Professional Documents

Culture Documents

CTHS430 02 IMA S223.856-01.en

Uploaded by

Patricio TamayoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CTHS430 02 IMA S223.856-01.en

Uploaded by

Patricio TamayoCopyright:

Available Formats

IMA

Installation Manual Appendix Doc. No. S 223.856.en

SANDVIK CTHS430:02

Tank unit installation drawings

This document is valid for:

Serial No. / Machine No. Signature

SANDVIK CTHS430:02

Tank unit installation drawings

Copyright 2012 Sandvik SRP AB.

All rights reserved. No parts of this document may be reproduced or copied in any form or by

any means without written permission from Sandvik SRP AB. All data and information in this

manual may be changed without further notice. Reservations for misprints.

Document number: S 223.856.en

Original instructions

Issue: 20120827

Version: 01

Document type: Installation Manual Appendix (IMA)

Sandvik

Stationsplan, SE-233 81 Svedala, Sweden

Tel: +46 (0)40 409000, Fax: +46 (0)40 409260

www.sandvik.com

A-3

IMA Sandvik CTHS430:02 Tank unit installation drawings

Appendix 1:

Tank unit installation drawings

A-4

2012 Sandvik SRP AB

S 223.856.en-01

IMA Sandvik CTHS430:02 Tank unit installation drawings

1.1 General

The following drawings show tank dimensions, connection positions and

dimensions, and access dimensions. All dimensions must be respected.

Dimensions are given in millimeters with inch dimension in brackets.

1.1.1 Mechanical drawings

1.1.2 Electrical and hydraulic drawings

1.1.3 Other documents

The tank can be installed on either side of the crusher.

Drawing name Drawing no. Note

Transportation drawing - Tank 452.5996

Installation outline - Tank 452.5995

Hose connection installation - with overview table 452.5584

Overpressure installation - with notes 452.6182

Element K7 Alt. 452.4911

Drawing name Drawing no. Note

Piping and Instrument diagram 452.6018

Connection diagram oil tank, standard 291.0053

Circuit diagram, standard 291.0052

Instrument list 195.0620

Sensor list 195.0621 Incl. ASRi

Document name

KPS 76-83 Danfoss Temperature setting on temperature switches TS1, TS2 and TS3

IMA Sandvik CTHS430:02 Tank unit installation drawings

A-5

2012 Sandvik SRP AB S 223.856.en-01

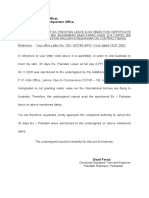

1.1.4 Lifting the tank

Drawing 452.5996: Transport drawing - Tank

Valid only with Installation Manual

The drawing shows the outer measures of the tank and how to lift it as safely

as possible.

Drain the tank completely from oil before lifting.

The tank must be lifted with suitable lifting slings. Always use both lifting

eyes mounted on the top.

Total maximum weight for the pair of lifting eyes is 350 kg (775 lbs).

The maximum angle between the lifting slings is 90.

The center of mass is shown with a sign (1):

1

A-6

2012 Sandvik SRP AB

S 223.856.en-01

IMA Sandvik CTHS430:02 Tank unit installation drawings

1.1.5 Mechanical connections

Drawing 452.5584: Hose connection installation with overview

table (standard and USA)

The drawing shows the points on the tank unit and the crusher where

connections are made. Each connection has a designation sign on or nearby

the connection point.

The table is an overview that shows general information about the

connections for the tank unit, the crusher and the accessories.

Abbreviations used in the table are:

STD for standard

Ext. for external threading

Int. for internal threading.

Hose connections CH/S430

Connection

line

Place Variant - seal

STD - 60 cone USA - 74 cone

N Crusher Ext. G 3/4"B Ext. JIC 1 1/16"-12

Tank Int. G 3/4" Ext. JIC 1 1/16"-12

M Crusher Ext. G 1 1/2"B Ext. JIC 1 7/8"-12

Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"-12

L Crusher Ext. R2" NPTF 2"-12

Tank Int. Rp 2" NPTF 2"-12

P Crusher Ext. G 3/4"B Ext. G 3/4"B

Tank Int. Rp 3/4" Int. Rp 3/4

Overpressure unit Int. Rp 3/4" Int. Rp 3/4

U Tank Int. Rp 1 1/4" Ext. JIC 1 7/8"-12

Air Cooler Int. Rp 1 1/4" Ext. JIC 1 7/8"-12

Water Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"-12

V Air Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"12

Water Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"-12

O Water Cooler Int. Rp 1 1/4" Ext. JIC 1 7/8"-12

J Water Cooler Int. Rp 1 1/4" Ext. JIC 1 7/8"-12

IMA Sandvik CTHS430:02 Tank unit installation drawings

A-7

2012 Sandvik SRP AB S 223.856.en-01

Drawing 452.6182: Overpressure installation with notes

Notes:

OA - The overpressure fan can be mounted either horizontal or vertical.

It is recommended to place it in a dust free area.

OB - Total hose length between the over-pressure unit and the crusher is

recommended to 2-15 m (6.6-40 ft).

OC - The regulator for compressed air should be adjusted at installation to be

between 600-1020 Pa (12.5-21.3 lb/ft

3

).

OD - It is important that the measure hose is mounted as the picture shows.

Otherwise there can be a vacuum in the measure hose, instead of over-

pressure and then the OPT1 transmitter will show zero value.

OE - Measuring hose for OPT1 in L11 (included in the delivery of L11).

Total hose lenght between the crusher and L11 is recommended to <25 m.

OF - Reference hose for OPT1 (mounted at the factory).

C - connection to crusher.

P - connection to tank.

VAR. 901 - Installation with fan without TIMS (Tank Instrumentation

Monitoring System).

VAR. 902 - Installation with fan with TIMS.

VAR. 903 - Installation with compressed air without TIMS.

A-8

2012 Sandvik SRP AB

S 223.856.en-01

IMA Sandvik CTHS430:02 Tank unit installation drawings

1.1.6 Piping and Instrument diagram

Drawing 452.6018

Designations

Position Description Note

B2N Pressure transmitter 25 MPa M12A Hydroset

B3N Temperature sensor TE2-Pt100 M12 ASRi

CB-T Connection box CBT ASRi

CV1 Check valve RP10A-01-C-N15-4 Hydroset

CV3 Check valve RV12A-01-C-N-05 Hydroset 1A

CV3 Check valve RV12A-01-C-N-05 Hydroset 1B

CV4 Valve by-pass 8 bar Main lubrication

CV5 Check valve RV25-01.1/0-3 Main lubrication

E7.1 Element K7 380V-1500W Main lubrication option

E7.2 Element K7 380V-1500W Main lubrication

E7.3 Element K7 380V-1500W Main lubrication

E7.4 Element K7 380V-1500W Main lubrication option

FS1 Level monitor Helifloat Main lubrication

FU1 Filter head PI 2214-47 R1 1/4 Main lubrication

FU1:a Oil filter HC 36 Main lubrication

FU3 Filter head PI 2205-56 Hydroset

FU3:a Filter cartridge HC2 Hydroset

FU4 Dirt trap SW/O 1 1/4-0,6mm Main lubrication

FU7 Dirt trap SW/O 1 1/4-0,6mm Main lubrication

FV8 Needle valve Hydroset

H10 Light emitting diode red 110-255 VAC D22 Main lubrication

HA1 Hydroset Valve 4.5 MPa As. Hydroset

LI1 Level indicator L=254mm M 12 Main lubrication

LI2 Level indicator L=508mm Hydroset

LV1 Check valve 1" w. drain 1/2" Main lubrication

M2 Motor 100-6 3611 400VY50 1,5 Main lubrication

M3 Motor IEC112-4 3001 440V50 4,0 Main lubrication

M6 Motor IEC 90-6 3011 400VY50 1,1 Hydroset

MP1 Measuring nipple G 1/4" Hydroset MA

MP2 Measuring nipple G 1/4" Hydroset MB

MP3 Measuring nipple G 1/4" Hydroset MC

OC1 Air/oil heat exchanger 400V50 1,5 kW Main lubrication

OC2 Heat exchanger HEX S722-40 Main lubrication

OS1 Oil screen Main lubrication

IMA Sandvik CTHS430:02 Tank unit installation drawings

A-9

2012 Sandvik SRP AB S 223.856.en-01

P1 Lubrication pump TG L 047-02 V Main lubrication

P2 Pump HPI P3 BAN 2004 L Hydroset

PI1 Manometer 100M20-2 0-6 MPa/PSI Hydroset

PI2 Manometer Pinionshaft lubrication

PS2 Pressure drop indicator PIS 3097/2,2Bar Main lubrication

RV2 Pressure relief valve 4.5MPa Hydroset

RV3 Pressure relief valve 4.5MPa Hydroset

RV4 Pressure relief valve 8.0MPa Hydroset

TI1 Thermometer Main lubrication

TS1 Thermostat KPS79 50-100C Main lubrication

TS2 Thermostat KPS77 20-60C Main lubrication

TS3 Thermostat KPS77 20-60C Main lubrication

TS4 Thermostat valve AVTA 25 Main lubrication

V1 Ball valve 1 1/4" Main lubrication

V10 Valve Shut-Off MA1-A1.1-SO4 Hydroset

V4 Ball valve 1/4" Hydroset

V5 Ball valve 1/2" Hydroset

Position Description Note

A-10

2012 Sandvik SRP AB

S 223.856.en-01

IMA Sandvik CTHS430:02 Tank unit installation drawings

This page is intentionally left blank

Valid only with installation Manual

01

1:10

1 1

2009-11-03

Xzn

Transport drawing - Tank

CTHS420/430

452.5996

Rev

No.

Date

Datum

Ritn.nr/Drawing No.

of

av Blad

Sheet

Skala/Scale Godk./Approved Beredd/Planned Konstr/Designed Ritad/Drawn Kontr./Checked Vyplacering

Proj. method

Gjutgods/Castings

ISO 8062-CT12 (SA 1121,300)

Toleransklass

Tolerance class

>4000mm

SS-ISO 2768-1-c

(SA 1121,100)

(SA 1121,100)

SS-ISO 2768-1-v

SS-ISO 2768-1-c

(SA 1121,100)

U-gngor/U-threads

SMS 1718-2A/2B (SA 1161,150)

(v) Mycket grov (c) Grov

(m) Medium

(m) Medel

M-gngor/M-threads

ISO 965-6H/6g (SA 1161,130)

Smltsvets.konstr / Welded constructions

SS-EN ISO 13920-B (SA 1121,200)

(c) Coarse (v) Very coarse

Svetsklasser enligt / Weld classes acc. to

SS-ISO 5817 (SA 1184,095)

Omej annat angivits gller / Unless otherwise specified

TOLERANSER/TOLERANCES

<4000mm

ISO 2768-1-m

(SA 1121,100)

ISO 2768-1-v

(SA 1121,100)

Generella toleranser fr linjra mtt och vinkelmtt/General tolerances for linear and angular dimensions

Bearb. med spnavskiljande verktyg (gller ej sgning)

Machined with cutting tools (does not include sawing)

Bearb. med icke spnavskiljande verktyg (inkluderar sgning)

Machined with non-cutting tools (includes sawing)

Fr brutna kanter och vinkelmtt

For broken edges and angular dimensions

Basmtt / Basic dimension :

E

Format

A3 s

u

p

p

o

r

t

o

f

t

h

e

e

x

is

t

in

g

la

w

.

T

h

is

d

r

a

w

in

g

a

n

d

a

ll t

h

e

e

n

c

lo

s

u

r

e

s

b

e

lo

n

g

t

o

u

s

. T

h

e

y

m

u

s

t

n

o

t

b

e

c

o

p

ie

d

o

r

d

u

p

lic

a

t

e

d

-

n

e

it

h

e

r

in

o

r

ig

in

a

l, n

o

r

in

m

o

d

if

ie

d

f

o

r

m

-

s

h

o

w

n

t

o

o

r

g

iv

e

n

t

o

a

t

h

ir

d

p

a

r

t

y

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

in

g

p

u

r

p

o

s

e

s

w

it

h

o

u

t

o

u

r

p

e

r

-

m

is

s

io

n

. A

s

t

o

in

f

r

in

g

e

m

e

n

t

s

h

e

r

e

o

f

, le

g

a

l a

c

t

io

n

w

ill b

e

t

a

k

e

n

w

it

h

t

h

e

mr1827Xzn

Nr.

Rev.

Ant.

No.

ndring

Modification

Datum

Date

Infrd

Changed

Godknd

Approved

00

01

See modification notice

2011-10-13

2009-11-18

mr1827

Xzn

mr1827

Xzn

Weight (Kg)

Vikt (kg)

310

(Skarpa kanter brytes / Sharp edges broken)

8

0

5

3

1

3

/

4

"

974 38 1/4"

4

0

7

1

6

"

516 20 1/4"

max. 90

Center of mass

Max. 350kg.

(Don't lift with oil in)

326 12 3/4"

456 18"

Center of mass

9DOLG RQO\ ZLWK LQVWDOODWLRQ 0DQXDO

m

i::ic

n

. /

: lc

in

frin

g

e

m

e

n

l: h

e

re

c

f, |e

g

c

| c

c

lic

n

w

i|| L

e

lc

k

e

n

w

ilh

lh

e

:u

p

p

c

rl c

f lh

e

e

x

i:lin

g

|c

w

.

I

h

i: c

rc

w

in

g

c

n

c

c

|| lh

e

e

n

c

|c

:u

re

: L

e

|c

n

g

lc

u

:. I

h

e

y

m

u

:l n

c

l L

e

c

c

p

ie

c

c

r c

u

p

|ic

c

le

c

- n

e

ilh

e

r in

c

rig

in

c

|, n

c

r in

m

c

c

ifie

c

fc

rm

- :h

c

w

n

lc

c

r

g

iv

e

n

lc

c

lh

irc

p

c

rly

c

r u

:e

c

fc

r m

c

n

u

fc

c

lu

rin

g

p

u

rp

c

:e

: w

ilh

c

u

l c

u

r p

e

r-

Fcr Lrcken ecge: cnc cngu|cr cimen:icn:

Fcr Lrulnc kcnler cch vinke|mcll

Mcchinec wilh ncn-culling lcc|: {inc|uce: :cwing)

8ecrL. mec icke :pcncv:ki|jcnce verklyg {ink|ucercr :cgning)

Mcchinec wilh culling lcc|: {cce: ncl inc|uce :cwing)

8ecrL. mec :pcncv:ki|jcnce verklyg {gc||er ej :cgning)

Genere||c lc|ercn:er fcr |injcrc mcll cch vinke|mcll/Generc| lc|ercnce: fcr |inecr cnc cngu|cr cimen:icn:

ICLEF/NSEF/ICLEF/NCES

Cmej cnncl cngivil: gc||er / Un|e:: clherwi:e :pecifiec

SS-EN lSC 1320-8 {S/ 1121,200)

Smc|l:vel:.kcn:lr / We|cec ccn:lruclicn:

SMS 1718-2//28 {S/ 111,150)

8c:mcll / 8c:ic cimen:icn :

lSC 5-H/g {S/ 111,130)

M-gcngcr/M-lhrecc:

{m) Mece|

{m) Mecium {c) Cccr:e

{c) Grcv

Filn.nr/Drcwing Nc.

8erecc/F|cnnec

lSC 278-1-m SS-lSC 278-1-c

{S/ 1121,100)

lSC 278-1-v

{S/ 1121,100)

SS-lSC 278-1-c

{S/ 1121,100)

SS-lSC 278-1-v

{S/ 1121,100)

{S/ 1121,100)

Svel:k|c::er en|igl / We|c c|c::e: ccc. lc

<4000mm

SS-lSC 5817 {S/ 1184,05)

lSC 802-CI12 {S/ 1121,300)

{v) Very cccr:e

{v) Myckel grcv

U-gcngcr/U-lhrecc:

>4000mm

Ic|ercnce c|c::

Ic|ercn:k|c::

Gjulgcc:/Cc:ling:

Filcc/Drcwn Kcn:lr/De:ignec

/2

Fcrmcl

Kcnlr./Checkec Gcck.//pprcvec Skc|c/Scc|e

1:10

Vyp|ccering

Frcj. melhcc

E

Dclum

Dcle

8|cc

1 Sheel

cv

1 cf

Nc.

Fev 01

Gcckcnc

/pprcvec

lnfcrc

Chcngec

Dclum

Dcle

/ncring

Mccificclicn

/nl.

Nc.

Nr.

Fev.

9LNW NJ

:HLJKW .J

ln:lc||clicn cul|ine - Icnk

CIHS420/430

Xzn mr1827Xzn

200-11-03

452.55

Xzn

mr1827

Xzn

mr1827

2009-11-06

2011-10-14

See modification notice

01

00

{Skcrpc kcnler Lryle: / Shcrp ecge: Lrcken)

5

0

3

7

1

/

2

7

7

0

3

0

1

/

4

5

2

1

/

2

4

0

2

5

1

/

4

1

8

3

/

4

11 47

115 45 1/2

1273 50

4

1

1

1

/

4

7

7

3

0

1

/

2

m

c

x

.

8

7

0

3

4

1

/

4

1

0

,

0

5

5

1

3

7

8

1

5

35 14

7

1

8

2

8

1

/

4

7

3

3

2

8

3

/

4

448 17 3/4 10 1/4

Ci| crcin

Ci| fi||ing

2

5

1

0

m

i::ic

n

. /

: lc

in

frin

g

e

m

e

n

l: h

e

re

c

f, |e

g

c

| c

c

lic

n

w

i|| L

e

lc

k

e

n

w

ilh

lh

e

:u

p

p

c

rl c

f lh

e

e

x

i:lin

g

|c

w

.

I

h

i: c

rc

w

in

g

c

n

c

c

|| lh

e

e

n

c

|c

:u

re

: L

e

|c

n

g

lc

u

:. I

h

e

y

m

u

:l n

c

l L

e

c

c

p

ie

c

c

r c

u

p

|ic

c

le

c

- n

e

ilh

e

r in

c

rig

in

c

|, n

c

r in

m

c

c

ifie

c

fc

rm

- :h

c

w

n

lc

c

r

g

iv

e

n

lc

c

lh

irc

p

c

rly

c

r u

:e

c

fc

r m

c

n

u

fc

c

lu

rin

g

p

u

rp

c

:e

: w

ilh

c

u

l c

u

r p

e

r-

Fcr Lrcken ecge: cnc cngu|cr cimen:icn:

Fcr Lrulnc kcnler cch vinke|mcll

Mcchinec wilh ncn-culling lcc|: {inc|uce: :cwing)

8ecrL. mec icke :pcncv:ki|jcnce verklyg {ink|ucercr :cgning)

Mcchinec wilh culling lcc|: {cce: ncl inc|uce :cwing)

8ecrL. mec :pcncv:ki|jcnce verklyg {gc||er ej :cgning)

Genere||c lc|ercn:er fcr |injcrc mcll cch vinke|mcll/Generc| lc|ercnce: fcr |inecr cnc cngu|cr cimen:icn:

ICLEF/NSEF/ICLEF/NCES

Cmej cnncl cngivil: gc||er / Un|e:: clherwi:e :pecifiec

SS-EN lSC 1320-8 {S/ 1121,200)

Smc|l:vel:.kcn:lr / We|cec ccn:lruclicn:

SMS 1718-2//28 {S/ 111,150)

8c:mcll / 8c:ic cimen:icn :

lSC 5-H/g {S/ 111,130)

M-gcngcr/M-lhrecc:

{m) Mece|

{m) Mecium {c) Cccr:e

{c) Grcv

Filn.nr/Drcwing Nc.

8erecc/F|cnnec

lSC 278-1-m SS-lSC 278-1-c

{S/ 1121,100)

lSC 278-1-v

{S/ 1121,100)

SS-lSC 278-1-c

{S/ 1121,100)

SS-lSC 278-1-v

{S/ 1121,100)

{S/ 1121,100)

Svel:k|c::er en|igl / We|c c|c::e: ccc. lc

<4000mm

SS-lSC 5817 {S/ 1184,05)

lSC 802-CI12 {S/ 1121,300)

{v) Very cccr:e

{v) Myckel grcv

U-gcngcr/U-lhrecc:

>4000mm

Ic|ercnce c|c::

Ic|ercn:k|c::

Gjulgcc:/Cc:ling:

Filcc/Drcwn Kcn:lr/De:ignec

/2

Fcrmcl

Kcnlr./Checkec Gcck.//pprcvec Skc|c/Scc|e

1:10

Vyp|ccering

Frcj. melhcc

E

Dclum

Dcle

8|cc

1 Sheel

cv

2 cf

Nc.

Fev 01

Gcckcnc

/pprcvec

lnfcrc

Chcngec

Dclum

Dcle

/ncring

Mccificclicn

/nl.

Nc.

Nr.

Fev.

V|kt [kg}

We|ght [Kg}

Hc:e ccnneclicn ln:lc||clicn

CH/S420, CH/S430

Xzn mr1827Xzn

200-03-27

452.5584

Xzn

mr1827

Xzn

mr1827

2009-09-07

2011-11-21

See modification notice

01

00

{Skcrpc kcnler Lryle: / Shcrp ecge: Lrcken)

8

I

M

N

F

8 [1 : 20}

F

F

M

N

I

b

O

WoterJo|| heot exchonger

J

V

M

b

b

A|rJo|| heot exchonger

V M

Drcwing 10.0175-00,

ilem 13 cnc 14

J

O

Drcwing 452.73-01,

ilem 30 cnc 31

Drcwing 452.73-01,

ilem 28 cnc 2

m

i::ic

n

. /

: lc

in

frin

g

e

m

e

n

l: h

e

re

c

f, |e

g

c

| c

c

lic

n

w

i|| L

e

lc

k

e

n

w

ilh

lh

e

:u

p

p

c

rl c

f lh

e

e

x

i:lin

g

|c

w

.

I

h

i: c

rc

w

in

g

c

n

c

c

|| lh

e

e

n

c

|c

:u

re

: L

e

|c

n

g

lc

u

:. I

h

e

y

m

u

:l n

c

l L

e

c

c

p

ie

c

c

r c

u

p

|ic

c

le

c

- n

e

ilh

e

r in

c

rig

in

c

|, n

c

r in

m

c

c

ifie

c

fc

rm

- :h

c

w

n

lc

c

r

g

iv

e

n

lc

c

lh

irc

p

c

rly

c

r u

:e

c

fc

r m

c

n

u

fc

c

lu

rin

g

p

u

rp

c

:e

: w

ilh

c

u

l c

u

r p

e

r-

Fcr Lrcken ecge: cnc cngu|cr cimen:icn:

Fcr Lrulnc kcnler cch vinke|mcll

Mcchinec wilh ncn-culling lcc|: {inc|uce: :cwing)

8ecrL. mec icke :pcncv:ki|jcnce verklyg {ink|ucercr :cgning)

Mcchinec wilh culling lcc|: {cce: ncl inc|uce :cwing)

8ecrL. mec :pcncv:ki|jcnce verklyg {gc||er ej :cgning)

Genere||c lc|ercn:er fcr |injcrc mcll cch vinke|mcll/Generc| lc|ercnce: fcr |inecr cnc cngu|cr cimen:icn:

ICLEF/NSEF/ICLEF/NCES

Cmej cnncl cngivil: gc||er / Un|e:: clherwi:e :pecifiec

SS-EN lSC 1320-8 {S/ 1121,200)

Smc|l:vel:.kcn:lr / We|cec ccn:lruclicn:

SMS 1718-2//28 {S/ 111,150)

8c:mcll / 8c:ic cimen:icn :

lSC 5-H/g {S/ 111,130)

M-gcngcr/M-lhrecc:

{m) Mece|

{m) Mecium {c) Cccr:e

{c) Grcv

Filn.nr/Drcwing Nc.

8erecc/F|cnnec

lSC 278-1-m SS-lSC 278-1-c

{S/ 1121,100)

lSC 278-1-v

{S/ 1121,100)

SS-lSC 278-1-c

{S/ 1121,100)

SS-lSC 278-1-v

{S/ 1121,100)

{S/ 1121,100)

Svel:k|c::er en|igl / We|c c|c::e: ccc. lc

<4000mm

SS-lSC 5817 {S/ 1184,05)

lSC 802-CI12 {S/ 1121,300)

{v) Very cccr:e

{v) Myckel grcv

U-gcngcr/U-lhrecc:

>4000mm

Ic|ercnce c|c::

Ic|ercn:k|c::

Gjulgcc:/Cc:ling:

Filcc/Drcwn Kcn:lr/De:ignec

/2

Fcrmcl

Kcnlr./Checkec Gcck.//pprcvec Skc|c/Scc|e

1:10

Vyp|ccering

Frcj. melhcc

E

Dclum

Dcle

8|cc

2 Sheel

cv

2 cf

Nc.

Fev 01

Gcckcnc

/pprcvec

lnfcrc

Chcngec

Dclum

Dcle

/ncring

Mccificclicn

/nl.

Nc.

Nr.

Fev.

V|kt [kg}

We|ght [Kg}

Hc:e ccnneclicn ln:lc||clicn

CH/S420, CH/S430

Xzn mr1827Xzn

200-03-27

452.5584

Xzn

mr1827

Xzn

mr1827

2009-09-07

2011-11-21

See modification notice

01

00

{Skcrpc kcnler Lryle: / Shcrp ecge: Lrcken)

STD - 60cone USA - 74cone STD - 60cone USA - 74cone

Crusher Ext. G 3/4"B Ext. JIC 1 1/16"-12 Crusher Ext. G 3/4"B Ext. JIC 1 1/16"-12

Tank Int. G 3/4" Ext. JIC 1 1/16"-12 Tank Int. G 3/4" Ext. JIC 1 1/16"-12

Crusher Ext. G 1 1/2"B Ext. JIC 1 7/8"-12 Crusher Ext. G 1 1/2"B Ext. JIC 1 7/8"-12

Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"-12 Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"-12

Crusher Ext. R2" NPTF 2"-12 Crusher Ext. R3" NPTF 3"-12

Tank Int. Rp 2" NPTF 2"-12 Tank Int. Rp 3" NPTF 3"-12

Crusher Ext. G 3/4"B Ext. G 3/4"B Crusher Ext. G 3/4"B Ext. G 3/4"B

Tank Int. Rp 3/4" Int. Rp 3/4 Tank Int. Rp 3/4" Int. Rp 3/4

Overpressure unit Int. Rp 3/4" Int. Rp 3/4 Overpressure unit Int. Rp 3/4" Int. Rp 3/4

Tank Int. Rp 1 1/4" Ext. JIC 1 7/8"-12 Tank Int. Rp 1 1/4" Ext. JIC 1 7/8"-12

Air Cooler Int. Rp 1 1/4" Ext. JIC 1 7/8"-12 Air Cooler Int. Rp 1 1/4" Ext. JIC 1 7/8"-12

Water Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"-12 Water Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"-12

Air Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"-12 Air Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"-12

Water Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"-12 Water Cooler Ext. G 1 1/2"B Ext. JIC 1 7/8"-12

O

Water Cooler Int. Rp 1 1/4" Ext. JIC 1 7/8"-12

O

Water Cooler Int. Rp 1 1/4" Ext. JIC 1 7/8"-12

J

Water Cooler Int. Rp 1 1/4" Ext. JIC 1 7/8"-12

J

Water Cooler Int. Rp 1 1/4" Ext. JIC 1 7/8"-12

Hose connections CH/S420

N

Variant - seal

M

Place

Connection

line

Hose connections CH/S430

N

M

Place

Variant - seal

Connection

line

L

P

U

V V

U

L

P

00

1:10

2 1

2010-04-21

Xzn

Overpressure installation

CH/S420, CH/S430, CH/S440, CH/S660

452.6182

Rev

No.

Date

Datum

Ritn.nr/Drawing No.

of

av Blad

Sheet

Skala/Scale Godk./Approved Beredd/Planned Konstr/Designed Ritad/Drawn Kontr./Checked Vyplacering

Proj. method

Gjutgods/Castings

ISO 8062-CT12 (SA 1121,300)

Toleransklass

Tolerance class

>4000mm

SS-ISO 2768-1-c

(SA 1121,100)

(SA 1121,100)

SS-ISO 2768-1-v

SS-ISO 2768-1-c

(SA 1121,100)

U-gngor/U-threads

SMS 1718-2A/2B (SA 1161,150)

(v) Mycket grov (c) Grov

(m) Medium

(m) Medel

M-gngor/M-threads

ISO 965-6H/6g (SA 1161,130)

Smltsvets.konstr / Welded constructions

SS-EN ISO 13920-B (SA 1121,200)

(c) Coarse (v) Very coarse

Svetsklasser enligt / Weld classes acc. to

SS-ISO 5817 (SA 1184,095)

Omej annat angivits gller / Unless otherwise specified

TOLERANSER/TOLERANCES

<4000mm

ISO 2768-1-m

(SA 1121,100)

ISO 2768-1-v

(SA 1121,100)

Generella toleranser fr linjra mtt och vinkelmtt/General tolerances for linear and angular dimensions

Bearb. med spnavskiljande verktyg (gller ej sgning)

Machined with cutting tools (does not include sawing)

Bearb. med icke spnavskiljande verktyg (inkluderar sgning)

Machined with non-cutting tools (includes sawing)

Fr brutna kanter och vinkelmtt

For broken edges and angular dimensions

Basmtt / Basic dimension :

E

Format

A3 s

u

p

p

o

r

t

o

f

t

h

e

e

x

is

t

in

g

la

w

.

T

h

is

d

r

a

w

in

g

a

n

d

a

ll t

h

e

e

n

c

lo

s

u

r

e

s

b

e

lo

n

g

t

o

u

s

. T

h

e

y

m

u

s

t

n

o

t

b

e

c

o

p

ie

d

o

r

d

u

p

lic

a

t

e

d

-

n

e

it

h

e

r

in

o

r

ig

in

a

l, n

o

r

in

m

o

d

if

ie

d

f

o

r

m

-

s

h

o

w

n

t

o

o

r

g

iv

e

n

t

o

a

t

h

ir

d

p

a

r

t

y

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

in

g

p

u

r

p

o

s

e

s

w

it

h

o

u

t

o

u

r

p

e

r

-

m

is

s

io

n

. A

s

t

o

in

f

r

in

g

e

m

e

n

t

s

h

e

r

e

o

f

, le

g

a

l a

c

t

io

n

w

ill b

e

t

a

k

e

n

w

it

h

t

h

e

mor Xzn

Nr.

Rev.

Ant.

No.

ndring

Modification

Datum

Date

Infrd

Changed

Godknd

Approved

00

2011-03-18

Xzn

Xzn

Weight (Kg)

Vikt (kg)

(Skarpa kanter brytes / Sharp edges broken)

15

30 200

F-F

173

125 24

4x 9

6

0

1

0

9

0

B (1 : 5)

C

P

C

P

OF

C

P

Approx. 50

E (1 : 5)

OD

5

4

2

2

9

5

2

4

7

B

A

1

3

2

6

5

301

4

6

0

4

2

0

4

0

0

4

5

0

327

400

4x 8,5

473

A

F

F

VAR-902

VAR-901

VAR-903

OB

OA

OB

OA

OC

OB

OA

L11

OE

OPT1

NOTES:

OA - The over pressure blower can be mounted horisontal and vertical. Its recomended to place the it in a dust free area.

OB - Total hose lenght betwen overpressure unitand crusher are recomended to 2-15 meters

OC - The regulator for compressed air should be adjusted at instalation to be between 600-1020 Pa

OD - Its important that the measure hose is mounted as the picture shown. Otherwise there can be vacuum in the measure

hose instead of overpressure then the OPT1 transmitter shown zero value.

OE - Measuring hose for OPT1 in -L11 ( Included in the delivery of -L11 )Total hose lenght betwen crusher and -L11 are

recomended to < 25 meters

OF - Reference hose for OPT1 ( Mounted from factory )

C - connection to crusher. P - connection to tank

VAR. 901 - Installation with fan without TIMS

VAR. 902 - Installation with fan with TIMS

VAR. 903 - Installation with compressed air without TIMS

00

1:10

2 2

2010-04-21

Xzn

Overpressure installation

CH/S420, CH/S430, CH/S440, CH/S660

452.6182

Rev

No.

Date

Datum

Ritn.nr/Drawing No.

of

av Blad

Sheet

Skala/Scale Godk./Approved Beredd/Planned Konstr/Designed Ritad/Drawn Kontr./Checked Vyplacering

Proj. method

Gjutgods/Castings

ISO 8062-CT12 (SA 1121,300)

Toleransklass

Tolerance class

>4000mm

SS-ISO 2768-1-c

(SA 1121,100)

(SA 1121,100)

SS-ISO 2768-1-v

SS-ISO 2768-1-c

(SA 1121,100)

U-gngor/U-threads

SMS 1718-2A/2B (SA 1161,150)

(v) Mycket grov (c) Grov

(m) Medium

(m) Medel

M-gngor/M-threads

ISO 965-6H/6g (SA 1161,130)

Smltsvets.konstr / Welded constructions

SS-EN ISO 13920-B (SA 1121,200)

(c) Coarse (v) Very coarse

Svetsklasser enligt / Weld classes acc. to

SS-ISO 5817 (SA 1184,095)

Omej annat angivits gller / Unless otherwise specified

TOLERANSER/TOLERANCES

<4000mm

ISO 2768-1-m

(SA 1121,100)

ISO 2768-1-v

(SA 1121,100)

Generella toleranser fr linjra mtt och vinkelmtt/General tolerances for linear and angular dimensions

Bearb. med spnavskiljande verktyg (gller ej sgning)

Machined with cutting tools (does not include sawing)

Bearb. med icke spnavskiljande verktyg (inkluderar sgning)

Machined with non-cutting tools (includes sawing)

Fr brutna kanter och vinkelmtt

For broken edges and angular dimensions

Basmtt / Basic dimension :

E

Format

A3 s

u

p

p

o

r

t

o

f

t

h

e

e

x

is

t

in

g

la

w

.

T

h

is

d

r

a

w

in

g

a

n

d

a

ll t

h

e

e

n

c

lo

s

u

r

e

s

b

e

lo

n

g

t

o

u

s

. T

h

e

y

m

u

s

t

n

o

t

b

e

c

o

p

ie

d

o

r

d

u

p

lic

a

t

e

d

-

n

e

it

h

e

r

in

o

r

ig

in

a

l, n

o

r

in

m

o

d

if

ie

d

f

o

r

m

-

s

h

o

w

n

t

o

o

r

g

iv

e

n

t

o

a

t

h

ir

d

p

a

r

t

y

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

in

g

p

u

r

p

o

s

e

s

w

it

h

o

u

t

o

u

r

p

e

r

-

m

is

s

io

n

. A

s

t

o

in

f

r

in

g

e

m

e

n

t

s

h

e

r

e

o

f

, le

g

a

l a

c

t

io

n

w

ill b

e

t

a

k

e

n

w

it

h

t

h

e

mor Xzn

Nr.

Rev.

Ant.

No.

ndring

Modification

Datum

Date

Infrd

Changed

Godknd

Approved

00

2011-03-18

Xzn

Xzn

Weight (Kg)

Vikt (kg)

(Skarpa kanter brytes / Sharp edges broken)

984.0671-00 575 50 or 60 332 50 or 60 1,64

984.0607-00 380 50 or 60 1,125

Part No.

Art. Nr.

Voltage Y (V)

Spnning Y (V)

Frequency Y

Voltage D (V)

Spnning D (V)

Frequency D

Effect (kW)

Effekt (kW)

Voltage Alt. List

2 1 984.0671-00 Element K7 575/332V-1640W 1.5

1 1 984.0607-00 Element K7 380V-1125W 1.5

Item No.

Pos. Nr.

452.4911-901

Part No.

Art. Nr.

Description

Benmning

Material

Material

Weight

Vikt

01

1:2

1 1

2008-05-07

hsv

Element Alt.

Element Alt.

452.4911

Rev

No.

Date

Datum

Ritn.nr/Drawing No.

of

av Blad

Sheet

Skala/Scale Godk./Approved Beredd/Planned Konstr/Designed Ritad/Drawn Kontr./Checked Vyplacering

Proj. method

Gjutgods/Castings

ISO 8062-CT12 (SA 1121,300)

Toleransklass

Tolerance class

>4000mm

SS-ISO 2768-1-c

(SA 1121,100)

(SA 1121,100)

SS-ISO 2768-1-v

SS-ISO 2768-1-c

(SA 1121,100)

U-gngor/U-threads

SMS 1718-2A/2B (SA 1161,150)

(v) Mycket grov (c) Grov

(m) Medium

(m) Medel

M-gngor/M-threads

ISO 965-6H/6g (SA 1161,130)

Smltsvets.konstr / Welded constructions

SS-EN ISO 13920-B (SA 1121,200)

(c) Coarse (v) Very coarse

Svetsklasser enligt / Weld classes acc. to

SS-ISO 5817 (SA 1184,095)

Omej annat angivits gller / Unless otherwise specified

TOLERANSER/TOLERANCES

<4000mm

ISO 2768-1-m

(SA 1121,100)

ISO 2768-1-v

(SA 1121,100)

Generella toleranser fr linjra mtt och vinkelmtt/General tolerances for linear and angular dimensions

Bearb. med spnavskiljande verktyg (gller ej sgning)

Machined with cutting tools (does not include sawing)

Bearb. med icke spnavskiljande verktyg (inkluderar sgning)

Machined with non-cutting tools (includes sawing)

Fr brutna kanter och vinkelmtt

For broken edges and angular dimensions

Basmtt / Basic dimension :

E

Format

A3 s

u

p

p

o

r

t

o

f

t

h

e

e

x

is

t

in

g

la

w

.

T

h

is

d

r

a

w

in

g

a

n

d

a

ll t

h

e

e

n

c

lo

s

u

r

e

s

b

e

lo

n

g

t

o

u

s

. T

h

e

y

m

u

s

t

n

o

t

b

e

c

o

p

ie

d

o

r

d

u

p

lic

a

t

e

d

-

n

e

it

h

e

r

in

o

r

ig

in

a

l, n

o

r

in

m

o

d

if

ie

d

f

o

r

m

-

s

h

o

w

n

t

o

o

r

g

iv

e

n

t

o

a

t

h

ir

d

p

a

r

t

y

o

r

u

s

e

d

f

o

r

m

a

n

u

f

a

c

t

u

r

in

g

p

u

r

p

o

s

e

s

w

it

h

o

u

t

o

u

r

p

e

r

-

m

is

s

io

n

. A

s

t

o

in

f

r

in

g

e

m

e

n

t

s

h

e

r

e

o

f

, le

g

a

l a

c

t

io

n

w

ill b

e

t

a

k

e

n

w

it

h

t

h

e

mkn hsv

Nr.

Rev.

Ant.

No.

ndring

Modification

Datum

Date

Infrd

Changed

Godknd

Approved

00

01 Voltage 220-240 removed

See modification note

2010-02-17

2009-04-14

Xzn

Xzn

Xzn

Xzn

Weight (Kg)

Vikt (kg)

(Skarpa kanter brytes / Sharp edges broken)

A-A

A

A

1 2

A-A

Voltage Y Voltage D

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

SANDVIK MINING AND CONSTRUCTION

Sandvik SRP AB SE-233 81 Svedala, Sweden

INSTRUMENT LIST

Plant:

Equipment Tag No:

Equipment Name: HYDROCONE CH/CS-420/430

Equipment Supplier:

INSTRUMENT TYPE APPLICATION REMARKS

Plant SRP Model Range Part No. Manufacturer

Tag No. Tag No.

-TI1 Thermometer Return oil temperature (main) ICF 60 0-120C 923.0192-00 LTR Lubr. system

-PI1 Pressure gauge Hydroset pressure 100M20-2 0-6 MPa 923.0379-00 Tempress Hydroset system

-PI2 Pressure gauge Oil pressure (main) 2748 D63 0-1.6 MPa 923.0193-00 Wika Lubr. system

-LI1 Oil level indicator Oil level in tank (main) H00361-007 High/Low 914.0170-00 Parker Hannifin Lubr. system

-LI2 Oil level indicator Oil level in tank (Hydroset) H00361-010 High/Low 914.0174-00 Parker Hannifin Hydroset system

IDENTIFICATION INSTRUMENT DETAILS

SANDVIK ROCK PROCESSING

Sandvik Rock Processing

Rev: 02

Date: 2012-04-05/ RRe

195.0620 instrument list ch_cs-420_430.xls

1 (1) .

0

6

0

R

9

3

0

1

0

6

0

R

9

3

0

1

IC.PI.P10.J1.00-520B2598

Thermostats

KPS 76 - 83

Instructions

T2 max.

(C)

T1 min.

(C)

T1 max.

(C)

KPS 76 80

40 70

KPS 77 130

KPS 79 200

KPS 80 220

KPS 81 250

KPS 83 300

L

(mm)

Ms St.18/8

75 060L326266 060L326766

110 060L327166 060L326866

160 060L326366 060L326966

10(6) A, 440 V a.c. L.R. 50A

220V, 12 W d.c. PILOT

2 IC.PI.P10.J1.00-520B2598

D

a

n

f

o

s

s

A

/

S

,

A

C

-

D

S

L

,

m

r

,

0

5

-

2

0

0

6

Type Code no. Dif. (C)

KPS 79 060L314166 9

KPS 83

060L313966

18

060L314066

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Isometric Sketch SheetDocument1 pageIsometric Sketch SheetPatricio TamayoNo ratings yet

- Estimating Costs of Dust Control Systems: Neceissity For Cost EstimatesDocument10 pagesEstimating Costs of Dust Control Systems: Neceissity For Cost EstimatesPatricio TamayoNo ratings yet

- CTHS430-02 SPC R223.1394-01Document82 pagesCTHS430-02 SPC R223.1394-01Patricio Tamayo100% (1)

- CTHS430-02 IM S223.855.en-01Document80 pagesCTHS430-02 IM S223.855.en-01Patricio Tamayo100% (2)

- CH430-02 WPC R223.1403-01Document22 pagesCH430-02 WPC R223.1403-01Patricio Tamayo100% (3)

- CTHS430-02 OMM S223.857.en-01Document118 pagesCTHS430-02 OMM S223.857.en-01Patricio Tamayo100% (5)

- 0 CH430-02 Declaration of Conformity S058.203.en-01Document1 page0 CH430-02 Declaration of Conformity S058.203.en-01Patricio TamayoNo ratings yet

- Seilzugschalter Kiepe PRS GBDocument30 pagesSeilzugschalter Kiepe PRS GBPatricio TamayoNo ratings yet

- Technische Daten MRS 001 (GB)Document2 pagesTechnische Daten MRS 001 (GB)Patricio TamayoNo ratings yet

- Schieflaufschalter-Kiepe MRS001 - GBDocument16 pagesSchieflaufschalter-Kiepe MRS001 - GBPatricio TamayoNo ratings yet

- Back To Article 39: Sample Example of A 2-Branch System With A Single Centrifugal Pump First Pipe BranchDocument3 pagesBack To Article 39: Sample Example of A 2-Branch System With A Single Centrifugal Pump First Pipe BranchPatricio TamayoNo ratings yet

- RepairDocument0 pagesRepairPatricio TamayoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 4df16180-cfb8-4594-95dc-360e7bcc5809Document10 pages4df16180-cfb8-4594-95dc-360e7bcc5809Swamy Dhas DhasNo ratings yet

- Change ManagementDocument20 pagesChange ManagementDrRameesha KalraNo ratings yet

- CMAA Standards of Practice PDFDocument131 pagesCMAA Standards of Practice PDFNjilou Lagatic100% (2)

- Cerro Corona RelaveraDocument81 pagesCerro Corona RelaveraRDario Dario Rosemary0% (1)

- WWW Guru99 ComDocument22 pagesWWW Guru99 ComAbu Nilu Mostofa JamalNo ratings yet

- Variable Speed DrivesDocument44 pagesVariable Speed Drivesmnt6176100% (2)

- Annexure D - SPIR PDFDocument4 pagesAnnexure D - SPIR PDFharmlesdragonNo ratings yet

- QSP 23 - Quality Assurance (R0) 010105Document10 pagesQSP 23 - Quality Assurance (R0) 010105ukali_csNo ratings yet

- Design For ExcellenceDocument22 pagesDesign For ExcellencePradeep N BNo ratings yet

- Project Initiation PhaseDocument19 pagesProject Initiation PhaseMOHAMMED ELKADIKINo ratings yet

- WPQT PHSSDocument1 pageWPQT PHSSFerdie OSNo ratings yet

- Iso 12944Document4 pagesIso 12944Kiran Kumar Yanmangandla100% (2)

- Non-Crimp Fabric CompositesDocument1 pageNon-Crimp Fabric CompositesMehmood AhmedNo ratings yet

- SINOPEC Lubricant CompanyDocument2 pagesSINOPEC Lubricant CompanyRaisul Islam NayanNo ratings yet

- SYS BIOS Inter-Processor Communication (IPC) and IO User's GuideDocument150 pagesSYS BIOS Inter-Processor Communication (IPC) and IO User's Guidemail87523No ratings yet

- Piled Foundation ReportDocument7 pagesPiled Foundation ReportDijo Mathews100% (1)

- P3 Summary ModelsDocument4 pagesP3 Summary ModelsMahfuzah MjNo ratings yet

- How To Modify SAP Released Transport To Unreleased Status - SAP BASIS ANSWERS - SAP BASIS ADMIN BLOGDocument2 pagesHow To Modify SAP Released Transport To Unreleased Status - SAP BASIS ANSWERS - SAP BASIS ADMIN BLOGivanNo ratings yet

- VUETRADE Installation Guide T Blade Post Supports - Vers2Document3 pagesVUETRADE Installation Guide T Blade Post Supports - Vers2saagar8No ratings yet

- Retrofit Masterpact M PlugnplayDocument21 pagesRetrofit Masterpact M Plugnplaynot bookNo ratings yet

- Technical Information Letter: Power Services Engineering TIL 2055-R1 Product ServiceDocument6 pagesTechnical Information Letter: Power Services Engineering TIL 2055-R1 Product ServiceMuratNo ratings yet

- Project Control Techniques - Variance ControlDocument9 pagesProject Control Techniques - Variance ControlgerrymolloyNo ratings yet

- The Chief Personnel Officer, Pakistan Railways Headquarters OfficeDocument7 pagesThe Chief Personnel Officer, Pakistan Railways Headquarters OfficesaadfarazkhanNo ratings yet

- Codes Standards Pubs UpdateDocument30 pagesCodes Standards Pubs UpdatejosethompsonNo ratings yet

- FujitsuDocument2 pagesFujitsuMei-Ann FloraNo ratings yet

- BAR-US SimGrip Product Brochure EnglishDocument19 pagesBAR-US SimGrip Product Brochure EnglishBarusRebarCouplersNo ratings yet

- Fire Departments - Safety Checklist For Fire Station Facility (Final)Document2 pagesFire Departments - Safety Checklist For Fire Station Facility (Final)DAVE HOWARDNo ratings yet

- Assignment 1: Vacuum Forming of Thermoplastic Sheets: CPB 30603-Qa & QC in Chemical Engineering TaskDocument9 pagesAssignment 1: Vacuum Forming of Thermoplastic Sheets: CPB 30603-Qa & QC in Chemical Engineering TaskSiti Hajar MohamedNo ratings yet

- Mitsubishi Manuals 538Document242 pagesMitsubishi Manuals 538Nui DirekNo ratings yet

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Document2 pagesRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)