Professional Documents

Culture Documents

Two Way Slab Design

Uploaded by

Asif RahmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Two Way Slab Design

Uploaded by

Asif RahmanCopyright:

Available Formats

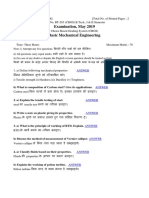

KAMOL CE 2K5- 0501033

TWO WAY SLAB DESIGN

`

# Design panel B & A

Taking D.L= 150 psf; LL= 100 psf

fy = 3500 psi; for panel B

= 4000 psi; for panel A

KAMOL CE 2K5- 0501033

PANEL B

Clear span,

la = 22-16/12= 20.67

lb = 24-16/12= 22.67

Minimum trial thickness,

h

= Perimeter/180

= 2x(20.67+22.67)12/180

= 5.78 6

Load Calculation

1. Dead load

2. Live load

= 6/12 x 150 x 1.2 = 90 psf

= 100 x 1.6

= 160 psf

Total load

Panel ratio, la/lb

= 250 psf

= 20.67/22.67 = 0.91 0.90

[If panel ratio is not find the co-efficient chart, then find out co-efficient by

interpolation method] Say, la/lb = 0.87 then interpolation between 0.90 &

0.85

N.B: Coefficient chart given by Design of Concrete structures- A.H. Nilson;

7th Edition; Page: 200 to 203

For panel ratio 0.90 find out co-efficient by Case-9

KAMOL CE 2K5- 0501033

Ca (-ve)

= 0.068

Cb (-ve)

= 0.025

Ca (+ve)DL = 0.026

Cb (+ve)DL = 0.015

Ca (+ve)LL = 0.036

Cb (+ve)LL = 0.022

Calculation of moment

M = Cw L2

(-ve) moment of continuous edge

Ma(-ve) = 0.068 x 250 x 20.672 x 12 = 87159 lb-in.

Mb(-ve) = 0.025 x 250 x 22.672 x 12=40087 lb-in.

(+ve) moment midspan

Ma (+ve)DL = 0.026 x 90 x 20.672 x 12

= 11997 lb-in.

Ma (+ve)LL = 0.036 x 160 x 20.672 x 12 = 29531 lb-in.

Total Ma (+ve) = 41528 lb-in.

Mb (+ve)DL = 0.015 x 90 x 22.672 x 12

= 8326 lb-in.

Mb (+ve)LL = 0.022 x 160 x 22.672 x 12 = 21708 lb-in.

Total Mb (+ve) = 30034 lb-in.

(-ve) moment of discontinuous edge

Mb(-ve) = 1/3 x Mb(+ve) = 1/3 x 30034 = 10011 lb-in.

KAMOL CE 2K5- 0501033

Depth check

max = 0.75 b

= 0.75 x 0.85 x 1 x fc/fy (87/87+fy)

= 0.75 x 0.85 x 0.85 x 3.5/60 (87/87+60)

[ 1 = 0.85 for fc 4000 psi ]

= 0.0187

Mn = fybd2 (1 - fy/1.7 fc)

87159 = 0.9 x 0.0187 x 60000 x 12 x d2 ( 1 0.0187 x

60000/ 1.7 x 3500)

d = 2.98 3 < 6

Hence OK

Steel Calculation

Maximum spacing, 2t = 2 x 6 = 12

As(min) = 0.0018bt = 0.0018 x 12 x 6 = 12 in2

Mn = Asfy( d a/2)

a = Asfy/0.85 fcb = As x 60000/0.85 x 3500 x 12

a = 1.68As

Now.

Mn = Asfy ( d 1.68As/2)

Mn = Asfy ( d 0.84As) (1)

KAMOL CE 2K5- 0501033

Compute the following table & find out As from equation (1) for

corresponding momentla

lb

Discontin. Midspan

Contin.

Discontin. Midspan

Contin.

M (lb-in)

+41528

-87159

-10011

+30034

-40087

As(in2)

0.13

0.23

0.03

0.09

0.13

la direction continues edge M = 87159 lb-in

From equation (1)

87159 = 0.90 x As x 60000 (6 0.84As)

As = 0.23 in2

la direction

For As = 0.13 in2

(midspan)

Spacing S = 12 x 0.11 /0.13 = 10.15 10 c/c [use 3# bar]

S = 10 < 12 Hence OK

Ext. top

Continues edge:

12 spacing required steel = 0.23 in2

2 x 10 spacing required steel = 0.23 x 2 x10 /12 = 0.38 in2

More required steel = 0.38 0.11 = 0.27 in2

5

KAMOL CE 2K5- 0501033

Nos. of Ext. top = 0.27/.011 = 2.45 2 nos.

lb direction

For use minimum reinforcement As = 0.12 in2

(midspan)

Spacing S = 12 x 0.11 /0.12 = 11 c/c [use 3# bar]

S = 11 < 12 Hence OK

Ext. top

Discontinues edge:

Use minimum reinforcement As = 0.12 in2

12 spacing required steel = 0.12 in2

2 x 11 spacing required steel = 0.12 x 2 x11/12 = 0.22 in2

More required steel = 0.22 0.11 = 0.11 in2

Nos. of Ext. top = 0.11/.011 = 1 no.

Continues edge:

As = 0.13 in2

12 spacing required steel = 0.13 in2

2 x 11 spacing required steel = 0.13 x 2 x11/12 = 0.23 in2

More required steel = 0.23 0.11 = 0.12 in2

Nos. of Ext. top = 0.12/.011 = 1.09 1 no.

No corner reinforcement required

KAMOL CE 2K5- 0501033

Reinforcement detailing

KAMOL CE 2K5- 0501033

KAMOL CE 2K5- 0501033

PANEL A

Clear span, la = 20.67 ; lb = 22.67

la /lb = 0.90 ; Total load = 250 psf

For panel ratio 0.90 find out co-efficient by Case-4

Ca (-ve)

= 0.06

Cb (-ve)

= 0.04

Ca (+ve)DL = 0.033

Cb (+ve)DL = 0.022

Ca (+ve)LL = 0.039

Cb (+ve)LL = 0.026

Calculation of moment

M = Cw L2

(-ve) moment of continuous edge

Ma(-ve) = 0.06 x 250 x 20.672 x 12 = 76904 lb-in.

Mb(-ve) = 0.04 x 250 x 22.672 x 12 = 61671 lb-in.

(+ve) moment midspan

Ma (+ve)DL = 0.033 x 90 x 20.672 x 12

= 15227 lb-in.

Ma (+ve)LL = 0.039 x 160 x 20.672 x 12 = 31992 lb-in.

Total Ma (+ve) = 47219 lb-in.

9

KAMOL CE 2K5- 0501033

Mb (+ve)DL = 0.022 x 90 x 22.672 x 12

= 12211 lb-in.

Mb (+ve)LL = 0.026 x 160 x 22.672 x 12 = 25655 lb-in.

Total Mb (+ve) = 37866 lb-in.

(-ve) moment of discontinuous edge

Ma(-ve) = 1/3 x Ma(+ve) = 1/3 x 47219 = 15739 lb-in

Mb(-ve) = 1/3 x Mb(+ve) = 1/3 x 37866 = 12622 lb-in.

Depth check

max = 0.75b

= 0.75 x 0.85 x 1 x fc/fy (87/87+fy)

= 0.75 x 0.85 x 0.85 x 4/60 (87/87+60)

[ 1 = 0.85 for fc 4000 psi ]

= 0.021

Mn = fybd2 (1 - fy/1.7 fc)

76904 = 0.9 x 0.021 x 60000 x 12 x d2 ( 1 0.021 x

60000/ 1.7 x 4000)

d = 2.63 3 < 6

Hence OK

Steel Calculation

Maximum spacing, 2t = 2 x 6 = 12

As(min) = 0.0018bt = 0.0018 x 12 x 6 = 12 in2

10

KAMOL CE 2K5- 0501033

Mn = Asfy( d a/2)

a = Asfy/0.85 fcb = As x 60000/0.85 x 4000 x 12

a = 1.47As

Now.

Mn = Asfy ( d 1.47As/2)

Mn = Asfy ( d 0.735As) (1)

Compute the following table & find out As from equation (1) for

corresponding momentla

lb

Discontin. Midspan

Contin.

Discontin. Midspan

Contin.

M (lb-in)

-15739

+47210

-76904

-12622

+37866

-61671

As(in2)

0.048

0.15

0.24

0.039

0.11

0.19

la direction continues edge M = 76904 lb-in

From equation (1)

76904 = 0.90 x As x 60000 (6 0.735As)

As = 0.24 in2

la direction

For As = 0.15 in2

(midspan)

Spacing S = 12 x 0.11 /0.15 = 8.8 8.5 c/c [use 3# bar]

11

KAMOL CE 2K5- 0501033

S = 8.5 < 12 Hence OK

Ext. top

Continues edge:

12 spacing required steel = 0.24 in2

2 x 8.5 spacing required steel = 0.24 x 2 x 8.5 /12 = 0.34 in2

More required steel = 0.34 0.11 = 0.23 in2

Nos. of Ext. top = 0.23/.011 = 2.09 2 nos.

Discontinues edge:

Use minimum reinforcement As = 0.12 in2

12 spacing required steel = 0.12 in2

2 x 8.5 spacing required steel = 0.12 x 2 x 8.5/12 = 0.17 in2

More required steel = 0.17 0.11 = 0.06 in2

Nos. of Ext. top = 0.06/.011 = 0.54 < 1

No ext. top require

lb direction

For use minimum reinforcement As = 0.12 in2

(midspan)

Spacing S = 12 x 0.11 /0.12 = 11 c/c [use 3# bar]

S = 11 < 12 Hence OK

12

KAMOL CE 2K5- 0501033

Ext. top

Discontinues edge:

Use minimum reinforcement As = 0.12 in2

12 spacing required steel = 0.12 in2

2 x 11 spacing required steel = 0.12 x 2 x11/12 = 0.22 in2

More required steel = 0.22 0.11 = 0.11 in2

Nos. of Ext. top = 0.11/.011 = 1 no.

Continues edge:

As = 0.19 in2

12 spacing required steel = 0.19 in2

2 x 11 spacing required steel = 0.19 x 2 x11/12 = 0.34 in2

More required steel = 0.34 0.11 = 0.23 in2

Nos. of Ext. top = 0.23/.011 = 2.09 2 no.

Special/Corner reinforcement

Maximum (+ve) moment from la

Use 3# @ 8.5 c/c

13

KAMOL CE 2K5- 0501033

Reinforcement detailing

14

KAMOL CE 2K5- 0501033

15

KAMOL CE 2K5- 0501033

ACI CODE FOR SLAB

16

You might also like

- Design and analysis of concrete roof beamsDocument30 pagesDesign and analysis of concrete roof beamsLee Yu Chan86% (7)

- Justine's Memoirs On Actual Freedom (Part - I)Document61 pagesJustine's Memoirs On Actual Freedom (Part - I)JustineNo ratings yet

- Soilmec R 625 Drill Rig PDFDocument8 pagesSoilmec R 625 Drill Rig PDFAsif RahmanNo ratings yet

- Allowable Soil Pressure: DL+RLL 150 KN/M DL+MLL 225 KN/MDocument19 pagesAllowable Soil Pressure: DL+RLL 150 KN/M DL+MLL 225 KN/MUno CasprowichNo ratings yet

- Design of Critical Two-Way SlabDocument8 pagesDesign of Critical Two-Way SlabBevelyn Manalo100% (1)

- Design of Two-Way Slab: GivenDocument21 pagesDesign of Two-Way Slab: GivenJohn Pierce GumapacNo ratings yet

- Analysis and Design of SlabDocument8 pagesAnalysis and Design of SlabKabir KhanNo ratings yet

- Structural Design Data and SpecificationsDocument6 pagesStructural Design Data and SpecificationsRoland CepedaNo ratings yet

- Ipt Design WorkDocument43 pagesIpt Design WorkMorice RwakataleNo ratings yet

- Steel and Concrete Beam DesignDocument12 pagesSteel and Concrete Beam DesignTalha tahirNo ratings yet

- Design of Two Way Slab: 2nd/3rd Floor Slab S1Document14 pagesDesign of Two Way Slab: 2nd/3rd Floor Slab S1John Paul Hilary EspejoNo ratings yet

- Design of Stair CaseDocument65 pagesDesign of Stair CaseNikhil100% (1)

- BS Ref Calculation Remarks: Purlins DesignDocument7 pagesBS Ref Calculation Remarks: Purlins DesignHauzhiNo ratings yet

- Two Way Slab REFDocument11 pagesTwo Way Slab REFSugan VijayanNo ratings yet

- NEW - Structural Design & Analysis (Pt. 1)Document23 pagesNEW - Structural Design & Analysis (Pt. 1)Rein Aira OrdanezNo ratings yet

- Structure Design PrinciplesDocument63 pagesStructure Design PrinciplesAbbdullah RayhanNo ratings yet

- Moment Coefficients For Continuous Beams and SlabsDocument10 pagesMoment Coefficients For Continuous Beams and Slabsdash1991No ratings yet

- A Design For Circular Concrete Tank Pca Design MethodDocument15 pagesA Design For Circular Concrete Tank Pca Design MethodajebNo ratings yet

- Design A RCC Retaining Wall To Retain Earth Up ToDocument9 pagesDesign A RCC Retaining Wall To Retain Earth Up ToMuhammad Farooq Zia100% (1)

- Design of Box CulvertDocument24 pagesDesign of Box CulvertAl Patrick Dela CalzadaNo ratings yet

- STRUCTURAL ANALYSIS (1 Storey)Document12 pagesSTRUCTURAL ANALYSIS (1 Storey)Yllor Koichi RamosNo ratings yet

- Slab DesignDocument13 pagesSlab DesignLimwell AquinoNo ratings yet

- Slab DesignDocument25 pagesSlab DesignSabin Leroy HmgnNo ratings yet

- ##FNuj Slab NotesDocument36 pages##FNuj Slab NotesthembalethuNo ratings yet

- Maxspan Slab WordDocument3 pagesMaxspan Slab WordJames Aswa100% (1)

- Design of Box CulvertDocument34 pagesDesign of Box CulvertAl Patrick Dela CalzadaNo ratings yet

- Design of foundation slab sections and reinforcementDocument7 pagesDesign of foundation slab sections and reinforcementsivaraju1No ratings yet

- Slab Design by LimwellDocument12 pagesSlab Design by LimwellLimwell AquinoNo ratings yet

- Design of Structures: 120 LB/FT 30 2500lb/ FT 4000 Psi F 40,000 PsiDocument10 pagesDesign of Structures: 120 LB/FT 30 2500lb/ FT 4000 Psi F 40,000 PsiSajid NazirNo ratings yet

- Chapter-4 Example Steel and TimberDocument16 pagesChapter-4 Example Steel and Timbernaoln89No ratings yet

- Design of Floor (Slab 4) : La LBDocument10 pagesDesign of Floor (Slab 4) : La LBAyreesh Mey SpntNo ratings yet

- Perhitungan Sambungan Baja BautDocument9 pagesPerhitungan Sambungan Baja BautDica Rasyid MaulidhaniNo ratings yet

- Design of SlabDocument48 pagesDesign of SlabErnestNo ratings yet

- Design For Reinforcement in Pier: Slenderness RatioDocument2 pagesDesign For Reinforcement in Pier: Slenderness RatioPreetam SundarayNo ratings yet

- Design of Column: Axial Buckling: Buckling CheckDocument4 pagesDesign of Column: Axial Buckling: Buckling CheckABINESH RNo ratings yet

- Design of Pile Cap and Abutment WallDocument20 pagesDesign of Pile Cap and Abutment Wallshashibhushan singh100% (1)

- Design of Second Floor (Slab 3) : La LBDocument11 pagesDesign of Second Floor (Slab 3) : La LBAyreesh Mey SpntNo ratings yet

- Slab On GradeDocument105 pagesSlab On Gradevijaystructural100% (6)

- Floor Slab Design Parameters and Reinforcement DetailsDocument18 pagesFloor Slab Design Parameters and Reinforcement DetailsKurt Nicolas Villegas Paquibo86% (7)

- Roof Deck Beam Design and AnalysisDocument251 pagesRoof Deck Beam Design and AnalysisJohn Paul Hilary EspejoNo ratings yet

- Design of Rectangular Water Tank with Dimensions 6m x 4m x 3.5mDocument268 pagesDesign of Rectangular Water Tank with Dimensions 6m x 4m x 3.5mchetanmale89% (28)

- Design of Shear Wall FootingDocument11 pagesDesign of Shear Wall FootingJohn Paul Hilary EspejoNo ratings yet

- Design of Two Way Slab: DESIGN FOR 2S-1 and 3S-1Document100 pagesDesign of Two Way Slab: DESIGN FOR 2S-1 and 3S-1Cesar MigoNo ratings yet

- Structural Analysis & DesignDocument8 pagesStructural Analysis & Designkurt paulo manaloNo ratings yet

- Design of BeamsDocument19 pagesDesign of BeamssnsatyanarayanaNo ratings yet

- 2020 Solution Module 4 Two-Way SlabsDocument5 pages2020 Solution Module 4 Two-Way SlabsAli HassanNo ratings yet

- Gorakhpur Bypass RobDocument9 pagesGorakhpur Bypass RobvivekNo ratings yet

- Design of Second Floor (Slab 2) : La LBDocument9 pagesDesign of Second Floor (Slab 2) : La LBAyreesh Mey SpntNo ratings yet

- Design of Floor (Slab 5) : La LBDocument12 pagesDesign of Floor (Slab 5) : La LBAyreesh Mey Spnt100% (1)

- Example 2 Simply Supported Beam - Flanged Section PDFDocument7 pagesExample 2 Simply Supported Beam - Flanged Section PDFWee Ren100% (1)

- Beam Design for 5m Simply Supported BeamDocument28 pagesBeam Design for 5m Simply Supported BeamSarah HaiderNo ratings yet

- Irrigation Division Chunar, Mirzapur: Design of Parapet Wall at Top of Jirgo DamDocument4 pagesIrrigation Division Chunar, Mirzapur: Design of Parapet Wall at Top of Jirgo Damgovind narayan ShuklaNo ratings yet

- Reinf. AreaDocument67 pagesReinf. AreaWaheed AhmadNo ratings yet

- Stairway 1Document10 pagesStairway 1Anissah ManialaNo ratings yet

- Design of Slab and Footing for Proposed TownhouseDocument7 pagesDesign of Slab and Footing for Proposed TownhouseNikolai GongoraNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Instructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYFrom EverandInstructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYNo ratings yet

- Standard TV SizesDocument9 pagesStandard TV SizesAsif RahmanNo ratings yet

- Chap 11 5 Bar SpliceDocument3 pagesChap 11 5 Bar SpliceLleiLleiNo ratings yet

- Competency Standards - Auto CADDocument34 pagesCompetency Standards - Auto CADAsif RahmanNo ratings yet

- Multi-Touch gestures on MacDocument4 pagesMulti-Touch gestures on MacAsif RahmanNo ratings yet

- CssDocument2 pagesCssAsif RahmanNo ratings yet

- Best All Liver Specialist Doctor in DhakaDocument8 pagesBest All Liver Specialist Doctor in DhakaAsif RahmanNo ratings yet

- Easy Format of No Objection CertificateDocument5 pagesEasy Format of No Objection CertificateAsif Rahman50% (2)

- Rubikscubeinstructions FullDocument6 pagesRubikscubeinstructions FullAkshay GoelNo ratings yet

- Competency Standards - Auto CADDocument34 pagesCompetency Standards - Auto CADAsif RahmanNo ratings yet

- All Glass Doors Data SheetDocument1 pageAll Glass Doors Data SheetAsif RahmanNo ratings yet

- Mix Design (Ratio)Document4 pagesMix Design (Ratio)Asif RahmanNo ratings yet

- Example 1-Special Moment FramesDocument16 pagesExample 1-Special Moment FramestoshicrystalNo ratings yet

- Fire TestDocument31 pagesFire TestAsif RahmanNo ratings yet

- css3 Cheat SheetDocument5 pagescss3 Cheat Sheetapi-242944016100% (1)

- Footing Design Guide: Types, Dimensions & ReinforcementDocument60 pagesFooting Design Guide: Types, Dimensions & ReinforcementAllain Dungo100% (3)

- Chapter 4 - Slender ColumnsDocument26 pagesChapter 4 - Slender ColumnsMohamed Salah100% (1)

- Lecture 4Document21 pagesLecture 4Armend AvdiuNo ratings yet

- EtabsDocument6 pagesEtabsEngr SwapanNo ratings yet

- BCA - Worked Examples Design of Concrete BuildingDocument258 pagesBCA - Worked Examples Design of Concrete BuildingSaw Is Saw100% (27)

- Design of 6 Storey Building in EtabsDocument51 pagesDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- Section DesignerDocument191 pagesSection DesignergreatwellwisherNo ratings yet

- Commercial Round 10ftDocument1 pageCommercial Round 10ftAsif RahmanNo ratings yet

- Any Problem To Call Me: 01712888249Document1 pageAny Problem To Call Me: 01712888249Asif RahmanNo ratings yet

- Etabs Multistory SteelDocument78 pagesEtabs Multistory SteelAjit ThoratNo ratings yet

- Icee Books LeafletDocument2 pagesIcee Books LeafletAsif RahmanNo ratings yet

- MicroStation For AutoCAD UsersDocument45 pagesMicroStation For AutoCAD Usersraomavuri8631No ratings yet

- Catalogue (HDPE) FinalDocument12 pagesCatalogue (HDPE) FinalJamalNo ratings yet

- Accord Building Standard DhakaDocument74 pagesAccord Building Standard DhakaVivek Kumar BhandariNo ratings yet

- Fire Resistance Assembly ChartDocument3 pagesFire Resistance Assembly ChartAsif RahmanNo ratings yet

- African American Women's LanguageDocument30 pagesAfrican American Women's LanguageRatih Santi MianawatiNo ratings yet

- MCQ With AnswersDocument4 pagesMCQ With AnswersAkai OakNo ratings yet

- BT 203 Basic Mechanical Engineering May 2019 PDFDocument2 pagesBT 203 Basic Mechanical Engineering May 2019 PDFKunta PatleNo ratings yet

- L o N G e V I T y NotesDocument24 pagesL o N G e V I T y NotesRajeswara Rao NidasanametlaNo ratings yet

- Catalog Company PDFDocument3 pagesCatalog Company PDFBukhori IsakNo ratings yet

- Thermal Comfort Bioclimatic Architecture StrategiesDocument21 pagesThermal Comfort Bioclimatic Architecture StrategiesJayshree RokdeNo ratings yet

- Beno K Pradekso - Solusi247 - In40aiDocument36 pagesBeno K Pradekso - Solusi247 - In40aiMuhammad HattaNo ratings yet

- Assignment # 02: (Bearing Capacity Analysis)Document3 pagesAssignment # 02: (Bearing Capacity Analysis)kKhalid YousafNo ratings yet

- Porirua Harbour Patterns and Rates of Sedimentation ReportDocument65 pagesPorirua Harbour Patterns and Rates of Sedimentation ReportPaul MarlowNo ratings yet

- Flowchart Common ShapesDocument3 pagesFlowchart Common ShapeslaptoptabingNo ratings yet

- IDAS Demonstration Setup Guide F3100D-F5120D PDFDocument146 pagesIDAS Demonstration Setup Guide F3100D-F5120D PDFTopcom Toki-Voki100% (2)

- Data Mining Course Learn Analytics RDocument5 pagesData Mining Course Learn Analytics RAntonio AlvarezNo ratings yet

- Kavindu Final.Document33 pagesKavindu Final.KavinduKarunarathnaNo ratings yet

- Foam ControlDocument28 pagesFoam ControlJoselu Ordoñez Ramos100% (1)

- CRC CDocument13 pagesCRC Cjosei_telspecNo ratings yet

- BHEL Haridwar Block 2 Heavy Fabrication, Training ReportDocument53 pagesBHEL Haridwar Block 2 Heavy Fabrication, Training ReportUdit Soni100% (5)

- How To Write An EssayDocument4 pagesHow To Write An EssayShah BaibrassNo ratings yet

- Sliding Mode Observers For Fault Detection and Isolation: Christopher Edwards !,, Sarah K. Spurgeon", Ron J. Patton#Document13 pagesSliding Mode Observers For Fault Detection and Isolation: Christopher Edwards !,, Sarah K. Spurgeon", Ron J. Patton#tannguyenvanNo ratings yet

- SOLVED NUMERICALS EXAMPLES in Machine LearningDocument59 pagesSOLVED NUMERICALS EXAMPLES in Machine LearningYash SinhaNo ratings yet

- Total Productive MaintenanceDocument41 pagesTotal Productive Maintenancejeff090288No ratings yet

- Aneka Cloud IntroductionDocument36 pagesAneka Cloud IntroductionPradeep Kumar Reddy ReddyNo ratings yet

- Daftar Pustaka: Poltekkes Kemenkes YogyakartaDocument6 pagesDaftar Pustaka: Poltekkes Kemenkes YogyakartaNurhadi KebluksNo ratings yet

- Integrating Information About The Cost of Carbon Through Activity Based Costing 2012 Journal of Cleaner ProductionDocument10 pagesIntegrating Information About The Cost of Carbon Through Activity Based Costing 2012 Journal of Cleaner ProductionLilian BrodescoNo ratings yet

- ACS SCPI Programming Guide V1 0Document29 pagesACS SCPI Programming Guide V1 0Pedro Boanerges Paz RomeroNo ratings yet

- Being in Control: The Fact That Variation Exists Means SPC Is Critical To Monitor Process BehaviourDocument2 pagesBeing in Control: The Fact That Variation Exists Means SPC Is Critical To Monitor Process BehaviourdumbledoreaaaaNo ratings yet

- NetAct Plan Editor 4.9-4 CNDocument4 pagesNetAct Plan Editor 4.9-4 CNAshraf JarjeesNo ratings yet

- Answer:: Near Relax Medical Hall, Vattepally, Falaknuma, HyderabadDocument2 pagesAnswer:: Near Relax Medical Hall, Vattepally, Falaknuma, HyderabadMohammed RaeesuddinNo ratings yet

- Project Vetting Worksheet-9472538Document4 pagesProject Vetting Worksheet-9472538kovzsanNo ratings yet

- Fourth Assignment.: Summary - Outcome of The ProgramDocument2 pagesFourth Assignment.: Summary - Outcome of The ProgramHasvdkNo ratings yet