Professional Documents

Culture Documents

Thermal Conductance

Uploaded by

Kristine Paula Gabrillo TiongCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Conductance

Uploaded by

Kristine Paula Gabrillo TiongCopyright:

Available Formats

thermal conductance

A measure of the ability of a material to transfer heat per unit time, given one unit area of the material and a temperature gradient through the thickness of the material. It is measured in watts per meter per degree Kelvin.

Thermal resistance is a heat property and a measurement of a temperature difference by which an object or material resists a heat flow (heat per time unit or thermal resistance). Thermal resistance is the reciprocal of thermal conductance. In physics, thermal conductivity (often denoted k, , or ) is the property of a material to conduct heat. It is evaluated primarily in terms of Fourier's Law for heat conduction. Heat transfer occurs at a higher rate across materials of high thermal conductivity than across materials of low thermal conductivity. Correspondingly materials of high thermal conductivity are widely used in heat sink applications and materials of low thermal conductivity are used as thermal insulation. Thermal conductivity of materials is temperature dependent. The reciprocal of thermal conductivity is called thermal resistivity.

The R-value is a measure of thermal resistance used in the building and construction industry. Under uniform conditions it is the ratio of the temperature difference across an insulator and the heat flux (heat transfer per unit area per unit time, ) through it or . The R-value being discussed is the unit thermal resistance. This is used for a unit value of any particular material. It is expressed as the thickness of the material divided by the thermal conductivity. For the thermal resistance of an entire section of material, instead of the unit resistance, divide the unit thermal resistance by the area of the material. For example, if you have the unit thermal resistance of a wall, divide it by the cross-sectional area of the depth of the wall to compute the thermal resistance. The unit thermal conductance of a material is denoted as C and is the reciprocal of the unit thermal resistance. This can also be called the [2] unit surface conductance, commonly denoted by h. The higher the number, the better the building insulation's effectiveness. R-value is the reciprocal of U-value. A thermal break or thermal barrier is an element of low thermal conductivity placed in an assembly to reduce or prevent the flow of thermal energy between conductive materials. In architecture and building construction some examples include the following: a thermal break is also a load-bearing thermal insulation system used in reinforced concrete structures to form a thermal break between cantilever structures and internal floor. Insulated glazing the air or gas between the panes stops the conductive thermal energy from passing through the glass. Metal window or curtain wall framing a separator material is used between the inner and outer frames to prevent the temperature transfer through the frame and condensation on the inside frame. Concrete work a single row of concrete masonry units (CMU block) is commonly set between the inner concrete slab and exterior concrete work to prevent the transfer of heat or cold through the slab.

[1]

Garage doors in some doors that have high R-rating insulation, a vinyl thermal break is used along the edges of each segment instead of rolled steel. Metal and wood framed buildings - an insulation material installed on the roof, walls and floor prevents thermal short circuit creating the heat transfer through the framing material and controls when desired (winter/summer)resulting in energy savings. Metal windows and doors - separating the frame into two separate interior and exterior pieces joined with a less conductive material reduces temperature transfer. Thermal breaks (made of substantially rigid, low thermal conductive polyamide or polyurethane which is mechanically locked in aluminum window framing can be more than a thousand times less conductive than aluminum and a hundred times less than steel.

Windows and doors - separating the frame into 2 separate interior and exterior pieces joined with a less conductive material between reduces temperature transfer. In addition thermal breaks can have the added benefit of reducing sound transmittance by dampening vibration Infiltration is the process by which water on the ground surface enters the soil. Infiltration rate in soil science is a measure of the rate at which soil is able to absorb rainfall or irrigation. It is measured in inches per hour or millimeters per hour. The rate decreases as the soil becomes saturated. If the precipitation rate exceeds the infiltration rate, runoff will usually occur unless there is some physical barrier. It is related to the saturated hydraulic conductivity of the near-surface soil. The rate of infiltration can be measured using an infiltrometer.

Weatherstripping is the process of sealing openings such as doors, windows, and trunks from the elements. The term can also refer to the materials used to carry out such sealing processes. The goal of weatherstripping is to prevent rain and water from entering entirely or partially and accomplishes this by either returning or rerouting water. A secondary goal of weatherstripping is to keep interior air in, thus saving energy on heating and air conditioning. utomotive weatherstripping is used extensively aboard automobiles, and can be found anywhere the interior compartment must be sealed from the environment. It must be both functional and cohesive with the body design of the vehicle. In addition to factors standard to weatherstripping, additional factors must be considered for vehicles, specifically in the engineering of the parts. For example, the weatherstripping must function the same while the vehicle is parked and at full speed; be flexible to accommodate motion vibrations; endure extreme temperatures of hot and cold; withstand long periods of sun exposure; and resist automotive liquids such as oil, gasoline, and windshield washer fluid (methanol). Weatherstripping also plays a part in maintaining satisfactory ride quality in the vehicle, being partially responsible for sealing noise out from the passenger compartment. Automobile flex when going over bumps, and vibrations cause relative motions between the relatively fixed body and movable parts like doors, windows, and sunroofs. This movement could allow water in the vehicle so the weatherstrip must compensate by filling the gap. Furthermore, this relative movement can cause noises such as squeaks, rattles, and creaks to be heard within the vehicle. Considering a standard four-door vehicle, the doors require 20 feet (6 meters) or more of material per door, windows require upwards of 10 feet (3 meters), and trunks require large amounts. Automotive weatherstripping can fail because of age or use.

[1]

Poorly performing weatherstripping should be reported to the car dealership if the vehicle is under warranty, as fixes may be known. The efficacy of weatherstripping can be significantly increased by specialty coatings during manufacture. Coatings for weatherstripping must adhere to all of these weatherstrip materials. Like other paints and coatings, a large variety of weatherstrip coatings are commonly available, with a large variety of coating performances. Silicone is the most difficult to adhere to, but at least one coating is commercially available. After bonding to the weatherstrip, these coatings provide chemical and ultraviolet resistance, decrease the static coefficient of friction (thereby reducing the force required to open or close [2] doors), and reduce or eliminate noise. In vehicles without coated weatherstripping, the weatherstripping is much more likely to cause the above-mentioned issues along with others such as rust following premature failure of the paint. That some cars have non-coated weatherstripping is surprising, given that the cost of the coating is less than US$1 to US$3 per vehicle, whereas the rubber and steel is tens of dollars; an entire car set of weatherstripping may be worth US$100 to US$300 in the total cost of the vehicle, which includes all labor and costs of the manufacturing equipment.

Radiant barriers or reflective barriers inhibit heat transfer by thermal radiation. Thermal energy may also be transferred via conduction or convection, however, and radiant barriers do not necessarily protect against heat transfer via conduction or convection. To improve the resistance to convection and conduction, a reflective insulation may be used by having the radiant barrier installed facing a dead air space or with a layer of traditional insulation like foam, fiberglass, or bubblepack.

How to Decide Between Batt Insulation and Loose-Fill Insulation

When it comes to deciding between batt insulation and loose-fill insulation, its important to keep in mind what you intend to insulate and what kind of insulation method you want to use. Both batt insulation and loose-fill insulation work very well you just need to decide which one you prefer.

Loose-fill insulation: Made out of small chunks of fibers, this insulation type is also known as blown insulation because its installed with a giant blower hose. Loose -fill insulation is also available in bags for filling gaps. When loose-fill insulation settles and compacts, you should vacuum out the old and start fresh.

Batt insulation: Made out of insulating fibers that are woven together to create a continuous blanket of material with a moisture barrier (either paper or foil) that is glued to one side. Batt insulation is available in 16 and 24 inch wide rolls (or 8 foot strips) to fit between the framing in ceilings and walls.

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Vaccination Summary List1Document1 pageVaccination Summary List1Kristine Paula Gabrillo TiongNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Request Letter and Authorization TiongDocument3 pagesRequest Letter and Authorization TiongKristine Paula Gabrillo TiongNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Wellness Registration Form1Document3 pagesWellness Registration Form1Kristine Paula Gabrillo TiongNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- GuidesDocument3 pagesGuidesKristine Paula Gabrillo TiongNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Observe Social DistancingDocument1 pageObserve Social DistancingKristine Paula Gabrillo TiongNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Personal Circumstances: NameDocument3 pagesPersonal Circumstances: NameKristine Paula Gabrillo TiongNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Position Knowledge Skills AttitudeDocument2 pagesPosition Knowledge Skills AttitudeKristine Paula Gabrillo TiongNo ratings yet

- Structure: TitleDocument15 pagesStructure: TitleKristine Paula Gabrillo TiongNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Insular Life Building PRNT!!!!!Document14 pagesInsular Life Building PRNT!!!!!Kristine Paula Gabrillo TiongNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Bedouin Black TentDocument20 pagesBedouin Black TentKristine Paula Gabrillo TiongNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Complex TrussesDocument1 pageComplex TrussesKristine Paula Gabrillo Tiong0% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- How To Apply:: Sole ProprietorsDocument1 pageHow To Apply:: Sole ProprietorsKristine Paula Gabrillo TiongNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Index Name of Casino Theme Image of Building Details of SignageDocument2 pagesIndex Name of Casino Theme Image of Building Details of SignageKristine Paula Gabrillo TiongNo ratings yet

- Rolled Oat Cookies Macaroons: Ingredients: IngredientsDocument2 pagesRolled Oat Cookies Macaroons: Ingredients: IngredientsKristine Paula Gabrillo TiongNo ratings yet

- ARTIGOCOBEMDocument11 pagesARTIGOCOBEMPradeep DonthaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Aluminium Plastic Composite PanelDocument9 pagesAluminium Plastic Composite PanelFrankie ChanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Telomere PDFDocument2 pagesTelomere PDFsoumita100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 2551 Blind Rev 17 English ManualDocument16 pages2551 Blind Rev 17 English ManualKadek Dwi PermanaNo ratings yet

- Unified Council: National Level Science Talent Search ExaminationDocument4 pagesUnified Council: National Level Science Talent Search ExaminationAnwesha SatpathyNo ratings yet

- PLATE & SHELL Heat Exchangers: A Shell & Tube AlternativeDocument4 pagesPLATE & SHELL Heat Exchangers: A Shell & Tube AlternativearianaseriNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Absorbance and Fluorescence Spectroscopies of Green Fluorescent ProteinDocument24 pagesAbsorbance and Fluorescence Spectroscopies of Green Fluorescent ProteinMadel Tutor ChaturvediNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- New Energy Efficient Car Built With 3d PrintingDocument3 pagesNew Energy Efficient Car Built With 3d PrintingKarthi KNo ratings yet

- 2-Varian 2005 Sample Prep WebDocument65 pages2-Varian 2005 Sample Prep Webalex_degarateNo ratings yet

- Liquid ALT (SGPT) Reagent SetDocument2 pagesLiquid ALT (SGPT) Reagent SetYahya RizkiNo ratings yet

- Load DistributionDocument44 pagesLoad Distributionሽታ ዓለሜNo ratings yet

- Area Classification: (IEC/EN 60529)Document1 pageArea Classification: (IEC/EN 60529)nestkwt1No ratings yet

- Transport in Plants PDFDocument10 pagesTransport in Plants PDFAlhiza JoaquinNo ratings yet

- Aphanizomenon Flos-Aquae - WikipediaDocument4 pagesAphanizomenon Flos-Aquae - WikipediaLucas Rueles da CunhaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Backwards Heat Equation InfoDocument1 pageBackwards Heat Equation InfoMelissa Marie HernandezNo ratings yet

- ch03 PDFDocument11 pagesch03 PDFFarhan KhanNo ratings yet

- Properties of Sea WaterDocument30 pagesProperties of Sea WaterHalima akterNo ratings yet

- Product Technical Data Manual April 2012 TOPCODocument181 pagesProduct Technical Data Manual April 2012 TOPCOJosé Del Orbe García100% (2)

- Utilization of Defatted Copra (Cocos Nucifera) As A Natural Coagulant For Surface Water TreatmentDocument1 pageUtilization of Defatted Copra (Cocos Nucifera) As A Natural Coagulant For Surface Water TreatmentmariniabrahanNo ratings yet

- Simultaneous Estimation of Paracetamol and NimesulideDocument4 pagesSimultaneous Estimation of Paracetamol and NimesulideBolgam PradeepNo ratings yet

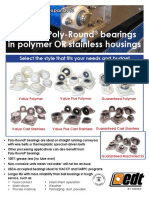

- Solution Poly-Round Bearings in Polymer OR Stainless HousingsDocument3 pagesSolution Poly-Round Bearings in Polymer OR Stainless HousingsLeroy AraoNo ratings yet

- Horizontal Vertical Horizontal Moment Node L/C FX KN Fy KN FZ KN MX KNM My KNMDocument7 pagesHorizontal Vertical Horizontal Moment Node L/C FX KN Fy KN FZ KN MX KNM My KNMEr Nilesh GajeraNo ratings yet

- 8.4 Performance Qualification Protocol For Dispensing BoothDocument13 pages8.4 Performance Qualification Protocol For Dispensing BoothArej Ibrahim AbulailNo ratings yet

- Hemanth Karmali & Deepak Pai - FomentoDocument46 pagesHemanth Karmali & Deepak Pai - FomentoNileshNo ratings yet

- BRITT - Hi-Bay LN6101 BrochureDocument1 pageBRITT - Hi-Bay LN6101 BrochureRenato Abalos100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lecture3 Example ShellandtuberatingcalculationsDocument4 pagesLecture3 Example Shellandtuberatingcalculationsunknown8787No ratings yet

- LSI Outdoor Lighting Price Book 1981Document20 pagesLSI Outdoor Lighting Price Book 1981Alan MastersNo ratings yet

- Student Exploration: Chemical EquationsDocument6 pagesStudent Exploration: Chemical EquationsAndreNo ratings yet

- KroenertDocument38 pagesKroenertYiğit IlgazNo ratings yet

- PHYS 2-Course Materials Fall-2019 Upto MidT.Document5 pagesPHYS 2-Course Materials Fall-2019 Upto MidT.Mohibbullah ShovonNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)