Professional Documents

Culture Documents

General Workflow

Uploaded by

Emmanuel Cervantes VelázquezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Workflow

Uploaded by

Emmanuel Cervantes VelázquezCopyright:

Available Formats

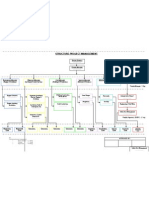

PROJECT PHASE

Project Definition, FEL1

100A Request for Proposal Lessons Learned

Conceptual Design, Schematic Design and FEL2

200-A Client to Identify Insurance Underwriter Client's Design Criteria, Standards and Preferences Client's Process Concepts/ Description/ Technology Client's existing system capacities and documentation Client's Record documentation (facilities, existing condition) Identify Applicable Codes Determine Seismic Design Criteria Room Descriptions and Requirements 200-B Site Plan Architectural Floor Plans Code Analysis 200-C Develop 20% PIDs and/or UFDs Equipment List Building and Process Control Requirements/Concepts 200-D Fire Alarm Concepts

Preliminary Design, Design Development, FEL3

300-A Code Analysis 300-B Develop Architectural Floor Plans Electrical Classification Drawing Identify Fluid Service Code Pipe/Valve Spec Index Update Site Plan Develop PIDs Update Equipment List Update Building and Process Control Requirements/Concepts Vendor Package Definition Develop Sequence of Operations Update Pipe Line List Develop Instrument List Data for Long Lead Instruments 300-C Update Fire Alarm Concepts 400-A

Final Design, Construction Documents, Detailed Design FEL4

400-A Final Code Analysis Finalize Instrument Data 400-B Finalize Site Plan Finalize Architectural Floor Plans Update PIDs

Construction, Start-Up, Post Pre-Turnaround, Turnaround Turnaround

600-A Receive Contractor/Field Markups

INPUTS

100-A Confirm Scope/ Schedule/Budget Prepare Scope of Work and Estimate 200-A Basis of Design Finalize Electrical load data

RFIs and Design Revisions

Review Submittals

Programming

Finalize Inputs/ Outputs List

Develop remaining Equipment, Data Sheets, Instrument Specifications Develop Long Lead Equipment, Data Sheets, Instrument and Materials

Construction Documents

Site Observations

Project Planning

Site Visits

WORKFLOW

200-B Preliminary Project Schedule Conceptual Studies/ Options

Basis of Design

Finalize Instrument Data

Equipment/Material Inspection at Vendor Shops

Bid Long Lead Equipment, Instruments and Materials

O&M Manuals

Pipe/Valve Specifications 400-B Software Test Plan and Procedures Develop Construction Cost Estimate

Develop Control System Architecture

Interdiscipline Coordination Check

Punch List

Instrument Cut Sheets

Pre-start-up Inspection

Constructability Review

Hardware Specification

Start-up and Commission Systems

Outline Long Lead Materials/Equipment/ Instrument Specifications

Configuration and Programming

Provide Training

Identify Materials of Construction 200-D

Initial Inputs/Outputs List Develop Construction Cost Estimate Constructability Review 300-B Design Studies Design Calculations Update Electrical Load Data

Software Implementation

Punch List

600-A

Approve Shop Drawings for Long Lead Equipment, Instruments and Materials

Record Drawings Instrument Wiring Diagrams and Loop Sheets Pneumatic Connection Diagrams Instrument Installation Details

200-C

Project Close-out

300-A

Identify Long Lead Materials/Equipment/ Instrument

Control System Hardware Selection Develop Control System Functional Spec Cable Schedule and Conduit Routing

Key Process Step External Input Review/Approval Cost Estimate Check Constructability Review

Control Panel Layouts Update Inputs/ Outputs List Panel Specifications

Instrument Location Drawings

Construction Specifications

Rev. 0, 27-Apr-2010 Instrument-Controls workflow 4-27-10.vsd

You might also like

- Engineering Work Flow ChartDocument1 pageEngineering Work Flow ChartSanjib Deka83% (6)

- FEED Deliverable List (Sample) - The Project Definition PDFDocument5 pagesFEED Deliverable List (Sample) - The Project Definition PDFPeter BridgeNo ratings yet

- Planningforengineering 12559824333307 Phpapp03Document12 pagesPlanningforengineering 12559824333307 Phpapp03Prashant AgrawalNo ratings yet

- Oil & Gas Project Phases Instrumentation Civil Electrical Mechanical ProcessDocument1 pageOil & Gas Project Phases Instrumentation Civil Electrical Mechanical ProcessfloredaNo ratings yet

- Requirements for FEED Study and PTE PreparationDocument3 pagesRequirements for FEED Study and PTE PreparationklmNo ratings yet

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisFrom EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisRating: 5 out of 5 stars5/5 (1)

- Planners and EPC ScopeDocument7 pagesPlanners and EPC ScopeRoshin99No ratings yet

- PIPING ENGINEERING MAN-HOUR ESTIMATEDocument14 pagesPIPING ENGINEERING MAN-HOUR ESTIMATEShabeer KiblaalamNo ratings yet

- Planners and EPC ScopeDocument4 pagesPlanners and EPC ScopeHamendra DeshveerNo ratings yet

- Developing Standard Logic For A Detailed Engineering Project Schedule in The Process IndustryDocument40 pagesDeveloping Standard Logic For A Detailed Engineering Project Schedule in The Process Industrysubir2160% (1)

- How To Estimate The Oil and Gas EPC Projects Duration by Herve BaronDocument2 pagesHow To Estimate The Oil and Gas EPC Projects Duration by Herve BaronAtifNo ratings yet

- Oil and gas engineering firm provides project management servicesDocument22 pagesOil and gas engineering firm provides project management serviceszhangj5100% (1)

- FEL DeliverablesDocument12 pagesFEL DeliverablesParvezNo ratings yet

- Urea EPC ScheduleDocument45 pagesUrea EPC Schedulevishal_madhukar100% (1)

- Typical Piping Project SequenceDocument13 pagesTypical Piping Project Sequencebusinessmannicholas100% (3)

- Oil& Gas Projects Guided TourDocument206 pagesOil& Gas Projects Guided TourZeeshan Ahuja100% (1)

- Engineering Work Package Rules of Credit PresentationDocument21 pagesEngineering Work Package Rules of Credit PresentationHansLopezNo ratings yet

- Feed Deliverable ListDocument8 pagesFeed Deliverable Listajuu100% (4)

- Eng. MGT Training From H.G. BaronDocument81 pagesEng. MGT Training From H.G. BaronMulhim Luthfi Riyadi100% (4)

- Deliverables Rule of ThumbDocument4 pagesDeliverables Rule of Thumbk13672100% (9)

- Estimating 100 Introduction To EstimatingDocument23 pagesEstimating 100 Introduction To EstimatingCarina Anselmo de Lima88% (8)

- Bases FEED EPC Parte 3viDocument229 pagesBases FEED EPC Parte 3viAbdelhamid LaroussiNo ratings yet

- Lire KZHXQ PDFDocument1 pageLire KZHXQ PDFأصلان أصلانNo ratings yet

- Engineering Project DeliverablesDocument18 pagesEngineering Project DeliverablesLeman IbishovaNo ratings yet

- Epc Project InterdepencyDocument101 pagesEpc Project InterdepencyKhaled Slevin100% (6)

- Project Management Man-Hour Cost Analysis: Case: Wärtsilä Energy SolutionsDocument32 pagesProject Management Man-Hour Cost Analysis: Case: Wärtsilä Energy SolutionsAziz EL100% (1)

- Project Structure Management ChartDocument1 pageProject Structure Management ChartArif Rachman100% (3)

- 0.a. Schedule Review, Rev1Document10 pages0.a. Schedule Review, Rev1sayafrands6252No ratings yet

- Workflow EngineeringDocument12 pagesWorkflow EngineeringbayuNo ratings yet

- Planning SchedulingDocument60 pagesPlanning SchedulingHarish GundaNo ratings yet

- Cost EstimateDocument107 pagesCost EstimateMahdi Daly0% (1)

- Engineering Deliverables for Chemical ProjectsDocument6 pagesEngineering Deliverables for Chemical Projectskamala 123100% (1)

- Systems Completion - Area Plan: Banyu Urip ProjectDocument13 pagesSystems Completion - Area Plan: Banyu Urip Projectsayafrands6252No ratings yet

- How To Develop A Wbs Apostolopoulosv2Document20 pagesHow To Develop A Wbs Apostolopoulosv2api-196007591100% (1)

- Project Control Guidelines PCDDocument12 pagesProject Control Guidelines PCDRic S. Malonga100% (1)

- Engineering Design QA: Holistic Workflow PhilosophyDocument11 pagesEngineering Design QA: Holistic Workflow PhilosophyMuhammad SaadullahNo ratings yet

- Oilgasengineering 131129020341 Phpapp02Document231 pagesOilgasengineering 131129020341 Phpapp02sj_scribd100% (5)

- Cost Control Budget DOP3000-PRC-007!0!03Document6 pagesCost Control Budget DOP3000-PRC-007!0!03kamlNo ratings yet

- Project Duration LawsDocument39 pagesProject Duration LawsOmerNo ratings yet

- EPC Projects BasicsDocument2 pagesEPC Projects Basicsmahmood75080% (5)

- Planning and Scheduling During Detailed EngineeringDocument34 pagesPlanning and Scheduling During Detailed EngineeringHedi Zarkouna91% (22)

- Project Execution ModelDocument99 pagesProject Execution ModelEdha Ali100% (3)

- FEED Process & Deliverables PDFDocument2 pagesFEED Process & Deliverables PDFhussnainreflect100% (3)

- How To Easily Estimate The Duration of An Oil & Gas EPC ProjectDocument2 pagesHow To Easily Estimate The Duration of An Oil & Gas EPC ProjectdhaferjabNo ratings yet

- Typical Piping Project SequenceDocument13 pagesTypical Piping Project SequenceZoebairNo ratings yet

- Deliverables List - EngineeringchecksDocument3 pagesDeliverables List - EngineeringchecksKarthik NagendraNo ratings yet

- Front End Engineering Design (FEED) ScheduleDocument1 pageFront End Engineering Design (FEED) ScheduleVinh Do Thanh100% (1)

- Detailed Engineering Design PhaseDocument8 pagesDetailed Engineering Design Phaserenjithv_494% (18)

- Even More Schedule for Sale: Advanced Work Packaging, for Construction ProjectsFrom EverandEven More Schedule for Sale: Advanced Work Packaging, for Construction ProjectsNo ratings yet

- Integrated Project Planning and Construction Based on ResultsFrom EverandIntegrated Project Planning and Construction Based on ResultsNo ratings yet

- Cost Estimating Manual for Pipelines and Marine Structures: New Printing 1999From EverandCost Estimating Manual for Pipelines and Marine Structures: New Printing 1999Rating: 5 out of 5 stars5/5 (2)

- Sibp Gep Design PlanningDocument8 pagesSibp Gep Design PlanningEnrique PomalesNo ratings yet

- Engineering PipingDocument18 pagesEngineering Pipingjmclaug502100% (3)

- Basis Estimate TemplateDocument2 pagesBasis Estimate TemplateEmmanuel Cervantes VelázquezNo ratings yet

- Project phases and deliverablesDocument1 pageProject phases and deliverablesEmmanuel Cervantes VelázquezNo ratings yet

- ANEXOS TÉCNICOS DE LAS BASES DE LICITACIÓNDocument23 pagesANEXOS TÉCNICOS DE LAS BASES DE LICITACIÓNEmmanuel Cervantes VelázquezNo ratings yet

- Ansi Isa-95.00.01-2000Document142 pagesAnsi Isa-95.00.01-2000Alexander Dueñas Salazar100% (9)

- Engineering Drawing Symbols v2Document98 pagesEngineering Drawing Symbols v2shaikh_nazarNo ratings yet

- Case Study Plant Layout 1Document22 pagesCase Study Plant Layout 1Gaurav ModiNo ratings yet

- Conceptual Plant LayoutDocument6 pagesConceptual Plant LayoutEmmanuel Cervantes VelázquezNo ratings yet

- Integrated Manufacturing SolutionsDocument15 pagesIntegrated Manufacturing SolutionsEmmanuel Cervantes VelázquezNo ratings yet

- Diplomado en Desarrollo de Proyectos de Ingenier+¡a IVDocument15 pagesDiplomado en Desarrollo de Proyectos de Ingenier+¡a IVEmmanuel Cervantes VelázquezNo ratings yet

- S 990001 Part 1 DraftDocument97 pagesS 990001 Part 1 DraftandhrimnirNo ratings yet

- Ansi Isa-95.00.01-2000Document142 pagesAnsi Isa-95.00.01-2000Alexander Dueñas Salazar100% (9)

- Symbolece PDFDocument12 pagesSymbolece PDFEmmanuel Del RosarioNo ratings yet

- Enterprise Control System Integration Part 3: Activity Models of Manufacturing Operations ManagementDocument104 pagesEnterprise Control System Integration Part 3: Activity Models of Manufacturing Operations ManagementJeff HekmatiNo ratings yet

- Isa 95.00.02-2001Document104 pagesIsa 95.00.02-2001Alexander Dueñas Salazar100% (4)

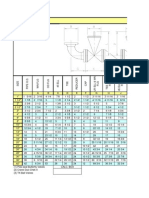

- Flanged and dished head dimensionsDocument10 pagesFlanged and dished head dimensionssnehal.deshmukhNo ratings yet

- ANEXOS TÉCNICOS DE LAS BASES DE LICITACIÓNDocument23 pagesANEXOS TÉCNICOS DE LAS BASES DE LICITACIÓNEmmanuel Cervantes VelázquezNo ratings yet

- Solid Works Model For The Pressure vessel-IIDocument1 pageSolid Works Model For The Pressure vessel-IIkarthikeashwarNo ratings yet

- Sample 5 B&WDocument1 pageSample 5 B&WEmmanuel Cervantes VelázquezNo ratings yet

- Anexo 2 Ejemplo Relación InterdisciplinariaDocument1 pageAnexo 2 Ejemplo Relación InterdisciplinariaEmmanuel Cervantes VelázquezNo ratings yet

- Anexo 1 - Atividades Disciplinas Basicas 1Document9 pagesAnexo 1 - Atividades Disciplinas Basicas 1Emmanuel Cervantes VelázquezNo ratings yet

- Sample 3 Color Page1Document1 pageSample 3 Color Page1Emmanuel Cervantes VelázquezNo ratings yet

- Steel Pipe VesselDocument279 pagesSteel Pipe VesselAhmadreza AminianNo ratings yet

- Universal Nozzle Calculator Ver 3 0Document10 pagesUniversal Nozzle Calculator Ver 3 0madodandembeNo ratings yet

- P&ID LegendDocument29 pagesP&ID LegendEmmanuel Cervantes VelázquezNo ratings yet

- Detailed Engineering Design PhaseDocument8 pagesDetailed Engineering Design Phaserenjithv_494% (18)

- Solid Works Model For The Pressure VesselDocument16 pagesSolid Works Model For The Pressure VesselkarthikeashwarNo ratings yet

- Sample 4 ColorDocument1 pageSample 4 ColorEmmanuel Cervantes VelázquezNo ratings yet

- ASME VIII-1 pressure vessel design code and operating conditionsDocument1 pageASME VIII-1 pressure vessel design code and operating conditionsNomi KhanNo ratings yet

- Content 24Document13 pagesContent 24Sutthiroj PeeraNo ratings yet

- Sample 5 CalcsDocument24 pagesSample 5 CalcsEmmanuel Cervantes Velázquez100% (2)