Professional Documents

Culture Documents

Comparative Measurements of Structure and Crack Motion During Blasting and Other Environmental Forces

Uploaded by

Henry AngelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparative Measurements of Structure and Crack Motion During Blasting and Other Environmental Forces

Uploaded by

Henry AngelCopyright:

Available Formats

Vibrations from Blasting Spathis & Noy (eds) 2010 Taylor & Francis Group, London, ISBN 978-0-415-48295-0

Comparative measurements of structure and crack motions during blasting and other environmental forces

C.T. Aimone-Martin & V.L. Rosenhaim

Aimone-Martin Associates, LLC, Socorro, New Mexico, USA

ABSTRACT: This paper summarizes findings of three case studies in which residential structures near blasting operations were instrumented to compare blast-induced motions with other dynamic and static influences more likely to cause cracking in walls. Ground vibrations at structures fell within the U.S. Bureau of Mines safe blasting criteria. Velocity transducers placed within structures to measure whole structure and midwall motions and displacement gages mounted across existing wall cracks to measure changes in crack width have been used. The crack gage is an ideal measurement tool to compare the influence of blasting on structure walls with other dynamic and static forces. Normal and expected non-blasting forces that daily occur in structures created deflections in crack widths that were far greater in amplitude than those created during blasting within safe criteria. The findings of these studies show conclusively that structure cracking is related to cyclical environmental influences of temperature and humidity changes, wind loading, every-day human activities around the house, and changes in soil moisture near structure foundations. These influences create induced wall deflections that can promote cracking in homes because they are far greater in magnitude than those induced by blasting vibrations. Weather- and human-induced cracking is normal and expected in all structures whereas carefully controlled blasting cannot possibly crack structures.

MEASURING STRUCTURE MOTIONS

Direct measurements of structure motions in response to blasting and other normal and expected environmental and human-induced influences have been made. Recent studies include instrumentation of one- and two-story residential structures of various construction types and ages near coal mine, quarry, and construction blasting operations. The purpose of these studies was to compare structure wall motions resulting from ground vibrations in compliance with safe blasting criteria with motions occurring in structures everyday. These criteria are used in the U.S. to protect structures from cracking. Velocity transducers located in corners recorded whole-structure or racking motions used to compute in-plane tensile strains. Transducers mounted on adjacent mid-walls measured out-of-plane displacements to estimate bending strains. Strains produced by ground vibrations were compared with wall strains from wind loading and normal, every-day human activities in structures. Displacement gages were used to measure the dynamic and static movements of an existing wall crack. Eddy-current gages mounted across a candidate crack and a section of un-cracked wall measured the changes in crack width during blasting, human activities, and during storms producing wind. Crack width changes were also measured during slow,

24-hour wall response to ambient environmental changes (temperature and humidity) and long-term foundation movements from soil moisture changes. Dynamic characteristics of 65 structures have been determined to date. Studies involving these structures were part of long-term community relations programs demonstrating safe blasting cannot contribute to structure cracking relative to other normal, everyday forces producing wall deflections larger than those produced by blasting. 1.1 Background

The U.S. Bureau of Mines and others conducted studies to document ground vibrations and structure motions causing cracking in wall materials such as plaster, drywall, and mortar. The threshold to damage in plaster for construction blasting was found by Langefors et al. (1958) to be 109 mm/s. Edwards & Northwood (1960) established a damage threshold between 102 and 127 mm/s for cracking in mortar and plaster in six structures near construction blasting. Wiss & Nicholls (1974) conducted blasts in glacial till near a single home and established ground velocities required to cause wall cracking in excess of 178 mm/s for gypsum wallboard. U.S. Bureau of Mines research resulted in no new cracks in drywall when ground vibrations were as high as 254 mm/s (Siskind et al. 1980) and 178 mm/s (Stagg et al. 1984).

97

The structure in the 1984 study, focusing on repeated effects of blasting on a single structure, was mechanically shaken at equivalent ground vibrations between 12.7 and 25.4 mm/s until the first new drywall crack was observed. Using a number of equivalent mechanical cycles simulating a blast to represent 400 annual blasts, the required time to cause the new drywall crack was 180 years. These studies have, in part, provided a scientific basis for safe blasting criteria shown in Figure 1 and widely used in the U.S. to protect structures from threshold cracking in the weakest wall materials. The frequency-based peak particle velocity (PPV) criteria provides 100% confidence that interior drywall will not crack when ground vibrations fall below this upper solid black line. Human perception studies of structure motions from blasting simulated by mechanical shaking indicate inhabitants can detect PPV as low as 0.254 mm/s while many become annoyed when PPV levels reach 9 mm/s (Wiss & Parmelee 1974). The fear of structure damage at very low levels of perceptible vibrations, well below safe limits, often results in blast-related damage complaints. Past crack observation studies have provided a scientific basis for ground vibration limits that protect structures from damage. For the large part, these studies involve houses scheduled or built specifically for demolition. Such studies are rare today. Community claims of blasting damage provide an opportunity to work with complainants to gather scientific evidence that blasting within safe criteria does not damage structures. It further allows the opportunity to measure and compare other environmental factors more likely to cause cracking in structures.

1.2

Comparative studies

The intentional cracking of structure walls from blasting is not always practical. However, direct measurements of crack width displacements across existing cracks in walls provide a means of comparing the relative influences of blasting and other normal and expected forces on in-plane wall strains. This paper describes instruments used to measure whole structure and crack displacements. Three case studies are presented.

STRUCTURE INSTRUMENTATION

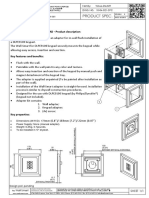

Figure 2 shows typical instrumentation locations in the upper and lower corners and in the middle of adjacent walls (mid-wall) in a structure room. Corner transducers measured whole structure motions in two horizontal directions aligned with walls and used to calculate in-plane tensile strains. The mid-wall transducers measured horizontal motions during wall flexure and used to calculate bending strains. LARCOR multi-component seismographs were used to digitally record four channels of seismic data. The exterior (master) unit consisted of a tri-axial geophone and an air pressure microphone. The geophone,

Upper corner

Midwall

Midwall

Lower corner

1000 U.S.Bureau of Mines safe vibration criteria Office of Surface Mines regulations PEAK PARTICLE VELOCITY (mm/s)

100

(a)

10

0.1 1 10

PEAK FREQUENCY (Hz)

100

(b)

(c)

Figure 1. U.S. Bureau of Mines safe blasting criteria including the Office of Surface Mining modification for surface coal mine blasting.

Figure 2. Velocity transducers mounted at corners and midwalls (a) and crack displacement gages (b), (c) mounted over existing cracks and on un-cracked wall material (c, lower left).

98

buried 150 mm in depth, was oriented so that the radial, R, and transverse, T, components were parallel with structure walls. This orientation is based upon recording motions parallel with one of the houses translation axes rather than the traditional direction relative to the vibration source. The air pressure microphone was installed 250 mm above the ground surface to record pressure pulses transmitted to the structure walls. To measure the effects of blasting and climate conditions (temperature and humidity) on changes in the width of an existing crack, Kaman eddy-current gages were typically installed as shown in Figure 2 and data collected using a field computer. Each Kaman gage, with a resolution of 0.1 m, consisted of mounting brackets placed on either side of the crack, of which one served as a target, and the other as an active element. Crack width displacements were isolated by computing the time-correlated difference between gages measurements affixed to the wall across the existing crack (crack gage) and on the uncracked surface (null gage). Seismographs and the crack displacement gage computer were connected in series, with the exterior master seismograph acting as the triggering unit and all other seismographs as slave units. The Kaman gage system was programmed to sample crack opening and closing every hour in response to diurnal environmental changes. When the master seismograph triggered, the displacement gage computer converted to burst mode and all units recorded data every 0.001 s. Temperature and relative humidity were recorded using a SUPCO data logger. A sample interval of 10 minutes was used.

where is the interior angle of the longest diagonal of the wall subjected to strain with reference to the wall horizontal dimension. Theta, , is calculated by taking the inverse tangent of the ratio of wall height to wall length. Out-of-plane wall bending strains were computed assuming the wall is a beam fixed at both corners (foundation and roof). It has been determined that the foundations are well coupled to the ground, or fixed. However, the roof can be modeled with varying degrees of fixity, ranging from relatively unconstrained to highly fixed. Bending strain is most conservatively estimated with the fixed-fixed analogy because this model predicts the highest strains in walls per unit of maximum relative displacement. These out-of-plane bending strains can be calculated as: 6d max L = L2 (3)

where L = bending strain in walls (microstrain) d = the distance from the neutral axis to the wall surface, or one half the thickness of the wall subjected to strain (mm). In general, bending strains are insignificant relative to in-plane tensile strains and most often contribute to interior structure noise from rattling of mid-walls.

CASE STUDIES

STRUCTURE WALL STRAINS

Structure wall corner velocity time histories were integrated to obtain displacements and the largest time correlated difference, max, between corner responses (upper minus lower) was found. Global shear strain was then determined by the following: max = max L (1)

Three case studies are presented to illustrate the range of measurements recorded for various structures in the vicinity of blasting operations. The emphasis of these studies is the responses of the existing wall cracks to blasting and other environmental forces present everyday in structures. 4.1 Case 1: Construction blasting

where max = global shear strain (microstrain) max = maximum differential displacement (mm) L = height of the wall subjected to strain (mm) In-plane tensile strains, important in the assessment of wall cracking potential, are a function of the wall dimensions. The maximum tensile strain, Lmax, was calculated from global shear strain by the equation:

L max = max ( sin )( cos )

(2)

The site is located southwest of Las Vegas, NV where construction blasting for housing development took place several times a day in mountain foothills. The local blasting ordinance limited ground vibrations to 12.7 mm/s. Figure 3 shows a plan view of blasting areas surrounding Case 1 structure in which instruments were placed. Measurements were recorded for 32 days over which the structure was subjected to 25 blasts. Structure motions were measured on an outside exterior corner in a two-story wood-frame home. The crack displacement gage was placed over a horizontal crack in exterior stucco shown in Figure 2(c). The highest blast registered 11.4 mm/s at the structure using 125 kg/delay. Figure 4 shows variations in ambient temperature and relative humidity with time over the measurement period

99

case 1 structure

CONSTRUCTION BLASTING AREAS

instrumented structures 8000 m

instrumentation placed on exterior stucco wall

Figure 3. structure.

40

Plan view of blasting area and instrumented

Temperature (oC)

20

0 100 Relative humidity (%) 50

0 250 217 150 97 50 0 100 200 300 400

TIME (hr)

cracks, promoting cracks to grow slowly over time under the right conditions. The greatest 24-hour width change occurred around 120 hours, producing a 120 m closure. The crack was influenced by a sharp drop in relative humidity. The crack movement time plot is expanded in Figure 5 to show the point in time when the largest amplitude blast occurred. Blast-induced dynamic crack motions are plotted adjacent to the static, weather-induced displacements and the time history is expanded below to the right. The blast generated 11.4 mm/s PPV at the structure that resulted in a 6.2 m maximum crack width change. Two nights previous around 157 hours, a storm producing high winds took place. Wind speeds measured at two airports within 7 km of the structure indicted gusts averaged 53 km/hour. The highest sustained wind-induced crack response of 7 m is shown in the lower left corner of Figure 5. Wind gusts in the Las Vegas area can exceed 128 km/hour and are therefore capable of influencing existing cracks at far higher displacement levels. Therefore, weather-induced displacements measured across the existing crack width far exceeded the maximum width change during a blast when the PPV was near the regulated limit. The probability that blasting could cause the existing crack to either lengthen or widen is negligible when considering the influences of weather-induced forces that prevail within structure walls on a daily basis. Wall strains computed from differential wall displacements for the highest amplitude blast were 27.8 106 and 9.8 106 strain for in-plane (tensile) and bending, respectively. Failure strain for stuccotype materials typically range from 500 to over 1000 106 strain. As such, the factor of safety against stucco wall cracking from wall displacements during blasting near the regulated limit is close to 18.

Crack displacement (micro-m)

250

Crack displacement (micro-m)

500

600

700

800

50

Figure 4. Variations in ambient temperature, humidity and corresponding crack displacements.

150

160

170

180

TIME (hr)

190

200

210

220

6.2 micro-m (blast)

(top two graphs). The variation in crack width changes is shown in the bottom graph. A positive increase in crack displacement corresponds with opening of the crack. In general, crack movement followed the trend in ambient humidity. When humidity increased, the crack opened and this occurred predominately during the night. During the day, as temperature increased and humidity decreased, cracks tended to close. It is this daily cycle that produced high stresses on the crack and in particularly, at the tips or ends of the

7 micro-m (wind)

Figure 5. Crack displacement plots showing comparisons of dynamic crack displacement time history for largest blast (middle), 53 km/hour wind gust (lower left), and static crack movement (top) in response to climate over a 4-day period.

100

4.2

Case 2: Quarry blasting

40

Temperature ( C)

A structure near a limestone quarry in Detroit, MI was instrumented. The structure was a two-story wood-frame home shown in Figure 6, located approximately 700 m from the blasting. Significant complaints to local authorities of alleged blast damage to homes by community members prompted the courts to limit blasting at 3.8 mm/s PPV . In preparation to respond to the courts, quarry operators initiated a structure response study. An upper floor bedroom facing the quarry was instrumented and a displacement gage mounted over a diagonal drywall crack at the lower edge of a window frame shown in Figure 6. Fifteen blasts took place during the study. Figure 7 shows time histories of climate and crack width changes over the 45-day study. The response of the interior crack was influenced by the operation of an air conditioning unit with the exception of several days after 900 hours cumulative study time. The largest 24-hour night-day change in crack width occurred around 920 hours as shown in the expanded displacement plot of Figure 8. The change in crack width was 514 m. Four days later, the blast generating the highest PPV of 1.7 mm/s at the structure took place using 43 kg/delay of explosives. The crack displacement time history is shown in the lower right of Figure 8 and the peak width change was 3.9 m, 131 times smaller than the largest weather-induced width change.

10 60 Relative humidity (%)

20 1000 Crack displacement (micro-m)

200 700 900 TIME (hr) 1100

Figure 7. Variations in ambient temperature, humidity and corresponding crack displacements.

1000

844

Crack displacement (micro-m)

330 200 900 1000

TIME (hr)

1100

3.9 micro-m (blast)

Figure 8. Dynamic crack displacement time history for largest blast occurring at 1010 hours (below) relative to a 24-hourr weather-induced change in crack width (top).

instrumented structure

300 m

instrumentation placed on interior drywall

Dynamic crack motions were recorded for human activities typical of those taking place everyday in residences. Crack displacements for three activities are shown in Figure 9 and include walking into the room, closing the double-hung window adjacent to the wall crack, and an object falling 1 m onto the floor. The peak crack motions ranged from 10.5 to 18.4 m and are 2.7 to 4.7 times larger than crack movement during the blast generating the highest PPV . Maximum in-plane and bending strains computed for the upper bedroom walls were 12.4 and 4.5 106 strain, respectively. Failure strains for drywall vary from 200 to 1100 106 strain. Therefore, it is not possible that blasting at such low levels of ground vibrations could possibly contribute to drywall cracking. 4.3 Case 3: Quarry blasting

Figure 6. Plan view of quarry, instrumented structure and crack gage over existing drywall crack on an outside wall.

Case 3 is a granite quarry in Charlotte, NC surrounded by a number of complainants who feel blasting is contributing to cracking in residences supported on concrete slabs foundations. Figure 10 shows a plan view

101

10.5 micro-m (walk into room)

18.4 micro-m (shut window)

13.2 micro-m (fall of backpack)

Figure 9. Crack displacement time histories for humaninduced activities in the room near the crack.

instrumented structure soils boring 300 m

Figure 10. structure.

Plan view of quarry and instrumented

of the quarry and the surrounding community to the northwest (upper left of map). The site soils have been identified as highly expansive clays, documented to cause foundation problems in lightly loaded structures. The quarry owners embarked on a new approach to community relations planning to address community blasting concerns. As part of this plan, a structure response study was initiated along with a soil boring and testing program to determine the engineering properties of local area soils. The one-story structure selected for instrumentation is shown in Figure 10 along with the interior drywall crack instrumented with a displacement gage. The horizontal crack was located on the interior of an outside wall next to a bedroom window facing the quarry. The study duration was 5 months over which 54 blasts were conducted. Four borings were drilled as shown in Figure 10 and undisturbed clay samples extracted for lab testing. Swell tests were conducted on all samples loaded to the existing overburden load including the weight of a typical residential structure. Percent swell and swell pressures were determined. An anchor point was placed in the surface soils outside the structure to measure soil movement in response to wetting and drying cycles. The device, shown in

the Figure 11 schematic, was fabricated of PVC pipe. A 127 mm collar was situated at the ground surface within the assumed zone of soil movement caused by changes in moisture. A 25.4 mm interior rod was grouted at the base of the 1.8 m hole and assumed to remain stationary, grounded well below the influence of moisture change. Two pairs of bolts inserted through pipe walls were used to measure outer pipe vertical movement relative to the inner stationary pipe. Measurements were taken once a week. Rainfall measurements were made across the road at the quarry plant rain gage station. Figure 12 shows time histories of climate data and crack movement (missing data indicates temporary instrument failure). The large swings in relative humidity over several days represented rainfall, keeping humidity high and contributing to moisture in the ground. The largest 24-hour crack displacement of 95 m occurred at 1150 hours. During periods of rainfall, the crack movement took on an unusual long-term inverted U shape between 1000 and 2000 hours shown in Figure 12. Superimposed on this trend are the 24-hour cycles of day-night response to temperature and humidity. The overall change in crack width during this time was 237 m. Figure 13 shows portion of the expanded crack displacements over which the blast with the highest explosives. The peak dynamic crack motion was 2.4 m in comparison with a night-day crack width change in response to climate of 76 m. The influence of this blast on crack movements was 31 times smaller than the influence of climate over this time period. Anchor point measurements for 68 days are plotted in Figure 14. The difference between the two pairs of bolts, plotted as anchor point movement, indicates the lower bolt moved down (as separation

reference bolts

127 mm OD

assumed swelling clay layer

25.4 mm OD, 2.2 m in length

grout

Figure 11. Section view and photo of top view of the anchor point used to measure subsurface soils vertical displacements near the structure foundation.

102

35

Temperature (C) 15 80

Relative humidity (%) 20 300

Crack displacement (micro-m) 0 0 1000 TIME (hr) 2000 3000

Figure 12. Variations in ambient temperature, humidity and corresponding crack displacements.

150

121

Crack displacement (micro-m)

between bolts increases) until around 50 to 60 days. At 55 days, a long period of measurable rainfall began and continued for 88 days with increasing rainfall amounts each day of rain. The response of the nearsurface clay soils to moisture intrusion as indicated by the bolt separation distance is apparent. The outer PVC collar moved upward with ground surface heave from increased accumulation of soil moisture. The reaction of the adjacent concrete slab foundation is indicated by the overall movement of the horizontal crack. By superimposing the crack width changes over the same time period in Figure 14, the effect surface soil heave had on the structure foundation is apparent. The uplift of the slab caused the horizontal crack in the outside wall to reduce in width (i.e. close). The potential for the local expansive soils to contribute to cracking in lightly loaded structures with concrete slab foundations was further investigated using lab swell tests. The test results showed swell pressures ranged from 31 to 45 kPa. The load imposed on slab foundations for the one-story structures in the neighborhood was calculated to be 14 kPa and verified by a structural engineer. The slab foundation load was 2.2 to 3.2 times less than potential upward pressures of the swelling clay. Hence, soil heave and foundation uplift were determined to be the cause of observed structure distress rather than quarry blasting. 5 SUMMARY AND CONCLUSIONS

45

0 3550 3600

TIME (hrs)

3650

3700

2.4 micro-m (blast)

Figure 13. Dynamic crack displacement time history (below) for the blast generating the highest PPV within a 24-hr night-day change in crack width of 76 micro-m.

Comparative data for structure response to blasting and normal environmental forces are shown in Tables 1 and 2 for three cases. In each case, the PPV is well within the U.S. safe limits that are protective of structures. The dynamic characteristics of the study structures, namely, natural frequency, damping or the decay of successive vibration peaks during free response, and amplification factor or the dynamic

86

0 1

Table 1. Dynamic response characteristics and wall strains for blast with highest peak particle velocity (PPV).

PRECIPITATION (mm)

BOLT SEPARATION (mm)

Strain (106) Case 1 2 3

(1) (2)

84

2 3

FN(1) (Hz) 9 9 11

Damping (%) 5.4 np 3.6

AF(2) 2.3 1.7 1.7

PPV (mm/s) 11.4 1.7 2.1

T(3) 27.8 12.4 16.2

B(4) 9.5 4.5 6.5

82 anchor point movement precipitation 80 0 20 40 60 80 CUMMULATIVE DAYS

4 5 6 100

Figure 14. Anchor point measurements compared with rainfall and crack displacements.

Natural frequency. Amplification factor. (3) In-plane tensile strain. (4) Mid-wall bending strain. np Not possible.

103

Table 2. Largest measured crack width changes (all measurements in micro-m). Case: Crack location 1: Stucco Other environmental forces Blast 24-hr(1) Type 6.2 120 514 Wind53 km/hr induced HumanWalking induced object fall shut window SoilHeave induced against foundation 7 10.5 13.2 18.4 237

In the case studies presented herein, a candidate crack, pre-existing in structure walls, was instrumented using displacement gages to record changes in crack width. Non-blasting forces that act everyday in structures from normal human activities, wind loading, and expansion of foundation soils have been shown to generate far greater changes in crack widths compared with blasting within safe guidelines. REFERENCES

Edwards, A.T. & Northwood, T.D. 1960. Experimental Studies of the Effects of Blasting on Structures. The Engineer. v. 210, pp. 538546. Langefors, U., Kihlstrom, B.K. & Westerber, H. 1958. Ground Vibrations in Blasting. Water Power. February. Siskind, D.E., Stagg, M.S., Kopp, J.W., & Dowding, C.H. 1980. Structure Response and Damage Produced by Ground Vibrations From Surface Mine Blasting, USBM RI 8507, United States Bureau of Mines. Stagg, M.S., Siskind, D.E., Stevens, M.G., & Dowding, C.H. 1984. Effects of Repeated Basting on a Wood-Frame House, USBM RI 8896, United States Bureau of Mines. Wiss, J.F. & Nicholls, H.R. 1974. A Study of Damage to a Residential Structure from Blast Vibrations. Res. Council for Performance of Structures, ASCE, New York. Wiss, J.F. & Parmelee, R.A. 1974. Human Perceptions of Transient Vibrations. J. Structure Div., ASCE, v. 100, No. ST4, Proc. Paper 10495, pp. 773787.

2: Drywall 3.7

3: Drywall 2.4

96

(1)

Influenced by temperature and relative humidity.

amplification of the upper structure relative to the ground vibrations driving structure motions is given. The values found in Table 1 are well within or below the ranges found by the U.S. Bureau of Mines for natural frequency (4 to 11 Hz), damping (3 to 10%) and amplification (2 to 4). Wall strains calculated from differential displacement between the upper and lower corners of structures and in mid-walls for blasting within safe limits do not exceed failure strains of wall materials and therefore cannot result in cracking.

104

You might also like

- Kimal Excursions Kimal Excursions: How Are We Doing? How Are We Doing?Document3 pagesKimal Excursions Kimal Excursions: How Are We Doing? How Are We Doing?Henry AngelNo ratings yet

- MD6640 Ex 49HR Brochure PDFDocument4 pagesMD6640 Ex 49HR Brochure PDFJoel TitoNo ratings yet

- Bucyrus Rotary Blast DrillsDocument12 pagesBucyrus Rotary Blast DrillsManu Rojas Escobar100% (1)

- GS Technical ManualDocument28 pagesGS Technical ManualHenry AngelNo ratings yet

- Instrumentacion Cross HoleDocument9 pagesInstrumentacion Cross HoleHenry AngelNo ratings yet

- 77 Palmstrom On Block Size and RQDDocument20 pages77 Palmstrom On Block Size and RQDcondorblancoNo ratings yet

- Manual DasylabDocument76 pagesManual DasylabHenry AngelNo ratings yet

- A Gi Earth ImagerDocument2 pagesA Gi Earth ImagerHenry AngelNo ratings yet

- Taller SquidDocument6 pagesTaller SquidHenry AngelNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Guide To Standards and Tolerances 2007 PDFDocument60 pagesGuide To Standards and Tolerances 2007 PDFbpdvietNo ratings yet

- Furring Channel (Dry Wall)Document3 pagesFurring Channel (Dry Wall)Jejomae Isberto Calising100% (1)

- New Home Quality Control FREE Snag ChecklistDocument14 pagesNew Home Quality Control FREE Snag ChecklistVineel BellapuNo ratings yet

- Ea 0042Document1 pageEa 0042fereetNo ratings yet

- Galvanized Steel TDMDocument41 pagesGalvanized Steel TDMbehaosziNo ratings yet

- Mock Wall Syllabus 1Document2 pagesMock Wall Syllabus 1api-352669853No ratings yet

- ASTM C 36 - Standard Specification For Gypsum Wallboard PDFDocument4 pagesASTM C 36 - Standard Specification For Gypsum Wallboard PDFibrahimNo ratings yet

- GIB Fire Rated Systems Nov.18 ONLINEDocument108 pagesGIB Fire Rated Systems Nov.18 ONLINEAhmedNo ratings yet

- MTO Generator Box CutDocument29 pagesMTO Generator Box Cutrony 2222No ratings yet

- Fire Performance Test of HytexRib-plus Wall CoveringDocument19 pagesFire Performance Test of HytexRib-plus Wall CoveringcrazyfordNo ratings yet

- 10 04 021 SPCDocument1 page10 04 021 SPCMichael Ben-DorNo ratings yet

- Masonry Cavity Wall Insulation IllustrationsDocument0 pagesMasonry Cavity Wall Insulation IllustrationsGonzalo Luque GarcíaNo ratings yet

- Boq 608553Document15 pagesBoq 608553sahil kotwalNo ratings yet

- BOQ and Specs for Civil, Interior, Electrical and AC WorksDocument21 pagesBOQ and Specs for Civil, Interior, Electrical and AC WorksRadwan Noman100% (1)

- KESSEL System 400 Rainwater Filter For Above or Underground Installation With or Without Filter BackwashDocument2 pagesKESSEL System 400 Rainwater Filter For Above or Underground Installation With or Without Filter Backwashcris62No ratings yet

- 31 Ultralite Rapid Flex s1 Uk NoRestrictionDocument4 pages31 Ultralite Rapid Flex s1 Uk NoRestrictionFloorkitNo ratings yet

- Absorption&Insulation DataDocument26 pagesAbsorption&Insulation Dataharoub_nasNo ratings yet

- Kodumaja Modulos The TreetDocument13 pagesKodumaja Modulos The TreetYanina GobbiNo ratings yet

- PDS Gyproc HandiBoardDocument2 pagesPDS Gyproc HandiBoardyudi permanaNo ratings yet

- Catalogo LithuaniaDocument98 pagesCatalogo LithuaniaRobby Rovira BarcenasNo ratings yet

- U-Values From Domestic Heating Design Guide v1.0Document13 pagesU-Values From Domestic Heating Design Guide v1.0gaurankushNo ratings yet

- Trafalgar Fyreflex S55776e3992ae6Document14 pagesTrafalgar Fyreflex S55776e3992ae6cliveNo ratings yet

- CDEP Pre-Board - Jan2012 - PlumbingDocument11 pagesCDEP Pre-Board - Jan2012 - PlumbingdizonabigailmaereyesNo ratings yet

- MST-Gypsum Board Installation To CeilingDocument5 pagesMST-Gypsum Board Installation To Ceilingadeniyi abiolaNo ratings yet

- Land Reclamation in Uttar PradeshDocument30 pagesLand Reclamation in Uttar PradeshSophia ChinNo ratings yet

- Under Screed PipingDocument2 pagesUnder Screed PipingVisakh VijayanNo ratings yet

- Interior wall and ceiling paint creates elegant finishDocument2 pagesInterior wall and ceiling paint creates elegant finishAly MendozaNo ratings yet

- Tehnologia Posi StrutDocument35 pagesTehnologia Posi Strutdanut_docNo ratings yet

- The Complete Diy Guide To Easy Home Repairs Quick Fixes For All Part of Your HomeDocument40 pagesThe Complete Diy Guide To Easy Home Repairs Quick Fixes For All Part of Your HomeTomasthc AitNo ratings yet

- Project Report On Gypsum Plaster BoardDocument5 pagesProject Report On Gypsum Plaster BoardEIRI Board of Consultants and PublishersNo ratings yet