Professional Documents

Culture Documents

Working of Breather Valve Working On Tanks

Uploaded by

540451140 ratings0% found this document useful (0 votes)

841 views4 pagesBreather valves basic operation & maintenance

Original Title

Working of Breather Valve Working on Tanks

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBreather valves basic operation & maintenance

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

841 views4 pagesWorking of Breather Valve Working On Tanks

Uploaded by

54045114Breather valves basic operation & maintenance

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

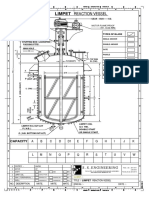

SERIES 8300

The Series 8300 range of Pressure & Vacuum Breather

Valves minimize vapour losses from storage tanks

during operations, whilst preventing internal pressure

and vacuum conditions from exceeding the tank design

limits. Hence, both product and vessel are protected, as

well as the tank environmental conditions.

INSTALLATION

The Pressure & Vacuum Breather Valve should be

mounted on tank roof nozzles as close as possible to

the tank roof, to ensure that pressure under the pallet is

maintained within 3% of the tank pressure.

FLANGE ADAPTORS

A range of steel adaptor flanges is available for non-

standard drilling on tank nozzle flange and for use

where tank flanges differ dimensionally for valve

flanges.

PRINCIPLE OF OPERATION

Figures 1 and 3 - indicate the position of both the

pressure and vacuum pallets, when tank and

atmospheric pressure are equal. i.e. both pallets are

fully seated.

Figures 2 - shows the position of both pallets, as set

pressure is reached, with escaping vapour lifting the

pressure pallet and holding the vacuum pallet closed.

Figures 4 - shows the position of both pallets, as set

vacuum is reached, with atmospheric pressure lifting the

hinged vacuum pallet to allow ingress of air into the tank,

whilst holding the pressure pallet closed.

VALVE SIZING

Tables 1 and 2 indicate flow rates for Series 8300 Open

Vent Pressure & Vacuum Breather Valves (2" to 12") in

both cubic feet per hour and cubic meters per hour, of

standard air.

FEATURES

COMBINED UNITS

Series 8300 Pressure & Vacuum Breather Valves can

be fitted in combination with Series 8350 Flame

Arresters.

Note - This type of installation reduces valve flow

capacities and thus special sizing calculations are

applicable. (See Table 3)

CHEMICAL SERVICE

Series 8300 Pressure & Vacuum Breather Valves can

be supplied in a range of alternative materials for

chemical and/or cryogenic services and can be used

with air dryers fitted at the vacuum inlet port, to protect

those products which could be adversely affected by

normal atmospheric air.

It is suitable for wide range of services in the petroleum,

chemical and related industries for land tankages only.

LOW BLOW-DOWN

Blow-down is the difference between opening and

closing pressures.

The floating diaphragm operation ensures that blow-

down is minimised to 10% for pressure relief and 10-

15% for vacuum relief.

LOW LEAKAGE

Figure 5 - shows capability of the resilient diaphragm to

wrap around the edge of the pallet seat. The high ratio

of seating force to seating area provides a tight seal.

As the pressure or vacuum rises, the relevant pallet

begins to lift, but the diaphragm wrap around at the

edge of the seat maintains a good seal.

As the pressure or vacuum continues to rise, the pallet

lifts further, but the diaphragm naturally assumes a

good seal.

When pressure or vacuum reaches the set conditions,

the pallet opens fully.

Tank Fitting

PV Breather Valves

Copyright TELTECH - www.telgroup.com

Slightly below setting

Valve tightly closed

Spacer

Valve open

Pallet starts to rise

Back-up Disc

Diaphragm

Retaining Plate

OPEN VENT PRESSURE & VACUUM BREATHER VALVES

CLOSED VENT PRESSURE & VACUUM

BREATHER VALVES

3" Closed Vent Valve

6" Closed Vent Valve

mm inch

50 2 271 171 308 43 1 3

80 3 327 241 398 44 1 3

100 4 386 267 471 44 2 6

150 6 433 400 622 44 4 4

200 8 540 518 779 48 4 4

250 10 651 648 949 54 6 6

300 12 759 759 1102 57 6 6

D

No.of

Studs

No.of

Bolts

Valve Size

A B C

DIMENSIONS

B

A

D

C

FIG. 5

411

133

2

2

9

1

5

1

3

4

0

632

210

3

4

3

2

6

2

4

9

8

FIG. 2 FIG. 1

FIG. 4 FIG. 3

Atmospheric

Pressure

Atmospheric

Pressure

To

Tank

To

Atmosphere Atmospheric

Pressure

Pressure

Pallet

Pressure

Pallet

Seat

Vacuum

Pallet

Pressure

Pallet

Vacuum

Pallet

A B C A B C A B

1" w.g. - - - 13.0 15.3 - 22.7 30.4

2" w.g. 7.3 8.3 - 15.0 17.2 - 27.0 30.0

3" w.g. 7.5 8.5 - 16.6 18.5 - 28.8 32.5

4" w.g. 8.0 9.0 - 17.7 20.0 - 31.4 35.4

6" w.g. 8.4 9.3 - 20.0 22.0 - 35.8 39.0

8" w.g. 8.7 9.5 - 22.2 24.0 - 38.4 42.1

14" w.g. 9.7 10.8 - 25.7 28.0 - 45.1 50.0

21.5" w.g. 10.3 11.2 11.8 28.0 30.7 32.6 50.5 54.7

1 psi - - - - - - - -

1.5 psi 12.5 13.3 14.1 35.7 38.0 41.0 63.0 69.0

0.75" w.g. - - - - - - - -

1" w.g. - - - 8.3 11.0 12.8 14.0 19.0

2.5" w.g. 3.5 4.3 4.9 8.0 9.9 11.6 15.0 20.5

TABLE 1 - OPEN VENTED VALVES (flow in thousands of

4" (100 mm

S

e

t

V

a

c

u

u

m

S

e

t

P

r

e

s

s

u

r

e

2" (50 mm) 3" (80 mm)

Over-pressure

A B C A B C A B C

25 mm w.g. - - - 0.35 0.41 - 0.62 0.73 -

50 mm w.g. 0.194 0.224 - 0.40 0.463 - 0.72 0.83 -

75 mm w.g. 0.21 0.235 - 0.457 0.515 - 0.81 0.91 -

100 mm w.g. 0.215 0.238 - 0.50 0.552 - 0.88 0.97 -

150 mm w.g. 0.227 0.253 - 0.54 0.61 - 0.95 1.06 -

200 mm w.g. 0.244 0.268 - 0.61 0.67 - 1.08 1.19 -

350 mm w.g. 0.266 0.29 - 0.72 0.78 - 1.23 1.37 -

550 mm w.g. 0.294 0.317 0.336 0.83 0.89 0.93 1.48 1.56 1.65

700 mm w.g. - - - - - - - - -

1050 mm w.g. 0.345 0.37 0.386 1.06 1.10 1.14 1.90 1.98 2.04

20 mm w.g. - - - - - - - - -

25 mm w.g. - - - 0.215 0.285 0.333 0.37 0.495 0.60

65 mm w.g. 0.093 0.113 0.13 0.22 0.265 0.305 0.41 0.50 0.59

S

e

t

V

a

c

u

u

m

S

e

t

P

r

e

s

s

u

r

e

Over-pressure

TABLE 2 - OPEN VENTED VALVES (flow in thousands of cubic me

2" (50 mm) 3" (80 mm) 4" (100 mm)

TABLE 3 - COMBINED BREATHER VALVE AND FLAME ARREST

A B C A B C A B C

1" w.g. - - - 5.5 8.0 - 9.9 14.2 -

2" w.g. 2.7 3.7 - 6.0 8.2 10.1 10.7 14.6 18.0

3" w.g. 2.95 3.85 4.65 6.4 8.4 10.25 11.5 15.2 18.5

4" w.g. 3.2 4.0 4.75 6.9 8.8 10.5 12.5 15.7 19.0

6" w.g. 3.6 4.3 5.0 7.8 9.5 11.0 14.3 17.3 20.0

8" w.g. 3.9 4.65 5.25 8.7 10.1 11.6 16.0 18.7 21.2

14" w.g. 4.9 5.5 6.1 10.5 12.0 13.3 19.5 22.0 24.3

21.5" w.g. 5.8 6.4 7.0 13.0 14.5 15.7 23.5 26.5 28.5

1.0 psi 6.5 7.2 7.8 14.4 15.7 17.2 25.5 28.6 31.0

1.5 psi 7.8 8.4 8.9 17.0 18.7 20.0 32.0 35.0 37.0

1" w.g. - - - 4.55 6.42 8.0 8.0 11.4 14.1

1.5" w.g. 2.15 2.95 3.63 4.75 5.7 8.1 8.3 11.5 14.3

2.5" w.g. 2.36 3.1 3.72 5.1 6.78 8.2 8.8 11.7 14.4

4" (100 mm) 2" (50 mm) 3" (80 mm)

S

e

t

V

a

c

u

u

m

S

e

t

P

r

e

s

s

u

r

e

Over-pressure

Above values are for Open Vented Valves, use 80% of values for Closed Vent Valves. Over-pressures A = 0.5 in.w.g., B = 1.0 in.w.g., C = 1.5 in.w.g.

Above values are for Open Vented Valves, use 80% of values for Closed Vent Valves. Over-pressures A = 10 mm w.g., B = 20 mm w.g., C = 30 mm w.g.

Above values are indicative only, as the combination of Breather Valve and Flame Arrester has not been subjected to exhaustive testing, as the valve alone.

C A B C A B C A B C A B C

- 49.0 59.5 - 77.0 98.0 - 129 160 - 174 216 -

- 60.0 70.0 - 87.0 110 - 159 186 - 214 254 -

- 69.5 79.0 - 100 120 - 183 210 - 252 285 -

- 76.0 86.0 - 110 128 - 201 231 - 277 313 -

- 87.0 97.0 - 126 141 - 234 263 - 320 362 -

- 97.0 110 - 139 155 - 262 292 - 358 395 -

- 124 135 - 176 191 - 329 352 - 468 498 -

58.0 140 155 165 213 226 237 377 412 447 560 585 610

- 160 173 183 236 246 257 428 470 505 627 645 670

74.0 - - - - - - - - - - - -

- - - - - - - 77.0 105 127 115 147 182

22.0 27.0 42.0 52.0 50.0 67.0 79.0 75.0 101 120 116 150 177

24.0 31.0 43.0 52.0 59.0 73.0 85.0 75.0 94.0 112 128 164 186

12" (300 mm)

Valve Size

f cubic feet per hour, of standard air)

m) 6" (150 mm) 8" (200 mm) 10" (250 mm)

A B C A B C A B C A B C

1.33 1.57 - 2.03 2.57 - 3.48 4.22 - 4.80 5.72 -

1.63 1.88 - 2.37 2.92 - 4.27 4.91 - 5.90 6.83 -

1.91 2.14 - 2.76 3.23 - 4.95 5.60 - 7.00 7.84 -

2.13 2.35 - 3.00 3.44 - 5.53 6.20 - 7.70 8.60 -

2.40 2.68 - 3.37 3.82 - 6.33 7.80 - 8.80 9.75 -

2.77 3.04 - 3.90 4.38 - 7.30 8.00 - 10.1 11.0 -

3.45 3.75 - 4.85 5.27 - 9.00 9.80 - 12.6 13.7 -

4.30 4.53 4.76 5.95 6.33 6.65 10.9 11.7 12.3 15.9 16.7 17.2

4.60 4.84 5.03 6.53 6.85 7.10 12.0 12.7 13.2 17.5 18.3 19.0

- - - - - - - - - - - -

- - - - - - 1.93 2.60 3.13 2.88 3.80 4.20

0.74 0.96 1.17 1.40 1.80 2.05 1.90 2.53 3.04 2.90 3.85 4.20

0.88 1.05 1.25 1.60 1.88 2.12 1.98 2.40 2.80 3.33 4.10 4.75

8" (200 mm) 6" (150 mm)

Valve Size

etres per hour, of standard air)

10" (250 mm) 12" (300 mm)

TER (flow in thousands of cubic feet per hour, of standard air)

A B C A B C A B C A B C

18.5 27.4 - 33.0 48.0 - 54.5 78.0 - 81.0 119 -

19.5 27.6 34.7 34.0 48.5 60.0 56.0 80.0 100 86.0 122 154

21.0 28.5 35.0 37.0 49.5 61.0 60.0 82.0 103 93.0 125 155

23.0 29.5 36.0 40.0 51.5 63.0 65.0 84.0 104 100 130 157

26.0 32.0 37.4 45.5 56.0 66.0 74.0 90.0 107 115 140 165

28.5 34.0 39.0 50.5 60.0 69.0 81.0 97.0 113 129 150 174

37.0 41.0 46.0 64.0 72.0 80.0 104 117 130 160 180 197

44.0 48.0 52.5 79.0 86.0 92.5 127 137 150 195 210 227

51.5 55.0 59.0 90.0 97.0 104 140 155 165 220 238 255

- - - - - - - - - - - -

16.6 23.7 29.6 30.0 43.0 53.0 49.0 69.5 86.0 71.0 100 124

17.5 24.3 30.0 32.0 44.0 54.5 50.5 70.0 86.0 74.0 102 125

19.0 25.0 30.5 35.0 45.5 55.0 55.0 73.0 88.0 80.0 105 127

8" (200 mm) 10" (250 mm) 12" (300 mm)

Valve Size

6" (150 mm)

SPECIFICATIONS

Sizes : 50 mm (2")

80 mm (3")

100 mm (4")

150 mm (6")

200 mm (8")

250 mm (10")

300 mm (12")

Pressure Settings

Minimum : 38 mm (2" valve size)

25 mm (3" to 10" valve sizes)

19 mm (12" valve size)

Maximum : 1056 mm (2" to 4" valve sizes)

704 mm (6" to 12" valve sizes)

Vacuum Settings

Minimum : 25 mm (All valve sizes)

Maximum : 65 mm (All valve sizes)

End Connections : ASA 150 FF

Outlet : 4"(for 3" Valve)

(for Closed Vent) 8"(for 6" Valve)

12"(for 10" Valve)

To process your enquiry, please furnish the following

information :

1. Enquiry/order number

2. Liquid and its flash point

3. Tank diameter and height

4. Type of tank and end connections

5. Pumping-in and pumping-out rates

6. Required pressure and vacuum settings

MATERIALS OF CONSTRUCTION

Body : Aluminium alloy LM-25

Seat : Aluminium alloy LM-25

Pallet : Aluminium

Screen : Stainless Steel AISI 304

Guides : Stainless Steel AISI 304

Diaphragm : Fluorinated Ethylene Propylene (FEP)

Hood : Galvanised Steel

Hardware : Mild Steel

(Optional) (Zinc Plated / Yellow Passivated)

RV 50 A O

Options

O = Open Vent

C = Closed Vent

Body Material

A = Aluminium

S = Stainless Steel

W = Cast Steel

Size

50 = 50 mm (2")

80 = 80 mm (3")

100 = 100 mm (4")

150 = 150 mm (6")

200 = 200 mm (8")

250 = 250 mm (10")

300 = 300 mm (12")

Pressure & Vacuum

Breather Valve

Series 8300

MODEL DESIGNATION

No.5030110133/R6/05-2005

Specifications are subject to change without notice.

All dimensions are in mm unless otherwise specified.

TELTECH INSTRUMENTATION PVT. LTD. A joint venture with Alma Ingenierie, France

TELLINE: +91 98200 37722 (24 hr) www.telgroup.com

MUMBAI HEAD OFFICE : Kamanwala Chambers, Sir P. M. Road, Mumbai 400 001, INDIA Tel : +91 (22) 56364999

Fax : +91 (22) 56336199 Email : teltechmumbai@telgroup.com

PUNE WORKS : 28/4B, Kharadi, Off Nagar Road, Pune 411 014, INDIA Tel : +91 (20) 27010008, 27012325, 27012623, 27012940

Fax : +91 (20) 27010485 Email : pune@telgroup.com

You might also like

- Technical Standards For Insulation-Mineral Wool-RockwoolDocument2 pagesTechnical Standards For Insulation-Mineral Wool-RockwooljaganNo ratings yet

- Zinc Anode 304 MZS Protects Steel Against CorrosionDocument2 pagesZinc Anode 304 MZS Protects Steel Against CorrosionBhanu Pratap ChoudhuryNo ratings yet

- Refractory Installation Preparation Guidelines 2.1 Preparation Prior To The Refractory Installation in The Cement Rotary KilnDocument10 pagesRefractory Installation Preparation Guidelines 2.1 Preparation Prior To The Refractory Installation in The Cement Rotary KilnkING100% (1)

- IIT Hyderabad Faculty Housing Design CalculationsDocument33 pagesIIT Hyderabad Faculty Housing Design CalculationssmijusNo ratings yet

- Shell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Document1 pageShell: Working Pressure of Shell (As Per Ibr 270 & 271 New Amendment)Karthic KeyanNo ratings yet

- Design partition plate for refinery distillation columnDocument5 pagesDesign partition plate for refinery distillation columnpippo2378793No ratings yet

- 07 Thermo Dyn Flue Design PDFDocument28 pages07 Thermo Dyn Flue Design PDFHomer SilvaNo ratings yet

- AFMC (Medical) Solved Paper 2013 PDFDocument32 pagesAFMC (Medical) Solved Paper 2013 PDFAnkur BanerjeeNo ratings yet

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- Master Foods 12 MDocument16 pagesMaster Foods 12 MSarfarazNo ratings yet

- Design and Study of Floating Roofs For Oil Storage TanksDocument12 pagesDesign and Study of Floating Roofs For Oil Storage TanksDavid RodriguesNo ratings yet

- Is 6533 Part-2 Design of Construction of Steel Chimney-CodDocument23 pagesIs 6533 Part-2 Design of Construction of Steel Chimney-CodRiaz M IbrahimNo ratings yet

- B.4.4 - STD Spec For Steel StacksDocument6 pagesB.4.4 - STD Spec For Steel StacksEkta SanguleNo ratings yet

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- Caesar Restraint Summary ExtendedDocument10 pagesCaesar Restraint Summary ExtendedrafiqhariyantoNo ratings yet

- A869-6-44-0005 PMS For RevampDocument950 pagesA869-6-44-0005 PMS For RevampMastram HatheshNo ratings yet

- Coke Drum Skirt ExampleDocument10 pagesCoke Drum Skirt Example2009tamerNo ratings yet

- Simple joint design in steel structuresDocument8 pagesSimple joint design in steel structuresNikola PejatovicNo ratings yet

- List of Moment of AreasDocument3 pagesList of Moment of AreasTk Kendrick LauNo ratings yet

- Calcs 6Document5 pagesCalcs 6Jedmar Flynn LimenNo ratings yet

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocument2 pages2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebNo ratings yet

- Dev Energy - GASIFIERDocument33 pagesDev Energy - GASIFIERvinay1999No ratings yet

- Instructed By: Hossein Sadeghi: An Introduction To Welded Tanks For Oil Storage, Api Standard 650Document287 pagesInstructed By: Hossein Sadeghi: An Introduction To Welded Tanks For Oil Storage, Api Standard 650Tania HuqNo ratings yet

- Second Moment of AreaDocument3 pagesSecond Moment of AreaArvind SinghNo ratings yet

- Limpet Reaction Vessel PDFDocument1 pageLimpet Reaction Vessel PDFarajamani78No ratings yet

- B313 Mitre Ver 1.1Document5 pagesB313 Mitre Ver 1.1nizardsouissiNo ratings yet

- Brackets for circular platforms at vertical vesselsDocument4 pagesBrackets for circular platforms at vertical vesselsameya natuNo ratings yet

- ACI 318-11 Appendix D Changes SummaryDocument2 pagesACI 318-11 Appendix D Changes SummaryJonathan SchauderNo ratings yet

- Comp 2Document9 pagesComp 2YYo YudiNo ratings yet

- ChimneyDocument20 pagesChimneyA.K.M Shafiq MondolNo ratings yet

- J3X & JF3X PDFDocument2 pagesJ3X & JF3X PDFMukiara LuffyNo ratings yet

- Drawing List Submitted To MECON 01Document1 pageDrawing List Submitted To MECON 01Christopher LewisNo ratings yet

- DraughtDocument33 pagesDraughtNipun SabharwalNo ratings yet

- Bunded Steel Fuel Tanks - SmallDocument1 pageBunded Steel Fuel Tanks - SmallNAHASALI11No ratings yet

- Nozzle neck thickness calculation UG-45Document2 pagesNozzle neck thickness calculation UG-45Lcm TnlNo ratings yet

- Sectional Properties Root DistanceDocument4 pagesSectional Properties Root DistanceVenkatasubramanian IyerNo ratings yet

- Scope Matrix PDFDocument5 pagesScope Matrix PDFNathanNo ratings yet

- 0421 Roofing - CombinedDocument6 pages0421 Roofing - CombinedRiski SuhardinataNo ratings yet

- CE8501 Notes PDFDocument53 pagesCE8501 Notes PDFprem rajanNo ratings yet

- Denso Valve Flange Tape Wrapping SpecDocument3 pagesDenso Valve Flange Tape Wrapping SpecNaufal Firmansyah100% (1)

- 1910.23 (Guarding Floor, Wall Openings, and Holes)Document9 pages1910.23 (Guarding Floor, Wall Openings, and Holes)oehl78No ratings yet

- Steel Stacks Desing GuideDocument23 pagesSteel Stacks Desing Guidecharlie kurzawskiNo ratings yet

- Ccsviiid1 2260Document2 pagesCcsviiid1 2260DieguitoOmarMoralesNo ratings yet

- Combined Status of BoqmDocument22 pagesCombined Status of Boqmhemant1284No ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal SattuNo ratings yet

- Sealing Compounds From Project Sales CorpDocument34 pagesSealing Compounds From Project Sales CorpProject Sales CorpNo ratings yet

- 6946-6-77-0005 Rev1Document24 pages6946-6-77-0005 Rev1Karthick VenkatswamyNo ratings yet

- CH Design-R1 PDFDocument12 pagesCH Design-R1 PDFmazumdar_satyajitNo ratings yet

- Denso Quantity Estimate Sheet PDFDocument2 pagesDenso Quantity Estimate Sheet PDFIvan RocoNo ratings yet

- Molasses Tank 18092020Document31 pagesMolasses Tank 18092020Keshav GopaulNo ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- ASME Boiler and Pressure Vessels Code - bpvc13Document1 pageASME Boiler and Pressure Vessels Code - bpvc13cristinelbNo ratings yet

- Wastewater Technical ManualDocument32 pagesWastewater Technical ManualagonzalezcordovaNo ratings yet

- Goulds PumpsDocument44 pagesGoulds PumpsCarlos Sagrit100% (1)

- L I G H TDocument4 pagesL I G H TPrem SharmaNo ratings yet

- IS 1239 and IS 3589 pipe sizesDocument4 pagesIS 1239 and IS 3589 pipe sizesPrem SharmaNo ratings yet

- Measurements, Sizes, Shafts, KeywaysDocument91 pagesMeasurements, Sizes, Shafts, KeywaysVenkat DoraNo ratings yet

- Showfou Electric BlowersDocument27 pagesShowfou Electric BlowersSon Trinh PhuongNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Untitled 1Document68 pagesUntitled 154045114No ratings yet

- Bill2 Jan Paschimanchal Vidyut Vitran Nigam LTDDocument1 pageBill2 Jan Paschimanchal Vidyut Vitran Nigam LTD54045114No ratings yet

- sssssss10 17 PDFDocument1 pagesssssss10 17 PDF54045114No ratings yet

- Current Transformer Secondary Types: IEEE C57.13 IEC 60044-1Document1 pageCurrent Transformer Secondary Types: IEEE C57.13 IEC 60044-154045114No ratings yet

- Equipment Exceptions List Sheet 1 of 1Document1 pageEquipment Exceptions List Sheet 1 of 154045114No ratings yet

- sssssss10 17 PDFDocument1 pagesssssss10 17 PDF54045114No ratings yet

- Insulation of A Core Pile: January 19, 2016Document1 pageInsulation of A Core Pile: January 19, 201654045114No ratings yet

- Minnesota and Wisconsin county home sale prices 2012-2013Document80 pagesMinnesota and Wisconsin county home sale prices 2012-201354045114No ratings yet

- sssssss10 17Document1 pagesssssss10 1754045114No ratings yet

- Construction Types: Split CoreDocument1 pageConstruction Types: Split Core54045114No ratings yet

- Check Aadhaar StatusDocument2 pagesCheck Aadhaar Status54045114No ratings yet

- sssssss10 04Document1 pagesssssss10 0454045114No ratings yet

- Oil Gas Industry GuidelinesDocument90 pagesOil Gas Industry GuidelinesAdhia Prenata Putra HuzaNo ratings yet

- sssssss10 01Document1 pagesssssss10 0154045114No ratings yet

- Questions ?: Thank YouDocument1 pageQuestions ?: Thank You54045114No ratings yet

- Government of India Department of Posts (Civil Wing) : Notice Inviting TenderDocument1 pageGovernment of India Department of Posts (Civil Wing) : Notice Inviting Tender54045114No ratings yet

- Current Transformer Basics GuideDocument1 pageCurrent Transformer Basics Guide54045114No ratings yet

- Viewtenddoc 13Document1 pageViewtenddoc 1354045114No ratings yet

- Viewtenddoc 6Document1 pageViewtenddoc 654045114No ratings yet

- Viewtenddoc 6Document1 pageViewtenddoc 654045114No ratings yet

- Earnest Money Bank Guarantee TitleDocument1 pageEarnest Money Bank Guarantee Title54045114No ratings yet

- Electrical maintenance tender detailsDocument1 pageElectrical maintenance tender details54045114No ratings yet

- 23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.00Document1 page23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.0054045114No ratings yet

- 23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.00Document1 page23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.0054045114No ratings yet

- Government of India Department of Posts (Civil Wing) : Notice Inviting TenderDocument1 pageGovernment of India Department of Posts (Civil Wing) : Notice Inviting Tender54045114No ratings yet

- CTDocument1 pageCT54045114No ratings yet

- Viewtenddoc 3Document1 pageViewtenddoc 354045114No ratings yet

- 11 KW Tertiary Treatment Feed PumpDocument4 pages11 KW Tertiary Treatment Feed Pump54045114No ratings yet

- Rated Voltage of Circuit Breaker: Current CurrentDocument2 pagesRated Voltage of Circuit Breaker: Current Current54045114No ratings yet

- EOCR CatalogueDocument12 pagesEOCR Catalogue54045114No ratings yet

- UniSim Heat Exchangers User Guide PDFDocument22 pagesUniSim Heat Exchangers User Guide PDFzhangyiliNo ratings yet

- Single Point Loading Working Model Specifications and Parts OverviewDocument4 pagesSingle Point Loading Working Model Specifications and Parts OverviewAnonymous CYdagI100% (1)

- Multiple Choice Bubble Sheet Template Customize This WordDocument3 pagesMultiple Choice Bubble Sheet Template Customize This WordAl Bin0% (1)

- GITAM Guidelines For MBA Project Work - 2018Document6 pagesGITAM Guidelines For MBA Project Work - 2018Telika RamuNo ratings yet

- C146-94a (2014) Standard Test Methods For Chemical Analysis of Glass SandDocument12 pagesC146-94a (2014) Standard Test Methods For Chemical Analysis of Glass SandAhmed AlzubaidiNo ratings yet

- Nursing ProcessDocument88 pagesNursing ProcessGerard On LineNo ratings yet

- Noritz N-063 Installation ManualDocument66 pagesNoritz N-063 Installation ManualbondsupplyNo ratings yet

- Timecode and SourcesDocument4 pagesTimecode and Sourcesapi-483055750No ratings yet

- Asphalt Laboratory Manual RevDocument13 pagesAsphalt Laboratory Manual RevKurian C ChackoNo ratings yet

- Example4 FatigueTools WS01-SNDocument23 pagesExample4 FatigueTools WS01-SNJosé Luciano Cerqueira CesarNo ratings yet

- Gases and Gas LawDocument5 pagesGases and Gas LawMaria mercedesNo ratings yet

- Doping Effects of Zinc On LiFePO4 Cathode MaterialDocument5 pagesDoping Effects of Zinc On LiFePO4 Cathode MaterialMarco Miranda RodríguezNo ratings yet

- Gabriel Feltran. "The Revolution We Are Living"Document9 pagesGabriel Feltran. "The Revolution We Are Living"Marcos Magalhães Rosa100% (1)

- TAURI User ManualDocument23 pagesTAURI User ManualChris Sad LHNo ratings yet

- ResumeDocument4 pagesResumeBazlaa HasmanNo ratings yet

- BATAM Selco Amprah Agustus (@) 2021Document31 pagesBATAM Selco Amprah Agustus (@) 2021rentalkiosNo ratings yet

- Ch05 - Deformation - HamrockDocument14 pagesCh05 - Deformation - HamrockMuhammad Mansor BurhanNo ratings yet

- Gamma Ray Log ShamshadDocument36 pagesGamma Ray Log Shamshadgadi_143100% (6)

- Speech Sound Disorders First Edition Ebook PDF VersionDocument57 pagesSpeech Sound Disorders First Edition Ebook PDF Versionzelma.bennett128100% (39)

- TFT-LCD TV/MONITOR SERVICE MANUALDocument54 pagesTFT-LCD TV/MONITOR SERVICE MANUALhimkoNo ratings yet

- Mahusay Module 4 Acc3110Document2 pagesMahusay Module 4 Acc3110Jeth MahusayNo ratings yet

- Lesson Plan in Science 10 2nd QuarterDocument5 pagesLesson Plan in Science 10 2nd QuarterJenevev81% (21)

- Elements of TQM: Dr. Sanjay MahalingamDocument7 pagesElements of TQM: Dr. Sanjay Mahalingamuday saiNo ratings yet

- Noam Text ליגר טסקט םעֹנDocument20 pagesNoam Text ליגר טסקט םעֹנGemma gladeNo ratings yet

- SAP PPM 5.0 Certification Exam TopicsDocument7 pagesSAP PPM 5.0 Certification Exam TopicsongkecanthoNo ratings yet

- USTHB Master's Program Technical English Lesson on Reflexive Pronouns and Antenna FundamentalsDocument4 pagesUSTHB Master's Program Technical English Lesson on Reflexive Pronouns and Antenna Fundamentalsmartin23No ratings yet

- NPPD Sri LankaDocument15 pagesNPPD Sri LankaasdasdNo ratings yet

- Fuji Noise Level Analyzer: For FUJI Digital Sound Detector FSB-8DDocument2 pagesFuji Noise Level Analyzer: For FUJI Digital Sound Detector FSB-8DMar WilkNo ratings yet

- PDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressDocument15 pagesPDF Manual de Reparaciones Estructurales Del Airbus A 320 CompressJosé LuisNo ratings yet

- TableDocument9 pagesTableShamlakan elghaoucheNo ratings yet