Professional Documents

Culture Documents

BoredPile CHecklist Update

Uploaded by

GnabBangCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BoredPile CHecklist Update

Uploaded by

GnabBangCopyright:

Available Formats

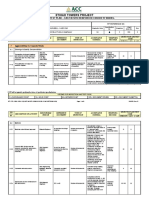

CHECKLIST FOR BORED CAST-IN-PLACE PILE

Page 1 of 3

CHECKLIST FOR BORED CAST-IN-PLACE PILE NO.

Checked By Engineer

CHECKLIST ITEMS

Project Name : _____________________________ Piling Contractor : _____________________________

Remarks

1.0

CONSTRUCTION METHOD AND TECHNIQUES Pile Diameter _______________________________

1.1

Concrete Grade _______________________________ Pile Raked Gradient ______ Vertical : ______ Horizontal Grab Construction (Using Crawler Crane, Casing Oscillator, etc) Rotary Drilling (Contiguous Flight Auger, Twin Head Rotary Drive) Rock Coring (Chisel, Core Barrel, Cross Head Cutter, Reamer, etc.) Direct Circulation Drill Indirect Circulation Drill Concreting Method Poured (With Tremie for Wet Hole Construction) Injected Reinforcement Reinforcement Cage : Main _______ Link _____________ (eg. 32T20) (eg. T12 @ 150 Spiral)

1.2

1.3

1.4

1.5

[Note: T = 460 N/mm , Y = 410 N/mm2 , R = 250 N/mm2 ] Lapping Length : ____________________________ Concrete Cover/ Spacer : ______________________

2.0

PILING EQUIPMENT AND ACCESSORIES Excavator - Crawler Crane (Grab method) - Rotary Drive (Continuous Flight Auger, Twin Rotary Head) Temporary Casing Drilling Fluid (Bentonite or other Slurry Stabilisation) Concrete Tremie Pipe (for concreting under water or wet hole) Hover with short length of chute (direct discharge method for dry hole)

3.0

Pile Position Setting Up Three reference points to be setup with respect to the proposed pile point.

GUE & PARTNERS SDN BHD

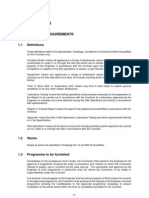

CHECKLIST FOR BORED CAST-IN-PLACE PILE

Section : OP-3-40 Revision : 0 Date : 03-05-2002 Page 2 of 3

4.0

BORED PILE CONSTRUCTION Predrilling - To determine the bored pile length

4.1

- To check verticality of borehole - To check any deviation in the distance of pile point to the reference points after soil boring. Stability Of Borehole Temporary steel casing with appropriate size and length (minimum 1m or below the unstable strata) should be applied to prevent loose materials falling into the bottom of borehole. Borehole to be filled with drilling fluid to stabilise the borehole [See note ##] unless stiff clayey soils are encountered. Verification Of Bedrock (If Required) Inspection of the excavated rock fragments The depth achieved (rock encountered / total length) to be compared with the borehole data and checked by a measurement tape. The bottom soundness is checked with a weight on a tape tamped on the founding strata. In-situ rock strength test (e.g. Point Load Test) to be conducted [See note ##]

4.2

4.3 -

Airlifting (Base Cleaning) 4.4 Use cleaning bucket to clean the base before carrying out air lifting. To ensure the cleanliness of the loose and caving-in soil at base. Make sure the hose is at the base of the pile (not suspended half-way).

Reinforcement Cage 4.5 - The length of the cages should match with the excavated depth. - Insert fabricated reinforcement cage into the cased borehole Check Lap length (if any) CONCRETING Concrete overbreak after each batch of concreting Pour in concrete (by tremie concrete method or direct discharge method), simultaneously displacing slurry. Check the density of fluid as in the specification. The bottom end of the tremie pipe should be always about one to two metres submerged below the level of the concrete. (Not to pull up too abrupt) Concreting could only be stopped at about 1m above the cut-off level Record any interruption on concreting (record the duration)

4.6 5.0

GUE & PARTNERS SDN BHD

CHECKLIST FOR BORED CAST-IN-PLACE PILE

Section : OP-3-40 Revision : 0 Date : 03-05-2002 Page 3 of 3

Test Cube : - at least 6 Nos. - achieve design strength (within 28 days) Concrete Slump Test Record : - Number of trucks - Discharge amount per trucks 6.0 PROOF DRILLING Core drilling to be carried out through piles to check the qualities of Concrete Contact between the rock and concrete Quality of the rock beneath the toe 7.0 CHECK BORED PILE SHAFT INTEGRITY Use High Strain Dynamic Load Test (HSDLT) Pile Integrity Test (PIT). Sonic Logging 8.0 8.1 POST-INSTALLATION Penetration length Piling Platform level : ___________ Borehole Drilling Record : ________ Predicted Length at site : ________ ( from HSDLT or PIT ) Compared penetration lengths with Borehole or Proof Drilling from Subsurface Investigation. Check As-built position of the bored pile group (Typically eccentricity < 75mm) COMPUTATION Estimate the amount of concrete and materials for each piles.

8.2

8.3

9.0

Signature by Engineer

Note : [##] represents the items that will be followed if only necessary.

You might also like

- Method Statement BorepileDocument47 pagesMethod Statement BorepileIera Jamil100% (1)

- Work Method Statement of Piling WorkDocument11 pagesWork Method Statement of Piling Worksangamesh yadahalliNo ratings yet

- ITP & Ceklis Bored PileDocument5 pagesITP & Ceklis Bored Pilefari_civil06No ratings yet

- Bored Pile - Method StatementDocument13 pagesBored Pile - Method Statementbtcong93100% (2)

- Checklist Pile Driving 1Document2 pagesChecklist Pile Driving 1irfanarman100% (2)

- Checklist For Bored Pile WorksDocument3 pagesChecklist For Bored Pile Worksmarvin100% (3)

- Method Statement For Bored PilesDocument18 pagesMethod Statement For Bored PilesKaushalye Mahanama Dissanayake100% (3)

- MS 01 - Bored PilesDocument31 pagesMS 01 - Bored PilesDinesh PriyankaraNo ratings yet

- Pre Piling ChecklistDocument1 pagePre Piling Checklistbill_lee_242No ratings yet

- Method Statement For Pile Chipping and Capping Beam: Vascon Engineers LTDDocument12 pagesMethod Statement For Pile Chipping and Capping Beam: Vascon Engineers LTDshahaji0% (1)

- Check List For Rebar & FormworkDocument1 pageCheck List For Rebar & FormworkEbrahimAbuZaid0% (1)

- MS For BoredDocument18 pagesMS For BoredsinlekmNo ratings yet

- Bored Piling Works - 8 Stages from Pre-boring to BackfillingDocument1 pageBored Piling Works - 8 Stages from Pre-boring to BackfillingAnonymous S7Cq7ZDgP100% (1)

- Bored Pile QC Flow ChartDocument1 pageBored Pile QC Flow ChartChung Yiung YungNo ratings yet

- Pre Excavation and Foundation Inspection ChecklistDocument2 pagesPre Excavation and Foundation Inspection ChecklistTwin Bulls50% (2)

- Bored PilingDocument3 pagesBored PilingAdonis AlabiNo ratings yet

- RCC Piling MethodDocument21 pagesRCC Piling MethodArju AbedinNo ratings yet

- Method Statement For Pile DrivingDocument2 pagesMethod Statement For Pile DrivingLim Han Jian100% (5)

- Appendix E: Checklist For Kerbstone WorksDocument3 pagesAppendix E: Checklist For Kerbstone WorksJericFuentes100% (2)

- Method Statement For Bored PilingDocument5 pagesMethod Statement For Bored Pilingjhc112386% (7)

- Checklist For ShutteringDocument4 pagesChecklist For ShutteringMir Masood Shah0% (1)

- Pile MethodologyDocument14 pagesPile MethodologyVelmurugan BalasubramanianNo ratings yet

- Bored Piles - Production MethodDocument10 pagesBored Piles - Production MethodFrank Stephens100% (1)

- Method Statement For Jet GroutingDocument2 pagesMethod Statement For Jet GroutingAlsonChin0% (1)

- Checklist FormworkDocument2 pagesChecklist FormworkSreyleap Nhet100% (2)

- Interpretation of Pile Integrity Test (PIT) Results by H.S. Thilakasiri 2006Document7 pagesInterpretation of Pile Integrity Test (PIT) Results by H.S. Thilakasiri 2006Ashokan Keloth100% (1)

- HG Power Transmission Sdn. BHD.: Method StatementDocument3 pagesHG Power Transmission Sdn. BHD.: Method StatementNabil Mazelan100% (2)

- Ho Chi Minh City Water Environment Improvement Project: Concrete Pour Record (Internal)Document4 pagesHo Chi Minh City Water Environment Improvement Project: Concrete Pour Record (Internal)Archie Joseph LlanaNo ratings yet

- Checklist For ConcretingDocument4 pagesChecklist For ConcretingManish KapadneNo ratings yet

- Steel Sheet Pile InstallationDocument59 pagesSteel Sheet Pile InstallationDevapradatta Nath100% (10)

- Checklist Site ClearingDocument1 pageChecklist Site ClearingAfraliza YusofNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksDocument8 pagesEtihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksjiniNo ratings yet

- ITP for Piling Inspection and TestingDocument4 pagesITP for Piling Inspection and Testingjitendra100% (1)

- RCC Pile Cap Works Method StatementDocument3 pagesRCC Pile Cap Works Method StatementShenbagaraja PandianNo ratings yet

- 5 Formwork ChecklistDocument2 pages5 Formwork ChecklistJamalAhmadNo ratings yet

- Bored Cast In-Situ Pile Method StatementDocument10 pagesBored Cast In-Situ Pile Method StatementVijay JamadarNo ratings yet

- Integrated Piling FormatDocument2 pagesIntegrated Piling Formatyash shah88% (34)

- CHECKLIST Precast Foundation Inspection ChecklistDocument1 pageCHECKLIST Precast Foundation Inspection ChecklistrahulsivaNo ratings yet

- Checklist-Structural Concrete Pre PouringDocument1 pageChecklist-Structural Concrete Pre Pouringajit karandikar100% (1)

- Inspection Request Form For Piling Works (Bored Pile)Document2 pagesInspection Request Form For Piling Works (Bored Pile)Wr Ar100% (1)

- Piles ChecklistDocument2 pagesPiles ChecklistKOMAL JOSHINo ratings yet

- Checklist - PCCDocument2 pagesChecklist - PCCajit karandikar100% (2)

- Method Statement Bored PileDocument9 pagesMethod Statement Bored PileAsma Farah100% (3)

- 01 Method Statement For Pile Cap Foundations (Findal)Document8 pages01 Method Statement For Pile Cap Foundations (Findal)Joe PS83% (6)

- (O) - 1 Bored PileDocument16 pages(O) - 1 Bored Pileautienhai100% (4)

- Bored Piling Method StatementDocument8 pagesBored Piling Method StatementTAHER AMMAR100% (1)

- Remedial Works for Excessive Deflections in PilesDocument8 pagesRemedial Works for Excessive Deflections in Pilestin aungtunNo ratings yet

- 7503-2 - Checklist For Precast StructureDocument8 pages7503-2 - Checklist For Precast StructureKannan KamalNo ratings yet

- RCC Pile Works ChecklistDocument1 pageRCC Pile Works ChecklistAyush PuriNo ratings yet

- Checklist For Rebar (Columns, Neck Columns and Plinth Wall) : QA/QC RequirementsDocument1 pageChecklist For Rebar (Columns, Neck Columns and Plinth Wall) : QA/QC Requirementsmanoj100% (1)

- Method Statement For Piling Work (Edited)Document18 pagesMethod Statement For Piling Work (Edited)Faeez Zain100% (6)

- Concrete Pour CardDocument1 pageConcrete Pour CardManish Patidar100% (3)

- Method Statement For Pile BreakingDocument3 pagesMethod Statement For Pile BreakingAnonymous YxBTH8lhZ100% (3)

- Pre Concreting ChecklistDocument1 pagePre Concreting Checklistbill_lee_24271% (7)

- Method Statement For Water Stopper-BSMMUDocument5 pagesMethod Statement For Water Stopper-BSMMUEngr. Masud RahmanNo ratings yet

- Method Statement For Surveying WorkDocument3 pagesMethod Statement For Surveying WorkShenbagaraja PandianNo ratings yet

- Standard Metal Pole FoundationsDocument26 pagesStandard Metal Pole FoundationsNanescu LilianaNo ratings yet

- Check List Format For Boared PileDocument6 pagesCheck List Format For Boared PileHiren Thakkar100% (1)

- Soil Nails As Per RDSO-204-212Document9 pagesSoil Nails As Per RDSO-204-212Kishore KumarNo ratings yet

- Chapter 3 Pile Construction SequenceDocument22 pagesChapter 3 Pile Construction SequenceFitsumbirhan AmanuelNo ratings yet

- Commercial Vehicles Types TiresF2018L01517 PDFDocument51 pagesCommercial Vehicles Types TiresF2018L01517 PDFGnabBangNo ratings yet

- FACTORIES AND MACHINERY AMD 2006 ActA1268bm PDFDocument28 pagesFACTORIES AND MACHINERY AMD 2006 ActA1268bm PDFGnabBangNo ratings yet

- Lifting Lug Calculation PDFDocument5 pagesLifting Lug Calculation PDFGnabBangNo ratings yet

- Guide TMP CreationDocument2 pagesGuide TMP Creationmira0604No ratings yet

- SI Spects Cidb 2Document33 pagesSI Spects Cidb 2rowatersNo ratings yet

- HIRARC GuideLine From DOSHDocument34 pagesHIRARC GuideLine From DOSHMohd Hadri50% (2)

- Earthworks COntent PageDocument1 pageEarthworks COntent PageGnabBangNo ratings yet

- UCS DolomiteDocument15 pagesUCS Dolomiteranjeevkumar100% (2)

- Certificate of Compliance and Completion CCC - CFO - PSPDocument3 pagesCertificate of Compliance and Completion CCC - CFO - PSPGnabBangNo ratings yet

- Rock SlopePresesntationDocument75 pagesRock SlopePresesntationJpver10000% (1)

- JKR Schedule of Unit RatesDocument50 pagesJKR Schedule of Unit RatesCheng75% (28)

- Design and Performance of Tubular Steel ScaffoldingDocument16 pagesDesign and Performance of Tubular Steel ScaffoldingGnabBang100% (1)

- Offshore Oil and Gas Industry - Abbreviations and AcronymsDocument40 pagesOffshore Oil and Gas Industry - Abbreviations and Acronymsmadonnite3781No ratings yet

- Citra Suct Ractangular - Over - Head - Water - Tank - (Complete)Document44 pagesCitra Suct Ractangular - Over - Head - Water - Tank - (Complete)GnabBangNo ratings yet

- Osha FS-3760Document2 pagesOsha FS-3760samNo ratings yet

- INTERPRET CIU TESTDocument7 pagesINTERPRET CIU TESTGnabBangNo ratings yet

- Scaffold TestDocument28 pagesScaffold TestAbdulSamadNo ratings yet

- Warranty FormatDocument1 pageWarranty FormatSEC Machines100% (1)

- Tech Proposal - KTA PumpsDocument1 pageTech Proposal - KTA PumpsGnabBangNo ratings yet

- Rubble Masonry RetWall SpecsDocument1 pageRubble Masonry RetWall SpecsGnabBangNo ratings yet

- Pile Test Loading CycleDocument1 pagePile Test Loading CycleGnabBangNo ratings yet

- Steel Tower For SignboardDocument1 pageSteel Tower For SignboardGnabBangNo ratings yet

- Staircase CollDocument1 pageStaircase CollGnabBangNo ratings yet

- Checklist - Rock Toe - NoRDocument4 pagesChecklist - Rock Toe - NoRGnabBangNo ratings yet

- Specification For Rock ExcavationDocument12 pagesSpecification For Rock ExcavationGnabBangNo ratings yet

- RC PilesDocument4 pagesRC Pileshasif21No ratings yet

- Nusa INtan STP - slopESDocument14 pagesNusa INtan STP - slopESGnabBangNo ratings yet

- Handrailing For Maintenance Stairway Hong Kong Ic2103jDocument1 pageHandrailing For Maintenance Stairway Hong Kong Ic2103jGnabBangNo ratings yet

- Steel Tower For SignboardDocument1 pageSteel Tower For SignboardGnabBangNo ratings yet

- Cut-Off Drain Details Hong Kong Ic2401fDocument1 pageCut-Off Drain Details Hong Kong Ic2401fGnabBangNo ratings yet

- Mediclaim - ChecklistDocument4 pagesMediclaim - ChecklistKarthi KeyanNo ratings yet

- Blackmagic RAW Speed TestDocument67 pagesBlackmagic RAW Speed TestLeonardo Terra CravoNo ratings yet

- 935 Ubi PBK Statement PDFDocument20 pages935 Ubi PBK Statement PDFTECHNO ACCOUNTNo ratings yet

- The Unseelie Prince Maze of Shadows Book 1 by Kathryn AnnDocument267 pagesThe Unseelie Prince Maze of Shadows Book 1 by Kathryn Annanissa Hri50% (2)

- Personality, Movie Preferences, and RecommendationsDocument2 pagesPersonality, Movie Preferences, and RecommendationsAA0809No ratings yet

- Mass ELA Releases ORQs Grade 8Document24 pagesMass ELA Releases ORQs Grade 8scmsliteracyNo ratings yet

- Colorimetric Determination of ManganeseDocument16 pagesColorimetric Determination of ManganeseidaayudwitasariNo ratings yet

- Creature Loot PDF - GM BinderDocument97 pagesCreature Loot PDF - GM BinderAlec0% (1)

- Sheet Metal FormingDocument13 pagesSheet Metal FormingFranklin SilvaNo ratings yet

- Inventory of Vacant Units in Elan Miracle Sector-84 GurgaonDocument2 pagesInventory of Vacant Units in Elan Miracle Sector-84 GurgaonBharat SadanaNo ratings yet

- Chapter 9 Screw ConveyorsDocument7 pagesChapter 9 Screw ConveyorsMarew Getie100% (1)

- The NicotinaDocument8 pagesThe Nicotinab0beiiiNo ratings yet

- EMB 690-1 SM Course Outline Spring 21Document8 pagesEMB 690-1 SM Course Outline Spring 21HasanNo ratings yet

- Valhalla Repair ManualDocument8 pagesValhalla Repair ManualKirby AllenNo ratings yet

- GTA Max Profit Bunker Locations Update v1.4Document1 pageGTA Max Profit Bunker Locations Update v1.4Sam FarrelNo ratings yet

- Coca Cola Live-ProjectDocument20 pagesCoca Cola Live-ProjectKanchan SharmaNo ratings yet

- Cross-Sectional Tomography: Oral and Maxillofacial RadiologyDocument7 pagesCross-Sectional Tomography: Oral and Maxillofacial RadiologyPhanQuangHuyNo ratings yet

- Aluminium FOil SearchDocument8 pagesAluminium FOil SearchAtul KumarNo ratings yet

- Entrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Document35 pagesEntrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Ameen KolachiNo ratings yet

- PWC Annual ReportDocument46 pagesPWC Annual ReportAigulNo ratings yet

- Kamera Basler Aca2500-20gmDocument20 pagesKamera Basler Aca2500-20gmJan KubalaNo ratings yet

- Commu I ReviewedDocument45 pagesCommu I ReviewedCabdirisaaq CabdisalanNo ratings yet

- Pathophysiology of Cardiogenic Pulmonary EdemaDocument8 pagesPathophysiology of Cardiogenic Pulmonary EdemaLili Fiorela CRNo ratings yet

- Present Perfect.Document1 pagePresent Perfect.Leidy DiazNo ratings yet

- The Meaning of Solar CookerDocument4 pagesThe Meaning of Solar CookerJaridah Mat YakobNo ratings yet

- Uhde Painting SpecificationDocument34 pagesUhde Painting Specificationmohamed elmasryNo ratings yet

- 09 Lift Cylinder Drift (Bulldozer) - CheckDocument2 pages09 Lift Cylinder Drift (Bulldozer) - CheckFredy Manrique AstoNo ratings yet

- Case NoDocument13 pagesCase NoLaurente JessicaNo ratings yet

- 8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features DescriptionDocument3 pages8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features Descriptionedward3600No ratings yet

- NT140WHM N46Document34 pagesNT140WHM N46arif.fahmiNo ratings yet