Professional Documents

Culture Documents

Design For 11early Thermal Cracking

Uploaded by

dhruvgokuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design For 11early Thermal Cracking

Uploaded by

dhruvgokuCopyright:

Available Formats

P Bamforth, J Shave, S Denton 3

c

y

ct

s

A

f

f

A

|

|

.

|

\

|

=

*

(1)

The area of concrete was taken as the gross cross sectional area unless the section was thicker

than 500mm, in which case a surface zone of 250mm at each face is taken.

A further check was then made, to satisfy crack width requirements.

( ) | |

ult th sh c

b

ct

s

R

w

A

f

f

A c c c

|

5 . 0

2

*

+

|

|

.

|

\

|

=

(2)

Although given directly as a required area to control cracking, the equation contains elements

relating to crack spacing and crack widths, combined into a single formula. By rearranging

Equation (2) to give crack width expressed as the product of crack spacing and crack inducing

strain as in Equation (3), comparisons with other standards may be more readily made.

cr r

S w c

max ;

=

(3)

Where:

| |

|

|

.

|

\

|

|

|

.

|

\

|

=

b

ct

s

c

b

ct

r

f

f

A

A

f

f

S

* *

max ;

5 . 0

2

(4)

and

( ) | |

ctu r ctu th sh cr

R c c c c c c 5 . 0 5 . 0 + =

(5)

For comparison, BS8007 had the following calculation procedure:

c

max max

S w =

(6)

Where:

|

2

max ;

|

|

.

|

\

|

=

b

ct

r

f

f

S

(7)

and

( ) | |

6

10 100

+ =

te cs

c c c or

( ) T R A = o c

(8)

Once expressed in this form it can be seen that the requirements of BS8007 and BD28 were

reasonably well aligned, with BS8007 presented in a similar style to the method in the

Eurocodes and CIRIA C660. There were, however, some differences in the way in which

creep and restraint were accounted for in BD28 and BS8007. Notwithstanding these

differences, the principles and the overall approach of BS8007 and BD28 were similar. For

completeness, comparisons have been drawn in this paper with both BD28 and BS8007 where

possible, relative to Eurocodes.

P Bamforth, J Shave, S Denton 4

The Eurocode Design Approach

The Eurocode design method comprises two stages. Firstly, the magnitude of free contraction

c

free

is estimated and a restraint factor R

ax

is applied to determine the restrained-strain which,

if of sufficient magnitude, may result in cracking. The way in which the restrained-strain is

distributed as cracking is then estimated based on the volume and distribution of

reinforcement and the nature of the restraint.

BS EN 1992-3 deals with two forms of restraint; continuous edge restraint and end restraint.

The nature of the restraint is assumed to influence the way in which cracking develops and

different approaches are adopted to estimate the magnitude of crack-inducing strain, i.e. that

component of strain which is relieved and exhibited as cracking.

Estimating the Risk of Cracking

Estimating restrained contraction

Similarly to the previous standards, BS EN 1992-3:2006 uses a strain based approach and

assumes that all compressive stresses induced during heating are relieved by creep. The

restrained contraction c

r

is estimated using the expression;

c

r

= R

ax

c

free

(9)

where R

ax

is the degree of external axial restraint and

free

is the free contraction assuming no

restraint. For early-age deformation

r

is estimated using the expression (10);

c

r

= (o

c

. T

1

+. c

ca

) K. R

ax

(10)

T

1

is the temperature drop; o

c

is the coefficient of thermal expansion of concrete; c

ca

is

autogenous shrinkage; and K is a coefficient for creep. A spreadsheet model for predicting T

1

is provided in CIRIA C660 which derives adiabatic temperature rise curves for a variety of

UK concretes. It is based on extensive testing at the University of Dundee

[7]

and was

validated against in situ measurements

[3]

. Autogenous shrinkage is calculated using the

expression of BS EN 1992-1-1.

Estimating the risk of cracking

The risk of cracking is estimated by comparing the restrained strain

r

with the tensile strain

capacity of the concrete

ctu

; for no cracking

ctu

>

r .

ctu

is estimated from the ratio of the

mean tensile strength, f

ctm

(t) and the modulus of elasticity E

cm

(t) at early-age (the 3-day value

is recommended if the specific time of cracking is not known). f

ctm

(t) and E

cm

(t) are estimated

using the expressions provided in EN 1992-1-1 and coefficients are applied to the ratio

f

ctm

(t)/E

cm

(t) which take account of both creep (0.65) and the effect of sustained loading (0.8).

The net effect of these coefficients is to increase

ctu

under short term loading by 0.8/0.65 =

1.27.

Estimating Minimum Area of Reinforcement

The minimum area of reinforcement A

s,min

is that which ensures that, if all of the tension in the

concrete prior to cracking is assumed to be transferred to the steel immediately after cracking,

P Bamforth, J Shave, S Denton 5

then the stress in the steel will be below its yield strength. Expressions used by BS 8007 and

BS EN 1992-1-1 are shown in Table 1.

In the design approach of BD28 and BS 8007 it was assumed that cracking is initiated from

the surface

[8]

. In practice however, it is more likely that, under conditions of external restraint

in which there is tension across the full section, cracking will be initiated at the point where

the temperature drop is the greatest, i.e. at the centre of the section (see Figure 1). Stress will

therefore be transferred from the full section to the reinforcement when a crack occurs. Hence

the underlying assumption regarding the surface zone may not be valid.

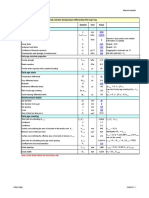

BD28 BS 8007 EN 1992-1-1

y

*

ct

c s

f

f

A A =

crit c

y

ct

c s A

f

f

A A = = ) A k (k

f

f

A k k A crit ct c

ky

eff ct,

ct c min s, = =

A

c

is the gross

cross section or a

surface zone of

250mm at either

edge

A

c

is the gross cross

section or a surface

zone of 250mm at

either edge

A

ct

is the area of concrete in tension

( )

7 . 0

. 0

cu ct

f 12 f =

f

ct

is the tensile

strength of the

concrete

f

ct,eff

is the tensile strength of the

concrete

f

y

is the yield

strength of the

steel

f

y

is the yield

strength of the steel

f

yk

is the yield strength of the steel

k allows for non-uniform and self-

equilibrating stress which leads to a

reduction in restraint forces

k = 1 for h 300mm

k = 0.65 for h 800mm

intermediate values are interpolated

k

c

takes account of the stress

distribution in the section = 1 for

pure tension

Table 1. Expressions for estimating the minimum area of reinforcement

R

e

s

t

r

a

i

n

t

R

e

s

t

r

a

i

n

t

R

e

s

t

r

a

i

n

t

R

e

s

t

r

a

i

n

t

Cracking propagated

from the centre where

temperature change is

greatest

t0

t1

t2

t3

Temperature profile

P Bamforth, J Shave, S Denton 6

Figure 1. Cross-section through a thick wall subject to external restraint

This revised view of crack development is reflected in the change in EN 1992-1-1 and has

been extended for the case of EATC in CIRIA C660 which has increased the coefficient k

(see Table 1) from 0.65 to 0.75 for h 800mm to take account of both the (generally)

parabolic temperature profile and the fact that in practice some compressive stresses must be

relieved by a drop in temperature before tensile stress are generated. A comparison of the

effective surface zones is shown in Figure 2.

Figure 2. Surface zones used in estimating the minimum area of reinforcement in

sections that are dominated by external restraint

The difference is most significant in thick sections that are at risk of cracking due to external

restraint, where the methods of EN 1992-1-1 and C660 assume that stress is transferred from

a much higher proportion of the section thickness (i.e. a much higher effective surface zone)

and hence lead to the requirements for more minimum reinforcement compared with BS 8007

and BD28.

Estimating Crack Spacing and Crack Width

The characteristic crack width w

k

(expected to be about 30% higher than the mean value

[9],

[10]

)

is estimated from the product of the crack-inducing strain

cr

and the crack spacing S

r,max

.

Crack spacing

The expressions for calculating crack spacing are given in Table 2. The same expressions

apply for both edge restraint and end restraint. The second term in the BS EN 1992-1-1:2004

P Bamforth, J Shave, S Denton 7

expression appears to be very similar to that of BS 8007. However, the way in which

e,eff

is

calculated leads to very different results. Consider a 500mm thick wall; if c = 40mm and =

20mm, the effective surface zone, h

e,ef

= 2.5(40 +20/2) = 125mm. For a 500mm wall this is

only half the value of 250mm used by BD28 and BS 8007. As the value of

p,eff

is inversely

proportional to h

e,ef

this will result in

p,eff

being double the value used by BD 28 and BS8007,

thus halving the value of the second term in the crack width expression. This difference is

partially offset by a cover term (3.4c) but the net effect is that, in this example, the crack

spacing estimated using EN 1992-1-1 will be significantly lower than the crack spacing

estimated using BS 8007. With no other changes this would lead to a significant reduction in

crack control reinforcement compared with BS 8007 as shown in Figure 3 (a).

BS 8007 and BD28/87 EN 1992-1-1

f

f

0.5 S

b

ct

max r,

=

eff p,

1

max r,

k

0.425 3.4c S + =

NO cover term c is the cover (mm)

f

ct

/f

b

is the ratio of the

tensile strength of the

concrete to the bond

strength, which for type 2

deformed bars = 0.67

k

1

is a coefficient which takes account

of the bond properties of the

reinforcement = 0.8 (and increased in

C660 to 1.14)

is the bar diameter (mm)

is the steel ratio based

on a surface zone of

250mm or h/2, whichever

is less

e,eff

is the effective steel ratio based

on an effective surface zone h

e.eff

to a

depth of 2.5 (c + /2) or h/2,

whichever is less

Hence,

0.335 S

max r,

= and,

eff p,

max r,

0.34 3.4c S + =

Table 2. Expressions for the calculation of crack spacing

30 mm

40 mm

50 mm

60 mm

70 mm

0

20

40

60

80

100

120

140

160

180

200

300 400 500 600 700 800 900 1000

Thickness (mm)

P

e

r

c

e

n

t

s

t

e

e

l

r

e

l

a

t

i

v

e

t

o

B

S

8

0

0

7

Cover

30 mm

40 mm

50 mm

60 mm

70 mm

0

20

40

60

80

100

120

140

160

180

200

300 400 500 600 700 800 900 1000

Thickness (mm)

P

e

r

c

e

n

t

s

t

e

e

l

r

e

l

a

t

i

v

e

t

o

B

S

8

0

0

7

Cover

(a) k

1

= 0.8 (EN 1992-1-1) (b) k

1

= 1.14 (CIRIA C660)

P Bamforth, J Shave, S Denton 8

Figure 3. The ratio of reinforcement requirements for design to EN 1992 and BS8007

(C30/37 concrete; plywood formwork; limiting early-age crack width to 0.15 mm; cover

as shown)

Observations by the authors suggest that the requirements of BD28 and BS 8007, while

having been generally applicable, have occasionally led to excessive crack widths and that it

would be unsafe to adopt a design that significantly reduces the current requirements. The

design parameters were therefore investigated. BS EN 1992-1-1:2004 recommends a factor

of 0.7 is applied to bond stress in cases when good bond cannot be guaranteed. In C660,

this factor has been considered applicable to k

1

in cases of EATC, so the bond coefficient k

1

is

increased from 0.8 to 1.14, since 0.8/0.7 = 1.14. Calculations using the increased value of k

1

are shown in Figure 3 (b) and lead to steel requirements that are closer to those of BS 8007

within the normal range of cover. Higher steel ratios than those suggested by BS 8007 are

generally associated with high cover.

Crack width

Up to this point in the design the nature of the restraint has not been considered. However, in

estimating crack width, BS EN 1992-3:2006 uses different expressions for estimating the

magnitude of crack-inducing strain

cr

.

For continuous edge restraint informative Annex M of BS EN 1992-3:2006 assumes

cr

=

r

i.e. the restrained-strain. CIRIA C660 proposes the expression

cr

=

r

0.5

ctu

i.e.

r

less

the residual strain in the concrete after cracking. (This approach is also taken by BD28.) In

each case the assumption is that the crack width is strain limited.

For end restraint only a different expression is used as follows;

1

1

E

. .k.f .k 0.5

e s

eff ct c e

|

|

|

|

.

|

\

|

+ =

cr

c

E

s

is the modulus of elasticity of the steel;

e

is the modular ratio; f

ct,eff

is the tensile stress in

the concrete immediately prior to cracking; is the steel ratio based on the full area of

concrete in tension [N.B. This is not the same as

p,eff

used in the calculation of crack

spacing]; k and k

c

are area coefficients described in Table 1. This expression assumes that the

crack width is limited by the stress transferred to the steel.

Under conditions of end restraint, even when the minimum steel ratio is exceeded, crack

widths may be significantly wider than achieved under conditions of edge restraint, although

fewer cracks may occur. For example, in a 400mm section with 16mm bars at 250mm centres

using C30/37, the crack width resulting from end restraint is estimated to be 1mm, while

under conditions of edge restraint the estimated crack width is in the order of 0.15mm.

The Influence of Cover

The net effect on crack width of cover alone is shown in Figure 4. This has been recognised

for many years. For example, Campbell-Allen & Hughes

[11]

recommended that the placing

of such reinforcement shall be as near to the surface of the concrete as is consistent with the

P Bamforth, J Shave, S Denton 9

requirements of adequate cover. However, in relation to control of EATC, the effect of

cover has not previously been quantified. Furthermore, recognising that the crack profile may

differ significantly from that of a crack developed by an element in flexure, it may be

inappropriate to adopt a similar expression to derive crack spacing and further research is

recommended in this area to avoid unnecessarily high volumes of reinforcement being used

when high cover is specified.

0.00

0.05

0.10

0.15

0.20

0.25

30 40 50 60 70

Cover (mm)

C

r

a

c

k

w

i

d

t

h

(

m

m

)

0

500

1000

1500

2000

30 40 50 60 70

Cover (mm)

A

r

e

a

o

f

r

e

i

n

f

o

r

c

e

m

e

n

t

(

m

m

2

)

(a) Effect of cover on crack width (b) Area of reinforcement (mm

2

/m/face)

required to achieve a crack width of 0.15mm

Figure 4. The Effect of Cover in a 300mm Wall Subject to a 30

o

C Temperature Drop

and 70% Restraint

Comparison Between Estimated and Observed Crack Widths

Comparisons between observed crack widths and predictions using current methods are

shown in Figure 5. These graphs are based on back analysis of measured data, as explained by

Bamforth

[12]

. It is clear that both BS 8007 and BS EN 1992 (without extension as

recommended in C660) lead to unsafe predictions of crack width for many of the examples.

In some cases the difference was as much as 50%. The method of CIRIA C660, which is

based on the method of BS EN 1992 but extended as described, shows a much better

correlation with the reported crack widths.

BS8007

0.0

0.1

0.2

0.3

0.4

0.5

0.2 0.25 0.3 0.35 0.4

Measured crack width (mm)

E

s

t

i

m

a

t

e

d

c

r

a

c

k

w

i

d

t

h

(

m

m

)

EN1992-3

0.0

0.1

0.2

0.3

0.4

0.5

0.2 0.25 0.3 0.35 0.4

Measured crack width (mm)

E

s

t

i

m

a

t

e

d

c

r

a

c

k

w

i

d

t

h

(

m

m

)

P Bamforth, J Shave, S Denton 10

CIRIA C660

0.0

0.1

0.2

0.3

0.4

0.5

0.2 0.25 0.3 0.35 0.4

Measured crack width (mm)

E

s

t

i

m

a

t

e

d

c

r

a

c

k

w

i

d

t

h

(

m

m

)

Figure 5. Comparison of observed and predicted crack widths using the methods of

BS 8007, BS EN 1992-3:2006 (without extension for EATC) and CIRIA C660

[12]

Conclusions

The design approach for early-age thermal cracking adopted by BS EN 1992-3:2006 is

broadly similar to that of BD 28 and BS 8007 but there are some significant and important

differences as follows;

1) Different values of surface zone are used to estimate the minimum area of

reinforcement

2) Different surface zones are used to estimated the steel ratio for calculating crack

width

3) BS EN 1992-1-1:2004 includes cover in the expressions for crack spacing and width.

This was not included in BS 8007 of BD 28

4) The term f

ct

/ f

b

(tensile strength/bond strength) has been replaced by the coefficient

k

1

5) Crack development and crack widths depend on whether the element is subject to

edge restraint or end restraint and this is reflected in different expressions for

calculating crack width

6) Autogenous shrinkage is assumed to occur in all grades of structural concrete

CIRIA C660 has recognised these changes and has proposed modifications to the design

parameters to complement EN 1992 and ensure that estimated crack widths reflect more

reliably those observed in practice.

Acknowledgements

The authors wish to thank the Construction Industry Research and Information Association

for their permission to publish this paper.

References

[1] BD28/87 Early Thermal Cracking of Concrete, Design Manual for Roads and Bridges

Vol 1 Section 3, Incorporating Amendment No 1, 1989, TSO

[2] British Standards Institution, 1987, Design of Concrete Structures for Retaining

Aqueous Liquids, BS8007:1987.

[3] Bamforth, P B, 2007, Early-age Thermal Crack Control in Concrete, CIRIA Report

C660, Construction Industry Research and Information Association, London.

P Bamforth, J Shave, S Denton 11

[4] Harrison, T A, 1992, Early-age Thermal Crack Control in Concrete, CIRIA Report

91, Construction Industry Research and Information Association, London.

[5] British Standards Institution, 1985, Structural Use of Concrete. BS8110:1985

[6] British Standards Institution , 1990, BS 5400-4:1990, Steel, concrete and composite

bridges. Code of practice for design of concrete bridges.

[7] Dhir, R K, Paine, K A and Zheng, L, 2006, Design data for low heat and very low heat

special cements, University of Dundee, Research Contract No. CTU/I53), Report

CTU/4006, September 2006

[8] Anchor, R D, Hill, A W and Hughes, B P, 1979, Handbook on BS 5337:1976 (The

structural use of concrete for retaining aqueous liquids) Viewpoint Publications,

Cement & Concrete Association, Slough.

[9] Narayanan, R S and Beeby, A W, Designers Guide to EN 1992-1-1 and EN 1992-1-2

Eurocode 2: Design of Concrete Structures. General rules and rules for buildings and

structural fire design, Thomas Telford.

[10] Beeby, A W, 1990, Fixings in cracked concrete The Probability of Coincident

Occurrence and Likely Crack Width, CIRIA Technical Note 136, Construction

Industry Research and Information Association, London.

[11] Campbell-Allen, D and Hughes, G W, 1981, Reinforcement to Control Thermal and

Shrinkage Cracking. Transaction of the Institution of Engineers, Australia, Civil

Engineering, August, Vol. CE23. No. 3.

[12] Bamforth, P B, 2008, A revised approach for the design of reinforcement to control

cracking in concrete resulting from restrained contraction - Case studies and

validation, ICE Research Project 0706, Project Report ICE/0706/007. Institution of

Civil Engineers, London. Project Report ICE/0706/007.

You might also like

- Design For Early Thermal CrackingDocument10 pagesDesign For Early Thermal Crackingdhruvgoku100% (1)

- Crack Width Analysis Software VerificationDocument8 pagesCrack Width Analysis Software VerificationSuhail Ahamed100% (1)

- Crack Width Evaluation For Flexural RC MembersDocument10 pagesCrack Width Evaluation For Flexural RC MembersAly AnisNo ratings yet

- Why Structural Designs Vary: Common Issues and Best PracticesDocument2 pagesWhy Structural Designs Vary: Common Issues and Best Practicesraj_anu130% (1)

- Post Tension MultistrandDocument15 pagesPost Tension MultistrandStephanie K ChanNo ratings yet

- Etc - BD 28-87Document1 pageEtc - BD 28-87arun_angshuNo ratings yet

- Flextural Cracking in Concrete StructureDocument11 pagesFlextural Cracking in Concrete StructuresjmorabadNo ratings yet

- Impact of Crack Width On Bond Confined and Unconfined RebarDocument10 pagesImpact of Crack Width On Bond Confined and Unconfined RebarbrahmabulNo ratings yet

- Reportbakker PDFDocument203 pagesReportbakker PDFShaileshRastogiNo ratings yet

- Upgrading of Railway Bridge at Woll I Creek SydneyDocument14 pagesUpgrading of Railway Bridge at Woll I Creek SydneyAndrew PetryszakNo ratings yet

- Crack control of internal restraint in Pile Cap TopDocument5 pagesCrack control of internal restraint in Pile Cap TopSravanthi Mehar100% (1)

- Concrete Pull Out Check PDFDocument1 pageConcrete Pull Out Check PDFMaliki MuhammedNo ratings yet

- Design of joints in segmental hollow box girder bridgesDocument6 pagesDesign of joints in segmental hollow box girder bridgesPunithan PunithanNo ratings yet

- C660 - Estimation of Autogenous Shrinkage According To EN1992-1-1Document2 pagesC660 - Estimation of Autogenous Shrinkage According To EN1992-1-1Harshana Prabhath100% (1)

- Stiffness of Concrete SlabsDocument61 pagesStiffness of Concrete SlabsfaumijkNo ratings yet

- EC2 Strut and Tie DesignDocument69 pagesEC2 Strut and Tie DesignWai Hoong EngNo ratings yet

- Moment Distribution Method ExplainedDocument37 pagesMoment Distribution Method ExplainedSuleiman Yusuf JibrilNo ratings yet

- Mac Alloy Post Tensioning - Macalloy 1030 - Nov 2011Document12 pagesMac Alloy Post Tensioning - Macalloy 1030 - Nov 2011Karl FarrugiaNo ratings yet

- C660 - Estimation of Drying Shrinkage According To EN1992-1-1Document3 pagesC660 - Estimation of Drying Shrinkage According To EN1992-1-1Madhusudan MandalNo ratings yet

- Early Thermal Cracking ConcreteDocument13 pagesEarly Thermal Cracking ConcreteOttawa Canada100% (2)

- Experimental Work For Mechanical Properties of Brick and Masonry PanelDocument8 pagesExperimental Work For Mechanical Properties of Brick and Masonry PanelHadi Iz'aanNo ratings yet

- Composite Beam DesignDocument33 pagesComposite Beam DesignihpeterNo ratings yet

- TGN Level 2 Note 9 Designing A Reinforced Concrete Retaining Wall - Oct2016Document4 pagesTGN Level 2 Note 9 Designing A Reinforced Concrete Retaining Wall - Oct2016Lee WhiteheadNo ratings yet

- EC2 Crack width and stress calculationDocument11 pagesEC2 Crack width and stress calculationselinaNo ratings yet

- Post-tensioning steel strands technical dataDocument28 pagesPost-tensioning steel strands technical datanovakno1No ratings yet

- Cracks in Immature ConcreteDocument2 pagesCracks in Immature ConcreterasikamalNo ratings yet

- Polystorm Performance AssessmentDocument4 pagesPolystorm Performance AssessmentHemant ChauhanNo ratings yet

- 03 12 General Design Design of Integral Bridges PDFDocument15 pages03 12 General Design Design of Integral Bridges PDFshardasiddhNo ratings yet

- Strengthening Design of Concrete Beams by Adition of Steel PlatesDocument10 pagesStrengthening Design of Concrete Beams by Adition of Steel PlatesgparratNo ratings yet

- Lecture-Introduction To EC2Document48 pagesLecture-Introduction To EC2denyfate100% (1)

- High Strength Concrete Columna With Intervening Normal Strength One Way Slabs and Beams FloorsDocument39 pagesHigh Strength Concrete Columna With Intervening Normal Strength One Way Slabs and Beams FloorsGan Chin PhangNo ratings yet

- ComFlor® ManualDocument132 pagesComFlor® ManualAhmedNo ratings yet

- Plate Girders 2008Document20 pagesPlate Girders 2008Tharmalingam VijayNo ratings yet

- EC2 Design CalculationsDocument81 pagesEC2 Design Calculationscollins unankaNo ratings yet

- Durability of ConcreteDocument33 pagesDurability of Concreteabdulwahab11No ratings yet

- Corbel Design PaperDocument13 pagesCorbel Design Paperkapola100% (2)

- CE5510B Advanced Structural Concrete Design To EC2: 10. Flat Slab SystemDocument17 pagesCE5510B Advanced Structural Concrete Design To EC2: 10. Flat Slab SystemwinminthetgeoNo ratings yet

- Corus - Design of Shs Welded JointsDocument48 pagesCorus - Design of Shs Welded JointsDylan RamasamyNo ratings yet

- Shear Strength of Circular ReinforcedDocument77 pagesShear Strength of Circular ReinforcedHafiz DoyoxNo ratings yet

- Steel reinforcement and concrete propertiesDocument3 pagesSteel reinforcement and concrete propertiesAngelo MoralNo ratings yet

- Laterally Loaded Pile Cap ConnectionsDocument151 pagesLaterally Loaded Pile Cap ConnectionschanakyaNo ratings yet

- Concrete Bridge Design and Construction Series: No. 12: Management of Concrete BridgesDocument6 pagesConcrete Bridge Design and Construction Series: No. 12: Management of Concrete BridgesJacob GrechNo ratings yet

- Liquid Loads on a Tank Wall using PCA TablesDocument1 pageLiquid Loads on a Tank Wall using PCA TablesKevin YewNo ratings yet

- Optimize Positioning of Relief Shelf in Cantilever Retaining WallDocument3 pagesOptimize Positioning of Relief Shelf in Cantilever Retaining WallGRD Journals100% (1)

- EC7 Fundamental Issues and Its Implications On Users PDFDocument24 pagesEC7 Fundamental Issues and Its Implications On Users PDFVardhanNo ratings yet

- Foreva - Water Civil EngineeringDocument4 pagesForeva - Water Civil EngineeringHuy Nguyen VanNo ratings yet

- How To Reinforce Concrete To Control CrackingDocument3 pagesHow To Reinforce Concrete To Control Crackingchutton681No ratings yet

- Computer Simulation of Cumulative Fatigue Damage: Facta UniversitatisDocument9 pagesComputer Simulation of Cumulative Fatigue Damage: Facta UniversitatisBilly ChrisNo ratings yet

- Reinforced Concrete To BS en 1992Document4 pagesReinforced Concrete To BS en 1992crayonlee365100% (2)

- RC Beam Torsion DesignDocument33 pagesRC Beam Torsion Design2011kumarNo ratings yet

- RC Deflection & CrackingDocument27 pagesRC Deflection & CrackingGerald Maginga50% (2)

- Cracks & Crack Control in Concrete Structures-2Document12 pagesCracks & Crack Control in Concrete Structures-2Kiran N S GowdaNo ratings yet

- EC2 Creep and Shrinkage LossesDocument9 pagesEC2 Creep and Shrinkage LossesSorin SavescuNo ratings yet

- CONCRETE 2011 Stress Block3 PDFDocument9 pagesCONCRETE 2011 Stress Block3 PDFThong NguyenNo ratings yet

- Simplified Procedures For Calculation of Instantaneous and Long-Term Deflections of Reinforced Concrete BeamsDocument12 pagesSimplified Procedures For Calculation of Instantaneous and Long-Term Deflections of Reinforced Concrete BeamssukolikNo ratings yet

- Software Verification: Example 17Document8 pagesSoftware Verification: Example 17sancloudNo ratings yet

- Speed Square Instruction Book 2Document23 pagesSpeed Square Instruction Book 2BrentChadwell100% (6)

- Currencies Whose Names Still Point To Silver Money - 4Document2 pagesCurrencies Whose Names Still Point To Silver Money - 4dhruvgokuNo ratings yet

- Currencies Whose Names Still Point To Silver Money - 3Document4 pagesCurrencies Whose Names Still Point To Silver Money - 3dhruvgokuNo ratings yet

- Currencies Whose Names Still Point To Silver Money - 5Document1 pageCurrencies Whose Names Still Point To Silver Money - 5dhruvgokuNo ratings yet

- Currencies Whose Names Still Point To Silver Money - 2Document5 pagesCurrencies Whose Names Still Point To Silver Money - 2dhruvgokuNo ratings yet

- Pace CriteDocument1 pagePace CritedhruvgokuNo ratings yet

- SpeedSquareInstructionBook3 PDFDocument22 pagesSpeedSquareInstructionBook3 PDFdhruvgoku0% (1)

- Currencies Whose Names Still Point To Silver Money - Silver BullionDocument6 pagesCurrencies Whose Names Still Point To Silver Money - Silver BulliondhruvgokuNo ratings yet

- Peter RiceDocument4 pagesPeter RicedhruvgokuNo ratings yet

- Pace CriteDocument1 pagePace CritedhruvgokuNo ratings yet

- Pace CriteDocument1 pagePace CritedhruvgokuNo ratings yet

- PACEcriteriaDocument2 pagesPACEcriteriadhruvgokuNo ratings yet

- Pace CriteriaDocument3 pagesPace CriteriaAnat HershkovitzNo ratings yet

- Solrx Pharmacy Review Book For Qualifying Exam-2 (OSCE) : E-Mail: 1-888-267-2464Document1 pageSolrx Pharmacy Review Book For Qualifying Exam-2 (OSCE) : E-Mail: 1-888-267-2464dhruvgokuNo ratings yet

- Nakshatra Basics PT Sanjay RathDocument1 pageNakshatra Basics PT Sanjay RathdhruvgokuNo ratings yet

- Solrx Pharmacy Review Book For Qualifying Exam-2 (OSCE) : E-Mail: 1-888-267-2464Document1 pageSolrx Pharmacy Review Book For Qualifying Exam-2 (OSCE) : E-Mail: 1-888-267-2464dhruvgokuNo ratings yet

- Revisions Handbook11e2pDocument7 pagesRevisions Handbook11e2pdhruvgokuNo ratings yet

- Design Example of A Six Storey Building: Dr. H. J. ShahDocument1 pageDesign Example of A Six Storey Building: Dr. H. J. ShahdhruvgokuNo ratings yet

- Abuse and Diversion of Controlled Substances 2Document19 pagesAbuse and Diversion of Controlled Substances 2dhruvgokuNo ratings yet

- FAA Advisory Circular Updates Heliport Design StandardsDocument196 pagesFAA Advisory Circular Updates Heliport Design Standardsiscrdmyslfagin100% (2)

- 104 Stdesign v3 Manual Feb2009Document85 pages104 Stdesign v3 Manual Feb2009jaykmseNo ratings yet

- Basic Snow Loading (O.B.C. 2012)Document1 pageBasic Snow Loading (O.B.C. 2012)dhruvgokuNo ratings yet

- Abuse and Diversion of Controlled SubstancesDocument20 pagesAbuse and Diversion of Controlled SubstancesdhruvgokuNo ratings yet

- Revisions Handbook11e2pDocument7 pagesRevisions Handbook11e2pdhruvgokuNo ratings yet

- Revisions Handbook11e2pDocument7 pagesRevisions Handbook11e2pdhruvgokuNo ratings yet

- Basic Snow Loading (O.B.C. 2012)Document1 pageBasic Snow Loading (O.B.C. 2012)dhruvgokuNo ratings yet

- Revisions Handbook11e2pDocument7 pagesRevisions Handbook11e2pdhruvgokuNo ratings yet

- Calculation List - Canadian Codes - TeklaDocument5 pagesCalculation List - Canadian Codes - TekladhruvgokuNo ratings yet

- Hello: File:///c - /Users/dgajjar/Desktop/hii - TXT (3/12/2018 10:27:36 AM)Document1 pageHello: File:///c - /Users/dgajjar/Desktop/hii - TXT (3/12/2018 10:27:36 AM)dhruvgokuNo ratings yet

- Qatar Gas Protective Coating ProcedureDocument99 pagesQatar Gas Protective Coating ProcedureBalaji Guru67% (3)

- Indian Standard For Industrial FlooringDocument10 pagesIndian Standard For Industrial FlooringRamprasad JeyaramNo ratings yet

- Optimum Design of Reinforced Concrete Raft Foundations Using Finite Element AnalysisDocument78 pagesOptimum Design of Reinforced Concrete Raft Foundations Using Finite Element AnalysisLaison GodloveNo ratings yet

- Stability of Ogee Shaped Weir & EstimateDocument18 pagesStability of Ogee Shaped Weir & EstimateHarish Kumar MahavarNo ratings yet

- Pump FoundationDocument33 pagesPump Foundationriaz16shaikNo ratings yet

- 18arc82 - Materials and Methods in Building Construction Viii Viii Semester C SectionDocument73 pages18arc82 - Materials and Methods in Building Construction Viii Viii Semester C SectionSAI BHAVANA AKURATINo ratings yet

- Manuscrip Human Hair NCR Phy Team PDFDocument66 pagesManuscrip Human Hair NCR Phy Team PDFJhun DavantesNo ratings yet

- PWD Project ReportDocument20 pagesPWD Project ReportSandeep PatelNo ratings yet

- UWUCWPhaseIIBNCBSW BOQDocument53 pagesUWUCWPhaseIIBNCBSW BOQUditha AnuruddthaNo ratings yet

- Juntas de ControlDocument5 pagesJuntas de ControlHeriberto Yau BNo ratings yet

- Retaining Wall With Pile - 2 Pile - Type ADocument114 pagesRetaining Wall With Pile - 2 Pile - Type Akaosar alamNo ratings yet

- Nitoproof 600 UAEDocument4 pagesNitoproof 600 UAECharles FernandesNo ratings yet

- TLE 7 Carpentry FundamentalsDocument39 pagesTLE 7 Carpentry FundamentalsessaNo ratings yet

- The Physical Condition of Albanian BridgesDocument10 pagesThe Physical Condition of Albanian BridgesyavuzyardimNo ratings yet

- Precast Concrete For Low-RiseDocument62 pagesPrecast Concrete For Low-RiseJune Suriyawanakul100% (4)

- N.SDS - 3 ENI Tech Doc Identif and Classif.Document36 pagesN.SDS - 3 ENI Tech Doc Identif and Classif.Chokri HmeidiNo ratings yet

- Specific Requirements & Scope of Work For RCC PilingDocument38 pagesSpecific Requirements & Scope of Work For RCC PilingTauqueerAhmadNo ratings yet

- SAES T 911 Latest VersionDocument60 pagesSAES T 911 Latest VersionAkhlaque ShamsiNo ratings yet

- Faculty of Architecture, Planning and Surveying QSD 132 - Construction of Technology (Material) Report of BlockDocument17 pagesFaculty of Architecture, Planning and Surveying QSD 132 - Construction of Technology (Material) Report of BlockdahliagingerNo ratings yet

- Fosroc Conplast SP430: Constructive SolutionsDocument2 pagesFosroc Conplast SP430: Constructive SolutionsVincent JavateNo ratings yet

- Lab Manual For UTMDocument200 pagesLab Manual For UTMDesmond TongNo ratings yet

- Concrete Structures Seismic Design GuideDocument60 pagesConcrete Structures Seismic Design GuideabadittadesseNo ratings yet

- Tunnel Formwork System GuideDocument22 pagesTunnel Formwork System GuidesuvraNo ratings yet

- Article1 KHATIB NabilDocument9 pagesArticle1 KHATIB NabilNabilNo ratings yet

- ACI Structural Journal (January 2014)Document11 pagesACI Structural Journal (January 2014)Tian NgNo ratings yet

- FMDDocument6 pagesFMDhazopmanNo ratings yet

- Lightweight aggregates from sludge and clayDocument6 pagesLightweight aggregates from sludge and clayMiguel Hernandez Rodriguez100% (1)

- ITA-AFTES - Guideline For The Design of Shield Tunnel Lining PDFDocument29 pagesITA-AFTES - Guideline For The Design of Shield Tunnel Lining PDFAnonymous PsEz5kGVaeNo ratings yet

- C566 PDFDocument3 pagesC566 PDFNaura RasyidaNo ratings yet

- TR Super Plasticizer 03Document20 pagesTR Super Plasticizer 03Mostafa Hussein AbdouNo ratings yet