Professional Documents

Culture Documents

GS Templates - Mat-5 v3

Uploaded by

glbforuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GS Templates - Mat-5 v3

Uploaded by

glbforuCopyright:

Available Formats

(The report is to be on the letterhead of the company preparing the report) Date issued: 11 June 2013

Green Star Short Report Round [1/2]

Green Star Office Design v3 Credit: Mat-5 Concrete Project Name: [name] Project Number: GS- [####]

Ensure all prompts shown in Blue text have been responded to.

Points available:

Points claimed: [1, 2, 3 or, N/A]

1. Credit Compliance

The following chapters of this template are relevant for projects targeting points for this credit:

1.1.

Reduction of Portland cement

The project has reduced the absolute quantity of Portland cement, as an average across all concrete mixes, by replacing it with supplementary cementitious materials. Based on credit compliance requirements, the project has replaced at least [30/40%] of Portland cement measured by mass across all concrete used in the project compared to the reference case as described in Table 2. Figures used in Table 1 are used to calculate the amount of Portland cement replaced in the project. [Not all/all] of the concrete mixes used in the project have exactly the same concrete strength grades shown in Table 1. If concrete strength grades shown below are not the same, provide links below to documentation provided by the concrete technologist or designer calculating concrete strength grades through linear interpolation of the two closest performing concrete mix reference cases.

Table 1 Portland cement content concrete strength grades as defined in AS1379

Concrete strength grade (MPa following AS1379)

Portland cement content to be used in establishing the reference case (kg Portland cement/m3 concrete) 280 310 360 440 550 550

20 25 32 40 50 65

(The report is to be on the letterhead of the company preparing the report) Date issued: 11 June 2013

80 100

610 660

Table 2 Concrete mix breakdown and credit achievement

Reference Case Portland Cement Content (kg/m3)

Mix Label

Mpa (following AS1379)

Volume (m )

Total Portland Cement Content Under the Reference Case

Actual Portland Cement Content (kg/m3)

Actual Total Portland Cement Content

[Mix 1] [Mix 2] [Mix 3] [Mix 4] [Mix 5] etc Overall Total Portland Cement (kg) Overall percentage of replacement (%) [x] [1-(y/x)(100)=%] [y]

Portland cement content was reduced by [%] and [1/2] point/s are claimed

[Please insert hyperlinks to documents which support this claim]

Therefore, as demonstrated in section 1.1 this project is eligible to achieve [1 or 2] point(s) for reducing greenhouse gas emissions and resource use associated with the use of Portland cement.

1.2.

Water and Aggregate

The project uses at least 50% captured or reclaimed water (measured across all concrete mixes in the project) for mixing concrete. One point [has/has not] been achieved for meeting water captured or reclaimed requirements and meeting one of the following criteria and calculated in Table 3: [At least 40% of coarse aggregate in the concrete is crushed slag or another alternative material (measured by mass across all concrete mixes in the project), and the use of the slag/alternative material has not increased the use of Portland cement by over five kilograms per cubic meter of concrete. This is demonstrated in Table 4.] [At least 25% of fine aggregate (sand) inputs in the concrete are manufactured sand or other alternative materials (measured by mass across all concrete mixes in the project), and the use of the

(The report is to be on the letterhead of the company preparing the report) Date issued: 11 June 2013

such material has not increased the use of Portland cement by over five kilograms per cubic meter of concrete. This is demonstrated in Table 5.]

Table 3 Water diversion

Mix Label

Mix Volume (m3)

Total (L/ m3)

Reclaimed or Total Reclaimed or Total Water Captured Captured Content Component (L/ m3) Component (L/ m3)

[Mix 1] [Mix 2] [Mix 3] [Mix 4] [Mix 5] Totals Overall percentage of replacement (%) [(y/x)(100)=%] [x] [y]

[Please insert hyperlinks to documents which support this claim]

Table 4 Coarse Aggregate

Alternative Coarse Aggregate Component (kg/ m3)

Mix Label

Mix Volume (m )

Total (L/ m )

Total Coarse Aggregate in Mix

Total Alternative Coarse Aggregate

[Mix 1] [Mix 2] [Mix 3] [Mix 4] [Mix 5] Totals Overall percentage of replacement (%) [(y/x)(100)=%] [x] [y]

[Please insert hyperlinks to documents which support this claim]

(The report is to be on the letterhead of the company preparing the report) Date issued: 11 June 2013

Table 5 Fine Aggregate

Alternative Fine Aggregate Component (kg/ m3)

Mix Label

Mix Volume (m3)

Total (L/ m3)

Total Fine Aggregate in Mix

Total Alternative Fine Aggregate

[Mix 1] [Mix 2] [Mix 3] [Mix 4] [Mix 5] Totals Overall percentage of replacement (%) [(y/x)(100)=%] [x] [y]

[Please insert hyperlinks to documents which support this claim]

Therefore, as demonstrated in section 1.2 this project is eligible to achieve [1] point for reductions in aggregate and water use associated with concrete production.

The following chapter is for projects that are targeting this credit as Not Applicable.

1.3.

Credit Not Applicable

The projects material cost of new concrete represents less than 1% of the projects contract value. This credit is therefore excluded from the points available used to calculate the Materials Category Score and is marked as Not Applicable.

Table 6.1 Cost of Concrete

Total Cost of New Concrete

[$]

Projects Contract Value [$] Percent Value of Concrete

[%]

[Please insert hyperlinks to documents which support this claim]

(The report is to be on the letterhead of the company preparing the report) Date issued: 11 June 2013

Therefore, as demonstrated in section 1.3 this credit is considered Not Applicable and is excluded from the points available used to calculate the Materials Category Score.

Discussion

[Insert any issues you would like to highlight and clarify to the Assessment Panel.]

Author Details: [Insert name, position and contact details of author] [Date]

Report end

You might also like

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Process of Ready Mixed ConcreteDocument27 pagesProcess of Ready Mixed ConcreteN P SrinivasaraoNo ratings yet

- ARUP Embodied Carbon Concrete 1Document17 pagesARUP Embodied Carbon Concrete 1Gabriel MacaulayNo ratings yet

- Green 070415Document52 pagesGreen 070415tcthomasNo ratings yet

- Three Equations Method For Normal Concrete Mix DesignDocument5 pagesThree Equations Method For Normal Concrete Mix DesignSEP-PublisherNo ratings yet

- BuildingsDocument22 pagesBuildingsSai PavanNo ratings yet

- What Is Green Concrete PDFDocument3 pagesWhat Is Green Concrete PDFVelchuri SairamNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix DesignmadkikNo ratings yet

- Technical Report TR 5 Conc Mix DesignDocument18 pagesTechnical Report TR 5 Conc Mix DesignSunil ReddyNo ratings yet

- Concrete Mix Design and Trail Mixes ReportDocument16 pagesConcrete Mix Design and Trail Mixes Reportrajeev kumarNo ratings yet

- Concrete Mix Design and Trail Mixes Technical ReportDocument16 pagesConcrete Mix Design and Trail Mixes Technical ReportSanjukta MajhiNo ratings yet

- Concrete Mix Design: RequirmentsDocument56 pagesConcrete Mix Design: RequirmentssushilkumarNo ratings yet

- Final ReportDocument9 pagesFinal Reportmohamed.ahmed.civil1No ratings yet

- Fly Ash Rigid PavementDocument4 pagesFly Ash Rigid PavementRaghav100% (1)

- Construction Materials Assessment UTSDocument23 pagesConstruction Materials Assessment UTSEddie Hall0% (1)

- Project Cost EstimationDocument8 pagesProject Cost Estimationmamuka kassaNo ratings yet

- 72 80 3857 Krissana Aug 2023 108 z1Document9 pages72 80 3857 Krissana Aug 2023 108 z1Muhammad EnricoNo ratings yet

- Paper waste improves concrete strengthDocument19 pagesPaper waste improves concrete strengthPavithraNo ratings yet

- Green Concrete and Sustainability of Environmental System - Yash KrishiDocument8 pagesGreen Concrete and Sustainability of Environmental System - Yash KrishiSree NivasNo ratings yet

- 2018 HCI C2H2 Economics - Prelim CSQ1 Suggested AnswersDocument4 pages2018 HCI C2H2 Economics - Prelim CSQ1 Suggested Answerstrizillion12No ratings yet

- 11.7 Crushing and Grinding: Emission CalculationsDocument4 pages11.7 Crushing and Grinding: Emission Calculationskiranpatil1014532No ratings yet

- Innovative Use of Paper Industry Waste (Hypo Sludge) in Design Mix ConcreteDocument5 pagesInnovative Use of Paper Industry Waste (Hypo Sludge) in Design Mix ConcreteCindy JonesNo ratings yet

- 11.5 Concrete Batch Plants: Emission CalculationsDocument4 pages11.5 Concrete Batch Plants: Emission CalculationsNaeem KhanNo ratings yet

- Mechanical and Elastic Behaviour of Concretes Made of Recycled-ConcreteDocument5 pagesMechanical and Elastic Behaviour of Concretes Made of Recycled-ConcreteIvan NikolaevNo ratings yet

- No22 Environmental BenefitsDocument4 pagesNo22 Environmental BenefitsGopala RaoNo ratings yet

- Design of In-Situ Soil Mixing - PDFDocument8 pagesDesign of In-Situ Soil Mixing - PDFDiego SkokNo ratings yet

- An Advanced Concrete Recycling Technology and Its Applicability Assessment Through Input-Output AnalysisDocument15 pagesAn Advanced Concrete Recycling Technology and Its Applicability Assessment Through Input-Output AnalysisAymanAlMahfuzNo ratings yet

- Carbon Footprint of Concrete Buildings Seen in The Life Cycle Perspective PDFDocument14 pagesCarbon Footprint of Concrete Buildings Seen in The Life Cycle Perspective PDFGoodson ChitsaNo ratings yet

- Recent Update On The Environmental Impact of Geopolymers: Guillaume Habert, Claudiane Ouellet-PlamondonDocument7 pagesRecent Update On The Environmental Impact of Geopolymers: Guillaume Habert, Claudiane Ouellet-PlamondonSami SbahieahNo ratings yet

- Concrete Mix Design: by K.ShahDocument48 pagesConcrete Mix Design: by K.ShahBùi Quang MinhNo ratings yet

- Flyash Pavement Advantage Lee - Sustainable Conf 2010Document6 pagesFlyash Pavement Advantage Lee - Sustainable Conf 2010Neha KulkarniNo ratings yet

- International Journal of Scientific Eng and Tech Research - Flakiness IndexDocument8 pagesInternational Journal of Scientific Eng and Tech Research - Flakiness IndexrealchicNo ratings yet

- RohanDocument21 pagesRohanmansikakaniNo ratings yet

- Project Document Template March 2000Document23 pagesProject Document Template March 2000nasrNo ratings yet

- Green ConcreteDocument22 pagesGreen ConcreteSyafiq ArtNo ratings yet

- Concrete Design Mix TutorialDocument5 pagesConcrete Design Mix TutorialRavi KumarNo ratings yet

- I Jite 14 April 2940Document4 pagesI Jite 14 April 2940reloaded63No ratings yet

- Green Concrete - Report For IBCDocument8 pagesGreen Concrete - Report For IBCAbhinav Srivastava67% (3)

- New Cement QuestionnaireDocument8 pagesNew Cement QuestionnaireSunil Meena100% (1)

- Environmental Impacts of Recycled Plastic ConcreteDocument9 pagesEnvironmental Impacts of Recycled Plastic Concreteomar heshamNo ratings yet

- MDL - BirlaDocument78 pagesMDL - BirlaMarcilioPradoNo ratings yet

- 2009ICJGREENDocument4 pages2009ICJGREENcibif40663No ratings yet

- Recycling Concrete Construction and Demolition Wastes: A Financial Feasibility ModelDocument10 pagesRecycling Concrete Construction and Demolition Wastes: A Financial Feasibility ModelEpherem DanielNo ratings yet

- The Investigation of The Impact of Lucobit Polymer On Bitumen PerformanceDocument10 pagesThe Investigation of The Impact of Lucobit Polymer On Bitumen PerformanceJessica ClarkNo ratings yet

- How focusing solely on CO2 emissions fails to encourage truly sustainable concreteDocument4 pagesHow focusing solely on CO2 emissions fails to encourage truly sustainable concreteKhaled Abdel SalamNo ratings yet

- Sustainability 13 08081Document15 pagesSustainability 13 08081محمد عقيل عبد الامير ستارNo ratings yet

- Study of Structural Performance and Durability of Concrete by Partial Replacement of Cement With Hypo Sludge (Paper Waste)Document5 pagesStudy of Structural Performance and Durability of Concrete by Partial Replacement of Cement With Hypo Sludge (Paper Waste)Innovative Research PublicationsNo ratings yet

- (2020) Beycioğlu, A.Document15 pages(2020) Beycioğlu, A.Ilyas H. AliNo ratings yet

- 16) Klemm A.J. Et Al 2019 Supplementary Cementitous Materials and Their Impact On Sustainable ConstructionDocument11 pages16) Klemm A.J. Et Al 2019 Supplementary Cementitous Materials and Their Impact On Sustainable ConstructionSOMNo ratings yet

- 100034014Document11 pages100034014Ar Vishul SaxenaNo ratings yet

- Analysis of Major Environmental Impact Categories of Road Construction MaterialsDocument18 pagesAnalysis of Major Environmental Impact Categories of Road Construction MaterialsDaniel MattosNo ratings yet

- Effect of Fly Ash On The Properties of CementDocument6 pagesEffect of Fly Ash On The Properties of CementInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Hafifi Che Wahid 2019 IOP Conf. Ser. Mater. Sci. Eng. 512 012010Document8 pagesHafifi Che Wahid 2019 IOP Conf. Ser. Mater. Sci. Eng. 512 012010eeydzahNo ratings yet

- Recycled Concrete: Sumia Alghlam Mostafa Jweli Nagat MaramiDocument21 pagesRecycled Concrete: Sumia Alghlam Mostafa Jweli Nagat MaramiSumia AlghlamNo ratings yet

- Partial Replacement of Cement with Marble PowderDocument11 pagesPartial Replacement of Cement with Marble PowderDipin Raj D KNo ratings yet

- Concrete Mix Design (Notes) PDFDocument11 pagesConcrete Mix Design (Notes) PDFMohamad Khaled Nordin100% (1)

- Maintenance in Cement PlantsDocument41 pagesMaintenance in Cement Plantsomid13020% (1)

- LCA Tire Course Project - Labib&BenaazouzDocument16 pagesLCA Tire Course Project - Labib&BenaazouzMohammed Yassine Labib0% (1)

- Production and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesFrom EverandProduction and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesNo ratings yet

- SPD15 Jeff Cooper UkDocument3 pagesSPD15 Jeff Cooper UkglbforuNo ratings yet

- J. Appl. Environ. Biol. Sci. 27329 335 2012Document7 pagesJ. Appl. Environ. Biol. Sci. 27329 335 2012glbforuNo ratings yet

- USWSaket Article 11Document14 pagesUSWSaket Article 11glbforuNo ratings yet

- USWSaket Article 11Document14 pagesUSWSaket Article 11glbforuNo ratings yet

- MHI Waleed Project SoftwareComparedDocument12 pagesMHI Waleed Project SoftwareComparedJavier Pasaca Xavi PscNo ratings yet

- Climate Change Energy and Decentralized Waste Management in SalemDocument18 pagesClimate Change Energy and Decentralized Waste Management in SalemglbforuNo ratings yet

- Water Act Guideline For Preparing Agricultural Feasibility Reports For Irrigation ProjectsDocument14 pagesWater Act Guideline For Preparing Agricultural Feasibility Reports For Irrigation ProjectsglbforuNo ratings yet

- J. Appl. Environ. Biol. Sci. 27329 335 2012Document7 pagesJ. Appl. Environ. Biol. Sci. 27329 335 2012glbforuNo ratings yet

- PDF/ajessp 2009 413 419Document7 pagesPDF/ajessp 2009 413 419glbforuNo ratings yet

- Solid Waste MGT IndiaDocument21 pagesSolid Waste MGT IndiavjipuppyNo ratings yet

- Table of ContentDocument9 pagesTable of ContentglbforuNo ratings yet

- 2471Document8 pages2471glbforuNo ratings yet

- Assessment of Irrigation Water Quality of Bogra District in BangladeshDocument12 pagesAssessment of Irrigation Water Quality of Bogra District in Bangladeshpeoples1231697No ratings yet

- SPD15 Jeff Cooper UkDocument3 pagesSPD15 Jeff Cooper UkglbforuNo ratings yet

- Solid Waste MGT IndiaDocument21 pagesSolid Waste MGT IndiavjipuppyNo ratings yet

- USWSaket Article 11Document14 pagesUSWSaket Article 11glbforuNo ratings yet

- Construction & Demolition WasteDocument7 pagesConstruction & Demolition WastefaridkhanNo ratings yet

- Recent Technologies in Structural Parameters With Green Energy in Smart BuildingDocument2 pagesRecent Technologies in Structural Parameters With Green Energy in Smart BuildingglbforuNo ratings yet

- Cavalline Paper 4-13-10Document15 pagesCavalline Paper 4-13-10glbforuNo ratings yet

- Calicut Tile Waste As An Alternative Coarse Aggregate For Lower Grade ConcretesDocument12 pagesCalicut Tile Waste As An Alternative Coarse Aggregate For Lower Grade ConcretesglbforuNo ratings yet

- Seismic Design of Pile Foundations For DifferentDocument10 pagesSeismic Design of Pile Foundations For DifferentniranjanbmazireNo ratings yet

- TaiwanDocument9 pagesTaiwanglbforuNo ratings yet

- The Potential of Recycled Ceramic Waste As Coarse Aggregates For ConcreteDocument3 pagesThe Potential of Recycled Ceramic Waste As Coarse Aggregates For ConcreteglbforuNo ratings yet

- 563Document16 pages563glbforuNo ratings yet

- Pile FoundationDocument9 pagesPile Foundationglbforu100% (1)

- Caltrans Bridge DesignDocument24 pagesCaltrans Bridge DesignAinie ButtNo ratings yet

- Effect of Support Reaction of Tbeam Skew Bridge SlabsDocument8 pagesEffect of Support Reaction of Tbeam Skew Bridge Slabsmadhu123iitkNo ratings yet

- Ppr2014 013narDocument9 pagesPpr2014 013narglbforuNo ratings yet

- Literature ReviewDocument4 pagesLiterature ReviewglbforuNo ratings yet

- Aci 212.3R - 2004 PDFDocument30 pagesAci 212.3R - 2004 PDFBhavanishankar ShettyNo ratings yet

- BAR Approximate Quantities: General NotesDocument1 pageBAR Approximate Quantities: General NotesSukrit GhoraiNo ratings yet

- Road Note 29: A Guide To The Structural Design of Pavements For New RoadsDocument43 pagesRoad Note 29: A Guide To The Structural Design of Pavements For New Roads7d5b3373100% (7)

- PDFDocument16 pagesPDFBibhuti B. BhardwajNo ratings yet

- What Are Some of The Thumb Rule of Construction Field - QuoraDocument13 pagesWhat Are Some of The Thumb Rule of Construction Field - Quoraimdadali sayyedNo ratings yet

- MS For Chamber ConstructionDocument17 pagesMS For Chamber ConstructionWilliam C. Pasamonte100% (1)

- BS EN 13748-1-2004 水磨石砖.内部用水磨石砖Document38 pagesBS EN 13748-1-2004 水磨石砖.内部用水磨石砖Ashraf Tomizeh50% (2)

- 3 Cells Box Culvert EstimateDocument105 pages3 Cells Box Culvert Estimatesaikumar yellankiNo ratings yet

- What Is Asphalt?: By: Engr Muhammad Bilal IsrarDocument3 pagesWhat Is Asphalt?: By: Engr Muhammad Bilal IsrarMuhammad Bilal IsrarNo ratings yet

- Qualidade Da ÁguaDocument16 pagesQualidade Da ÁguaJanaina LeitinhoNo ratings yet

- Light Weight Concrete PropertiesDocument16 pagesLight Weight Concrete PropertiesdNo ratings yet

- QC Issues - Optimizing Sprayed Concrete PerformanceDocument25 pagesQC Issues - Optimizing Sprayed Concrete PerformanceNguyễn Khắc HiệpNo ratings yet

- Design of Formwork for Concrete StructuresDocument30 pagesDesign of Formwork for Concrete StructuresSantosoNo ratings yet

- Deckshield by FlowcreteDocument3 pagesDeckshield by FlowcreteJay GalvanNo ratings yet

- Build Up Rate Format - PavingDocument4 pagesBuild Up Rate Format - PavingFaiz Ahmad75% (4)

- Method Statement of Control Building Sibundong Hydro PowerDocument11 pagesMethod Statement of Control Building Sibundong Hydro PowerEko PrasetyoNo ratings yet

- Static and Seismic Analysis of A Single-Tower Cable-Stayed BridgeDocument171 pagesStatic and Seismic Analysis of A Single-Tower Cable-Stayed BridgeranawaqasahmedNo ratings yet

- AC ULTRATECH OPC 43 WeekNo 46Document1 pageAC ULTRATECH OPC 43 WeekNo 46jatin mradul3137gmail.comNo ratings yet

- Mit PDFDocument64 pagesMit PDFyayoNo ratings yet

- EEE-Speaker3 - Engr. CLEMENTE - Full Paper-2022 PICE MNCTC PDFDocument6 pagesEEE-Speaker3 - Engr. CLEMENTE - Full Paper-2022 PICE MNCTC PDFShy AbuizaNo ratings yet

- Mastercast 141: Guidelines and Recommendations For UseDocument12 pagesMastercast 141: Guidelines and Recommendations For UseayeblessNo ratings yet

- Design + Construction Magazine (October To December 2019)Document86 pagesDesign + Construction Magazine (October To December 2019)Khuta JhayNo ratings yet

- Inspection Checklist: Concrete Screed PlacementDocument2 pagesInspection Checklist: Concrete Screed PlacementZiaul HaqNo ratings yet

- AP PGECET Civil Engg 2015 Question Paper & Answer Key DownloadDocument16 pagesAP PGECET Civil Engg 2015 Question Paper & Answer Key Downloadpavani83% (6)

- Final ReportDocument77 pagesFinal ReportVivek SharmaNo ratings yet

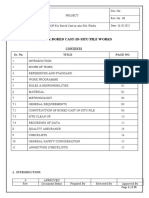

- SOP FOR Bored Cast in Situ Pile WorkDocument13 pagesSOP FOR Bored Cast in Situ Pile Workom prakashNo ratings yet

- BLDG STD Spec 2004Document703 pagesBLDG STD Spec 2004PcEngNo ratings yet

- Bricklayer - The essential guide to brick masonry skillsDocument4 pagesBricklayer - The essential guide to brick masonry skillsLee CwNo ratings yet

- Getrac E EbookDocument8 pagesGetrac E Ebookchithirai10No ratings yet

- RLB Construction Cost Report Jun-2021Document27 pagesRLB Construction Cost Report Jun-2021Sucipto100% (1)