indicator is lit during program control (PV Display) Indicates the Process/Measured value It is lit when the Setting Value(SV) is being displayed on the lower display 11

OUNT STEP PRO

PTN RUN PV SV

www.scotle.com

Scotle Technology Group Ltd

TIME MV SV (SV/MV/TIME display) It indicates the Setting Value(SV), Manipulating Value(MV), or Time(TIME) (The display content can be changed by the DISP/SELECT key) It is lit when the Alarm1 output is ON (Communication indicator) It flashes when the controller is in active communication with a host computer

AL1 COM

Program Parameters Setting

Ramp Rate1: A ramp consists of a slope(linear gradient) and a target setpoint. The control setpoint increases or decreases at a linear ramp rate from the actual measured value until a specified target setpoint is reached. The relative positions of the actual measured value and the target setpoint determine whether the slope of the ramp is positive or negative. Parameters R1, R2, R3... express the ramping rate in unites per minute(0.01~99.99), parameters L1, L2, L3... the appropriate target setpoint in display units. If R1 = END, the program will be ended when the program runs to the slope. Target Setpoint 1: The target value to which the setpoint ramps when the programmer has been placed into RVN. Dwell period 1: In a Dwell period, the target setpoint, which has been attained, remains unchanged for a fixed period. All the dwell periods are defined by their duration in minutes with parameters D1, D2, D3...(0~9999). When the program is running, these parameter display the time remaining in the active dwell period. If the parameter equals zero, the dwell period is skipped. When the controller runs in the PV displaying status: 1). Select the target program pattern number with the PTN/ key. 2). press SET/PROG key, the first program parameter appears in the upper display. The value associated with this parameter will be shown in the lower display. 3). Use and key to modify the value. 4). Press the PAR/SET key, the next parameter appears. At the same time, the modification has been saved in the memory. Use and key to modify the value. Repeat this procedure till all the parameters are set. Or if there is no key operation within 16 seconds, the menu times out automatically.

12

www.scotle.com

Scotle Technology Group Ltd

Program Parameter List

13

www.scotle.com

Scotle Technology Group Ltd

Rework Operation Steps

1be all set

Fixed motherboard

shift sensor sensor press close to BGA chip

Adjust the height of heating head with adjustment knobPromptBGA chip in the middle of heating head heating head away from BGA chip2CM

14

www.scotle.com

Scotle Technology Group Ltd

2Start heating

1Open power switch. 2Select the appropriate temperature program segment, and then press the start switch. In the operation can press the stop switch, stop operating.

3After the program is running, repairing automatic alarm, and automatically cut off the heating power, this time you can check the following solder ball BGA chip is completely liquefied, BGA chips should be subject to settlement, floating state

3Heating completed 1 Close Switch for top and bottom Then Moving Heating head and Sensor 2 Remove motherboard Clear insulating tape 3 BGA Rework Station Cooled ,Then close Total Power

Warning

� � If BGA Rework Station NO Cooling Do not close the Total Power !

When the temperature is not cooled, do not touch heating module!

Prompt

1 Installed the equipment in stable work platform to use where the air mobility should be small as possible .Avoid it closing to air conditioners, fans and the other outlet.

15

www.scotle.com

Scotle Technology Group Ltd

2 IR6000 Rework Station sensor Direct contact with motherboardSo Temperature display is Actual temperature 3 In order to avoid damage to the motherboard capacitorSO use insulation tape please Maintenance completed ,then Removal of insulation tape So as to avoid short-circuit 4 After removal of BGA chip PCB Bonding Pad Need to clean up Avoid cold solder joint See BGA chip tin completely liquefied, Then To move the BGA chipSo as to avoid Bonding Pad Damage 5 BGA chips should be subject to settlement, floating state Prohibited in all solder ball did not fully liquefied, by force if removal of chips, so as to avoid pad off, chip or motherboard scrap! 6 To improve success rate of Rework , PCB and chips need drying and processing in principle PCB board or chip moist heat process will occur in the burst phenomenon, the Rework process may hear the blasting sound of a minorAccording to actual situation Please self-control. 7 PCB board heating time is too long or repeated several times the surface heating will lead to discoloration. 8 Users from modifying temperature parametersPlease use scrap PCB testedHeating whole time about 10 seconds before the end of solder balls should be fully liquefiedf the liquefaction advanced or delayed,Should be regulating up/down the temperature setting. So as to avoid heat damage to chips or low-temperature sealing-off 9 The factory equipped with two sets of programmable temperature control table used parameters:

The attached curve setting for reference

16

www.scotle.com

Scotle Technology Group Ltd

Rework temperature curve to set examples

1Lead Sn63Pb37 numeric numeric slope/S al value temperature al value r1 0.45 L1 85 r2 r3 2Lead-free slope/S Sn96.5Ag3Cu0.5 r1 r2 r3 r4 1 1 L2 L3 150 185 Temperature time S d1 d2 d3 numeric al value S 85 40 40 numeric al value S 92 40 40 40 numeric al value S 90 45 40 45 numeric al value S 90 40 50 45 numeric al value S 90 40 60 65 numeric al value S 90 45 60 65

numeric numeric al value temperature al value 0.45 1 1 1 L1 L2 L3 L4 85 150 180 220

Temperature time S d1 d2 d3 d4

3. Lead (Computer)

numeric numeric slope/S al value temperature al value r1 r2 r3 r4

Temperature time S d1 d2 d3 d4 Temperature time S d1 d2 d3 d4 Temperature time S d1 d2 d3 d4 Temperature time S d1 d2 d3 d4

0.5 L1 90 0.85 L2 135 0.8 L3 170 1 L4 185 numeric numeric 4. Lead-free slope/S al value temperature al value (Computer) r1 0.45 L1 90 r2 1 L2 145 r3 1 L3 180 r4 1 L4 220 numeric numeric 5For XBOX slope/S al value temperature al value r1 0.40 L1 90 r2 0.85 L2 135 r3 1 L3 170 r4 1 L4 220 numeric numeric al value temperature al value 0.40 L1 90 0.85 L2 135 1 L3 180 1 L4 220

6For PS3

slope/S r1 r2 r3 r4

17

www.scotle.com

You might also like

- HR6000 ManualDocument18 pagesHR6000 ManualFrancisco Jose Padrino GoyaNo ratings yet

- LY IR6500 v.2 Description ManualDocument6 pagesLY IR6500 v.2 Description ManualPedro Vera0% (1)

- Smart Relay: Ordering InformationDocument5 pagesSmart Relay: Ordering InformationbhagyeshNo ratings yet

- Railway GateDocument46 pagesRailway GateRocky SinghNo ratings yet

- Scotle Hr6000 ManualDocument14 pagesScotle Hr6000 ManualFrancisco LopezNo ratings yet

- Ssc5x86h ManDocument29 pagesSsc5x86h ManValdenir DuarteNo ratings yet

- CPU921-922 6ES5998-0UL22 (E) OCRDocument548 pagesCPU921-922 6ES5998-0UL22 (E) OCRnasir_khan_24No ratings yet

- A75DE ManualDocument20 pagesA75DE ManualJohnTPNo ratings yet

- Intelligent Street Light Control While Obstacle PassingDocument32 pagesIntelligent Street Light Control While Obstacle Passingprashanthi_komatireddyNo ratings yet

- Asus PRIME A320I K Repair Guide PDFDocument9 pagesAsus PRIME A320I K Repair Guide PDFroberto cNo ratings yet

- E3325 Vga SW PDFDocument0 pagesE3325 Vga SW PDFTa Manh HungNo ratings yet

- 2080-LC10-12DWD: M810 8di 4ai Config 4do Source 12V DC Catalogue NoDocument3 pages2080-LC10-12DWD: M810 8di 4ai Config 4do Source 12V DC Catalogue NojkhkbkbjbjhNo ratings yet

- NPS711B9Document504 pagesNPS711B9funkyznNo ratings yet

- DSE2541 Installation Instructions PDFDocument2 pagesDSE2541 Installation Instructions PDFBERANGER DAVESNE DJOMALIA SIEWENo ratings yet

- Dkg-109 Automatic Mains Failure UnitDocument46 pagesDkg-109 Automatic Mains Failure UnitmohsenNo ratings yet

- Adaptive Prediction Model Accuracy in The Control of Residential Energy ResourcesDocument6 pagesAdaptive Prediction Model Accuracy in The Control of Residential Energy ResourcesMario SammyNo ratings yet

- LG - 42pq10r Plasma TVDocument25 pagesLG - 42pq10r Plasma TVCristian ChanampaNo ratings yet

- Manual Pluto DataDocument8 pagesManual Pluto DataDouglas RodriguesNo ratings yet

- Raptor Ser Ies High Perfor Mance Mo Tor DrivesDocument7 pagesRaptor Ser Ies High Perfor Mance Mo Tor DrivesJohn-Michael 'J' BillsNo ratings yet

- ASUS PRIME B450M-K Repair GuideDocument11 pagesASUS PRIME B450M-K Repair GuideRodolfo DantasNo ratings yet

- Simatic Net S7-400 - Industrial Ethernet CP 443-1 (EX30)Document80 pagesSimatic Net S7-400 - Industrial Ethernet CP 443-1 (EX30)Ale LoveraNo ratings yet

- Panasonic DVD Sa-Vk450eeDocument126 pagesPanasonic DVD Sa-Vk450eefunpinochio0% (1)

- PC Control Using TV RemoteDocument46 pagesPC Control Using TV RemoteManojKumarNo ratings yet

- ASUS TUF-GAMING-X570-PLUS-WIFI-Repair GuideDocument10 pagesASUS TUF-GAMING-X570-PLUS-WIFI-Repair Guidemm aaNo ratings yet

- Aoc 1619swa+Service+ManualDocument51 pagesAoc 1619swa+Service+ManualGarotinho Latino AmericanoNo ratings yet

- Service Manual 21GIII-08 SLIMDocument33 pagesService Manual 21GIII-08 SLIMAlexandra BarzaianuNo ratings yet

- Mosfet 30f124 330v 220a Canal NDocument7 pagesMosfet 30f124 330v 220a Canal NEdisson Alarcon MoraNo ratings yet

- KQCPET6 V4 InstructionDocument80 pagesKQCPET6 V4 Instructiontall1100% (1)

- Samsung Pl42d5sx RCLDocument33 pagesSamsung Pl42d5sx RCLOscar RamirezNo ratings yet

- Aiwa TV C2121 PDFDocument43 pagesAiwa TV C2121 PDFAsallimitNo ratings yet

- LL MSL 100G PDFDocument36 pagesLL MSL 100G PDFAlexandre FurtadoNo ratings yet

- ZM-R6200 BGA Rework Station SpecificationDocument3 pagesZM-R6200 BGA Rework Station SpecificationshibilvNo ratings yet

- Power Electronic (Pe) SystemDocument63 pagesPower Electronic (Pe) SystemFarid DafaNo ratings yet

- Fid en Tia L On Fid en Tia L: IPX41-D3Document54 pagesFid en Tia L On Fid en Tia L: IPX41-D3evandro efbasseNo ratings yet

- Manual TX-NR626 enDocument140 pagesManual TX-NR626 enalex_heavy100% (1)

- Analyses Procedure No Post Problem On Laptop Motherboard Circuit PDFDocument3 pagesAnalyses Procedure No Post Problem On Laptop Motherboard Circuit PDFDelwar HossainNo ratings yet

- Eb355 80 4Document44 pagesEb355 80 4David CochlinNo ratings yet

- SC100 Handbook A A4Document80 pagesSC100 Handbook A A4Difa Agfi Desebrio SyahNo ratings yet

- Sony PDP-01 Plasma TrainingDocument91 pagesSony PDP-01 Plasma Trainingdann222No ratings yet

- MTP 610 P 210 Manual Book LeonicsDocument2 pagesMTP 610 P 210 Manual Book LeonicsRido ManikNo ratings yet

- dx-9100 Extended Digital ControllerDocument128 pagesdx-9100 Extended Digital Controllermubs73No ratings yet

- Y3F SS 112D DataSheetDocument3 pagesY3F SS 112D DataSheetkhadiro mahboulNo ratings yet

- MultiPad 7.0 Ultra PMP3370Document27 pagesMultiPad 7.0 Ultra PMP3370Oldman TestNo ratings yet

- Sony Vaio Vgn-Ns Series Foxconn m790!1!01 Rev 1.0 SCHDocument54 pagesSony Vaio Vgn-Ns Series Foxconn m790!1!01 Rev 1.0 SCHCarlos Henrique RibasNo ratings yet

- Unor3smbus 2.inoDocument6 pagesUnor3smbus 2.inoM. Randy AswinNo ratings yet

- Mikromeia Board For PIC18FJDocument2 pagesMikromeia Board For PIC18FJmorghabiNo ratings yet

- Pioneer Plasma PDP-502MX - ARP3037Document78 pagesPioneer Plasma PDP-502MX - ARP3037littlem2aNo ratings yet

- Data Communication and Computer NetworksDocument105 pagesData Communication and Computer NetworksTalha HashmiNo ratings yet

- Mainboard+FY16+2K+GN2S QW+&+QT+Segments+Easy+Repair+Guide (GN2S)Document28 pagesMainboard+FY16+2K+GN2S QW+&+QT+Segments+Easy+Repair+Guide (GN2S)oscarmdNo ratings yet

- Ups SL500Document82 pagesUps SL500semen1963No ratings yet

- Dap011 DDocument24 pagesDap011 Dsontuyet82No ratings yet

- Features: Hybrid Power Boost (HPB) and Narrow VDC (NVDC) Combo Battery Charger With Smbus InterfaceDocument2 pagesFeatures: Hybrid Power Boost (HPB) and Narrow VDC (NVDC) Combo Battery Charger With Smbus InterfaceRohithRenNo ratings yet

- Datasheet PM851 MSATA v10Document2 pagesDatasheet PM851 MSATA v10ivanlawms6745No ratings yet

- Scotle Technology Group Ltd. Scotle IR6000 V3. BGA Rework Station. User Manual.Document17 pagesScotle Technology Group Ltd. Scotle IR6000 V3. BGA Rework Station. User Manual.zigmund zigmundNo ratings yet

- (改)LY IR9000 -Manual-EnglishDocument22 pages(改)LY IR9000 -Manual-EnglishStopper_Time100% (1)

- Achi Ir Pro SC ManualDocument16 pagesAchi Ir Pro SC ManualestebanNo ratings yet

- Ir-Pro-Sc ManualDocument21 pagesIr-Pro-Sc ManualLászló KádárNo ratings yet

- IR6500 v.2 Manual EnglishDocument13 pagesIR6500 v.2 Manual EnglishJuan Carlos HerreraNo ratings yet

- GM330 ManualDocument18 pagesGM330 ManualLászló KádárNo ratings yet

- 2019-08-04 Crochet World - Sanet.St PDFDocument68 pages2019-08-04 Crochet World - Sanet.St PDFSharon Taylor100% (6)

- Supply Chains Operating Performance Second EditionDocument20 pagesSupply Chains Operating Performance Second EditionSharon TaylorNo ratings yet

- Your Social Media Strategy F0IGXCVDDocument115 pagesYour Social Media Strategy F0IGXCVDSharon TaylorNo ratings yet

- Coastal Living - September 2016Document116 pagesCoastal Living - September 2016Sharon Taylor100% (1)

- Yaris Air ConditioningDocument263 pagesYaris Air ConditioningAndrej Krajnc100% (2)

- Sanet - ST - Practical Poultry MarchApril 2019 PDFDocument68 pagesSanet - ST - Practical Poultry MarchApril 2019 PDFSharon TaylorNo ratings yet

- Power Steering PDFDocument93 pagesPower Steering PDFWaldo Fuentes100% (1)

- Canon Ir2200 Ir2800 Ir3300 Service ManualDocument189 pagesCanon Ir2200 Ir2800 Ir3300 Service Manualburgasss83% (6)

- Lexmark 4505 E230 E232 E234 E23x E33x Service ManualDocument160 pagesLexmark 4505 E230 E232 E234 E23x E33x Service ManualmariofoNo ratings yet

- 33 Origines Islandicae A Collection of The More Important Sagas VOL. I PDFDocument756 pages33 Origines Islandicae A Collection of The More Important Sagas VOL. I PDFwuchimjNo ratings yet

- Manual Service BizhubDocument272 pagesManual Service BizhubSharon TaylorNo ratings yet

- Herbed Garlic Bread CheesesteaksDocument2 pagesHerbed Garlic Bread CheesesteaksSharon TaylorNo ratings yet

- If OprDocument351 pagesIf OprSharon Taylor100% (1)

- Proces Verbal Receptie SF AvimiDocument2 pagesProces Verbal Receptie SF AvimiSharon TaylorNo ratings yet

- Explodedviewpartlistscx 4600Document60 pagesExplodedviewpartlistscx 4600Fernando GambinoNo ratings yet

- Jaja Binks - TXTXDocument1 pageJaja Binks - TXTXSharon TaylorNo ratings yet

- Transcribe Me General Style Guide September 2013Document18 pagesTranscribe Me General Style Guide September 2013Sharon Taylor100% (1)

- DL (Download Library) : ID-No - DLBT0901217EN01Document2 pagesDL (Download Library) : ID-No - DLBT0901217EN01Sharon TaylorNo ratings yet

- Covet Garden 30Document32 pagesCovet Garden 30Sharon Taylor100% (1)

- DreamhouseDocument1 pageDreamhouseSharon TaylorNo ratings yet

- MD5 & Sha-1Document1 pageMD5 & Sha-1Sharon TaylorNo ratings yet

- Led Cube 8x8x8Document83 pagesLed Cube 8x8x8Sharon TaylorNo ratings yet

- Dreamhouse 2Document1 pageDreamhouse 2Sharon TaylorNo ratings yet

- Make Any Woman Squirt PDFDocument42 pagesMake Any Woman Squirt PDFSharon Taylor43% (199)

- A Crash Course in Seduction:: The Inner Circle's GuideDocument0 pagesA Crash Course in Seduction:: The Inner Circle's GuideSharon TaylorNo ratings yet

- IFRTool LogDocument3 pagesIFRTool LogCiolpan GeorgeNo ratings yet

- A Crash Course in Seduction:: The Inner Circle's GuideDocument0 pagesA Crash Course in Seduction:: The Inner Circle's GuideSharon TaylorNo ratings yet

- Make Any Woman Squirt PDFDocument42 pagesMake Any Woman Squirt PDFSharon Taylor43% (199)

- Parasplit: A Scalable Architecture On Fpga For Terabit Packet ClassificationDocument8 pagesParasplit: A Scalable Architecture On Fpga For Terabit Packet ClassificationDevNo ratings yet

- Mr. Arindam Dasgupta: Completed Teradata Basic V2R5 CertificationDocument2 pagesMr. Arindam Dasgupta: Completed Teradata Basic V2R5 Certificationad0032869No ratings yet

- Infoblox Datasheet Bloxone DdiDocument3 pagesInfoblox Datasheet Bloxone DdiSudhakar AruchamyNo ratings yet

- CS611 - Advanced Algorithms - Chapter 2 Slides - Part1Document41 pagesCS611 - Advanced Algorithms - Chapter 2 Slides - Part1mohamed fathyNo ratings yet

- Introduction To Mobile Computing: Dr. Sumi HelalDocument44 pagesIntroduction To Mobile Computing: Dr. Sumi HelalabiNo ratings yet

- Mitac 8575aDocument219 pagesMitac 8575aJuan BravoNo ratings yet

- PLC ExercisesDocument27 pagesPLC ExercisesAnas Hafez100% (1)

- Cinema 3D Sound Blu-Ray Home Cinema System: Service ManualDocument147 pagesCinema 3D Sound Blu-Ray Home Cinema System: Service ManualbeetorNo ratings yet

- Compensation of Distribution System Voltage Using DVR - Power Delivery, IEEE Transactions On Power DeliveryDocument7 pagesCompensation of Distribution System Voltage Using DVR - Power Delivery, IEEE Transactions On Power Deliveryreza hariansyahNo ratings yet

- XJ2000 4483 - Datasheet 1Document2 pagesXJ2000 4483 - Datasheet 1jbolarisNo ratings yet

- Apphwid 1Document11 pagesApphwid 1Briina S.No ratings yet

- Pmeucm DTMDocument112 pagesPmeucm DTMFelipe GuzmánNo ratings yet

- T5010 ManualDocument1,156 pagesT5010 Manual123chessNo ratings yet

- Dbms NotesDocument59 pagesDbms NotesRehan SabirNo ratings yet

- 2019 07 01 Computer ShopperDocument142 pages2019 07 01 Computer ShopperAgus BoboNo ratings yet

- Nanoscope Analysis v140r1 Download InstructionsDocument1 pageNanoscope Analysis v140r1 Download InstructionsArgosNo ratings yet

- Elm327ds PDFDocument68 pagesElm327ds PDFIvan Francisco Lorenzatti100% (1)

- Control-D Getting Started GuideDocument100 pagesControl-D Getting Started Guideborisg3No ratings yet

- Lab Report No. 6Document11 pagesLab Report No. 6Sohaib ChoudharyNo ratings yet

- Markem Imaje 9450 DS HQ A1Document2 pagesMarkem Imaje 9450 DS HQ A1Angel de Dios100% (1)

- Infineon-Design Guide LLC Converter ICE2HS01G-An-V01 00-EnDocument26 pagesInfineon-Design Guide LLC Converter ICE2HS01G-An-V01 00-EnAhmed AlagmyNo ratings yet

- Technology Listening and VocabularyDocument2 pagesTechnology Listening and VocabularySofíaNo ratings yet

- SKEMA - Daonm3mb6eo MBDocument32 pagesSKEMA - Daonm3mb6eo MBglepunkNo ratings yet

- Wireless and Mobile Network ArchitectureDocument592 pagesWireless and Mobile Network ArchitectureMadhuri DesaiNo ratings yet

- Output Configurations and Connections: NPN Open CollectorDocument2 pagesOutput Configurations and Connections: NPN Open Collectordorin serbanNo ratings yet

- Switching & Transmission MediaDocument43 pagesSwitching & Transmission MediaVicky VigneshNo ratings yet

- LAB 5-PE-LabDocument7 pagesLAB 5-PE-LabLovely JuttNo ratings yet

- UIPath - Processes and LibrariesDocument85 pagesUIPath - Processes and LibrariesvenkataramanasaNo ratings yet

- VijeoCitect 7.0 Service Pack 4 - Release NotesDocument35 pagesVijeoCitect 7.0 Service Pack 4 - Release Notesjm sNo ratings yet

- SyncServer S650 SAASM 00002904CDocument6 pagesSyncServer S650 SAASM 00002904CponidiNo ratings yet

- University of Chicago Press Fall 2009 Distributed TitlesFrom EverandUniversity of Chicago Press Fall 2009 Distributed TitlesRating: 1 out of 5 stars1/5 (1)

- University of Chicago Press Fall 2009 CatalogueFrom EverandUniversity of Chicago Press Fall 2009 CatalogueRating: 5 out of 5 stars5/5 (1)