Professional Documents

Culture Documents

A Pi 510 Practice Exams

Uploaded by

Kande RameshCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Pi 510 Practice Exams

Uploaded by

Kande RameshCopyright:

Available Formats

4 15 September 2004 Dammam, Saudi Arabia

API 510 PREPARATORY Final Exam (Open Book)

1. For UT examination using Pulse- Echo Technique, thickness calibration was performed at 80F. An on-stream UT reading at a TML on a pressure vessel (operating at 680F) was indicated as 50 mm. Its actual thickness will be approximately: a. b. c. d. 2. 44 mm 47 mm 48.5 mm 50 mm

What will be the size of nozzle to shell weld for nozzle weld configuration? Conforming to Fig.-j of UW-16. (Nom. Shell thickness = 28 mm., Nom. Nozzle thickness = 16mm., weld size t2= 12mm) a. b. c. d. 8 mm 10 mm 12mm 14 mm

3.

During the recent planned internal inspection showed two piits of following description. (Min. vessel thickness required = 5/8 including C.A = 1/8). Pits are separated by 12 inch distance( edge to edge) Pit A: Pit B: Available thickness at bottom of pit = 0.4 inch. Pit dia. = 1.5 Available thickness at bottom of pit = 0.34 inch. Pit dia. = 0.75

Your assessment is: a. b. c. d. Pitting is not harmful hence acceptable Pit A may be ignored but not Pit B Pit B may be ignored but not Pit A Both pits can not be ignored

4.

Following combination of Base metal and welding electrode was qualified by a certain PQR. Impact testing is not required. Base Metal = SA 285 Gr C Plates, 3/4" thk Welding electrode = AWS E 7015, This PQR will qualify which of the following combinations of Base Metal Welding electrodes. a. b. c. d. 1" thk SA 515gr 60 plates, E 6013 electrodes 1 " thk SA 285 grc plates, E 6013 electrodes 1 thk plates plates SA516gr70, E 7018 electrodes None of above

5.

The recommended minimum development time in minutes allowed for a material made of high temperature alloy is: a. b. c. d. 5 min 15 min 10 min 6 min

6.

A weld procedure is qualified in 1G position. This procedure can be used for welding in positions: a. b. c. d. 1G 2G 4G All of the positions

7.

A 1 thickness C.S. weld with 2mm acceptable reinforcement was to be radiographed. The applicable hole type penetrameter on (source side) and essential hole shall be: a. b. c. d. ASME ASME ASME ASME 30 25 20 30 2T 2T 2T 4T

8.

A radiograph for a long seam in new pressure vessel (UW 51) of 25mm thick plate shows 3mm crack, and 6 mm long isolated

slag. Your decision regarding acceptance of the radiograph will be: a. b. c. d. 9. Repair crack, repair slag Repair slag, accept crack Repair crack, accept slag Accept crack, accept slag

For a vessel which is planned for internal inspection after 8 years what should be the minimum remaining corrosion allowance in the vessel if corrosion rate is 150 microns per year. a. b. c. d. 2.0 2.4 1.2 None mm mm mm of above

10.

For vessel 2.5 inch thick, MDMT specified was 60F and material of construction used was SA 515 gr 60, without impact testing. The vessel failed later due to brittle failure. Maintainance Department says SA 516 GR 60 should have been used. What is your assessment? a. b. c. d. SA 515 GR 60 failed but 516 gr 60 would not have failed 516gr 60 would not have made any difference Impact strength was not apparent reason for failure b and c above

11.

A pressure vessel constructed according to ASME Sec. VIII, Div. 1 with shell thickness 7/8 (Material of Construction P No. 4, group no. 1) is to be repaired by using insert plates. The requirement of radiography to be incorporated in repair procedure shall be: a. b. c. d. Full radiography Spot radiography May be a, or b depending on joint efficiency Data is not adequate

12.

After completion of alterations a pressure test is: a. Normally required

b. c. d. 13.

Subject to approval of the jurisdiction , appropriate NDE shall be required where pressure test is not performed Substituting NDE for a pressure test after an alteration ay be done only after consulting a pressure vessel engineer experienced in pressure vessel design All of the above

A procedure qualification test was carried out for a groove weld on a plate with weld metal thickness of 16 mm thickness by SMAW process. The test was found satisfactory. This procedure can be used with SMAW for weld thickness of: a. b. c. d. 5 to 32 mm 0 to 16 mm Any thickness 0 to 32 mm

14.

In liquid penetrant testing, a procedure is qualified to a temperature of 15 degree C. Pick up a correct statement. a. b. c. d. The same procedure The same procedure The same procedure The same procedure than 150C is qualified from 100C to 520C is restricted to maximum of 150C only shall be applied to 5 0C to 100C shall be applied to temperature more

15.

An in-service vessel with seamless 2:1 Ellipsoidal head 60 inch ID, 400 psi design pressure, (corrosion allowance = 0) and (S = 20000 psig) was inspected. Available thickness of only 5/8 was observed on the crown portion. The knuckle thickness was found to be adequate. Your assessment is: a. b. c. d. Head thickness in crown portion is still ok for operation. Thickness is inadequate. Depends on the opinion of third party inspector Depends on the opinion of API 510 inspector

16.

Choose correct hydrostatic test pressure from given options for a vessel with following data: Design pressure Design temperature = = 200 psi 675 F

M.O.C = Allow stress (Ambient) = Allow stress (675F) = a. b. c. d. 17. 350 psig 260 psig 312 psig None of above

SA 537 Cl.1 18,000 psi 15,000 psi

The temperature measured at a weld layer for a magnetic material is around 450C, but weld is in vertical position. It is decided to carryout a surface NDT method. Choose a suitable NDT method. a. b. c. d. Penetrant testing wet developer Magnetic particle testing with dry particles-prod type Magnetic particle testing with dry particles-yoke type None of above

18.

A weld procedure is qualified on pipe OD = 2, in 1G position. This procedure can be used for welding: a. b. c. d. 6 OD pipe in 1G only 2 OD pipe in 1G only Any diameter pipe in any position Pipes smaller than 2 OD in 1G only

19.

During the External inspection, observed resistance of electrical grounding connections for Pressure vessels was 42 ohms. Your advice is: a. b. a. b. Accept Resistance must be reduced to 25 Ohms Maximum Resistance must be increased to 25 Ohms minimum Depends on opinion of electrical engineer.

20.

For a certain nozzle to shell joint (No corrosion allowance is required.) following data is presented. Shell thickness provided Nozzle I.D. Pad size Thickness of pad = = = = 0.42 inch. 3.2 in. 6.4 in. O. D. 0.42.

Your assessment is: a. b. c. d. 21. Nozzle is adequately reinforced. Reinforcement is inadequate. Data is inadequate: nozzle thickness must be given. Data is inadequate: design shell thickness must be given.

For procedure qualifications with the GTAW process _______ is Non-essential variable. a. b. c. d. Change of P No. Change of A No. Change of F No. Groove design

22.

The crown portion for torispherical head (ID=40 inches) may be considered as the portion lying entirely within a circle whose centre will be same as head centre and diameter will be: a. b. c. d. 36 40 32 200

23.

For 2:1 Ellip. Head (ID=75 inches), the crown portion would lie within similar circle of diameter: a. b. c. d. 60 30 54 48

24.

In liquid penetrant examination the maximum permitted rounded indication size for circumferential welds with plate thickness up to 1 inch will be: a. b. c. d. 1/8 1/16 3/16

25.

For a vertical with column int. dia. = 48'' and height (tan-tan) =98 ft., the hydrostatic head for bottom dished head (2:1 Ellip. type) will be: a. b. c. d. 40.6 psi 42.4 psi 43.3 psi None of above

26.

Leak tightness of the relief valves is tested by conducting: a. b. c. d. Water Bubble test with water head = 0.5 at the set pressure Water Bubble test with water head = 1.0 at set pressure Water Bubble test with water head = 0.5 at 90% of the set pressure None of above

4 -15 September 2004 Dammam, Saudi Arabia

API 510 PREPARATORY

Final Exam Open Book Answer Key

Q. NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

ANSWER A C A C C D A C B A A D D A A C A C B A D C A C C C

REFERENCE ASME V, SE 797, 8.5 ASME VIII, UW 16 (j) Notes API 510, 5.7 (b) ASME IX, Tables QW 451, QW 422 & QW - 423 ASME V, Table T-672 ASME IX, QW - 203 ASME V, Table T 276 ASME VIII, UW - 51 API 510, 6.4 ASME VIII, Fig. UCS - 66 API 510 and ASME VIII, Table UCS - 57 API 510, 7.2.10 ASME IX, Table QW 451.1 ASME V, T-652 API 510, 57 (e) and ASME VIII, UG-32 (f) ASME VIII, UG - 99 General Knowledge ASME IX, QW 452.3 API 572, 10.3.9 Pad OD = 2d and pad thickness shell thk is always ok ASME IX, Table QW 256 and QW 402.1 API 510, 5.7 (e) API 510, 5.7 (e) ASME VIII, Appendix 8, 8.4 h = 100 ft.; head = 100 x 0.433 = 43.3 psi (BOK) API 576, 6.2.15 & Fig. 40

10

4 15 September 2004 Dammam, Saudi Arabia

API 510 PREPARATORY Final Exam (Closed Book)

Note: Choose only one answer which you think is most appropriate. Write your answers in a separate answer sheet.

1.

Post weld heat treatment of vessel welds generally results in: a. b. c. d. Improvement in ductility Increase of tensile strength Increase of strength and ductility None of the above

2.

The __________ shall be responsible to the owner-user for determining that the requirements of API 510 for inspection, and testing are met. a. b. c. d. Vessel engineer Authorised inspector Repair organisation Operating personnel

3.

Vessels that are known to have a remaining life of over __________ years or that are protected against external corrosion need not have insulation removed for the periodic external inspection. a. b. c. d. 10 15 5 20

4.

After an inspection interval is completed and if calculations indicate that an inaccurate rate of corrosion has been assumed initially, how do you determine the corrosion rate for the next inspection period? a. b. Check the original calculations to find out what the error is in the original assumption. Unless the corrosion rate is changed by Jurisdiction, the initial rates shall be used.

c. d. 5.

The corrosion rate shall be adjusted to agree with the actual rate found. Call in a corrosion specialist

If a vessel is made up of unknown materials and computations must be made to determine the MAWP what can the inspector or the vessel engineer do to establish the MAWP? a. b. c. The lowest grade material and highest joint efficiency in the applicable code may be assumed for calculations. Assume MOC as SA 283 Gr.C and joint efficiency = 0.7 The vessel made of the unknown material must be removed from service and vessel of known material must be installed. The vessel of unknown material shall be subjected to hydrostatic tests while having strain gages on it to determine its yield strength and thus allowable stress.

d.

6.

An RBI assessment can be used to alter the inspection strategy provided: a. b. c. d. The degradation methods are identified and evaluated The RBI is fully documented. A third party conducts the RBI Both A and B above

7.

What climatic area may require a very active program for corrosion under insulation? a. b. c. d. Cooler dry locations. Very cold locations with year round temperature less than 25F Warmer, wet locations Warmer dry locations

8.

Soil-to-air (S/A) interfaces for partially buried vessels are a location where localized corrosion may take place. If the buried part is excavated for inspection, how deep should the excavation be to determine if there is hidden damage? a. b. c. d. 12 to 18 inches 6 to 12 inches 12 to 24 inches 6 to 18 inches

9.

Environmental cracking of austenite stainless steels is caused many times by: a. b. c. d. Exposing areas to high-velocity and high-turbulence streams Excessive cyclic stresses that are often very low Exposure to chlorides from salt water Creep of the material by long time exposure to high temperature and stress

10.

Where can fatigue cracking typically be first detected? a. b. c. d. At points of low-stress intensification such as reinforced nozzles At points of high-stress intensification such as branch connections At points where cyclic stresses are very low At points where there are only the primary stresses

11.

The term away from weld for recalculating the required thickness (Vessels with E<1), means area lying away from weld __________ on either side of the weld or __________ times the minimum measured thickness on either side of the weld, whichever is greater. a. b. c. d. 1, 1", 2", 2, 4 2 2 4

12.

Minimum Design thickness for a vessel shell is 10 mm. Following four plates were received with actual thickness equal to: 10.2 mm, 9.7mm, 10.3mm, and 9.6 mm. As per ASME Sec. VIII Div.1, how many plates will you release for vessel fabrication? a. b. c. d. 1 2 3 All 4

13.

What type of repairs and procedures may the inspector give prior general authorisation to continue (provided the inspector is satisfied with the competency of the repair organization)?

a. b. c. d. 14.

Major repairs and minor procedures Limited or routine repairs Major alterations and re-ratings Minor re-ratings and alterations

Temper embrittlement is: a. b. c. d. Brittleness due to low temperature operation Brittleness due to Hydrogen Sulphide attack at high temperatures (exceeding 700F) Loss of ductility in Crsteels due to incorrect PWHT and High temperature service None of above

15.

Sour crude is more corrosive than sweet crude because: a. b. c. d. Sour crude is heavier than is sweet crude Sweet crude has more waxing tendency (compared to sour crude) which forms protective layer on metallic surfaces hence sweet crudes are less corrosive. Sour crude contains high content H2S and sulpher compared to sweet crude which lead to several types of corrosion None of the above

16.

HCl is more corrosive in refining sour crudes because: a. b. c. d. In presence of H2S, corrosion of iron by HCl becomes cyclic reaction regenerating HCl. HCl liberates chlorine in presence of sulpher which causes stress corrosion cracking HCl liberates Hydrogen in presence of sulpher causing Hydrogen embrittlement. None of the above

17.

In planning for an internal inspection of a vertical vessel that has acidic corrodents, what type of corrosion would you expect to find on the vessel shell from inside? a. b. c. d. Hydrogen blistering near liquid level Hydrogen blistering on top dished head Hydrogen blistering near the bottom of vessel None of above

18.

H2S is in sour crude is more harmful in presence of: a. b. c. d. Oxygen Water (i.e., Wet H2S) Sulphur a and c above

19.

The leak tightness of the relief valves is tested on the test block at a pressure equal to: a. b. c. d. Same as set pressure 90% of the set pressure Same as reseat pressure None of the above

20.

The principal reason for inspecting a pressure relief device is to determine: a. b. c. d. Condition of pressure relief device and if it is functioning properly The remaining life of pressure relief device. The spring coil diameter. The body thickness.

21.

Which of the following tests must be conducted on a valve as soon as it has been received in the shop for inspection? a. b. c. d. Visual inspection Hydrotesting of valve body Radiographic testing Check set-pressure

22.

API 576 does not address: a. b. c. d. Valve testing on test benches in shop Application of rupture discs Training requirements for mechanics involved in inspection and repair of pressure relieving devices All of the above

23.

For vessels which are supported on concrete saddles and working in an area where the humidity is high which areas on them are typically susceptible to external corrosion?

a. b. c. d. 24.

At the anchor bolts in the foundation At the Points of contact of the metal surface with the concrete All of the above None of the above

Inspection records contain the following information for a particular thickness measurement location (TML) on a dished head. (Thk. in inches) On the basis of this information, the long-term corrosion rate for the location is: Thickness 0.500 0.425 0.400 a. b. c. d. Year 0 5 10

1 mils per year. 5 mils per year. 10 mils per year. 100 mils per year.

25.

A certain C.S. vessel which required impact testing was required to have PWHT initially according to code requirement. After 10 years when repaired by welding PWHT is to be carried out. Performing PWHT is found to be impracticable. Which of the following is relevant (as per API-510)? a. b. c. d. PWHT may be exempted, if proper NDE is carried out. Carry out temper-bead welding as alternative to PWHT. Carry out both hydro-testing and pneumatic testing in lieu of the PWHT. Carry out preheating to minimum 200F

26.

A cylindrical shell with thickness = 4.0, ID=96, S=17100 and E=0.85 and C.A. = 1/8 showed metal loss of 1/4 in areas 8 on either side of the longitudinal welds. You analysis of situation is: a. Recalculate shell thickness tminimum considering E=1.0

b. c. d. 27.

The thinned area is on or within weld area hence (a) above can not be adopted Prepare repair procedure and restore the metal loss as per API -510 b and c above

Materials used for making repair by welding in carbon steel vessels shall have the following limitations? a. b. c. d. They shall meet the requirements stipulated in NACE Standard. The carbon content shall not be over 0.35% Welding repair shall be done by using only the GTAW process All of the above

28.

For non-continuous corrosive service with remaining life 25 years, external inspection shall be performed not later than: a. b. c. d. 10 years 12.5 years 5 years None of above

29.

An ellipsoidal head has an internal diameter of 76 inches and depth of 21 inches (including a straight face dimension of 2 inches). What should its spherical (crown) radius be? a. b. c. d. 76.9 inches 15.6 inches 68.4 inches All of the above

30.

For carrying out temper bead welding technique in lieu of PWHT, apart from other requirements, which of the following is acceptable? a. b. The root and final pass of weld shall be radiographed. Weld metal shall be deposited for second pass while the first pass below the second pass is still not cooled down and its cooling rate is retarded due to the heat of second pass

c. d. 31.

After depositing each layers of the weld, the weld shall be DP checked. Both b and c

Calculate the remaining life and external insp. interval of a vessel given the following data: Actual thickness = 0.955 inch Minimum thickness required = 0.755 inch Thickness at previous inspection 5 years prior to present inspection = 1.025 inch a. b. c. d. 20 years, 10 years 14 years, 5years 28 years, 10 years None of the above

32.

Vessel containing lethal substance with shell thickness of 20mm requires: a. b. c. d. Spot radiography (RT-3) Full length radiography (RT-1) No radiography (RT-4) Penetrant is sufficient if radiography testing is not available

33.

A vessel which was inspected six years ago and had shell thickness = 0.870. As on today the thickness as reported by filed inspection is 0.786. What was the corrosion rate over last six years? a. b. c. d. 10 mpy 12 mpy 14 mpy none of above

34.

If the vessel in above question has minimum permissible thickness = 0.618 for the present design conditions. What will be estimated remaining life of the vessel if corrosion rate remains same? a. b. 10 years 12 years

c. d. 35.

14 years None of above

For a vessel, remaining life is estimated as 22 years from now, next planned internal and external inspection shall not be later than: a. b. c. d. 11 Years, 5 Years 10 Years, 5 Years 5 Years, 5 Years None of the above

36.

What is the maximum defect permitted on the convex surface of a welder qualification bend test after bending? a. b. c. d. inch 1/8 inch 1/16 inch 3/16 inch

37.

Certification of contaminants shall be obtained for all PT materials used on: a. b. c. d. Carbon steels Ferritic stainless steels Austenitic stainless steels None of the above

38.

The scope of the ASME Boiler and Pressure Vessel, Code, Section V includes: a. b. c. d. NDE acceptance criteria How to perform NDE to achieve a desired result Where to do NDE (i.e. what welds to examine) All of above. for magnetizing equipment, the

39.

For Ammeter calibration allowable tolerance is: a. b. c. d. +5% +10% +15% +20%

40.

Which of the following are commonly preferred to know the process side degradation of pressure vessels? a. b. b. c. On stream inspection. Internal inspection External inspection as alternative to internal inspection Any of above is OK

41.

For MT examination by Prod technique the magnetizing current required depends on: a. b. c. d. Prod Spacing Thickness of item under Inspection a & b above None of above

42.

While deciding the governing thickness for crown portion for corroded 2:1 ellipsoidal head, API 510 stipulates that & crown thickness shall be calculated: a. b. c. d. According to relevant ellipsoidal dished head formula According to code formula for spherical heads with head radius equal to 0.9 D, where D is shell dia meter. Thickness of crown shall be same as knuckle thickness. None of the above.

43.

For a vertical column, Int. dia. = 48'' and height (T-T) = 80ft, The vessel MAWP is 60 psi. The vessel part MAWP for bottom dished head (2:1 Ellip type) will be: a. b. c. d. 94.6 psi 82.8 psi 95.5 psi None of above

44.

How is hammer testing utilized? a. b. c. d. As a preliminary survey for thinned areas. As a independent test method for which ASNT Certification in NDT is available As a important tool in the hands of the Authorized inspection only To carry out Carpy impact test

10

45.

Which of the following represent grouping of weld-metals in ASME IX? a. b. c. d. P Nos. F Nos. S Nos. A Nos.

46.

Which is/are advantage of magnetic particle testing over penetrant testing? a. b. c. d. It can detect surface discontinuities with foreign material imbedded in them. It is faster on individual parts. It can detect near-surface discontinuities. All of the above.

47.

Double wall Double image technique is used for the radiography of: a. b. c. d. Plate welds Tubular products with outer diameter less than 3.5 inch Large pipes with outer diameter 200 mm and above Heavy castings

48.

As per ASME Sec. VIII Div. 1, if permanent deformation is observed due to over pressure during hydrotesting: a. b. c. d. The inspector should ask for re-test using proper test pressure and new pressure gauges. Follow-up the hydro-testing by a pneumatic test at proper pressure, taking suitable precautions as given in code The inspector may ask for providing additional stiffening rings around vessel and carry out re-hydro test at proper test pressure. The inspector may reject the vessel.

49.

The size of a properly deposited equal fillet weld is shown as 10 mm. The throat dimension for this weld will be approximately: a. b. 10 mm 8 mm

11

c. d. 50.

7 mm 9 mm

If any setting is noticed on a vessel, which of the following should be done: a. b. c. d. Conduct RT after 48 hours of observing the defective condition Nozzles and adjacent shell areas should be inspected for distortion and cracking Use acoustic emission monitoring All of the above

51.

The rate of erosion varies as: a. b. c. d. Square of fluid velocity Linearly with velocity Varies as cube of velocity Varies as square root of velocity

52.

Cracks and laminations look similar from surface however, generally: a. b. c. d. Cracks run normal to vessels surfaces Lamination runs slant or parallel to surface a and b above None of above

53.

The pH of an acidic solution is: a. b. c. d. Less than 7 Greater than 7 It is 7 Greater than 10

54.

The nonmetallic coating disbonding in a vessel can be better detected by: a. b. c. d. Eddy current testing Holiday detection Ultrasonic testing Acoustic emission testing

12

55.

External inspection of a pressure vessel starts with: a. b. c. d. Ladder, stairs, walkway and platforms of the vessel Insulation, skirt and foundation The external surfaces, of vessel Dimensional check of the vessel

56.

Before carrying out an inter service inspection on a vessel put in-service for quite some time what the inspector should do first a. b. c. d. Check Check Check Check the the the the material in which it is constructed. permanent file of the vessel. progressive history file of the vessel. original thickness report.

13

14

4 -15 September 2004 Dammam, Saudi Arabia

API 510 PREPARATORY

Final Exam Closed Book Answer Key

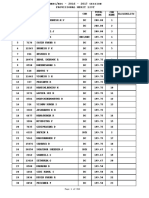

Q. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 ANS. A B A C B D C D C B B C B C C A A B B A D C B C B D B C REFERENCE General Knowledge API 510, 4.4 API 510, 6.3 API 510, 6.4 API 510, 6.7 API 510, 6.2 API 572, 8.2.1 API 572, 8.2.9 IRE II, 202.064 API 510, 5.2 API 510, 5.7 (d) ASME VIII, UG 16 (c) API 510, 7.11 API 510, 5.2 IRE, Ch. II, 202.023 IRE, Ch. II, Page 12 API 572, Page 29 API 572, Page 28 API API API API API API API API API API 576, 576, 576, 576, 572, 510, 510, 570, 510, 510, 6.2.15 6.1 6.28 Scope 10.3.5 6.4 7.2.3.2 5.7 (d) 7.2.8 6.3 Q. 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 ANS. REFERENCE C API 510, 5.7 (e) B API 510, 3.19 B API 510, 6.3, 6.4 B ASME VIII, UG 11 (a) C API 510, 6.4 B API 510, 6.4 C API 510, 6.3, 6.4 B ASME IX, QW - 163 C ASME V, Art. 6, App. II B ASME V, Art. 1, Scope B ASME V, Art. 7, T-761 B API 510, 6.1 B ASME V, Art. 7, T-752.2 B API 510, 5.7 (e) C BOK, 80 + 82 x 0.433 A API 572, 10.8.1 D ASME IX, Table QW - 442 ASME V, Art. 7, Scope & Gen. D Knowledge B ASME V, Art. 2, T-271 (b) D ASME VIII, UG - 99 C BOK, 10 x 0.7 = 7 mm B API 572, 10.38 C IRE II, 203.02 C API 572, Page 31 A IRE II, Page 10 B API 572, 10.4.6 A API 572, 10.3.2 C API 572, 10.4.3

15

16

You might also like

- LG Refridge ServiceManualDocument79 pagesLG Refridge ServiceManualMichael Dianics100% (1)

- ASME VIII Open Book ExamDocument8 pagesASME VIII Open Book Examraymondpayson447No ratings yet

- The Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFDocument36 pagesThe Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFrogersampaiocostaNo ratings yet

- The Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFDocument36 pagesThe Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFrogersampaiocostaNo ratings yet

- A Novel ZVS-ZCS Bi-Directional Flyback DC-DCDocument6 pagesA Novel ZVS-ZCS Bi-Directional Flyback DC-DCArceu CamposNo ratings yet

- API-510 Practice Exam QuestionsDocument18 pagesAPI-510 Practice Exam QuestionsAshish Patel100% (2)

- API 572 (Question Answers)Document39 pagesAPI 572 (Question Answers)Hina Khurshid67% (3)

- NDT Study Material PCN UT II PDFDocument88 pagesNDT Study Material PCN UT II PDFJeganeswaran80% (5)

- API 653 PC Final OpenDocument7 pagesAPI 653 PC Final OpenMuhammad Nozar100% (1)

- Mayo College: Dining Hall at AjmerDocument79 pagesMayo College: Dining Hall at AjmerFaquruddinNo ratings yet

- API 510-Kuwait Petroleum QuestionsDocument160 pagesAPI 510-Kuwait Petroleum QuestionsKamal Niazi Khan100% (21)

- API 510 Certification Prep: 60-hr Pressure Vessel Inspector CourseDocument1 pageAPI 510 Certification Prep: 60-hr Pressure Vessel Inspector CourseAbu Huraira0% (1)

- Ground Improvement TechniquesDocument29 pagesGround Improvement TechniquesMeEr AahilNo ratings yet

- API 572 Practise QuestionDocument58 pagesAPI 572 Practise Questionbelonk_182100% (6)

- API 510 PC Final Exam ClosedDocument12 pagesAPI 510 PC Final Exam ClosedAbdel-Rahman Taha Merdan100% (1)

- Application Form PDFDocument8 pagesApplication Form PDFJeganeswaranNo ratings yet

- Pump Mechanical Seals GuideDocument41 pagesPump Mechanical Seals GuideArief Hidayat100% (1)

- API 570 QuizDocument6 pagesAPI 570 Quizjacquesmayol100% (1)

- Eddy Current Nortec-600 Manual PDFDocument12 pagesEddy Current Nortec-600 Manual PDFEswaranNo ratings yet

- 510 Practice Exam 5 OB QuestionsDocument0 pages510 Practice Exam 5 OB QuestionsGireesh Hegde100% (1)

- Api 510 Questions & Answers (Closed 1)Document12 pagesApi 510 Questions & Answers (Closed 1)Mohammed Shakil100% (3)

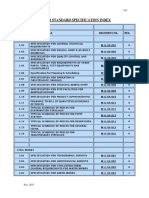

- Water Standard Specification Index As On Dec 2015Document10 pagesWater Standard Specification Index As On Dec 2015afp15060% (1)

- Piping Inspection Questions and Answers for ASME B31.3 Code ComplianceDocument13 pagesPiping Inspection Questions and Answers for ASME B31.3 Code CompliancePPatelNo ratings yet

- Api 510 Q&aDocument13 pagesApi 510 Q&aShaikh Aftab100% (1)

- Bay.t-510 Close Prac Exam #3Document22 pagesBay.t-510 Close Prac Exam #3Karim Mamdouh50% (2)

- API 510 Study QuestionsDocument49 pagesAPI 510 Study QuestionsMichael Clapham50% (4)

- API 570 Day 5 Book (1 To 130)Document137 pagesAPI 570 Day 5 Book (1 To 130)melvinNo ratings yet

- Lightning Protection System Design PDFDocument46 pagesLightning Protection System Design PDFhportezNo ratings yet

- DNVGL-ST-F101 Submarine Pipeline Systems-415-416 PDFDocument2 pagesDNVGL-ST-F101 Submarine Pipeline Systems-415-416 PDFJeganeswaranNo ratings yet

- API 510 Open Book Q&ADocument138 pagesAPI 510 Open Book Q&AMohammed Shakil25% (4)

- API 572 (Question Answers)Document39 pagesAPI 572 (Question Answers)Muhammad Shoaib100% (1)

- API 570 Mock Exam Closed BookDocument17 pagesAPI 570 Mock Exam Closed Bookaasatti100% (1)

- API 510 - Open 2 & Open 8Document11 pagesAPI 510 - Open 2 & Open 8EswaranNo ratings yet

- Api 510 Preparatory ExamDocument13 pagesApi 510 Preparatory Exameldobie3100% (1)

- 1 API 653 Memories March 2014 ExamDocument20 pages1 API 653 Memories March 2014 ExamHaris Khan83% (6)

- API 570-Final Model Exam-Open Book Without AnswersDocument6 pagesAPI 570-Final Model Exam-Open Book Without Answersbanana100% (1)

- Api 510 Q&a-2Document32 pagesApi 510 Q&a-2Mohammed ShakilNo ratings yet

- API-510 Exam Prep Course Practice Exam #3 SolutionsDocument14 pagesAPI-510 Exam Prep Course Practice Exam #3 SolutionsKarim MamdouhNo ratings yet

- API 510 Exam May 2016Document5 pagesAPI 510 Exam May 2016abdoNo ratings yet

- API 510 QuestionsDocument8 pagesAPI 510 QuestionsTAYYAB FAROOQ100% (2)

- API 510 Exam OpenDocument3 pagesAPI 510 Exam OpenalouisNo ratings yet

- Examination Question 510Document12 pagesExamination Question 510ohengjkt100% (1)

- API 510 Closed Book QuestionsDocument16 pagesAPI 510 Closed Book QuestionsRavindra S. Jivani100% (1)

- Api 510 Practice Exam B (150 Questions) : Design Temp Test TempDocument45 pagesApi 510 Practice Exam B (150 Questions) : Design Temp Test Temperagorn100% (2)

- API 510 CB Mockup 3 R0 26112010Document18 pagesAPI 510 CB Mockup 3 R0 26112010essnelsonNo ratings yet

- API 510 PC 20 31 Aug05 Final Exam OpenDocument4 pagesAPI 510 PC 20 31 Aug05 Final Exam OpennikafiqNo ratings yet

- API Recert QuestionsDocument8 pagesAPI Recert Questionsrama77No ratings yet

- The Location Markers Required by ASME V Are Required To Appear As Radiographic ImagesDocument6 pagesThe Location Markers Required by ASME V Are Required To Appear As Radiographic ImagesSadiq KhattakNo ratings yet

- Tolerante Table Groase Laminate La Cald EN 10029-2011 PDFDocument2 pagesTolerante Table Groase Laminate La Cald EN 10029-2011 PDFDaniel C.No ratings yet

- API 576 ExerciseDocument10 pagesAPI 576 Exerciseariyamanjula2914100% (1)

- API 510 Final Exam Bank Pressure Vessel QuestionsDocument4 pagesAPI 510 Final Exam Bank Pressure Vessel QuestionsMo'tasem Serdaneh0% (1)

- API 510 Questions June 02 2004 1Document10 pagesAPI 510 Questions June 02 2004 1Ariq FauzanNo ratings yet

- API 510 Practice Exam B Questions and AnswersDocument25 pagesAPI 510 Practice Exam B Questions and AnswersMastram Hathesh100% (6)

- API 510 Exam 5 ClosedDocument4 pagesAPI 510 Exam 5 ClosedweerasinghekNo ratings yet

- API 510 Mid-Session Exam (Open Book) : Instructions: Choose Only One Answer Which You Think Is Most AppropriateDocument6 pagesAPI 510 Mid-Session Exam (Open Book) : Instructions: Choose Only One Answer Which You Think Is Most AppropriatesnamprogNo ratings yet

- Open Book API 510 Practice Exam B Do Not Mark On Your Exam, Use The Answer Sheets ProvidedDocument16 pagesOpen Book API 510 Practice Exam B Do Not Mark On Your Exam, Use The Answer Sheets ProvidedBeantickNo ratings yet

- 510 IRS Pune Open Book Questions FinalDocument6 pages510 IRS Pune Open Book Questions Finaljaheer1No ratings yet

- 63 Multiple Choice Questions: No Answer GivenDocument16 pages63 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvR100% (1)

- Api 510 Preparatory Bench Mark Quiz: AppropriateDocument120 pagesApi 510 Preparatory Bench Mark Quiz: AppropriateCss Sfaxien100% (1)

- Daily Points To Recall (Day 8) : Page 1 of 3Document3 pagesDaily Points To Recall (Day 8) : Page 1 of 3chowhkNo ratings yet

- API 510.jan 2022 (Open & Closed)Document79 pagesAPI 510.jan 2022 (Open & Closed)Ali BEN YESAADNo ratings yet

- API 510 Prep Course QuestionsDocument30 pagesAPI 510 Prep Course QuestionsRanaweera AriyamanjulaNo ratings yet

- NDT Company Training ScheduleDocument7 pagesNDT Company Training ScheduleEswaranNo ratings yet

- Open Book Answers:: BAY Technical Associates, Inc. 1Document8 pagesOpen Book Answers:: BAY Technical Associates, Inc. 1tommy3021100% (1)

- API 653 PC 15may04 Exam 4 ClosedDocument5 pagesAPI 653 PC 15may04 Exam 4 ClosedShaalan AliNo ratings yet

- API 570 Exam 574 QuizDocument3 pagesAPI 570 Exam 574 Quizessnelson100% (2)

- 1 API 570 Bench Mark Quiz 1 55Document56 pages1 API 570 Bench Mark Quiz 1 55rodholfho100% (1)

- 177538089-API-570-Final-Exam-Questions - REALIZARDocument26 pages177538089-API-570-Final-Exam-Questions - REALIZARALe Infinito100% (1)

- 510 Closed Exam B, Rev8Document20 pages510 Closed Exam B, Rev8yrdna nawaiteosNo ratings yet

- API 510 - Book 6Document119 pagesAPI 510 - Book 6nathaniel ekaikoNo ratings yet

- SGMF Hose BunkeringDocument15 pagesSGMF Hose BunkeringFilipNo ratings yet

- Comprehensive Elevator ManualDocument23 pagesComprehensive Elevator ManualIlham fitriansyahNo ratings yet

- 31.3 Open QBDocument13 pages31.3 Open QBAnonymous Somc4sDNo ratings yet

- API 510 Final Model Exam-Open Book Page 1 of 6Document6 pagesAPI 510 Final Model Exam-Open Book Page 1 of 6jay2kay5793No ratings yet

- Final Exam (Open) : Weld Reinf. 1/8" THKDocument7 pagesFinal Exam (Open) : Weld Reinf. 1/8" THKNuwan RanaweeraNo ratings yet

- api 510 اسئلة متنوعة لكل الكورسDocument42 pagesapi 510 اسئلة متنوعة لكل الكورسhussam ghiathNo ratings yet

- Api 570 Final Practice ExamDocument23 pagesApi 570 Final Practice ExamCong BuiNo ratings yet

- FINAL EXAMINATION API 570 Open BookDocument3 pagesFINAL EXAMINATION API 570 Open BookdenarlijeronNo ratings yet

- WS-QS-FM-006 Record of Pre-Certification Experience R1Document1 pageWS-QS-FM-006 Record of Pre-Certification Experience R1JeganeswaranNo ratings yet

- Mild Steel Unequal Angle Bars (Metric Series) Size Thickness Unit Weight MM MM KG/MDocument1 pageMild Steel Unequal Angle Bars (Metric Series) Size Thickness Unit Weight MM MM KG/MJeganeswaranNo ratings yet

- 653 10-20-2020 CertDocument1 page653 10-20-2020 CertJeganeswaranNo ratings yet

- Revision of ISO 17025 (2017 Ed) PDFDocument22 pagesRevision of ISO 17025 (2017 Ed) PDFkingstonNo ratings yet

- 188ADocument2 pages188AJeganeswaranNo ratings yet

- WS-QS-FM-012 Application For Initial Examination LEVEL 3 Rev 2Document6 pagesWS-QS-FM-012 Application For Initial Examination LEVEL 3 Rev 2JeganeswaranNo ratings yet

- NDT AtoDocument24 pagesNDT AtoShabbir KhanNo ratings yet

- NDT Sa Ut 015 Rev 1Document22 pagesNDT Sa Ut 015 Rev 1Jeganeswaran100% (1)

- Asset Care Counts - 16 - November 2012Document2 pagesAsset Care Counts - 16 - November 2012koohestani_afshinNo ratings yet

- Application Form PDFDocument8 pagesApplication Form PDFJeganeswaranNo ratings yet

- Welding NotesDocument1 pageWelding NotesJeganeswaranNo ratings yet

- Seamless Pipe Certificate DOC171115Document2 pagesSeamless Pipe Certificate DOC171115JeganeswaranNo ratings yet

- Lem Tek 57Document71 pagesLem Tek 57MohdHuzairiRusliNo ratings yet

- MBBS/BDS Provisional Merit List 2016-2017Document846 pagesMBBS/BDS Provisional Merit List 2016-2017EswaranNo ratings yet

- Exam - TWI (India) - 2019 Candidate ScheduleDocument3 pagesExam - TWI (India) - 2019 Candidate ScheduleJeganeswaranNo ratings yet

- 2 Passport PhotoDocument1 page2 Passport PhotoJeganeswaranNo ratings yet

- EX07 Doc 2 (Rev.4) TWI Record of Vision TestsDocument1 pageEX07 Doc 2 (Rev.4) TWI Record of Vision TestsJeganeswaranNo ratings yet

- Senior Welding Application Form PDFDocument8 pagesSenior Welding Application Form PDFJeganeswaranNo ratings yet

- Carbon Hollow Bar ST 52Document2 pagesCarbon Hollow Bar ST 52JeganeswaranNo ratings yet

- ASTM G62 87 Reapproved 1998 PDFDocument5 pagesASTM G62 87 Reapproved 1998 PDFGuha ArnabNo ratings yet

- KrishnakumarDocument1 pageKrishnakumarJeganeswaranNo ratings yet

- Solex Adj ProcedureDocument6 pagesSolex Adj Procedureprivate 2No ratings yet

- SHD30 and SHD30-45 Models: (Standard)Document2 pagesSHD30 and SHD30-45 Models: (Standard)Roger TorrejonNo ratings yet

- CZ-RTC4 - Service ManualDocument68 pagesCZ-RTC4 - Service ManualAnonymous 31Airw50% (2)

- Pneumatic Slotting MachineDocument3 pagesPneumatic Slotting MachineSwami NathanNo ratings yet

- DensicatDocument8 pagesDensicatAdel SukerNo ratings yet

- Question Paper Code:: Reg. No.Document2 pagesQuestion Paper Code:: Reg. No.tamilarasi87thulasiNo ratings yet

- Kaplan Turbine Working As A Propeller CFD InvestigDocument11 pagesKaplan Turbine Working As A Propeller CFD InvestigclaudehackerNo ratings yet

- Medium Power Substation Instruction ManualDocument24 pagesMedium Power Substation Instruction ManualOmar GraterolNo ratings yet

- Indirect and Non-Calorimetric MethodsDocument44 pagesIndirect and Non-Calorimetric MethodsMadhuvanti GowriNo ratings yet

- IPM 200 Series: Internal Permanent Magnet MotorsDocument7 pagesIPM 200 Series: Internal Permanent Magnet MotorsLuu JosNo ratings yet

- 200VLD-H SS No EconomizerDocument2 pages200VLD-H SS No EconomizerAnas ElwakilNo ratings yet

- Makita 8271DWAE Bedienungsanleitung D328acDocument48 pagesMakita 8271DWAE Bedienungsanleitung D328acJonathan Giovanni Asti CastilloNo ratings yet

- Measuring Instrument Accuracy LimitsDocument2 pagesMeasuring Instrument Accuracy LimitsDan DanubiusNo ratings yet

- Overhead Phil MC KeownDocument30 pagesOverhead Phil MC KeownAditya AoleNo ratings yet

- Edited Economics AsDocument476 pagesEdited Economics AsShakeela ShanmuganathanNo ratings yet

- Deepwater Training Seminar Presented ToDocument36 pagesDeepwater Training Seminar Presented ToSergio Jesus MarquezNo ratings yet

- Understanding ThermodynamicsDocument4 pagesUnderstanding Thermodynamicscory kurdapyaNo ratings yet

- Graviner MK6 Oil Mist DetectorDocument4 pagesGraviner MK6 Oil Mist DetectorDhanielNo ratings yet

- U3 Oxidation and Reduction PPT WatermarkDocument45 pagesU3 Oxidation and Reduction PPT Watermarkapi-125934329No ratings yet

- Kiln Audit Heat Balance Tool - Data Entry Sheet 4 - CoolerDocument1 pageKiln Audit Heat Balance Tool - Data Entry Sheet 4 - CoolerMohamed SelimNo ratings yet

- Report 04.02.20Document4 pagesReport 04.02.20Kartik SoniNo ratings yet