Professional Documents

Culture Documents

Trainer Instructions - Boilers and Thermic Fluid Heaters

Uploaded by

pradeep4545Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trainer Instructions - Boilers and Thermic Fluid Heaters

Uploaded by

pradeep4545Copyright:

Available Formats

Trainer Instructions: Boilers and Thermic Fluid Heaters

From: Energizing Cleaner Production a Guide for Trainers, UNEP/InWEnt, 2007 Title Objective Minimum duration and approach BOILERS AND THERMIC FLUID HEATERS To obtain an understanding of boilers and thermic fluid heaters, including types of boilers, how to assess their performance and the main areas for energy conservation. � � 1.5 sessions (2 hours), including the quiz and workshop exercise Recommended approach: spend 1 session (1.5 hours) on the PowerPoint presentation. It is unlikely that much time is left at the end of this session, therefore it is recommended to go through the quiz as a group (10 minutes). Participants should spend 30 minutes on completing the workshop exercise and it takes about 15 minutes to go through the solution. In the agenda the workshop exercise for fuels and combustion is placed in the same session as the boilers workshop exercise. Presentation: 54 slides Textbook chapter: 42 pages Introduction Types of boilers Assessment of boiler Energy efficiency opportunities Pose questions during the presentation. Some suggested questions are included in the trainer notes underneath each slide, for example What type of boilers do you know should be asked before the types of boilers are explained. Take the quiz with 10 multiple choice questions. Carry out the workshop exercise. Participants can be asked the following: A company is considering replacing an oil-fired boiler of 10 tons per hour with a coal-fired boiler of the same capacity. With the help of the data provided, calculate the following: 1. Annual oil consumption in tons per year 2. Annual coal consumption in tons per year 3. Annual fuel cost savings in million US$ The following data is given: - Heat content of steam 660 kCal/kg - Feed water inlet temperature 600 oC - Daily operating hours 24 - Number of days / year 300 - Efficiency of oil-fired boiler 82%

Energizing Cleaner Production Trainer Instructions

� � Contents � � � � � � �

Assessment of participants

Efficiency of coal-fired boiler 72% Cost of oil US$ 300/ton Cost of coal US$ 45/ton GCV of oil 10,000 kCal/kg GCV of coal 4,200 kCal/kg

If participants have difficulties completing the exercise, it may be helpful to give them the four calculations they should make to determine the annual oil and coal consumption: a. Boiler operation hours b. Annual steam production c. Energy (Q) required to produce the amount of steam calculated under (b) d. Amount of coal or oil required by multiplying the energy Q by the GCV of coal or oil Participants should not have difficulties to calculate the annual fuel cost savings so there is no need to give them formulae for question 3. Other comments � � Case study options from www.energyefficiencyasia.org or other sources can be included in this session as illustrations of how other companies reduce energy consumption and costs. If the workshop exercise for fuel and combustion is not combined with the boiler workshop exercise, then there will be time left at the end of the second session. There are several possibilities to use the remaining time: - Explain the monitoring instruments that typically are used in determining boiler performance: combustion analyzer, thermocouple and infrared thermometer. See the session Monitoring Equipment for more details. This option may be particularly useful if the course does not include a specific session on monitoring equipment. - Explain cogeneration under Energy Efficiency Opportunities during the boiler session, as cogeneration is based on combined heat (steam) and power generation. This is especially useful if the course does not include the cogeneration session. See the session on Cogeneration for more details.

Energizing Cleaner Production Trainer Instructions

You might also like

- Energy Efficient Opearation of BoilersDocument44 pagesEnergy Efficient Opearation of BoilersBorivoj Stepanov100% (1)

- Boiler EfficiencyDocument28 pagesBoiler Efficiencybzkizo_sbbNo ratings yet

- 4.1 BoilerDocument28 pages4.1 Boilerrashm006ranjanNo ratings yet

- SQ - 4.1 - Boiler (Table Format)Document11 pagesSQ - 4.1 - Boiler (Table Format)Gajanan JagtapNo ratings yet

- Redesigning Boilers Solves Problems and Saves MoneyDocument9 pagesRedesigning Boilers Solves Problems and Saves MoneyfelramNo ratings yet

- Boiler PerformanceDocument53 pagesBoiler PerformanceHariri Dwi KusumaNo ratings yet

- Coal-Fired Power Plant Heat Rate Improvement Options, Part 2 - PowermagDocument11 pagesCoal-Fired Power Plant Heat Rate Improvement Options, Part 2 - PowermagRavi SatyapalNo ratings yet

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- A Paper4 QueDocument4 pagesA Paper4 Quezoom20No ratings yet

- Energy Performance Assessment of BoilersDocument5 pagesEnergy Performance Assessment of BoilersUsama SufyanNo ratings yet

- Improving Steam Boiler EfficiencyDocument229 pagesImproving Steam Boiler EfficiencyMuhammad Junaid90% (10)

- SME Case Study-Steel Re-Rolling MillDocument4 pagesSME Case Study-Steel Re-Rolling MillVijay RathiNo ratings yet

- GT5D-AbuDhabiDocument3 pagesGT5D-AbuDhabifred681100% (1)

- Thermal Systems and Energy Efficiency GuideDocument17 pagesThermal Systems and Energy Efficiency Guideasura22nov100% (1)

- ModernmethodDocument9 pagesModernmethodSIL PROJECTSNo ratings yet

- Condensing Boiler Technology Module IVDocument62 pagesCondensing Boiler Technology Module IVMadanKarkiNo ratings yet

- ME 525 April 17, 2020 Internal Combustion Engine Performance Problems Set 1 InstructionsDocument2 pagesME 525 April 17, 2020 Internal Combustion Engine Performance Problems Set 1 Instructionssixela arugalNo ratings yet

- Engineering Encyclopedia: Boilers and Furnaces Performance and EfficiencyDocument39 pagesEngineering Encyclopedia: Boilers and Furnaces Performance and Efficiencytasnim100% (1)

- Proj Yashvardan CescDocument44 pagesProj Yashvardan CescRahul RoyNo ratings yet

- I1 Boiler Selection 10 20Document11 pagesI1 Boiler Selection 10 20balaibesartekstilNo ratings yet

- 03-03-2020-1583242499-6-IJME-4. IJME - Efficiency Improvement of Boiler Through Design Optimization at Kuwait Oil and Gas Companies - ReviewedDocument14 pages03-03-2020-1583242499-6-IJME-4. IJME - Efficiency Improvement of Boiler Through Design Optimization at Kuwait Oil and Gas Companies - Reviewediaset123No ratings yet

- Energy Savings Calculator For Boiler Replacement ProjectsDocument14 pagesEnergy Savings Calculator For Boiler Replacement ProjectsPower MuruganNo ratings yet

- Boiler Learning ModuleDocument158 pagesBoiler Learning ModuleMallinatha PNNo ratings yet

- Lecture 4 Combustion Engines and Efficiencies Part 2Document21 pagesLecture 4 Combustion Engines and Efficiencies Part 2kudra emmanuelNo ratings yet

- Projects: Term ProjectDocument2 pagesProjects: Term ProjectCoursePinNo ratings yet

- Research Paper Ic EngineDocument4 pagesResearch Paper Ic Enginecakwn75t100% (1)

- No - Ntnu Inspera 2486629Document138 pagesNo - Ntnu Inspera 2486629Keila ChavesNo ratings yet

- Modern Method to Determine Recovery Boiler EfficiencyDocument8 pagesModern Method to Determine Recovery Boiler EfficiencyJéssica Bonow HinterholzNo ratings yet

- Boilers Performance Evaluation of Zuara Desalination PlantDocument7 pagesBoilers Performance Evaluation of Zuara Desalination PlantHassan M. OsmanNo ratings yet

- Steam15 BenchmarkDocument2 pagesSteam15 BenchmarkGustavo Garces GuerreroNo ratings yet

- Energy Efficiency Assessment BookDocument170 pagesEnergy Efficiency Assessment BookNoel Dunn100% (4)

- ASME - PTC4.1 .Boiler Efficiency TestDocument29 pagesASME - PTC4.1 .Boiler Efficiency TestBC Harish92% (13)

- EconomizerDocument7 pagesEconomizernsralmasiNo ratings yet

- Foundrybench D19 Good Practice GuideDocument196 pagesFoundrybench D19 Good Practice GuideGangadharKasinathSastryNo ratings yet

- Energy Savings Calculator For Boiler ReplacementsDocument14 pagesEnergy Savings Calculator For Boiler ReplacementsSanjeev KachharaNo ratings yet

- Boiler Efficiency and CombustionDocument12 pagesBoiler Efficiency and Combustionhafidhrahadiyan2No ratings yet

- Plate CombustionDocument20 pagesPlate CombustionKim Howard Castillo100% (1)

- Studi Unjuk Kerja Boiler Kapasitas 18 Ton/Jam Di Lingkungan Pabrik Kelapa SawitDocument8 pagesStudi Unjuk Kerja Boiler Kapasitas 18 Ton/Jam Di Lingkungan Pabrik Kelapa SawitAlde AndroNo ratings yet

- M06-022 - Improving Energy Efficiency of Boiler Systems - USDocument71 pagesM06-022 - Improving Energy Efficiency of Boiler Systems - USbjuanlunabNo ratings yet

- Boilers HeatersDocument24 pagesBoilers HeatersPato FuentesNo ratings yet

- Petroleum Processing Course CatalogDocument23 pagesPetroleum Processing Course CatalogPandhu100% (1)

- Modeling and Energy Analysis of A Diesel and Biodiesel Fuelled EngineDocument5 pagesModeling and Energy Analysis of A Diesel and Biodiesel Fuelled EngineMikael Bezerra Cotias Dos SantosNo ratings yet

- Performance Analysi S of BTPS (NTPC) Thermal Power PlantDocument7 pagesPerformance Analysi S of BTPS (NTPC) Thermal Power PlantInnovative Research PublicationsNo ratings yet

- Effective Energy Management For Boilers and Fired SystemsDocument22 pagesEffective Energy Management For Boilers and Fired SystemsSuleman Tariq67% (3)

- TE - Turbomachinery - IA 1 Syllabus and Question Bank - 09 - 02 - 2023Document2 pagesTE - Turbomachinery - IA 1 Syllabus and Question Bank - 09 - 02 - 2023todankarpratham15No ratings yet

- Paper 4A SolutionDocument10 pagesPaper 4A SolutionSHAMSIK2002No ratings yet

- EE3T3Document2 pagesEE3T3Murthy MandalikaNo ratings yet

- 2011 - Fuel Quality Guide-Ignition and CombustionDocument27 pages2011 - Fuel Quality Guide-Ignition and CombustionaleventNo ratings yet

- Energy-Efficient Boilers & Burners: SeriesDocument4 pagesEnergy-Efficient Boilers & Burners: SeriesblindjaxxNo ratings yet

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewFrom EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewNo ratings yet

- Energy and Process Optimization for the Process IndustriesFrom EverandEnergy and Process Optimization for the Process IndustriesNo ratings yet

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)

- Steam Generation from Biomass: Construction and Design of Large BoilersFrom EverandSteam Generation from Biomass: Construction and Design of Large BoilersRating: 4.5 out of 5 stars4.5/5 (8)

- Underground Gas Storage Facilities: Design and ImplementationFrom EverandUnderground Gas Storage Facilities: Design and ImplementationNo ratings yet

- Industrial and Process Furnaces: Principles, Design and OperationFrom EverandIndustrial and Process Furnaces: Principles, Design and OperationNo ratings yet

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- Process Plant Design: Heinemann Chemical Engineering SeriesFrom EverandProcess Plant Design: Heinemann Chemical Engineering SeriesRating: 3.5 out of 5 stars3.5/5 (11)

- Using Welding Inspection ToolsDocument9 pagesUsing Welding Inspection Toolspradeep4545No ratings yet

- Sump Drawing PDFDocument1 pageSump Drawing PDFpradeep4545No ratings yet

- Insurance BillDocument13 pagesInsurance BillSureshKarnanNo ratings yet

- Pressure VesselDocument32 pagesPressure VesselYonjon SubhaNo ratings yet

- Draw Off Sump PDFDocument2 pagesDraw Off Sump PDFpradeep4545No ratings yet

- Trunnion CalculationDocument3 pagesTrunnion Calculationpradeep4545No ratings yet

- Welder QualificationDocument57 pagesWelder QualificationPravin KhilariNo ratings yet

- UT Level III exam questions on NDT techniquesDocument2 pagesUT Level III exam questions on NDT techniquespradeep4545No ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- 2D Pdf-Ribbon Type Helical Blade.27-04Document1 page2D Pdf-Ribbon Type Helical Blade.27-04pradeep4545No ratings yet

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 pagesWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- Shortcut KeysDocument3 pagesShortcut KeysPreetham PjNo ratings yet

- Welder QualificationDocument57 pagesWelder QualificationPravin KhilariNo ratings yet

- Thakore, Shuchen B. Bhatt, B. I. Introduction To Process Engineering and Design PDFDocument760 pagesThakore, Shuchen B. Bhatt, B. I. Introduction To Process Engineering and Design PDFyaya toure67% (3)

- Barde Roadlines 27.02.2019Document2 pagesBarde Roadlines 27.02.2019pradeep4545No ratings yet

- Draw Off Sump PDFDocument2 pagesDraw Off Sump PDFpradeep4545No ratings yet

- PF Resin PDFDocument40 pagesPF Resin PDFpradeep4545No ratings yet

- Stresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle Supports - Zick (1951) OriginalDocument11 pagesStresses in Large Horizontal Cylindrical Pressure Vessels On Two Saddle Supports - Zick (1951) OriginalBryan Pérez PérezNo ratings yet

- Training ContentsDocument1 pageTraining Contentspradeep4545No ratings yet

- PF Resin PDFDocument40 pagesPF Resin PDFpradeep4545No ratings yet

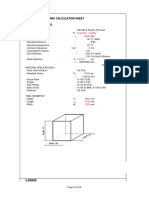

- Rectangular TankDocument5 pagesRectangular Tankpradeep4545No ratings yet

- Process parameters and dimensions required for valve selectionDocument2 pagesProcess parameters and dimensions required for valve selectionpradeep4545No ratings yet

- Cage - Venturi AssemblyDocument1 pageCage - Venturi Assemblypradeep4545No ratings yet

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Fans & Blowers-Calculation of PowerDocument20 pagesFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- CycloneDocument10 pagesCyclonepradeep4545No ratings yet

- SS 316L Corrosion Resistant Stainless Steel Technical Data SheetDocument2 pagesSS 316L Corrosion Resistant Stainless Steel Technical Data Sheetpradeep4545No ratings yet

- Electrician Training - Troubleshooting and Fault FindingDocument11 pagesElectrician Training - Troubleshooting and Fault FindingOgunjimi Taofiki AdebisiNo ratings yet

- Curved Data KEW PUMP KSSE 3 1Document1 pageCurved Data KEW PUMP KSSE 3 1Haryono SyalimNo ratings yet

- Glowing TreesDocument2 pagesGlowing TreesJonathan SwiftNo ratings yet

- HVTS-70/50: Portable High-Voltage Test SystemDocument2 pagesHVTS-70/50: Portable High-Voltage Test SystemvhendrayawanNo ratings yet

- CFX Intro 12.0 WS5 Centrifugal PumpDocument23 pagesCFX Intro 12.0 WS5 Centrifugal PumpfunkystealthpigNo ratings yet

- PV connector technical specifications from JinkoSolarDocument1 pagePV connector technical specifications from JinkoSolarqiTNo ratings yet

- Generate Electricity From Park Revolving DoorDocument39 pagesGenerate Electricity From Park Revolving Doortariq7660% (5)

- O Level Physics 2018 Past PaperDocument20 pagesO Level Physics 2018 Past PaperfordalNo ratings yet

- WARNING SIGNS OF KICKSDocument45 pagesWARNING SIGNS OF KICKSMartin RiwuNo ratings yet

- Rod BaffelsDocument2 pagesRod BaffelsVenkatesh SivarchanaNo ratings yet

- Vietnamese Olympiad English exam passageDocument6 pagesVietnamese Olympiad English exam passageLê Thanh ThảoNo ratings yet

- Hydraulic Turbines: Turbines and That Con Vert Mechanical Energy IntoDocument22 pagesHydraulic Turbines: Turbines and That Con Vert Mechanical Energy IntosaitejaNo ratings yet

- PAUT Course Material PDFDocument189 pagesPAUT Course Material PDFYassine Koot100% (3)

- ATSDocument8 pagesATSserban_elNo ratings yet

- Huawei PI OverviewDocument15 pagesHuawei PI OverviewHdz EdilNo ratings yet

- AERMOTORDocument12 pagesAERMOTORSharid PickeringNo ratings yet

- Background Study: SCBA) Shown in Figure 2Document11 pagesBackground Study: SCBA) Shown in Figure 2Miza AneesaNo ratings yet

- Ogjournal20150706 DLDocument136 pagesOgjournal20150706 DLrasyid93No ratings yet

- LM 3900Document16 pagesLM 3900Fredy CasillaNo ratings yet

- Marine Propulsion Engines GuideDocument20 pagesMarine Propulsion Engines GuideyoungfpNo ratings yet

- Hydrostatic Testing Procedure 02250-1Document2 pagesHydrostatic Testing Procedure 02250-1RanielNo ratings yet

- 29B - Acid Gas Removal TechnologyDocument17 pages29B - Acid Gas Removal Technologyarlucky5459100% (1)

- Water Supply Sanitary Eng PDFDocument5 pagesWater Supply Sanitary Eng PDFReddy NaveenNo ratings yet

- Preparation Before Storage of Aviation BatteriesDocument1 pagePreparation Before Storage of Aviation BatteriesRaymond ZamoraNo ratings yet

- HAZID Workshop PDFDocument45 pagesHAZID Workshop PDFNora Afzam Abd Wahab100% (1)

- WP 3325 B 3 - 5 Basbooster Incl. N - Pack: Technical DataDocument2 pagesWP 3325 B 3 - 5 Basbooster Incl. N - Pack: Technical DataMarcos AssialdiNo ratings yet

- Diagrama Electr 325c ExcavaDocument2 pagesDiagrama Electr 325c ExcavaTecnicos-mexicanos Soto100% (3)

- Sliit L Epdc 15Document108 pagesSliit L Epdc 15sulochana priyashanNo ratings yet

- PH1031 Wednesday Batch July-Dec 2016Document2 pagesPH1031 Wednesday Batch July-Dec 2016devajithNo ratings yet

- Chapter 3 - Work Energy and PowerDocument22 pagesChapter 3 - Work Energy and PowerKenny Jay LabianoNo ratings yet