Professional Documents

Culture Documents

Installation Instructions - General

Uploaded by

MONACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Instructions - General

Uploaded by

MONACopyright:

Available Formats

1/31/2014

Installation Instructions - General

Installation Instructions - General

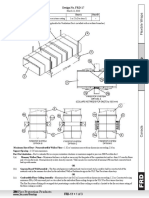

Operational Description - Centrifugal Separator As the air, gas, or steam flow enters the separator, it is forced through a centrifugal element. There the heavier moisture droplets and dry particles are centrifuged to the outer periphery of the flow and are impinged against the vessel's wall. The flow forms a helical pattern as its path extends to the drain side of the separator. The flow then reverses by way of a center vortex. This center return vortex is a danger point where re-entrainment is most likely. The exclusive Wright-Austin Vortex Containment Plate "VCP" combats reentrainment by providing a quiet zone where the entrainment is permitted to fall out of the flow. This arrangement effectively segregates the removed entrainment from the outlet flow. Maintenance and Spare Parts Wright-Austin separators have no moving parts. All components are either bolted or welded into place. Therefore parts lists are not available. The seprators are bolted, threaded, or welded into the lines. They are self-cleaning, and do not need lubrication or maintenance. For this reason, lubricating, operating and maintenance manuals are not available. Performance Wright-Austin separators, when properly sized, installed, and drained, will remove 99% of all liquid and solid entrainment where particle size exceeds 10 microns. Caution All threaded connections not being used must be plugged at time of installation. For Positive Drainage of Separator Install trap a minimum of 6" below separator drain. For every inch of horizontal piping to trap, add one inch to the vertical piping. Do not reduce separator drain size except at trap inlet. Never (with one exception) allow the top of the trap to extend above separator drain connection. Add 1/4" balance (vent) line where shown for air and other gas (not steam) installations.

Air and Gas (not steam) Service

http://swtnst.co.kr/produc/html/wa%20html/558.htm

1/4

1/31/2014

Installation Instructions - General

No. 90-AC 2" Type T cast iron separator 4" Type T cast iron separator removing removing moisture from a moisture and oil from a compressed air compressed air distribution line. line. No. 230-AC trap to drain. A sediment 3/4" No. 90-AC float type trap pocket, as shown, should be provided for installed below separator to drain. air and gas service (instead of a strainer). This is the only type air and gas drain trap installation that does not require a balance (vent) line.

Prime trap with water before turning air pressure on.

http://swtnst.co.kr/produc/html/wa%20html/558.htm

2/4

1/31/2014

Installation Instructions - General

3/4" No. 90-AC SISO (side inlet, side outlet) float trap installed on air receiving tank where floor clearance is at a minimum

Steam Service

Above: 2" Type T separator installed in 300 PSI steam line to turbine. 1-1/4" "Y" strainer and 3/4" No. 71 steam trap to drain. Below: 4" Type T separator removing moisture from a steam header at 125 PSI. One inch "Y" strainer and 510-C combination bucket and thermostatic trap to drain.

http://swtnst.co.kr/produc/html/wa%20html/558.htm

3/4

1/31/2014

Installation Instructions - General

http://swtnst.co.kr/produc/html/wa%20html/558.htm

4/4

You might also like

- Type DTL DryDocument6 pagesType DTL DryMONANo ratings yet

- Cursive 48 RefDocument1 pageCursive 48 RefMONANo ratings yet

- Best Practices For Condensate Removal On Steam Lines - TLVDocument5 pagesBest Practices For Condensate Removal On Steam Lines - TLVMONANo ratings yet

- Separator Drain Traps - Eaton Corporation - FiltrationDocument2 pagesSeparator Drain Traps - Eaton Corporation - FiltrationMONANo ratings yet

- Caution: Products & SolutionsDocument4 pagesCaution: Products & SolutionsMONANo ratings yet

- Cursive 36 RefDocument1 pageCursive 36 RefMONANo ratings yet

- 00620Document14 pages00620MONANo ratings yet

- 488109Document4 pages488109MONANo ratings yet

- 66B Breathing AirDocument11 pages66B Breathing AirMONANo ratings yet

- 20450Document8 pages20450MONANo ratings yet

- A032 035Document4 pagesA032 035MONANo ratings yet

- Pump OperationsDocument1 pagePump OperationsMONANo ratings yet

- ChromAccessories GCAcc GasPurifiersNTraps P268to275Document8 pagesChromAccessories GCAcc GasPurifiersNTraps P268to275MONANo ratings yet

- Compressed Air System Design ManualDocument26 pagesCompressed Air System Design ManualBadrul HishamNo ratings yet

- Internet Version For Reference Only: Gas Water HeaterDocument28 pagesInternet Version For Reference Only: Gas Water HeaterMONANo ratings yet

- Energy Saving in The Filtration and Drying of Compressed AirDocument31 pagesEnergy Saving in The Filtration and Drying of Compressed AirMONANo ratings yet

- 66B Breathing AirDocument11 pages66B Breathing AirMONANo ratings yet

- Internet Version For Reference Only: Gas Water HeaterDocument28 pagesInternet Version For Reference Only: Gas Water HeaterMONANo ratings yet

- Document Information Pages (List of NFPA Codes & Standards)Document16 pagesDocument Information Pages (List of NFPA Codes & Standards)MONANo ratings yet

- PVV 540 PumpDocument14 pagesPVV 540 PumpMONANo ratings yet

- Odwadniacz Plywakowy UNA 13 P (INS) (En)Document14 pagesOdwadniacz Plywakowy UNA 13 P (INS) (En)MONANo ratings yet

- Aspen Exchanger Design and Rating V7.3.2: Release NotesDocument42 pagesAspen Exchanger Design and Rating V7.3.2: Release NotesMONANo ratings yet

- Chilled Water System Installation Operation Maintenance Manual 2811 15340Document36 pagesChilled Water System Installation Operation Maintenance Manual 2811 15340MONANo ratings yet

- Reciprocating Compressor Optimum Design PDFDocument6 pagesReciprocating Compressor Optimum Design PDF최승원No ratings yet

- Pump Different FluidsDocument5 pagesPump Different FluidsMONANo ratings yet

- Tgifb 4Document20 pagesTgifb 4MONANo ratings yet

- Maintenance Tips For Heat ExchangerDocument4 pagesMaintenance Tips For Heat ExchangerMONANo ratings yet

- Appendix 2CDocument159 pagesAppendix 2Crmm99rmm99No ratings yet

- TLV JA3 Air Drain TrapDocument2 pagesTLV JA3 Air Drain TrapMONANo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tank-A Tank-B Tank-C: Bus BayDocument4 pagesTank-A Tank-B Tank-C: Bus BayMohit AgarwalNo ratings yet

- Profile Geogabinfra PDFDocument19 pagesProfile Geogabinfra PDFदेवराज सिंह गहरवारNo ratings yet

- ELECT-TIC-2.1 - (Material Receiving Inspection For MV Power Cables & Accessories)Document2 pagesELECT-TIC-2.1 - (Material Receiving Inspection For MV Power Cables & Accessories)Muhammad IrfanNo ratings yet

- GVAR210 Exploded ViewDocument4 pagesGVAR210 Exploded ViewUEENo ratings yet

- Single Handle Pull-Out Kitchen Faucet PFXC5150: Parts BreakdownDocument1 pageSingle Handle Pull-Out Kitchen Faucet PFXC5150: Parts BreakdownCraig SmithNo ratings yet

- Hydroflex 30/hydroflex 30S: General DescriptionDocument1 pageHydroflex 30/hydroflex 30S: General DescriptionNicky LimNo ratings yet

- FRD17Document3 pagesFRD17Raul FloresNo ratings yet

- Arriostre de VigasDocument20 pagesArriostre de VigasGonzalo Guerrero CáceresNo ratings yet

- Estocure WB - BS 7542 - Curing Efficiency - T2017Document2 pagesEstocure WB - BS 7542 - Curing Efficiency - T2017Chamith VirangaNo ratings yet

- Ex ArisuDocument12 pagesEx ArisuJeiner Leyva BernalNo ratings yet

- Technical Datasheet: Pacific®CSV Cast Steel ValvesDocument16 pagesTechnical Datasheet: Pacific®CSV Cast Steel ValvesAnderson SiqueiraNo ratings yet

- Meca Report 2015 11 r270 C Barka PrestressDocument91 pagesMeca Report 2015 11 r270 C Barka Prestressajay katrojNo ratings yet

- Bacton Case StudyDocument6 pagesBacton Case StudyNoel BactonNo ratings yet

- IK - Manufacturers - XLSX 7 19 18Document428 pagesIK - Manufacturers - XLSX 7 19 18Naveen TripuraneniNo ratings yet

- Blasting Guidance ManualDocument170 pagesBlasting Guidance ManualJaviera AlejandraNo ratings yet

- Literature Study: by Kataru Lohith Krishna Reg No:RA1811201010070Document10 pagesLiterature Study: by Kataru Lohith Krishna Reg No:RA181120101007099 kingsNo ratings yet

- 5231R 06Document13 pages5231R 06BddbvffffnhebrbbrNo ratings yet

- Polymold Catalog 2020Document26 pagesPolymold Catalog 2020Sachin SampatNo ratings yet

- Welded Wire MeshDocument23 pagesWelded Wire MeshSushmit Sharma100% (1)

- Plastic Design GuidelinesDocument241 pagesPlastic Design Guidelines2023ht30006No ratings yet

- Chemdur - 42 RHDocument3 pagesChemdur - 42 RHICPL-RWPNo ratings yet

- TestDocument1 pageTestDiji RakshaNo ratings yet

- 2011 Understanding Stakeholders' Perspective of Cost Estimation in Project ManagementDocument15 pages2011 Understanding Stakeholders' Perspective of Cost Estimation in Project ManagementHellen HuamanNo ratings yet

- How To Build Your Own Recycled Plastic Bottle Greenhouse - Education ProjectDocument6 pagesHow To Build Your Own Recycled Plastic Bottle Greenhouse - Education ProjectAn Energy-Efficient Solar-Heated Greenhouse100% (4)

- Pages From AWS D1.1-D1.1M-2015 - Structural Welding Code-Steel Table 9.10Document2 pagesPages From AWS D1.1-D1.1M-2015 - Structural Welding Code-Steel Table 9.10Solikhul HarisNo ratings yet

- Tutorial 09Document2 pagesTutorial 09秦瑋駿No ratings yet

- Universiti Kuala Lumpur Malaysian Spanish Institute: Name: Mohamad Adib Fahmi Bin MahadzirDocument9 pagesUniversiti Kuala Lumpur Malaysian Spanish Institute: Name: Mohamad Adib Fahmi Bin MahadzirAizzat ZackNo ratings yet

- Piling: Information Provided Rules Definition Coverage Rules Supp MentDocument1 pagePiling: Information Provided Rules Definition Coverage Rules Supp MentVimalNo ratings yet

- Washing Machine Manual Kenmore HE5tDocument76 pagesWashing Machine Manual Kenmore HE5tmachnerdNo ratings yet

- Introduction of Aluminum FormworkDocument19 pagesIntroduction of Aluminum FormworkJanice YuanNo ratings yet