Professional Documents

Culture Documents

Padeye Cal

Uploaded by

huangjlCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Padeye Cal

Uploaded by

huangjlCopyright:

Available Formats

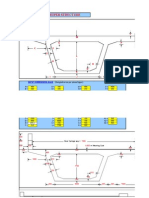

CALCULATION-REPORT

STRENGTH CHECK OF LIFTING PADEYE

( FOR PADEYE TYPE 55 ton )

1. ) CONDITIONS :

Specifications: AISC & API-RP2 1.2 In practice a horizontal force of 5% of the static sling load should be applied simultanrously with the sling load.

1.1 1.3 Try : main & cheek plate materials to Q345B Fy 1.4 = 295 N / mm

2

The lifting shackle pin diameter , ( 55 ton shackle , type BX class S( 6 ).)

B C

= 70.00 = 3.00 = B+C = 73.00 = D pin-hole / 2 = 36.50 300 170 40 120 = = = = = = = = = = =

mm mm

The pin hole diameter in the lifting padeye , D pin-hole Radius of pin hole , Width of main plate , Center of pin hole from base , Thickness of main plate , Radius of main plate , Radius of cheek plate , Thickness of cheek plate , Width of stiffener plate , Thickness of stiffener plate , Effective bearing angle , Resultant force angle , 1.5 Taking padeye extreme case : Max . Load

( Total Load Factor = R hole W H M THK RM R CH CH THK ST W ST THK

mm mm mm mm mm mm OK!

( > 1.25 * Dpin-hole ) 100.00 mm 20 250 20 120 67 825.00 mm mm mm DEGREES DEGREES KN

a q

F3

1.5 )

FSL B Tpl Fbr Abr fbr = = = = = = = < = 550.00 KN

Static Sling Load

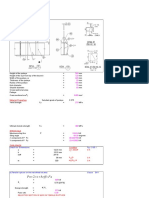

2. ) CHECK FOR BEARING

Pin diameter , Total plate thk , Bearing force , Bearing area ,

70.00 mm M THK + 2 * CH THK 80 825000 5864.31 F br / A br 140.68 0.9 * F y 265.5 mm N mm 2 N / mm 2 N / mm 2 OK!

= T pl * ( B / 2 * a * p / 180 )

3. ) CHECK FOR PULL - OUT DOUBLE SHEAR

PAGE 1 / 6

CALCULATION-REPORT

Shear force Shear area ( effective ) ,

Ash =

Fsh

825000

N mm 2

2

4 * CH THK ( R CH - R hole ) + 2 * MTHK ( RM - Rhole = )11760.00

fv

= = < =

fsh / Ash 70.15 0.4 * F y 118.0 825000 N / mm N / mm N

OK!

4. ) CHECK FOR TENSION

Tensile force ,

FT

Consider section along lower semi-circumference of cheek plate A t e1 Effective net area , = ( p * R CH + 2 * ( R M -R CH ) ) * M THK

f

t1

= = = < =

14166.37 F T / A t e1 58.24 0.60 * F y 177.00

mm

N / mm

N / mm 2

OK!

Consider straight section through bore centreline. Effective net area ,

A t e2 =

4 * CH THK ( R CH - R hole ) + 2 * MTHK ( RM - Rhole = )11760.00

mm 2

2

t2

= = < =

F T / A t e2 70.15 0.45 * F y 132.75 0.4 * F y 118.0 N / mm

2

N / mm

N / mm 2

OK!

5. ) WELD CHECK BETWEEN MAIN + CHEEK PLATE 1. Max. allowable weld stress for weld with Q345B steel , 2.

Fss= =

Min. required weld area

AW = F 3 * CH THK / ( FW * (2 * CH THK +M THK )) = S 1747.88 mm

2

Fillet weld size ( equal legs ) , Therefore, use 15 mm

= A W / (0.707 * p * 2 * R CH ) = 3.93 mm

equal legs, for cheek plateson padeye.

= = 322353 759417 N N mm 2 mm mm

2

6. ) BENDING STRESS CHECK H F3 = F 3 * COS ( q ) V F3 A BASE = = F 3 * SIN ( q ) M THK * W + 2 * ST W * ST THK E

Effective area at base of padeye main plate and stiffener plates,

= 22000

Neutral axis location , Eccentric distance , Moment of inertia & section modulus @ N.A. ,

I xx =

X= 150.00

= 30.00

(W/2)

M THK * W 3 / 12 + 2 * (ST W * ST THK 3 / 12 + S TW * ST THK * ((W / 2)+ST THK / 2) S xx = 346333333.3 = I xx / (X +ST THK) = 2037254.902 mm

4

mm 3 mm 4

Moment of inertia & section modulus @ Y-Y ,

I yy = M THK 3 * W / 12 + 2 * ST THK * ST W 3 / 12 S yy = 53683333.33 = I yy / ( ST W / 2)

PAGE 2 / 6

CALCULATION-REPORT

= 429466.6667 6.1 ) IN - PLANE BENDING CHECK

mm 3

Moment force , Tensile stress ,

M f

ti

= ABS ( H F3 * H - V F3 * E ) = 32017545.65 = V F3 / A BASE = 34.52 < 0.60 * F y N - mm N / mm 2

2

Bending stress ,

ba

= = = < =

N / mm 177.00 M * (W - X + ST THK ) / I xx 15.72 0.66* F y 194.70 N / mm N / mm

OK!

OK!

6.2 ) SHEAR CHECK ON CONNECTIONS

Along main plate & T.O.S. (Effective area no-including stiffener plates)

= = < =

H F3 / ( M THK * W ) 26.86 0.40 * F y 118.00 N / mm N / mm

2

OK!

6.3 ) OUT - OF - PLANE BENDING

* * Consider 5 % contingency for side load caused by out of plane pull due to error between actual and theoretical C.G., wind load & load swing.

FL = 0.05 * F SL = = =

+ [ 2 * R1 * CHTHK * (

27500 64 84

N mm mm

)2 ] * 2 + 2 *

3 R2 * MTHK 12

I @ Bore centre ( Y-Y) R1 = R CH - R hole R2 = R M - R hole

IC yy = = = = =

2*

3 R1 * CHTHK 12

CHTHK + MTHK 2

5547333

SC yy M CL fb

IC yy

mm 4 / ( CH THK + M THK / 2 )

= = = < =

138683.33 1003750 7.24 0.66 * F y 194.7 53683333.33 429466.6667 5678750 13.22 0.66 * F y 194.70

mm

Moment @ Bore centreline

F L * R hole M CL / SC yy N - mm N / mm 2 N / mm 2 mm 4 mm 4

OK!

I at the base of the padeye ( Y - Y)

I yyb S yyb MB f bb = = = = I yy S yy F L * ( H + R hole ) M B / S yyb = = = = < =

Moment @ Bore T.O.S. ( Base )

N - mm 2 N / mm N / mm 2

OK!

AISC unity check at padeye base UC = ( f ti / 0.6F y ) + ( f ba / 0.66F y ) + ( f bb / 0.66F y=) 0.34

< 1.0 OK!

PAGE 3 / 6

CALCULATION-REPORT

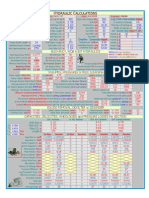

STRENGTH CHECK OF LIFTING PADEYE

( FOR PADEYE TYPE 35 ton )

1. ) CONDITIONS :

Specifications: AISC & API-RP2 1.2 In practice a horizontal force of 5% of the static sling load should be applied simultanrously with the sling load.

1.1 1.3 Try : main & cheek plate materials to Q345B Fy 1.4 = 325 = 60.00 = 3.00 = B+C = 63.00 = D pin-hole / 2 = 31.50 = 300 = 170 = 30 = 120 N / mm 2

The lifting shackle pin diameter , ( 35 ton shackle , type BX class S( 6 ).) Pin hole clearance , The pin hole diameter in the lifting padeye , Radius of pin hole , Width of main plate , Center of pin hole from base , Thickness of main plate , Radius of main plate , Radius of cheek plate , Thickness of cheek plate , Width of stiffener plate , Thickness of stiffener plate ,

B C

mm mm mm mm mm mm mm mm OK!

D pin-hole

R hole W H M THK RM R CH CH THK ST W ST THK

( > 1.25 * Dpin-hole ) = 100.00 mm = 20 = 160 = 20 = 120 = 67 = 525.00 350.00 mm mm mm DEGREES DEGREES KN KN

Effective bearing angle , Resultant force angle , 1.5 Taking padeye extreme case : Max . Load

( Total Load Factor =

a q

F3 FSL B Tpl Fbr Abr fbr

1.5 )

Static Sling Load

2. ) CHECK FOR BEARING

Pin diameter , Total plate thk , Bearing force , Bearing area ,

= 60.00 mm = M THK + 2 * CH THK = 70 = 525000 = 4398.23 = F br / A br = 119.37 < 0.9 * F y = 292.5 mm N mm 2 N / mm 2 N / mm 2 N mm 2 N / mm 2 N / mm 2 OK! OK!

= T pl * ( B / 2 * a * p / 180 )

3. ) CHECK FOR PULL - OUT DOUBLE SHEAR

Shear force Shear area ( effective ) ,

Ash =

Fsh

4 * CH THK ( R CH - R hole ) + 2 * MTHK ( RM - Rhole )

= 525000 = 10790.00 = fsh / Ash = 48.66 < 0.4 * F y = 130.0

fv

4. ) CHECK FOR TENSION

PAGE 4 / 6

CALCULATION-REPORT Tensile force ,

FT = 525000 N

Consider section along lower semi-circumference of cheek plate A t e1 Effective net area , =

f

t1

( p * R CH + 2 * ( R M -R CH ) ) * M THK

= 10624.78 = F T / A t e1 = 49.41 < 0.60 * F y = 195.00

mm 2 N / mm 2 N / mm 2 OK!

Consider straight section through bore centreline. Effective net area ,

A t e2 =

4 * CH THK ( R CH - R hole ) + 2 * MTHK ( RM - Rhole )

= 10790.00 = F T / A t e2 = 48.66 < 0.45 * F y = 146.25

mm 2 N / mm 2 N / mm 2 OK!

t2

5. ) WELD CHECK BETWEEN MAIN + CHEEK PLATE 1. Max. allowable weld stress for weld with Q345B steel , 2.

Fss

= 0.4 * F y = 130.0 N / mm 2 mm 2

Min. required weld area

AW = F 3 * CH THK / ( FW * (2 * CH THK +M THK )) S = 1153.85

Fillet weld size ( equal legs ) , Therefore, use 12 mm

= A W / (0.707 * p * 2 * R CH ) = 2.60 mm

equal legs, for cheek plateson padeye.

= 205134 = 483265 = 15400 N N mm 2 mm mm (W/2)

6. ) BENDING STRESS CHECK H F3 = F 3 * COS ( q ) V F3 A BASE = = F 3 * SIN ( q ) M THK * W + 2 * ST W * ST THK

Effective area at base of padeye main plate and stiffener plates, Neutral axis location , Eccentric distance , Moment of inertia & section modulus @ N.A. ,

I xx

X

E

= 150.00 = 0.00

3 3 2 = M THK * W / 12 + 2 * (ST W * ST THK / 12 + S TW * ST THK * ((W / 2)+ST THK / 2) ) 4 = 231553333.3 mm = I xx / (X +ST THK) 3 = 1362078.431 mm

S xx

Moment of inertia & section modulus @ Y-Y ,

I yy

3 3 = M THK * W / 12 + 2 * ST THK * ST W / 12 4 = 14328333.33 mm

S yy 6.1 ) IN - PLANE BENDING CHECK

= I yy / ( ST W / 2)

3 = 179104.1667 mm

Moment force , Tensile stress ,

M f

ti

= ABS ( H F3 * H - V F3 * E ) = 34872753.22 N - mm = V F3 / A BASE = 31.38 < 0.60 * F y N / mm 2 OK!

Bending stress ,

ba

N / mm 2 = 195.00 = M * (W - X + ST THK ) / I xx = 25.60 < 0.66* F y = 214.50 N / mm 2 N / mm 2

OK!

6.2 ) SHEAR CHECK ON CONNECTIONS

Along main plate & T.O.S. PAGE 5 / 6

= H F3 / ( M THK * W )

CALCULATION-REPORT (Effective area no-including stiffener plates)

= 22.79 < 0.40 * F y = 130.00 6.3 ) OUT - OF - PLANE BENDING N / mm 2 N / mm 2 OK!

* * Consider 5 % contingency for side load caused by out of plane pull due to error between actual and theoretical C.G., wind load & load swing.

FL = 0.05 * F SL = 17500 = 69 = 89 N mm mm

I @ Bore centre ( Y-Y) R1 = R CH - R hole

R2 IC yy SC yy = = = =

R M - R hole

2*

3 3 R1 * CHTHK CHTHK + MTHK R2 * MTHK + [ 2 * R1 * CHTHK * ( )2 ] * 2 + 2 * 12 2 12 mm 4 3914583 mm 3 IC yy / ( CH THK + M THK / 2 ) = 111845.24

Moment @ Bore centreline

M CL fb = = F L * R hole M CL / SC yy = 551250 = 4.93 < 0.66 * F y = 214.5 N / mm 2 OK! N - mm N / mm 2

I at the base of the padeye ( Y - Y)

I yyb S yyb = = I yy S yy

4 = 14328333.33 mm

4 = 179104.1667 mm

Moment @ Bore T.O.S. ( Base )

MB f bb = = F L * ( H + R hole ) M B / S yyb = 3526250 = 19.69 < 0.66 * F y = 214.50 N / mm 2 OK! N - mm N / mm 2

AISC unity check at padeye base UC = ( f

ti

/ 0.6F y )

(f

ba

/ 0.66F y ) + ( f

bb

/ 0.66F y )

0.37 OK!

< 1.0

PAGE 6 / 6

You might also like

- Spreader BeamDocument7 pagesSpreader BeamAnonymous sfkedkymNo ratings yet

- Pad-Eye MainDocument8 pagesPad-Eye MainPradeep ChitluriNo ratings yet

- Swimming Pool-BoQDocument8 pagesSwimming Pool-BoQSolomon Ahimbisibwe100% (1)

- Fixed Base Plate-ACI CodeDocument5 pagesFixed Base Plate-ACI CodeMuthukumaran Sivalingam100% (1)

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsYash RamiNo ratings yet

- Padeye DolphinDocument38 pagesPadeye DolphinMuhammad FadelNo ratings yet

- PE-PP-10-1-F3 Rev. 7.0 PLNG SSI Check List Confirmation ListDocument22 pagesPE-PP-10-1-F3 Rev. 7.0 PLNG SSI Check List Confirmation ListLuis Enrique LavayenNo ratings yet

- Heat TransferDocument1 pageHeat TransferhuangjlNo ratings yet

- Heat TransferDocument1 pageHeat TransferhuangjlNo ratings yet

- Padeye - 01Document9 pagesPadeye - 01ramNo ratings yet

- App 10 Longitudial Shear 2 UC 283Document3 pagesApp 10 Longitudial Shear 2 UC 283yuNo ratings yet

- Vibration Analysis PDFDocument6 pagesVibration Analysis PDFBipin RohitNo ratings yet

- Fatigue Analysis of AL SHAHEEN Field Crown PlateDocument9 pagesFatigue Analysis of AL SHAHEEN Field Crown PlateRajat KatyalNo ratings yet

- FILLET WELD STRENGTH CALCULATIONSDocument8 pagesFILLET WELD STRENGTH CALCULATIONSshadab521No ratings yet

- Lifting Analysis Report - Mahadi KurniawanDocument31 pagesLifting Analysis Report - Mahadi KurniawanDian SasNo ratings yet

- DEP 34.19.20.11-Gen PASSIVE FIRE PROTECTION FOR ONSHORE FACILITIESDocument24 pagesDEP 34.19.20.11-Gen PASSIVE FIRE PROTECTION FOR ONSHORE FACILITIESmahesh100% (2)

- Box Culvert - FRLDocument3 pagesBox Culvert - FRLvinoraamNo ratings yet

- Decoduct Cable Management Systems 03-04-2013Document54 pagesDecoduct Cable Management Systems 03-04-2013Giemy P GeorgeNo ratings yet

- Stability CritariaDocument9 pagesStability CritariaAbu Bakar Siddke RumiNo ratings yet

- Bolt Tension & Torque CalculationDocument1 pageBolt Tension & Torque CalculationhuangjlNo ratings yet

- ABS Fatigue Life Assessment 2014Document1 pageABS Fatigue Life Assessment 2014Fandy SipataNo ratings yet

- API WSD Punch CodeCheckDocument7 pagesAPI WSD Punch CodeCheckKhải TrươngNo ratings yet

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Box Girder Super Structure Design DetailsDocument98 pagesBox Girder Super Structure Design DetailsMark Christopher Del Rosario100% (1)

- 11, Tuas Basin Close. Singapore, 638806: 集永成預制水泥廠私人有限公司 Ces-Precast Pte LtdDocument3 pages11, Tuas Basin Close. Singapore, 638806: 集永成預制水泥廠私人有限公司 Ces-Precast Pte LtdSiow TingNo ratings yet

- Calculation Sheet: Padeye Calculations LoadsDocument15 pagesCalculation Sheet: Padeye Calculations Loadsshani5573No ratings yet

- Input Rev. NO: L + (c1 + c2) TWDocument6 pagesInput Rev. NO: L + (c1 + c2) TWMudasir MughalNo ratings yet

- DANA-Technical Note (TN)Document8 pagesDANA-Technical Note (TN)Samsul Imran BahromNo ratings yet

- Lifting LugDocument39 pagesLifting LugSasikumar JothiNo ratings yet

- Abs Terlurangp35 (Rohs)Document2 pagesAbs Terlurangp35 (Rohs)AdirSchoierNo ratings yet

- Lashing FormulaDocument1 pageLashing FormulaMuhammad FitrahNo ratings yet

- Liquid Coating Resins and AdditivesDocument12 pagesLiquid Coating Resins and AdditivesDhruv SevakNo ratings yet

- X388allegato1 2X Offshore Cranes BDocument15 pagesX388allegato1 2X Offshore Cranes BMostafa BatourNo ratings yet

- Surge Tank Size and CostDocument1 pageSurge Tank Size and CosthuangjlNo ratings yet

- Lifting Lug AnalysisDocument3 pagesLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Bottom Trunnion (-) 45m - With Shear Plate Extension (0 Deg)Document10 pagesBottom Trunnion (-) 45m - With Shear Plate Extension (0 Deg)nallay1705No ratings yet

- Pump CalculationDocument4 pagesPump CalculationhuangjlNo ratings yet

- Insulators Short Form WebDocument20 pagesInsulators Short Form WebSofyan Andika YusufNo ratings yet

- Section Properties: Design of Padeye As Per Aisc 360-2005Document5 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNo ratings yet

- #754 v-3103 Spreader & Lifting 60 DegreeDocument12 pages#754 v-3103 Spreader & Lifting 60 DegreeHafizi HZnumismatic100% (1)

- NYB Fan Handbook - 2007Document112 pagesNYB Fan Handbook - 2007José Pedro Casagrande Trentín100% (1)

- Baseplate Biaxial MZDocument26 pagesBaseplate Biaxial MZD SRINIVAS100% (1)

- Skid LiftDocument2 pagesSkid LiftAmi PutraNo ratings yet

- B. Equivalent Axial (N) and Lateral (Q) Loads: SD SDDocument2 pagesB. Equivalent Axial (N) and Lateral (Q) Loads: SD SDRahul Malani100% (1)

- SVS Well hydraulic calculations and drilling parametersDocument1 pageSVS Well hydraulic calculations and drilling parametershuangjlNo ratings yet

- Design Lifting Hook Plate LiftingDocument3 pagesDesign Lifting Hook Plate LiftingSaravan KumarNo ratings yet

- Wing Plate BucklingDocument2 pagesWing Plate BucklingSai SushankNo ratings yet

- Calculation Sheet: Padeye Calculations LoadsDocument14 pagesCalculation Sheet: Padeye Calculations Loadsandi_nu0% (1)

- Estimating TemplateDocument16 pagesEstimating TemplatehuangjlNo ratings yet

- PT Gunanusa Utama Fabricators: Calculation SheetDocument27 pagesPT Gunanusa Utama Fabricators: Calculation SheetriandiNo ratings yet

- Lifting LugDocument5 pagesLifting LugFarid Tata100% (1)

- TQ-0305-R00 - Calculo Estrutura PDFDocument4 pagesTQ-0305-R00 - Calculo Estrutura PDFPeterson MagroNo ratings yet

- Padeye .5MT CHKDocument12 pagesPadeye .5MT CHKDhanraj VasanthNo ratings yet

- Load CalcDocument69 pagesLoad Calcmyusuf_engineerNo ratings yet

- Padeye Design CheekDocument1 pagePadeye Design CheekPawan ShettyNo ratings yet

- A4-P 1.0 enDocument13 pagesA4-P 1.0 enmkpqNo ratings yet

- Technical Standards and Commentaries For Port and Harbours Faclilities in JapanDocument5 pagesTechnical Standards and Commentaries For Port and Harbours Faclilities in JapandalifyNo ratings yet

- NPSH CalculationDocument1 pageNPSH CalculationhuangjlNo ratings yet

- Calculation of DavitDocument2 pagesCalculation of DavitpiziyuNo ratings yet

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- GoM Offshore Structures Design CriteriaDocument32 pagesGoM Offshore Structures Design CriteriaDonald.KNo ratings yet

- Pec Eval Exam 3Document29 pagesPec Eval Exam 3Joel JusayNo ratings yet

- Pad Eye Connected To Bottom PieceDocument7 pagesPad Eye Connected To Bottom PieceAsaru Deen0% (1)

- API 650 Tank Data Sheet SummaryDocument3 pagesAPI 650 Tank Data Sheet SummaryhuangjlNo ratings yet

- Mayer Stark and Ambrose 2000 Fatigue Design Procedures PDFDocument7 pagesMayer Stark and Ambrose 2000 Fatigue Design Procedures PDFMas Arman TewoNo ratings yet

- Lifting Lug 75 TDocument2 pagesLifting Lug 75 Trustamriyadi0% (1)

- Astm A574Document8 pagesAstm A574nmclaughNo ratings yet

- Bolt Torques For ASME B16.5 Flanges With Sheet Gaskets To ASME B16.21Document30 pagesBolt Torques For ASME B16.5 Flanges With Sheet Gaskets To ASME B16.21huangjlNo ratings yet

- Lifting Lug Load Capacity Vs Crack Length CalculationDocument26 pagesLifting Lug Load Capacity Vs Crack Length CalculationMohamed NkNo ratings yet

- SWI PadeyeDocument11 pagesSWI PadeyeFian ArdiyanaNo ratings yet

- Lifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Document7 pagesLifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Steve MoonNo ratings yet

- Induced Draft Cooling Tower PM Emissions SpreadsheetDocument1 pageInduced Draft Cooling Tower PM Emissions SpreadsheethuangjlNo ratings yet

- Design Against CreepDocument112 pagesDesign Against CreepRishabh TripathiNo ratings yet

- Padeye Check SttandardDocument36 pagesPadeye Check SttandardRiandi HartartoNo ratings yet

- PowderCoatingResins ProductGuide 0Document20 pagesPowderCoatingResins ProductGuide 0zizitroNo ratings yet

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADocument1 page2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNo ratings yet

- 6a Padeye Aisc 360 2005Document6 pages6a Padeye Aisc 360 2005mjlazoNo ratings yet

- 8 Padeye - Spreadsheet Check1Document4 pages8 Padeye - Spreadsheet Check1oluomo1No ratings yet

- PadeyeDocument14 pagesPadeyeMarshall Minggat AmpiNo ratings yet

- Buckling strength analysis of stiffened flat plateDocument8 pagesBuckling strength analysis of stiffened flat plateding liuNo ratings yet

- Calc Sheet Design PadeyeDocument8 pagesCalc Sheet Design PadeyeFernando Humberto100% (1)

- Wind Pressure Calculation As per SP-1275Document7 pagesWind Pressure Calculation As per SP-1275Siva baalanNo ratings yet

- Padeye Design AnalysisDocument8 pagesPadeye Design AnalysisMyatmyat SwewinNo ratings yet

- Sum FHT MD-SLDDocument5 pagesSum FHT MD-SLDNebula RockbandNo ratings yet

- Corbel and NibDocument17 pagesCorbel and NibCatherine Mohanji GeraNo ratings yet

- Shell BC-10 - FPSO Hogging and Sagging Enforced Displacements On Topsides Roel SoelemanDocument6 pagesShell BC-10 - FPSO Hogging and Sagging Enforced Displacements On Topsides Roel SoelemanRoel SoelemanNo ratings yet

- 5 Asmeviii A-24 Clamp ConnectionDocument6 pages5 Asmeviii A-24 Clamp ConnectionpastylNo ratings yet

- GB5782 外形尺寸及重量表 六角头 -C级 GB5780Document2 pagesGB5782 外形尺寸及重量表 六角头 -C级 GB5780huangjlNo ratings yet

- Fuel Pump HP CalculationsDocument8 pagesFuel Pump HP CalculationshuangjlNo ratings yet

- 职场英语对话Document21 pages职场英语对话huangjlNo ratings yet

- Piping Design Maximun Flow Rate in Piping SystemDocument1 pagePiping Design Maximun Flow Rate in Piping SystemhuangjlNo ratings yet

- Volumes AndweightsDocument2 pagesVolumes AndweightsmohdnazirNo ratings yet

- Tank Volumes & Surf AreasDocument4 pagesTank Volumes & Surf AreashuangjlNo ratings yet

- 03 Heat ExchangerDocument17 pages03 Heat ExchangerhuangjlNo ratings yet

- Tank 2bDocument1 pageTank 2bMukeshSharmaNo ratings yet

- RIG TableDocument258 pagesRIG TablehuangjlNo ratings yet

- Conical TankDocument2 pagesConical TankhuangjlNo ratings yet

- Fuel Pump HP CalculationsDocument8 pagesFuel Pump HP CalculationshuangjlNo ratings yet

- Load Capacity Crack Length CalculationDocument28 pagesLoad Capacity Crack Length Calculationharikrishnanpd3327No ratings yet

- PipeData Rev ADocument5 pagesPipeData Rev AhuangjlNo ratings yet

- insulation cal (绝热厚度计算)Document4 pagesinsulation cal (绝热厚度计算)huangjlNo ratings yet

- Tank VolDocument4 pagesTank VolgrabettyNo ratings yet

- Tanks Hell Min ThicknessDocument1 pageTanks Hell Min ThicknesshuangjlNo ratings yet

- ElasticityDocument3 pagesElasticityAbel Antonio PancheNo ratings yet

- Arandelas Hill Side A325Document1 pageArandelas Hill Side A325Oscar SanabriaNo ratings yet

- J-STD-004B:: A New Twist On An Old StandardDocument34 pagesJ-STD-004B:: A New Twist On An Old StandardKishor JadhavNo ratings yet

- Engineering Ceramics GuideDocument29 pagesEngineering Ceramics GuideAnil Kumar YaduganNo ratings yet

- 201211A AQTTB Underground Thermal ExpansionDocument2 pages201211A AQTTB Underground Thermal ExpansionAndreas KalamarasNo ratings yet

- Grundfosliterature 6142401Document136 pagesGrundfosliterature 6142401cristinaleitonNo ratings yet

- Fatima WorkDocument6 pagesFatima WorkMaharNadirAliNo ratings yet

- ProMEP - FireFighting Vendor ListDocument7 pagesProMEP - FireFighting Vendor ListBadr groupNo ratings yet

- Revised MS For WaterproofingDocument9 pagesRevised MS For WaterproofingChamux skalNo ratings yet

- Macam Macam ValveDocument6 pagesMacam Macam ValveAhmadufiNo ratings yet

- Thermo Poly RockDocument15 pagesThermo Poly RockParvathy Uv100% (1)

- Vortex CNC Cooler System HBWDocument7 pagesVortex CNC Cooler System HBWHannan RizqiNo ratings yet

- Circuit BreakerDocument15 pagesCircuit Breakerneenu_tNo ratings yet

- Glass Performance DataDocument4 pagesGlass Performance DataJOSEPH APPIAHNo ratings yet

- A859A859M-04 (Reapproved 2014) PDFDocument5 pagesA859A859M-04 (Reapproved 2014) PDFHadi HowaidaNo ratings yet

- Effect of Curing Period on Concrete Compressive StrengthDocument13 pagesEffect of Curing Period on Concrete Compressive StrengthJirehmaeCatubigFraycoNo ratings yet

- RFT Course by Hatem ElbadryDocument79 pagesRFT Course by Hatem ElbadryEgyptian ResearcherNo ratings yet