Professional Documents

Culture Documents

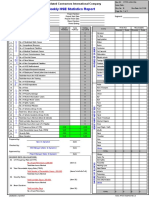

2013 OH&S Strategic Plan Scorecard

Uploaded by

rodrigo_gon57Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2013 OH&S Strategic Plan Scorecard

Uploaded by

rodrigo_gon57Copyright:

Available Formats

2013 OH&S Strategic Plan - FSAO DRAFT

Recommended Actions & Agreement Summary

Purpose and Desired Outcomes

Continuously improve an environment that ensures the health and safety of the workforce, while meeting or exceeding legal requirements. Zero

injuries and Healthy Employees- 24/7 .Drive to ZERO fatalities and serious injuries

2013 OBJECTIVES

WHAT

Target - ( Stretch targets for Fatalities and SII = Zero)

SBC

1.1 Improve the Safety Metrics targets/Stretchs

Fatalities # (e/c/jv)

Serious Injuries # (e/c/jv)

HPI:SII Ratio

FTOV Rate

LTCR

Occupational Absence Rate

DART Rate

LTCR - Contractors in construction

LTCR - Services Contractors

Fire Incidence Rate

1.2 Achieve the Leading Safety Metrics targets

% Closure to Plan of Corporate PCAs

Safe Behavior Index (red observations)

Near Miss Ratio

Resolution Index

8D Quality and Tracking

Integrated Safety Risk Assess.

Percent of workstations assessed (S /IH/Ergo)

Red workstations

Yellow workstations

Ergo Assessment (EST) to 100% of productive jobs by end 1stQtr

% of improvement on Red workstations

TBT

CAM

TPG

PAC

VAP

Troller

FSAO

zero

zero

zero

zero

zero

zero

zero

zero

30%

50%

30%

zero

100%

100%

zero

20%

>5

>5

>5

>5

>5

>5

>5

>5

improve

improve

improve

improve

improve

improve

improve

improve

5%

5%

5%

5%

5%

5%

5%

5%

5%

0%

5%

0%

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

0%

0%

10%

0%

10%

10%

0%

10%

10%

10%

10%

10%

10%

10%

0%

10%

10%

10%

10%

0%

20%

0%

0%

10%

100%

100%

100%

100%

100%

100%

100%

100%

<3%

<3%

<3%

<3%

<3%

<3%

<3%

<3%

1:80

1:80

1:80

1:80

1:80

1:80

1:80

1:80

>95%

>95%

>95%

>95%

>95%

>95%

>80%

>95%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

TBD

TBD

TBD

TBD

TBD

TBD

TBD

TBD

15%

15%

15%

15%

15%

15%

15%

15%

100%

100%

100%

100%

100%

100%

100%

100%

TBD

TBD

TBD

TBD

TBD

TBD

TBD

TBD

WHO

WHEN

Plant Mgrs & OHS

Plant & ME Mgrs

Jun-13

1s. Qtr 2013

Plant Mgrs

Plant Mgrs & OHS

Plant Mgrs & OHS

Plant Mgrs & Medical

Plant Mgrs & Medical

1s. Qtr 2013

Monthly

Bi-monthly

Monthly

Quarterly

2. Monitor, Measure, Analyze and Report Performance

Conduct the facility/regional SPRB reviews according with the TD&M

Track and communicate H&S performance via the BPR process

Plant Mgrs & OHS

Plant Mgrs & OHS

Monthly Review

Monthly Review

3. Verify Processes and Conduct Audits

Conduct integrated FPS/SOS self-Assessments/Validation

Ensure 100% adherence to in plant Change Management procedure.

Drive PPE and PTA standard compliance.

Verify safety PMs in Maximo by Plant Safety.

Plant Mgrs & OHS

Plant & ME Mgrs

Plant Mgrs & OHS

Plant Mgrs & OHS

Bi-annual

Bi-annual

Monthly Review

Monthly Review

Drive increased reporting of high potential incidents and implement agreed global improvements.

Plant Mgrs & OHS

As Occurred

Share improvement actions identified as part of the global 8D reviews

Plant Mgrs & OHS

As Occurred

Plant Mgrs & OHS

Plant Mgrs & Medical

1s. Qtr 2013

Monthly Review

Plant Mgrs & OHS

Plant Mgrs & OHS

Daily

As Occurred

Plant Mgrs & OH&S

1s. Qtr 2013

1. Identify, Control and Manage Health & Safety Risk

Measure and minimize pedestrian/PMHV shared zones

Develop local safety plan to Implement Service and Construction contractor management program,

ensure tier 2 and 3 are covered

Implement global driver safety improvement programs.

Control adverse workplace chemical and ergonomic exposures.

Each plant to have local top 6 action plan (safety six-pack)

Drive an effective Case Management Process at each plant

Conduct health promotion and risk control programs.

4 - Develop and Implement Systemic & Sustainable Preventative and Corrective Actions

5 - Manage Compliance to Legal Requirements

1.3 Achieve the medical metrics target

Case Management (No. of lost days per case)

Medical Absenteeism reduction

Medical Surveillance compliance

Develop and implement OHS legal compliance matrix in all plants

>95% Medical Surveillance compliance

5%

5%

5%

5%

5%

5%

5%

5%

3%

>95%

3%

>95%

3%

>95%

3%

>95%

3%

>95%

3%

>95%

3%

>95%

3%

>95%

Health Promotion Interventions (4-pack)

1.4 Verify Safety Processes and Conduct Audits

100%

100%

100%

100%

100%

100%

100%

100%

Visible daily safety leadership at all levels

100%

100%

100%

100%

100%

100%

100%

100%

Implement the SPL and simple guides to the critical standards in FSAO locations.

Conduct integrated FPS/SOS self-assessments during 2013.

TBD

TBD

TBD

TBD

TBD

TBD

TBD

TBD

Strategic Considerations

Leverage technical competency model to ensure capability for all SOS roles .

Leverage communication system to maintain awareness at all levels.

Identification of the top 6 failures of safety programs and address with 6-Pack approach

Continue Efforts on Employee health promotion, prevention and risk control

Securing adequate funding for facility safety improvements

6. Communicate, Train and Coach

Perform a gap analysis on technical knowleage / skills of the H&S plant professionals to enable

them to be capable to coach / support all SOS key process requirements through a technical training

plan.

2013 Ford South America OHS Scorecard

A. Reactive Safety Indicators (performance YTD)

1. First Time Occupational Visits

(FTOV's)

Number of cases per month

Oct

Nov

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

18

2

0

4

7

8

5

44

5

4

0

6

14

11

0

40

13

7

0

5

18

17

2

62

27

4

0

7

9

18

5

70

11

4

0

6

14

11

5

51

13

5

0

4

7

5

3

37

24

4

0

5

7

4

6

50

20

5

0

7

9

11

4

56

13

2

0

2

11

12

6

46

Jan

Feb

Mar

Apr

Sep

Oct

Nov

2

0

0

1

2

0

0

5

0

0

0

0

3

1

0

4

3

1

0

0

1

1

0

6

1

2

0

0

2

1

0

6

1

0

0

0

7

0

0

8

3. Occupational Absence Rate

(OAR)

Jan

Feb

Mar

Apr

May

Jun

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP) *

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

328

0

0

557

77

22

0

984

136

0

0

402

80

3

0

621

287

18

0

405

94

21

0

825

360

25

0

447

97

21

0

950

268

20

0

634

116

31

0

1069

271

40

0

632

97

20

0

1060

4. Days Away & Restricted Time

Case Rate (DART)

Jan

Feb

Mar

Apr

6

0

0

3

2

1

0

12

0

0

0

2

5

2

0

9

6

1

0

0

2

3

0

12

6

2

0

3

3

3

0

17

Jan

Feb

Mar

Apr

0

0

0

0

2

0

0

2

0

0

0

0

1

0

0

1

1

1

0

0

0

1

0

3

0

0

0

0

0

1

0

1

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP) *

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

2. Lost-Time Case Rate (LTCR)

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP) *

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP)

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

5. Serious Injuries and Illnesses (SII)

- EMPLOYEES

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP)

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

Number of cases per month

May

Jun

Jul

Aug

1

0

0

0

4

0

0

5

0

0

0

1

2

0

0

3

Cases 2013

YTD

Cases 2012

YE

FTOVR 2013

YTD

FTOVR

2012 YE

2013 Obj.

(improve)

B/W than

2012

G/Y/R

Status

144

37

0

46

96

97

36

456

114

49

2

47

180

215

46

653

4.22

2.64

0.00

1.60

3.35

5.55

9.96

3.54

2.91

2.73

0.80

1.34

4.60

8.72

10.02

4.01

2.88

2.70

0.79

1.33

4.55

8.63

9.92

3.97

-45%

3%

100%

-19%

27%

36%

1%

12%

R

R

G

R

G

G

G

G

Cases 2013

YTD

Cases 2012

YE

LTCR 2013

YTD

LTCR 2012

YE

2013 Obj. (5%)

Dec

B/W than

2012

G/Y/R

Status

13

5

0

1

41

6

1

67

0.26

0.21

0.00

0.07

1.15

0.17

0.00

0.39

0.33

0.28

0.00

0.03

1.05

0.24

0.22

0.41

0.31

0.27

0.00

0.03

1.00

0.23

0.21

0.39

20%

24%

#DIV/0!

-131%

-10%

28%

100%

5%

G

G

G

R

R

G

G

G

2013 Obj. (5%)

B/W than

2012

G/Y/R

Status

84.8

13.6

0.0

238.6

23.3

2.9

0.4

79.2

21%

29%

#DIV/0!

26%

-27%

-177%

100%

17%

G

G

G

G

R

R

G

G

2013 Obj. (5%)

B/W than

2012

G/Y/R

Status

Dec

1

0

0

0

5

0

0

6

0

0

0

0

7

0

0

7

9

3

0

2

33

3

0

50

Jul

Aug

Sep

Oct

Nov

Dec

Lost days

2013 YTD

268

40

0

855

109

21

0

1293

255

0

0

800

71

10

0

1136

232

0

0

613

151

0

0

996

2405

143

0

5345

892

149

0

8934

Number of cases per month

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Cases 2013

YTD

44

7

0

18

47

25

1

142

1.23

0.28

0.00

0.56

1.36

0.74

0.00

0.89

1.12

0.39

0.00

0.51

1.20

1.01

0.22

0.87

1.06

0.37

0.00

0.48

1.14

0.96

0.21

0.83

-10%

27%

#DIV/0!

-9%

-14%

26%

100%

-2%

R

G

G

R

R

G

G

R

SII 2012

YE

2013 Obj. (FSAO

15%)

B/W than

2012

G/Y/R

Status

0.102

0.167

0.000

0.029

0.051

0.081

0.000

0.074

0.087

0.142

0.000

0.025

0.043

0.069

0.000

0.063

71%

57%

#DIV/0!

100%

-516%

-41%

#DIV/0!

-37%

G

G

G

G

R

R

G

R

Monthly Number of lost days

5

0

0

4

8

1

0

18

6

1

0

2

5

0

0

14

4

0

0

1

2

0

0

7

4

0

0

1

5

0

0

10

Number of cases per month

May

Jun

Jul

Aug

0

0

0

0

1

0

0

1

0

0

0

0

1

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

2

0

0

2

lost days 2012 OAR 2013 YTD OAR 2012

YE

YE

3,497

256

0

8,778

960

76

2

13,569

70.47

10.18

0.00

185.42

31.16

8.52

0.00

69.45

Cases 2012 DART 2013 YTD DART 2012

YE

YE

5

0

0

0

7

3

0

15

42

4

0

16

39

13

0

114

Oct

Nov

Dec

Cases 2013

YTD

Cases 2012

YE

SII 2013 YTD

Sep

1

1

0

0

9

2

0

13

4

3

0

1

2

2

0

12

0.029

0.071

0.000

0.000

0.314

0.114

0.000

0.101

0

0

0

0

2

0

0

2

89.31

14.28

0.00

251.12

24.54

3.08

0.44

83.37

2013 Ford South America OHS Scorecard

6. Serious Injuries and Illnesses (SII)

- CONTRACTS

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP)

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

Jan

Feb

Mar

Apr

0

0

0

0

0

0

0

0

1

0

0

1

1

0

0

3

0

0

0

2

0

0

0

2

0

0

0

0

1

0

0

1

Jan

Feb

Mar

Apr

0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Jan

Feb

Mar

Apr

0

0

0

0

1

0

0

1

1

2

0

1

3

1

0

8

0

0

0

2

0

1

0

3

0

0

0

0

5

0

0

5

Jan

Feb

Mar

Apr

0

0

0

0

0

0

0

0

0

0

0

0

2

0

0

2

0

0

0

0

0

0

0

0

1

0

0

0

2

0

1

4

7. Contractor LTCR (Construction)

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP)

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

8. Contractor LTCR (Services

/suppliers)

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP)

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

10. Fire Incident Rate

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP)

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

Number of cases per month

May

Jun

Jul

Aug

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

1

0

0

0

1

0

0

0

1

0

0

0

1

0

0

0

1

Number of cases per month

May

Jun

Jul

Aug

0

0

0

0

0

0

1

1

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

1

0

0

0

1

0

0

0

1

Number of cases per month

May

Jun

Jul

Aug

1

0

0

1

1

1

0

4

0

0

0

1

1

1

0

3

0

0

0

1

4

1

0

6

0

0

0

1

0

1

1

3

Number of cases per month

May

Jun

Jul

Aug

0

1

0

0

0

0

0

1

0

0

0

0

0

0

0

0

0

1

0

0

1

0

0

2

0

0

0

0

0

0

1

1

G= Better than Obj.

GYR Code:

Sep

Oct

Nov

Cases 2013

YTD

Cases 2012

YE

C-LTCR 2013

YTD

C-LTCR

2012 YE

2013 Obj. (FSAO

Dec

15%)

B/W than

2011

G/Y/R

Status

1

0

1

6

0

1

0

9

0.139

0.000

0.000

0.122

0.192

0.000

0.000

0.111

0.052

0.000

0.181

0.076

0.000

0.220

0.000

0.068

0.044

0.000

0.154

0.065

0.000

0.187

0.000

0.058

-167%

#DIV/0!

100%

-61%

-200%

100%

#DIV/0!

-63%

R

G

G

R

R

G

G

R

1

0

0

0

0

0

0

1

2

0

0

6

2

0

0

10

Sep

Oct

Nov

Dec

Cases 2013

YTD

Cases 2012

YE

C-LTCR 2013

YTD

C-LTCR

2012 YE

2013 C-LTCR

Obj.(5%)

B/W than

2012

G/Y/R

Status

1

0

0

3

3

0

0

7

3.57

0.00

0.00

0.11

0.53

0.00

0.72

0.28

0.39

0.00

0.00

0.24

0.97

0.00

0.00

0.37

0.37

0.00

0.00

0.23

0.92

0.00

0.00

0.35

-815%

#DIV/0!

#DIV/0!

56%

46%

#DIV/0!

#DIV/0!

23%

R

G

G

G

G

G

R

G

0

0

0

0

0

0

0

0

1

0

0

1

1

0

1

4

Sep

Oct

Nov

Dec

Cases 2013

YTD

Cases 2012

YE

C-LTCR 2013

YTD

C-LTCR

2012 YE

2013 C-LTCR

Obj.(5%)

B/W than

2012

G/Y/R

Status

9

1

4

13

17

3

0

47

0.21

0.30

0.00

0.20

1.77

3.39

0.83

0.47

0.53

0.12

0.74

0.19

1.63

0.75

0.00

0.42

0.50

0.11

0.70

0.18

1.55

0.71

0.00

0.40

60%

-146%

100%

-6%

-8%

-351%

#DIV/0!

-13%

G

R

G

R

R

R

G

R

1

0

0

1

0

1

0

3

3

2

0

8

15

7

1

36

FIR 2013 YTD

Oct

Nov

Dec

Fires 2013

YTD

Fires 2012 YE

Sep

FIR 2012

YE

2013 FIR Obj.

(FSAO 10%)

B/W than

2012

G/Y/R

Status

1

2

0

0

5

1

2

11

2

0

0

1

7

1

1

12

0.03

0.14

0.00

0.00

0.17

0.06

0.55

0.09

0.05

0.00

0.00

0.03

0.18

0.04

0.22

0.07

0.05

0.00

0.00

0.03

0.14

0.04

0.20

0.06

41%

#DIV/0!

#DIV/0!

100%

3%

-43%

-152%

-22%

G

R

G

G

Y

G

R

R

B/W than

Obj.

G/Y/R

Status

324%

86%

#DIV/0!

754%

-4%

951%

#DIV/0!

156%

G

G

G

G

R

G

G

G

0

0

0

0

0

1

0

1

Y= Better than previous year

R= worse than previous year

B. Proactive Safety Metrics (performance YTD)

11. Near Miss Ratio (NMR)

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP)

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

Jan

Feb

Mar

375

22

3

168

110

79

21

778

167

19

3

174

313

317

10

1003

371

41

4

123

256

263

12

1070

Number of near-misses registered in OHSIM per month

Apr

May

Jun

Jul

Aug

Sep

325

45

4

151

200

289

57

1071

329

58

4

164

376

243

31

1205

349

73

3

140

263

343

43

1214

363

71

3

174

363

356

50

1380

397

62

3

151

283

340

45

1281

380

55

6

121

368

292

25

1247

Oct

Nov

Dec

N-Misses 2013

YTD

N-Misses

2012 YE

N-M per LTC 2013

YTD

3056

446

33

1366

2532

2522

294

10249

3832

485

54

2975

2554

2771

225

12896

339.6

148.7

#DIV/0!

683.0

76.7

840.7

#DIV/0!

205.0

2013 N-M per LTC

Objective. (1:80)

80

80

80

80

80

80

80

80

2013 Ford South America OHS Scorecard

12. Safe Behaviour Index (SBI)

SBC

TBT

TPG

CAP

PAP

VAP

Troller

Total

Safe Behaviour Index (SBI) 2013 Objective

G/Y/R Status

90%

95%

0%

5%

G

90%

92%

0%

2%

G

90%

95%

0%

5%

G

90%

93%

0%

3%

G

90%

90%

0%

0%

G

90%

95%

0%

5%

G

90%

92%

0%

2%

G

90.0%

93.1%

0.0%

3%

G

14. Resolution Index (RI)

SBC

TBT

TPG

CAP

PAP

VAP

Troller

New issues identified (current month)

Accumulated number of identified issues (YTD)

Number of Issues resolved (current month)

Accumulated number of issues resolved (YTD)

2013 Resolution Index Objective -

284

2179

236

2095

95%

96%

1%

G

139

438

108

391

95%

89%

-6%

R

10

44

9

42

95%

95.5%

0%

G

356

1078

315

1027

95%

95.3%

0%

G

217

2065

358

1962

95%

95.0%

0%

G

197

2406

186

2285

95%

95.0%

0%

G

15

67

15

67

95%

100.0%

5%

G

Total

1218

8277

1227

7869

95%

95.1%

0%

G

15. Integrated Safety Risk Assessment (ISRA)

SBC

TBT

TPG

CAP

PAP

VAP

Total Number of Workstations

No.of workstations assessed

% of Accomplishment

Red Stations 2013 YTD

Yellow Stations 2013 YTD

Red Stations 2012 YE

Yellow Stations 2012 YE

Yellow Stations 2013 Obj = (15%)

Red Stations 2013 Obj = ZERO

% of Accomplishment on RED stations

% of Accomplishment on YELLOW stations

1598

1598

100%

86

980

132

980

833

593

593

100%

56

127

71

127

108

138

138

100%

0

0

0

0

0

687

687

100%

179

468

123

607

516

1231

1033

84%

190

194

17

0

18

2181

2181

100%

1251

106

1501

190

162

Troller

230

106

Total

7731

7409

35%

0%

147 G0

21%

0%

G0

19

16. Ergonomics Process

SBC

TBT

TPG

CAP

Total Number of Workstations

No.of workstations assessed

% of Accomplishment

1598

1598

100%

86

132

593

593

100%

56

71

51

21%

#REF! G#REF!

138

138

100%

0

0

687

687

100%

25

39

2013 SBI YTD

Red (Compliance <75%) Obj=<3%

Balance B/(W) Than Objective

2013 Resolution Index YTD

Balance B/(W) Than Objective

G/Y/R Status

96%

68

2

32

1

1830

1877

1876

1905

1619

G/Y/R Status

Red Stations 2013 YTD

Red Stations 2012 YE

Red Stations 2013 Obj

% of Accomplishment on RED stations

35%

G/Y/R Status

GYR Code:

46%

#REF! G#REF!

Progress equal or better than timing

17. High Potential - Serious Injuries Ratio (Objective

#DIV/0!

#DIV/0!

G0

0

#DIV/0!

#REF! G #REF!

-46%

153%

G139

91

36%

#REF! G#REF!

-1018%

1078%

-18 R-194

17%

295%

29 G84

-113%

-100%

286 R28

2%

10%

286 R

28

PAP

VAP

2181

2181

100%

535

731

Troller

230

106

Total

1231

261

21%

29

13

-123%

#REF! R#REF!

Progress 10% behind Timing

46%

53

22

27%

-141%

#REF! G#REF!

#REF! R#REF!

7731

5564

72%

784

1008

22%

#REF! G

#REF!

Progress >10% Behind Timing

SBC

TBT

TPG

CAP

PAP

VAP

Troller

Total

24

3

8.0

G

5

1

5.0

G

4

0

#DIV/0!

G

21

6

3.5

G

29

11

2.6

R

9

2

4.5

G

3

0

#DIV/0!

G

95

23

4.1

G

18. CORPORATE ICA / PCA implementation Obj.

SBC

TBT

TPG

CAP

PAP

VAP

Troller

Total

No. of ICA/PCA required

No. of ICA/PCA implemented

YTD % of implementation

Better / Worse than Objective

18

16

89%

11%

G

19

18

95%

5%

G

18

16

89%

11%

G

19

16

84%

16%

G

19

15

79%

21%

G

18

15

83%

17%

G

18

16

89%

11%

G

18

16

89%

11%

G

19. REGIONAL ICA / PCA implementation

SBC

TBT

TPG

CAP

PAP

VAP

Troller

Total

No. of ICA/PCA required

No. of ICA/PCA implemented

YTD % of implementation

Better / Worse than Objective

24

24

100%

0%

G

24

24

100%

0%

G

24

19

79%

21%

R

24

19

79%

21%

G

24

20

83%

17%

R

24

17

71%

29%

R

24

21

88%

13%

R

168

144

86%

14%

R

No. Of High Potential Incidentes YTD

No. Of Serious Injuries YTD

HP:SII Ratio YTD

G/Y/R Status

C. Other Safety Indicators (performance YTD)

G/Y/R Status

G/Y/R Status

2013 Ford South America OHS ScorecardBehind Schedule

On Time

20. Integrated SOS Self-assessment Align with FPS

Schedule

2012 Validation scores

1st Q2013 SOS Self assessment - March 2013

3rd Q2013 SOS Self assessment - September 2013

SBC

Comp

Adhe

71

100

98%

73%

75%

100%

TBT

Comp

Adhe

78

100

83%

83%

95%

90%

TPG

Comp

Adhe

86

100

CAP

Comp

Adhe

99

73

99%

83%

94%

82%

PAP

Comp

Adhe

99

56

92%

63%

83%

59%

NA

SBC

TBT

TPG

CAP

100%

100%

100%

100%

100%

100%

100%

100%

100%

50%

100%

100%

100%

100%

65%

100%

100%

100%

100%

50%

83.3%

G

75.0%

G

77.5%

G

75.0%

G

75.0%

G

G/Y/R Status

G/Y/R Status

G= >90%

GYR Criteria:

22. Focused Audits

1.- Combustion Safety audit

2 - Overhead Doors Safety audit

3.- ECPL Safety Audit

4 - Electrical Safety Audit (NR-10)

5 - Machine Guarding Safety Audit

6 - Lift-Crane Safety Audit

7 - High Risk Assessment - FAS08-038

8 - Monthly PMHV focused audits

2012 YTD Percent of Compliance

G/Y/R Status

PAP

VAP

Troller

100%

100%

100%

100%

50%

100%

100%

100%

100%

75%

100%

100%

100%

100%

80%

79.2%

G

80.0%

G

Percent of implementation

21. Safety Analysis and interventions (SIX PACK)

1 Maintenance / Preventive Maint.

2 Work rules and procedures

3 Tools/Equipments

4 Material Storage / PMHV

5 Engineering / Design

6 PPE

Overall Implementation Results

VAP

Troller

Total

Comp Adhe Comp Adhe Comp Adhe

99

78

99

74

99

74

75%

63%

85%

69%

89%

72%

86%

70%

96%

74%

92%

76%

Y= Between 85 - 90%

Average

100%

100%

100%

100%

67%

0%

77.9%

G

R= Less than 85%

Frequency

SBC

TBT

TPG

CAP

PAP

VAP

Troller

Average

Qtrly

Qtrly

Qtrly

May and Nov

Jul

50%

50%

50%

50%

100%

100%

100%

75%

71.9%

G

75%

75%

75%

50%

100%

0%

100%

95%

71.3%

R

50%

50%

50%

50%

100%

100%

100%

90%

73.8%

G

50%

50%

50%

50%

100%

100%

100%

94%

74.3%

G

75%

50%

75%

50%

100%

50%

50%

50%

50%

100%

0%

100%

97%

62.1%

R

50%

50%

75%

50%

100%

100%

100%

97%

77.8%

G

57.1%

53.6%

60.7%

50.0%

100.0%

57.1%

100.0%

90.4%

% of

Compliance

2013 Obj.

B/W Than

Objective

G/Y/R

Dec

95%

95%

95%

95%

95%

95%

95%

95%

1%

5%

5%

5%

-6%

5%

5%

3%

G

G

G

G

G

G

G

G

B/W Than

Objective

-11%

-10%

-37%

24%

25%

8%

-20%

7%

Sep

1st Qtr

Monthly

100%

85%

66.9%

R

71.1%

G

D. Health Indicators (performance YTD)

23. Medical Surveillance Compliance

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP)

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

% of Compliance with medical exams schedule by Month

Mar

Apr

May

Jun

Jul

Aug

Sep

Nov

Feb

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

80%

100%

100%

100%

100%

100%

100%

85%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

97%

81%

0%

0%

0%

96%

100%

100%

100%

89%

100%

100%

98%

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

% MA 2013

YTD

% MA 2012

YE

MA 2013 Obj.

(3%)

5.08

5.31

1.32

4.87

3.90

1.63

1.21

3.16

5.88

3.84

1.57

4.21

4.60

2.17

0.96

3.18

3.85

4.34

1.38

4.05

4.80

4.25

1.86

3.24

3.75

4.49

1.07

4.41

4.40

3.84

2.75

3.14

3.64

5.05

0.79

4.30

4.50

5.58

2.75

3.41

3.85

5.32

0.31

4.34

3.90

6.37

2.30

3.44

4.28

4.68

0.67

3.84

3.90

5.57

1.92

3.28

3.95

4.07

1.81

3.77

3.90

3.01

1.64

2.93

4.82

4.99

3.26

3.38

0.00

4.34

4.68

1.35

4.13

3.77

4.03

1.94

3.19

3.92

4.24

0.99

5.42

5.03

4.37

1.62

3.42

3.80

4.11

0.96

5.26

4.88

4.24

1.57

3.32

24. Medical Absenteeism

Sao Bernardo Plant (SBC)

Taubate Plant (TBT)

Tatui Proving Grounds (TPG)

Camacari/Bahia (CAP)

Pacheco - Argentina (PAP)

Valencia - Venezuela (VAP)

Troller Plant

Total FSAO

Oct

Jan

100%

100%

Monthly percentage

3.87

2.05

2.90

0.00

0.00

G/Y/R Status

R

R

R

G

G

G

R

G

25. Case Management Process

No. of Medical leave Cases at YE 2012

2012 Objective (5%)

No. of medical leave cases at the end of current month (YTD)

Balance B/(W) Than Objective

G/Y/R Status

Avg. Lost days per case 2012 YE

2013 Objective (5%)

Total No. of lost days at end of current month in 2013

Avg. Lost days per case at end of current month in 2013

Balance B/(W) Than Objective

G/Y/R Status

26. Employee Health indicators Total plant population

A. OBESITY

No. of employees with Obesity

Obesity Prevalence

B. TOBACCO SMOKING

No. of employees with smoking habits

Tobacco Smoking Prevalence

C. DIABETES

No. of employees with diabetes

Diabetes Prevalence

Diabetics UNDER Control

Diabetics UNDER Control (percentage)

D. HYPERTENSION

No. of Employees with Hypertension

Hypertension Prevalence

Hypertensive Under Control

Hypertensive Under Control (percentage)

G/Y/R Status

G/Y/R Status

TBT

25

24

33

-32%

PAP

VAP

2013TPG

Ford SouthCAP

America OHS

Scorecard

1

136

762

304

1

1

0%

129

101

26%

724

143

81%

289

432

-42%

Troller

FSAO

2

1.9

6

-200%

1,288

808

40%

1 Qtr

2Qtr

3Qtr

4Qtr

1356

244

130

819

778

93,056

921

-18%

141

572

66,525

2,379

141

-5%

69

63

31,965

74

-17%

397

27%

290

276

262

249

10%

232

124

31,022

6,129

337

-45%

182

-47%

56

53

91

91

-71%

134

543

SBC

TBT

TPG

CAP

PAP

VAP

2,226

320

4,035

3,136

2,285

Troller

464

FSAO

4,098

1,925

47.0%

449

20.2%

60

18.8%

385

9.5%

1,235

39.4%

903

39.5%

24

5.2%

4,981

30.1%

606

14.8%

166

7.5%

13

4.1%

82

2.0%

824

26.3%

237

10.4%

30

6.5%

1,958

11.8%

446

10.9%

397

89.0%

69

3.1%

69

100.0%

13

4.1%

13

100.0%

57

1.4%

32

56.1%

240

7.7%

219

91.3%

33

1.4%

32

97.0%

8

1.7%

7

87.5%

866

5.2%

769

88.8%

1,388

33.9%

1231

88.7%

G

192

8.6%

177

92.2%

G

31

9.7%

31

100.0%

G

222

5.5%

151

68.0%

G

440

14.0%

386

87.7%

G

163

7.1%

162

99.4%

G

48

10.3%

40

83.3%

G

2,484

15.0%

2,178

87.7%

G

SBC

TBT

TPG

CAP

PAP

VAP

Troller

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

100%

33%

100%

100%

100%

100%

100%

100%

75%

G

75%

G

75%

G

75%

G

58%

G

75%

G

75%

G

Percent of implementation

27. Employee Health Initiatives (FOUR PACK)

Overweight / Obesity.

Diabetes

Hypertension

Smoking Cessation

Overall Implementation Results

SBC

126

129

92

27%

16564

Average

100%

100%

90%

0%

73%

G

You might also like

- Brief HSE Procedures ContentsDocument2 pagesBrief HSE Procedures Contentsarifayee-1No ratings yet

- Occupational health and safety A Complete Guide - 2019 EditionFrom EverandOccupational health and safety A Complete Guide - 2019 EditionNo ratings yet

- Annual Safety Activity Plan of UAIL Site, Rev.-03Document1 pageAnnual Safety Activity Plan of UAIL Site, Rev.-03Sheikh AshfaqueNo ratings yet

- Weekly safety report for Goshu Kohsan CoDocument3 pagesWeekly safety report for Goshu Kohsan CoNacorn Panchanawaporn50% (2)

- Monthly Health and Safety Statistic ReportDocument1 pageMonthly Health and Safety Statistic Reportsubhanmusadiq100% (5)

- HSE Statistics PDFDocument5 pagesHSE Statistics PDFRashid100% (1)

- HSE Inspection Report 2nd Week April 2015Document5 pagesHSE Inspection Report 2nd Week April 2015adi50% (2)

- HSE StatisticsDocument5 pagesHSE Statisticsgiri943100% (1)

- Safety ObservationDocument48 pagesSafety Observationpooloo70100% (1)

- Hse Statistics Report Pp701 Hse f04 Rev.bDocument1 pageHse Statistics Report Pp701 Hse f04 Rev.bMohamed Mouner100% (1)

- Safety ActivitiesDocument37 pagesSafety ActivitiesEleonor Maderazo100% (1)

- Hse StatisticsDocument1 pageHse Statisticskrissregion100% (1)

- HEO Monthly HSE Perfomance Report 24 FeDocument11 pagesHEO Monthly HSE Perfomance Report 24 Feabdulla kasim100% (1)

- Safety Budget Project DetailsDocument4 pagesSafety Budget Project DetailsSuthar Rajesh GNo ratings yet

- HSE Monthly ReportDocument11 pagesHSE Monthly ReportAlfredo Medina Cano100% (7)

- HSE BUDGET 2015iDocument22 pagesHSE BUDGET 2015iGabriel Bolatito100% (2)

- HSE Training History FormDocument4 pagesHSE Training History FormAnonymous 1wDPsonNo ratings yet

- MONTHLY SAFETY REPORTDocument1 pageMONTHLY SAFETY REPORTNowfal Habeeb100% (1)

- HSE Dashboard For Single SiteDocument23 pagesHSE Dashboard For Single SiteFOZCAN100% (2)

- SAFETY Statistics AprDocument1 pageSAFETY Statistics AprSantos RexNo ratings yet

- Assessment Profile Sheet: Assessor (S) Labor Posture ActivityDocument70 pagesAssessment Profile Sheet: Assessor (S) Labor Posture ActivityAnonymous iI88Lt100% (1)

- Weekly Monthly Performance Report - Jerin Sam KurianDocument5 pagesWeekly Monthly Performance Report - Jerin Sam Kurianjerin sam kurianNo ratings yet

- + Contractor Safety Weekly Statistic Report FormDocument1 page+ Contractor Safety Weekly Statistic Report FormNathaniel Kwek100% (2)

- Monthly Safety ReportDocument2 pagesMonthly Safety ReportPrakash PalaiNo ratings yet

- Project Details: HSE Action Tracker-Data Filter CreteriaDocument18 pagesProject Details: HSE Action Tracker-Data Filter CreteriaNexar GendeNo ratings yet

- HSE Statistics (Monthly) - Package I November-2016Document182 pagesHSE Statistics (Monthly) - Package I November-2016makdelNo ratings yet

- Monthly HSE Statistics SeptemberDocument2 pagesMonthly HSE Statistics SeptemberRaza Muhammad SoomroNo ratings yet

- Monthly Safety Report February 2019Document2 pagesMonthly Safety Report February 2019Anonymous eFF9uwuuNo ratings yet

- HSE Statistics Presentation ExampleDocument23 pagesHSE Statistics Presentation ExampleKhuda BukshNo ratings yet

- Project Monthly SHEQ Planning FormDocument3 pagesProject Monthly SHEQ Planning FormParashuram PatilNo ratings yet

- Hse Plan 2016Document9 pagesHse Plan 2016T Bayu Pratama100% (4)

- Form Subcontractor Daily HSE Statistics ReportDocument2 pagesForm Subcontractor Daily HSE Statistics ReportadityaNo ratings yet

- HSE Committee Meeting Rev1Document25 pagesHSE Committee Meeting Rev1Khaled Ismail100% (1)

- Monthly Safety Observation Report For 2012Document6 pagesMonthly Safety Observation Report For 2012Ariel Dela Cruz100% (5)

- Dashboard For Safety Related ItemsDocument9 pagesDashboard For Safety Related ItemsRichard Thodé Jr100% (1)

- Oil India Limited: Onshore Emergency Response PlanDocument23 pagesOil India Limited: Onshore Emergency Response Planaji sathyanandanNo ratings yet

- HSE Dashboard Upstream November 2016Document49 pagesHSE Dashboard Upstream November 2016Hermann Klier100% (1)

- Entity Quarterly OHS Performance ReportDocument3 pagesEntity Quarterly OHS Performance ReportwritemeyouNo ratings yet

- HSE Dashboard For Multiple SitessDocument11 pagesHSE Dashboard For Multiple SitessAfroz Alam0% (1)

- 2013 Mom Hse 033 PDFDocument18 pages2013 Mom Hse 033 PDFebsmsartNo ratings yet

- Monthly Safety Report (April)Document8 pagesMonthly Safety Report (April)csacas sacscNo ratings yet

- Monthly OHSE ReportDocument4 pagesMonthly OHSE ReportMutee MustafaNo ratings yet

- Weekly Project-W HSE Report RPCO 26th Mar To 1st AprDocument14 pagesWeekly Project-W HSE Report RPCO 26th Mar To 1st Aprabhinav djNo ratings yet

- Monthly HSE Report: 7536 Safe Work HoursDocument2 pagesMonthly HSE Report: 7536 Safe Work HoursmahendkakdeNo ratings yet

- EHS QuestionaireDocument26 pagesEHS QuestionaireR.GanesanNo ratings yet

- HSE Program 2016 ReviewDocument4 pagesHSE Program 2016 ReviewNurAjiNo ratings yet

- Accident, Incident and Near-Miss Reporting ProcedureDocument11 pagesAccident, Incident and Near-Miss Reporting ProcedureSalim Muftah100% (1)

- Master Hazards Risks RegisterDocument113 pagesMaster Hazards Risks RegisterIvanNo ratings yet

- HSC Monthly Report FormatDocument1 pageHSC Monthly Report Formatloveson709100% (11)

- GEN-005 Low Pressure Turbine and Generator Coupling and Decoupling Alignment CheckDocument3 pagesGEN-005 Low Pressure Turbine and Generator Coupling and Decoupling Alignment Checkacanbasri1980No ratings yet

- Monthly Safety Report Stats DirectionsDocument2 pagesMonthly Safety Report Stats DirectionsIzan Fadlullah IdrisNo ratings yet

- HSE Inspection PlanDocument35 pagesHSE Inspection PlanXozan100% (3)

- Legal Compliance Evaluation ProgramDocument7 pagesLegal Compliance Evaluation Programazee730% (1)

- Monthly HSE Performance Report April 2018-AD 540Document70 pagesMonthly HSE Performance Report April 2018-AD 540Mohamed ThowfeekNo ratings yet

- Osh PlanDocument11 pagesOsh PlanjookapleeNo ratings yet

- HSE Presentation 115/13.8KV S/SDocument23 pagesHSE Presentation 115/13.8KV S/SNabil AhmadNo ratings yet

- July SMR RevDocument2 pagesJuly SMR RevShyam SadanandanNo ratings yet

- H&S Monthly StatsDocument6 pagesH&S Monthly StatsvarunstuffNo ratings yet

- Weekly HSE Report Feb .2013Document12 pagesWeekly HSE Report Feb .2013sakthivelNo ratings yet

- 2018 Nutrition Month ReportDocument1 page2018 Nutrition Month ReportAnn RuizNo ratings yet

- Literature Review On Female InfertilityDocument7 pagesLiterature Review On Female Infertilityea68afje100% (1)

- Aripiprazole medication guideDocument3 pagesAripiprazole medication guidemissayayaya100% (1)

- Nothing But The Truth D2Document89 pagesNothing But The Truth D2Jamie Nicholas100% (1)

- JP - Health and Wholeness Through The Holy CommunionDocument62 pagesJP - Health and Wholeness Through The Holy Communionjevontan90% (10)

- Insulation MBMA-NAIMA Acousticical Performance Guide Noise SoundDocument26 pagesInsulation MBMA-NAIMA Acousticical Performance Guide Noise SoundDianna LambertNo ratings yet

- Plant and Animal Cells Crossword Puzzle: FreebieDocument5 pagesPlant and Animal Cells Crossword Puzzle: FreebieAref DahabrahNo ratings yet

- Eugenics in The United StatesDocument14 pagesEugenics in The United StatesSnark Jacobs100% (1)

- Asian Organized CrimeDocument17 pagesAsian Organized CrimeMagr EscaNo ratings yet

- Test Procedure (HTC)Document1 pageTest Procedure (HTC)raja qammarNo ratings yet

- Bioreactor For Air Pollution ControlDocument6 pagesBioreactor For Air Pollution Controlscarmathor90No ratings yet

- Rainwater Harvesting: Dr. Muhammad Anwar Baig Iese, Scee NUST H-12, IslamabadDocument30 pagesRainwater Harvesting: Dr. Muhammad Anwar Baig Iese, Scee NUST H-12, IslamabadTalha Bin UmeedNo ratings yet

- Prevention of Surgical Site Infections: Pola Brenner, Patricio NercellesDocument10 pagesPrevention of Surgical Site Infections: Pola Brenner, Patricio NercellesAmeng GosimNo ratings yet

- Cash Flow Analysis: Restaurant Business PlanDocument44 pagesCash Flow Analysis: Restaurant Business Plankavirao87No ratings yet

- Reducing Malaria Infections in Sub-Saharan AfricaDocument2 pagesReducing Malaria Infections in Sub-Saharan AfricaStansa SeniaNo ratings yet

- Ganga Pollution CasesDocument3 pagesGanga Pollution CasesRuchita KaundalNo ratings yet

- Effects of Sucrose Concentration On Cell Respiration in YeastDocument7 pagesEffects of Sucrose Concentration On Cell Respiration in YeastRachel Utomo83% (23)

- Tabata Its A HIITDocument8 pagesTabata Its A HIITbertabastionniNo ratings yet

- Coca Cola Primary Activities: 1. Inbound Logistics Include Functions Like Receiving, Warehousing, and Managing InventoryDocument5 pagesCoca Cola Primary Activities: 1. Inbound Logistics Include Functions Like Receiving, Warehousing, and Managing InventoryJaene L.No ratings yet

- Oplan Nena (Violation of RA 10364 Expanded Anti-Trafficking in Person Act of 2012)Document3 pagesOplan Nena (Violation of RA 10364 Expanded Anti-Trafficking in Person Act of 2012)Jhunary MunarNo ratings yet

- Bill 192: An Act To Ensure Student Health and Safety in The Classroom by Regulating Ambient Air Quality in SchoolsDocument8 pagesBill 192: An Act To Ensure Student Health and Safety in The Classroom by Regulating Ambient Air Quality in SchoolsCtv MontrealNo ratings yet

- McDonlads Vs Burger KingDocument6 pagesMcDonlads Vs Burger KingSamuel Tyre Jr.No ratings yet

- Escala de Violencia e Índice de SeveridadDocument11 pagesEscala de Violencia e Índice de SeveridadpsiserviciosprofesioNo ratings yet

- SureFlo RDocument2 pagesSureFlo RKen NgNo ratings yet

- Stormwater CalculationDocument66 pagesStormwater CalculationDinesh DurairajNo ratings yet

- BrochureDocument2 pagesBrochureRajib DasNo ratings yet

- Examiner's report on F6 Taxation (UK) December 2010 paperDocument3 pagesExaminer's report on F6 Taxation (UK) December 2010 paperyorcpl200No ratings yet

- UK & India Health Insurance Actuarial ExamDocument4 pagesUK & India Health Insurance Actuarial ExamVignesh SrinivasanNo ratings yet

- Soa Group Health TrackDocument2 pagesSoa Group Health TrackwasabiwafflesNo ratings yet

- Safety Audit Format Gs ManmadDocument3 pagesSafety Audit Format Gs ManmadsunilNo ratings yet

- Allen Carr's Easy Way for Women to Lose Weight: The original Easyway methodFrom EverandAllen Carr's Easy Way for Women to Lose Weight: The original Easyway methodRating: 4.5 out of 5 stars4.5/5 (18)

- Breaking the Habit of Being YourselfFrom EverandBreaking the Habit of Being YourselfRating: 4.5 out of 5 stars4.5/5 (1454)

- How to Talk to Anyone: Learn the Secrets of Good Communication and the Little Tricks for Big Success in RelationshipFrom EverandHow to Talk to Anyone: Learn the Secrets of Good Communication and the Little Tricks for Big Success in RelationshipRating: 4.5 out of 5 stars4.5/5 (1135)

- The Fast800 Diet: Discover the Ideal Fasting Formula to Shed Pounds, Fight Disease, and Boost Your Overall HealthFrom EverandThe Fast800 Diet: Discover the Ideal Fasting Formula to Shed Pounds, Fight Disease, and Boost Your Overall HealthRating: 5 out of 5 stars5/5 (37)

- The Stress-Proof Brain: Master Your Emotional Response to Stress Using Mindfulness and NeuroplasticityFrom EverandThe Stress-Proof Brain: Master Your Emotional Response to Stress Using Mindfulness and NeuroplasticityRating: 4.5 out of 5 stars4.5/5 (109)

- Deep Sleep Hypnosis: Guided Meditation For Sleep & HealingFrom EverandDeep Sleep Hypnosis: Guided Meditation For Sleep & HealingRating: 4.5 out of 5 stars4.5/5 (103)

- Midnight Meditations: Calm Your Thoughts, Still Your Body, and Return to SleepFrom EverandMidnight Meditations: Calm Your Thoughts, Still Your Body, and Return to SleepRating: 5 out of 5 stars5/5 (2)

- Deep Sleep Meditation: Fall Asleep Instantly with Powerful Guided Meditations, Hypnosis, and Affirmations. Overcome Anxiety, Depression, Insomnia, Stress, and Relax Your Mind!From EverandDeep Sleep Meditation: Fall Asleep Instantly with Powerful Guided Meditations, Hypnosis, and Affirmations. Overcome Anxiety, Depression, Insomnia, Stress, and Relax Your Mind!Rating: 4.5 out of 5 stars4.5/5 (10)

- Really Very Crunchy: A Beginner's Guide to Removing Toxins from Your Life without Adding Them to Your PersonalityFrom EverandReally Very Crunchy: A Beginner's Guide to Removing Toxins from Your Life without Adding Them to Your PersonalityRating: 5 out of 5 stars5/5 (26)

- Outlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisFrom EverandOutlive: The Science and Art of Longevity by Peter Attia: Key Takeaways, Summary & AnalysisRating: 4 out of 5 stars4/5 (1)

- Summary of The 4-Hour Body: An Uncommon Guide to Rapid Fat-Loss, Incredible Sex, and Becoming Superhuman by Timothy FerrissFrom EverandSummary of The 4-Hour Body: An Uncommon Guide to Rapid Fat-Loss, Incredible Sex, and Becoming Superhuman by Timothy FerrissRating: 4.5 out of 5 stars4.5/5 (81)

- Summary: Fast Like a Girl: A Woman’s Guide to Using the Healing Power of Fasting to Burn Fat, Boost Energy, and Balance Hormones: Key Takeaways, Summary and AnalysisFrom EverandSummary: Fast Like a Girl: A Woman’s Guide to Using the Healing Power of Fasting to Burn Fat, Boost Energy, and Balance Hormones: Key Takeaways, Summary and AnalysisRating: 3 out of 5 stars3/5 (2)

- The Creation Frequency: Tune In to the Power of the Universe to Manifest the Life of Your DreamsFrom EverandThe Creation Frequency: Tune In to the Power of the Universe to Manifest the Life of Your DreamsRating: 5 out of 5 stars5/5 (549)

- Bedtime Stories for Adults: Tales to Soothe the Tired SoulsFrom EverandBedtime Stories for Adults: Tales to Soothe the Tired SoulsRating: 4 out of 5 stars4/5 (3)

- Allen Carr's Easy Way to Quit Vaping: Get Free from JUUL, IQOS, Disposables, Tanks or any other Nicotine ProductFrom EverandAllen Carr's Easy Way to Quit Vaping: Get Free from JUUL, IQOS, Disposables, Tanks or any other Nicotine ProductRating: 5 out of 5 stars5/5 (31)

- Boundless: Upgrade Your Brain, Optimize Your Body & Defy AgingFrom EverandBoundless: Upgrade Your Brain, Optimize Your Body & Defy AgingRating: 4.5 out of 5 stars4.5/5 (66)

- Forever Strong: A New, Science-Based Strategy for Aging WellFrom EverandForever Strong: A New, Science-Based Strategy for Aging WellNo ratings yet

- The Ikigai Journey: A Practical Guide to Finding Happiness and Purpose the Japanese WayFrom EverandThe Ikigai Journey: A Practical Guide to Finding Happiness and Purpose the Japanese WayRating: 5 out of 5 stars5/5 (27)

- Breaking the Stronghold of Food: How We Conquered Food Addictions and Discovered a New Way of LivingFrom EverandBreaking the Stronghold of Food: How We Conquered Food Addictions and Discovered a New Way of LivingRating: 4.5 out of 5 stars4.5/5 (23)

- Glucose Goddess Method: A 4-Week Guide to Cutting Cravings, Getting Your Energy Back, and Feeling AmazingFrom EverandGlucose Goddess Method: A 4-Week Guide to Cutting Cravings, Getting Your Energy Back, and Feeling AmazingRating: 5 out of 5 stars5/5 (59)

- Happy Gut: The Cleansing Program to Help You Lose Weight, Gain Energy, and Eliminate PainFrom EverandHappy Gut: The Cleansing Program to Help You Lose Weight, Gain Energy, and Eliminate PainRating: 3.5 out of 5 stars3.5/5 (6)

- 369: Manifesting Through 369 and the Law of Attraction - METHODS, TECHNIQUES AND EXERCISESFrom Everand369: Manifesting Through 369 and the Law of Attraction - METHODS, TECHNIQUES AND EXERCISESRating: 5 out of 5 stars5/5 (50)

- Summary of The Body Keeps the ScoreFrom EverandSummary of The Body Keeps the ScoreRating: 4.5 out of 5 stars4.5/5 (18)

- Proteinaholic: How Our Obsession with Meat Is Killing Us and What We Can Do About ItFrom EverandProteinaholic: How Our Obsession with Meat Is Killing Us and What We Can Do About ItRating: 4.5 out of 5 stars4.5/5 (19)

- The Happiest Baby on the Block: The New Way to Calm Crying and Help Your Newborn Baby Sleep LongerFrom EverandThe Happiest Baby on the Block: The New Way to Calm Crying and Help Your Newborn Baby Sleep LongerRating: 4.5 out of 5 stars4.5/5 (58)

- Eat to Lose, Eat to Win: Your Grab-n-Go Action Plan for a Slimmer, Healthier YouFrom EverandEat to Lose, Eat to Win: Your Grab-n-Go Action Plan for a Slimmer, Healthier YouNo ratings yet

- Metabolism Revolution: Lose 14 Pounds in 14 Days and Keep It Off for LifeFrom EverandMetabolism Revolution: Lose 14 Pounds in 14 Days and Keep It Off for LifeNo ratings yet