Professional Documents

Culture Documents

Rsu 410

Uploaded by

Ion Logofătu AlbertOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rsu 410

Uploaded by

Ion Logofătu AlbertCopyright:

Available Formats

Freight vehicle specific interface requirements

RSU

410

Bogie components

[1] 1.1

Introduction This section contains bogie related requirements which are specific to freight vehicles. All requirements in RSU 200 which are common requirements also apply to freight vehicles.

[2] 2.1 Refer to RSU 210 for common wheel requirements. RSU 211 RSU 212 2.2 Wheels, design & manufacture. Wheels, minimum operational requirements.

Wheels

W-37 type freight wheels 2.2.1 The 920 mm diameter wheel design designated W37 originating in NSW is prone to failure circumferentially around the web, and may be found fitted to 9R and 18R type roller bearing axlebox equipped wheelsets with wheels produced for the PTC of NSW and manufactured between 1975 and 1981. This wheel design can be readily identified by the presence of a recessed chucking groove around the inner circumference of the wheel rim. Suspect wheels can be identified by the following heat numbers, and must be scrapped when found, regardless of the year. Regular inspection of wheels is required to cull suspect wheels from service. 2.2.2 Suspect heat numbers. 1975 1976 1977 H1066 H2570, H2866, H2868, H2870, H2872, H2956, H2990, H3014, H3045, H3054, H3070 H3050, H3074, H3078, H3113, H3155, H3159, H3164, H3231, H3439, H3480 Wheel profiles The standard ANZR profile is the base wheel profile. (see Appendix G of this manual) ROA Intersystem worn wheel profile (also known as the QR modified or ANZR-2 profile) This wheel profile is not recommended for future application to freight vehicles operating on the Rail Infrastructure Corporation network. See clause 3.5.

[3] 3.1 3.2

3.3

Worn wheel profile (MOD 2) This wheel profile is not recommended for future application to freight vehicles operating on the Rail Infrastructure Corporation network. See clause 3.5.

3.4

Worn wheel profile (MOD 3) This profile is depicted on drawing 206-931, (see Appendix G of this manual), and is mandatory for freight vehicles operating exclusively on the Hunter Valley coal network and having standard three piece bogies. The MOD 3 profile may be utilised on vehicles operating outside the Hunter Valley coal network subject to approval by the Rail Infrastructure Corporation.

Version 2.0 April 2002

Rail Infrastructure Corporation

Page 1 of 3

RSU 410

Bogie components

3.5

Intersystem profile The profile depicted as WRP 2000 in Appendix G of this manual is the recommended wheel profile for future wheel replacement and reprofiling on all locomotives, freight and passenger vehicles operating on the Rail Infrastructure Corporation network.

[4] 4.1 Refer to RSU 220 for common axle requirements. RSU 221 RSU 222 Axles, design & manufacture Axles, minimum operational requirements

Axles

[5] 5.1

Wheel and axle assembly Refer to RSU 230 for common wheel and axle assembly requirements.

[6] 6.1 Refer to RSU 240 for common axle bearing assembly requirements.

Axle bearing assemblies

[7] 7.1

Bogie frames and associated componentry Refer to RSU 250 for common requirements for bogie frames and associated componentry.

[8] 8.1 Refer to RSU 260 for common vehicle suspension requirements. RSU 261 Suspension springs RSU 262 Suspension damping RSU 263 Resilient suspension components 8.2

Vehicle suspension

Suspension damping defects Vehicles shall comply with the ROA Manual of Engineering Standards and Practices, section 24.2.7. Reclamation of friction wedge assemblies Friction wedges shall not be reclaimed by welding under any circumstances. Where friction wedge pockets are reclaimed by welding, all welding shall be ground to form a flat surface with no pronounced ridges. Undressed weld beads shall not be permitted in wedge pockets.

8.3

Page 2 of 3

Rail Infrastructure Corporation

Version 2.0 April 2002

Bogie components

RSU 410

8.4

Operation of vehicles with defective suspension damping. If it is desired to continue moving vehicles with the defects stated in RSU 262 section 2, the load must be transhipped and the empty vehicle may proceed to the nearest repair location at the prevailing track speed limit not exceeding 50 km/h.

Version 2.0 April 2002

Rail Infrastructure Corporation

Page 3 of 3

You might also like

- WD 14 Abr 07 (1) - 1Document18 pagesWD 14 Abr 07 (1) - 1IndrajeetNo ratings yet

- Brakes and Pneumatic Equipment: Locomotive Hauled Passenger Vehicle Specific Interface Requirements RSUDocument2 pagesBrakes and Pneumatic Equipment: Locomotive Hauled Passenger Vehicle Specific Interface Requirements RSUIon Logofătu AlbertNo ratings yet

- 72 Stone Spec FinalDocument48 pages72 Stone Spec Finalsantro421No ratings yet

- MR FeroviarDocument90 pagesMR FeroviarCosoreci FlorinNo ratings yet

- Manual de Normas para Ruedas y Ejes de LocomotorasDocument42 pagesManual de Normas para Ruedas y Ejes de LocomotorasestephaniNo ratings yet

- AAR Manual of Standards and Recommended Practices Wheels and AxlesDocument42 pagesAAR Manual of Standards and Recommended Practices Wheels and AxlesestephaniNo ratings yet

- Draft - Specification COuplerDocument15 pagesDraft - Specification COuplerSinter PlanningNo ratings yet

- 08.03.19 Draft Specification of T-OUT Transport WagonDocument23 pages08.03.19 Draft Specification of T-OUT Transport WagonManjeet BhatiaNo ratings yet

- ManualforGIJReprint-2022withACSNo 8Document44 pagesManualforGIJReprint-2022withACSNo 8Puneet AggarwalNo ratings yet

- Functional Specification FOR Chain Pulley BlockDocument9 pagesFunctional Specification FOR Chain Pulley BlockVinayaga MoorthiNo ratings yet

- Specification TM 1902 280119Document47 pagesSpecification TM 1902 280119santro421No ratings yet

- H Type CBCDocument22 pagesH Type CBCmailbkrao0% (1)

- Commercial Engine Bulletin: Engine, Turbine Assembly - Steady - State Operation Avoidance Range LimitDocument1 pageCommercial Engine Bulletin: Engine, Turbine Assembly - Steady - State Operation Avoidance Range LimitturboshaftNo ratings yet

- Specification For Motorized Gear Units (Mgus) IPSS:1-03-008-03Document8 pagesSpecification For Motorized Gear Units (Mgus) IPSS:1-03-008-03HEMANTKHERANo ratings yet

- Cbcbdgfinaldraft 13101Document21 pagesCbcbdgfinaldraft 13101di jinNo ratings yet

- Draft STR For Periodic Repair, Rehabilitation of Motorized Bogie Frames For 3-Phase Electric LocomotivesDocument15 pagesDraft STR For Periodic Repair, Rehabilitation of Motorized Bogie Frames For 3-Phase Electric Locomotivesdattu33No ratings yet

- 15419Document29 pages15419tushar11singhNo ratings yet

- Rail - Design and Rating PDFDocument7 pagesRail - Design and Rating PDFCK TangNo ratings yet

- Final Specification - STR No. WD-40-LWLH25 Bogie-K-class Dated 26-02-16 PDFDocument61 pagesFinal Specification - STR No. WD-40-LWLH25 Bogie-K-class Dated 26-02-16 PDFAbhishek Tripathi100% (1)

- Final Draft - Wd-02-Bcnahsm1-2017Document10 pagesFinal Draft - Wd-02-Bcnahsm1-2017uzb37039No ratings yet

- Arai - in .Ais .073-1.2008Document20 pagesArai - in .Ais .073-1.2008mes138172No ratings yet

- Rsu 430Document2 pagesRsu 430Ion Logofătu AlbertNo ratings yet

- WD 23Document13 pagesWD 23Jatinder KumarNo ratings yet

- Ceb A 72-6048Document11 pagesCeb A 72-6048turboshaftNo ratings yet

- BR Block 08Document16 pagesBR Block 08mailbkraoNo ratings yet

- HKKJR LJDKJ Jsy Ea KyDocument18 pagesHKKJR LJDKJ Jsy Ea KymailbkraoNo ratings yet

- API 613 Fifth Edition Special Purpose Gear Units For Petroleum, Chemical and Gas Industry Services - Overview PresentationDocument8 pagesAPI 613 Fifth Edition Special Purpose Gear Units For Petroleum, Chemical and Gas Industry Services - Overview PresentationLymePark100% (1)

- API 613 - TurbolabDocument0 pagesAPI 613 - TurbolabDelfinsh100% (1)

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 73-10-04Document6 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 73-10-04anony8103No ratings yet

- Aramco Engineering - Evaluating Motor SpecificationsDocument161 pagesAramco Engineering - Evaluating Motor Specificationsdeepu220100% (1)

- WD 13 Bobrn 2011Document16 pagesWD 13 Bobrn 2011Kartik MendirattaNo ratings yet

- QCS 2010 Part 07 Vehicle Crash BarriersDocument13 pagesQCS 2010 Part 07 Vehicle Crash BarriersRotsapNayrbNo ratings yet

- Final Specification - STR No. WD-40-LWLH25 Bogie-K-class Dated 26-02-16Document61 pagesFinal Specification - STR No. WD-40-LWLH25 Bogie-K-class Dated 26-02-16ksvinyk7193No ratings yet

- Rolls-Royce: Commercial Engine BulletinDocument1 pageRolls-Royce: Commercial Engine BulletinturboshaftNo ratings yet

- Rail Inspection Vehicle (RIV) SpecificationDocument30 pagesRail Inspection Vehicle (RIV) SpecificationAyush SharmaNo ratings yet

- WD 06 BRN 2011Document14 pagesWD 06 BRN 2011Samir KarNo ratings yet

- Draft Spec. WD-05-BFNS-2017Document10 pagesDraft Spec. WD-05-BFNS-2017soutan chakrabortyNo ratings yet

- 981101Document44 pages981101JESUSCALVILLONo ratings yet

- PUB 6 18 2010 10 23 53 AM AIS-008 Rev1 FDocument71 pagesPUB 6 18 2010 10 23 53 AM AIS-008 Rev1 FSadique ShaikhNo ratings yet

- 71-BD-15 DraftDocument15 pages71-BD-15 DraftRakesh JainwalNo ratings yet

- Nat'l Highway Traffic Safety Admin., DOT 571.119Document8 pagesNat'l Highway Traffic Safety Admin., DOT 571.119Nadia NoversegaNo ratings yet

- Vol3 Section04Document8 pagesVol3 Section04M Sabri SapangalloNo ratings yet

- 15419Document29 pages15419Sadashiva SahooNo ratings yet

- CEB A 72aDocument1 pageCEB A 72aturboshaftNo ratings yet

- Maintenance Handbook On Roller Bearing Fitted On WDM2 Diesel Locomotive - English - 2Document58 pagesMaintenance Handbook On Roller Bearing Fitted On WDM2 Diesel Locomotive - English - 2Sourav PaulNo ratings yet

- Tub EtambouDocument8 pagesTub EtambouSpeedy Gonzales Riba RibaNo ratings yet

- Specification For Machine For AbrasionDocument3 pagesSpecification For Machine For AbrasionSajidAliKhanNo ratings yet

- 20316344D1198 LDocument56 pages20316344D1198 LBang Ochim0% (1)

- Ceb A 72 4095Document10 pagesCeb A 72 4095turboshaftNo ratings yet

- WD 01 Bosths 04 PDFDocument13 pagesWD 01 Bosths 04 PDFM PankajNo ratings yet

- TM HM 338Document37 pagesTM HM 338Mohamad SaquibNo ratings yet

- SAE J2562 - Nov 2005 - Surface Vehicle Recommended PracticeDocument22 pagesSAE J2562 - Nov 2005 - Surface Vehicle Recommended PracticeatulmkaushalNo ratings yet

- WD 62 Misc 17Document13 pagesWD 62 Misc 17Mayur UrkudeNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- CH1H - Introduction To Specimas SystemDocument4 pagesCH1H - Introduction To Specimas SystemIon Logofătu AlbertNo ratings yet

- Using Water As A MedicineDocument4 pagesUsing Water As A MedicineIon Logofătu AlbertNo ratings yet

- Technical Specification For Road Rail Equipment FSS550Document70 pagesTechnical Specification For Road Rail Equipment FSS550Ion Logofătu AlbertNo ratings yet

- Vickers DCV With Manual LatchDocument12 pagesVickers DCV With Manual LatchIon Logofătu AlbertNo ratings yet

- Bonfignioli EWP Wheel Drives PDFDocument8 pagesBonfignioli EWP Wheel Drives PDFIon Logofătu AlbertNo ratings yet

- General Specification For Radial Type Motorised Cable ReelersDocument5 pagesGeneral Specification For Radial Type Motorised Cable ReelersIon Logofătu AlbertNo ratings yet

- CH2H - Hydrodynamic Drive InfoDocument2 pagesCH2H - Hydrodynamic Drive InfoIon Logofătu AlbertNo ratings yet

- Rail Wheel DrawingsDocument27 pagesRail Wheel DrawingsIon Logofătu AlbertNo ratings yet

- 300 Signs and Symptoms of Celiac DiseaseDocument7 pages300 Signs and Symptoms of Celiac DiseaseIon Logofătu AlbertNo ratings yet

- Rubber BandsDocument11 pagesRubber BandsIon Logofătu AlbertNo ratings yet

- Hogan Copy of New Price List Updted (As at 4 5 2011)Document16 pagesHogan Copy of New Price List Updted (As at 4 5 2011)Ion Logofătu AlbertNo ratings yet

- Know Your Honey. Different Types of Honey and Their Health BenefitsDocument11 pagesKnow Your Honey. Different Types of Honey and Their Health BenefitsIon Logofătu AlbertNo ratings yet

- 7 Ways To Reduce Man Boobs & Decrease Estrogen LevelsDocument9 pages7 Ways To Reduce Man Boobs & Decrease Estrogen LevelsIon Logofătu AlbertNo ratings yet

- Steel ChartDocument5 pagesSteel ChartTommie PrinslooNo ratings yet

- Tips For Growing TomatoesDocument30 pagesTips For Growing TomatoesIon Logofătu Albert100% (1)

- List of Standards On File: Noise ManagementDocument2 pagesList of Standards On File: Noise ManagementIon Logofătu AlbertNo ratings yet

- John Yudkin .The Man Who Tried To Warn Us About SugarDocument5 pagesJohn Yudkin .The Man Who Tried To Warn Us About SugarIon Logofătu Albert100% (2)

- Amygdala: For Other Uses, See Amygdala (Disambiguation)Document16 pagesAmygdala: For Other Uses, See Amygdala (Disambiguation)Ion Logofătu AlbertNo ratings yet

- Risk ManagementDocument12 pagesRisk ManagementIon Logofătu AlbertNo ratings yet

- Using Water As A MedicineDocument4 pagesUsing Water As A MedicineIon Logofătu AlbertNo ratings yet

- The Grape CulturistDocument5 pagesThe Grape CulturistIon Logofătu AlbertNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Daniel Hanna Complete List of Roses I Have Grown in SydneyDocument79 pagesDaniel Hanna Complete List of Roses I Have Grown in SydneyIon Logofătu AlbertNo ratings yet

- Pruning Grapevines: Young VinesDocument1 pagePruning Grapevines: Young VinesIon Logofătu AlbertNo ratings yet

- Banana and Vanilla Tea CakeDocument10 pagesBanana and Vanilla Tea CakeIon Logofătu AlbertNo ratings yet

- Case Study 10 Treatment ProgramDocument5 pagesCase Study 10 Treatment ProgramIon Logofătu AlbertNo ratings yet

- Demerits GeneralDocument13 pagesDemerits GeneralIon Logofătu AlbertNo ratings yet

- Info BroucherDocument2 pagesInfo BroucherIon Logofătu AlbertNo ratings yet

- Case Study 12 Treatment Program1Document3 pagesCase Study 12 Treatment Program1Ion Logofătu AlbertNo ratings yet

- Case Study 10 Treatment ProgramDocument5 pagesCase Study 10 Treatment ProgramIon Logofătu AlbertNo ratings yet

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument6 pagesEngine Controls (Powertrain Management) - ALLDATA RepairNürburgring AutotechnikNo ratings yet

- Hyster 46 33Document8 pagesHyster 46 33Amit TawteNo ratings yet

- SUZUKI SWIFT 1992-2001 VEHICLE WIRING - AlarmSelloutDocument4 pagesSUZUKI SWIFT 1992-2001 VEHICLE WIRING - AlarmSelloutRahul Singh MoshalNo ratings yet

- SDF DataDocument8 pagesSDF DataGreat ProfessionalNo ratings yet

- Renault Triber - Official Review - Team-BHPDocument17 pagesRenault Triber - Official Review - Team-BHPramkumar31No ratings yet

- Dump Truck SafetyDocument1 pageDump Truck SafetyMusharaf ShahNo ratings yet

- REMUS Product Range CarDocument48 pagesREMUS Product Range Caraitor622No ratings yet

- Can Am Outlander Pro 570 2020 154 PDFDocument1 pageCan Am Outlander Pro 570 2020 154 PDFEduard GrigoreNo ratings yet

- "C" Frame: Pump, Variable Delivery PVM 064, 076, 098 &130Document5 pages"C" Frame: Pump, Variable Delivery PVM 064, 076, 098 &130Ulises KomatsuNo ratings yet

- Autek CitroenDocument30 pagesAutek Citroenegribbell100% (1)

- 50 ZVDocument376 pages50 ZVDedy setiawanNo ratings yet

- PDF Toyota Tiger 1kz 2001 DLDocument26 pagesPDF Toyota Tiger 1kz 2001 DLToon KazaNo ratings yet

- Remf-132 Efficient Control of Active Steering System in CarsDocument3 pagesRemf-132 Efficient Control of Active Steering System in CarsretechNo ratings yet

- 03kj PARTS FICHE PDFDocument614 pages03kj PARTS FICHE PDFmattNo ratings yet

- Grafityx Mod Menu V4Document16 pagesGrafityx Mod Menu V4HudaNo ratings yet

- NTPC Ta EntitlementDocument1 pageNTPC Ta EntitlementParmanand RautNo ratings yet

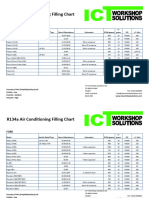

- R134a Air Conditioning Filling ChartDocument3 pagesR134a Air Conditioning Filling Chartreg100% (1)

- Tramites Lista Julio 2023Document3 pagesTramites Lista Julio 2023udc oficina centralNo ratings yet

- Komatsu Wb91 93r 2 Operation Maintenance ManualDocument20 pagesKomatsu Wb91 93r 2 Operation Maintenance Manualrita100% (29)

- Which Is The Best Excavator?: 7 AnswersDocument4 pagesWhich Is The Best Excavator?: 7 AnswersMuhammad IqbalNo ratings yet

- Forklift SafetyDocument20 pagesForklift Safetyعلي المرزوقNo ratings yet

- Qdoc - Tips - Mazda Abs Led DiagnosisDocument19 pagesQdoc - Tips - Mazda Abs Led DiagnosismarinochamorroNo ratings yet

- Power Train: 6Y-2303 Clutch Gp-TransmissionDocument19 pagesPower Train: 6Y-2303 Clutch Gp-TransmissionDANIEL VARGAS RODRIGUEZNo ratings yet

- Member Benefit Brochure: Good Sam Roadside AssistanceDocument20 pagesMember Benefit Brochure: Good Sam Roadside AssistanceWilliamNo ratings yet

- Motor Abdul Latif Jameel TPL Schedule - : Policy Number P1216-ALT-ALJ-000003/R3 - / 79711Document2 pagesMotor Abdul Latif Jameel TPL Schedule - : Policy Number P1216-ALT-ALJ-000003/R3 - / 79711Fahad AhmadNo ratings yet

- Mileage Claim FormDocument13 pagesMileage Claim FormKhin CNo ratings yet

- Sistema SCR Iveco TrakkerDocument13 pagesSistema SCR Iveco TrakkerSamuel Moreno88% (8)

- IB-401 - RS200 - Migration To Gen10 ABS Mitsubishi CPVDocument5 pagesIB-401 - RS200 - Migration To Gen10 ABS Mitsubishi CPVDeibid RVNo ratings yet

- Main Trailer Setup: Iwp Installation Work Package 020Document9 pagesMain Trailer Setup: Iwp Installation Work Package 020HowardWrightNo ratings yet

- LG936L Parts Catalogue PDFDocument260 pagesLG936L Parts Catalogue PDFShawn Feng100% (2)