Professional Documents

Culture Documents

Hot Rolled China Steel

Uploaded by

edgarc999Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Rolled China Steel

Uploaded by

edgarc999Copyright:

Available Formats

- 1 -

1. Brief Introduction

China Steel CorporationCSCwas established in December 1971 and started its production in December

1977. After four stages of consecutive expansion, the annual production capacity of crude steel has reached

11.5 million metric tons. The major products include steel plates, steel bars, wire rods, hot-rolled coils,

cold-rolled coils, coated coils, electrical steel coils, and electro-galvanized coils. All of these products are

widely used in various downstream manufacturing industry for enhancing competitiveness and forming a

mutual beneficial interdependence between the CSC and customers. CSC proved it to be a reliable and

innovated supplier of steel products. The accreditation certificate of ISO 9001, ISO/TS 16949, IECQ, ELV,

the Taiwan Accreditation FoundationTAFand J IS MARK approvals were obtained to demonstrate CSC's

commitment to keep progressing in quality management system.

Providing cost-effective and superior quality of products and services to diversities satisfied customer is the

original mission of CSC. The company has therefore put a great deal of effort in expanding and modernizing

its facilities, and continually improving the products quality and developing new products as well to help

customers to create more value-added products. The newly developed hot rolled steel products such as CSC

HC1085, CSC HM-690T, CSC HC 15B22, ASTM A572 GR.50 TYPE 1, J FS A1001 J SH590Y, J FS A1001

J SH780R and API 5L X52M PSL2 were introduced to meet the stringent market demands.

Plant Greenery

- 2 -

Brief introductions of new products are as follows:

CSC HM-690T

high strength HR steel coils possessing high strength, excellent toughness & weldability, that are

best used in general structural parts, light drawing processing, heavy duty machinery, automobile

parts

CSC HC 1085

high carbon HR steel coils referencing J IS G4401 SK85 with feature of withstanding high

temperature coating, that are best used in gardening tools, hand tools

CSC HC 15B22

high strength boron-manganese HR steel coils possessing excellent formability & weldability,

which will attain strength of 1470MPa through subsequent quench & temper, that are best used in

automobile parts for improvement of crashworthiness

ASTM A572 GR.50 TYPE1

high strength low-alloy HR steel coils applicable to structural use, that are best used in sections and

stiffening plates

API 5L X52M PSL2

HR steel coils applicable to welded oil line pipe with option feature of resistance to hydrogen

induced cracking (HIC) if used in harsh environments

JFS A1001 JSH780R

HR steel coils possessing high strength, excellent toughness & weldability, applicable to high

strength, thinning, light forming, that are best used in automobile parts such as electric window lift

mechanisms, door control rod, airbag components, collision-resistant beams

JFS A1001 JSH590Y

HR steel coils possessing high strength, excellent stretchability, applicable to high strength,

thinning, hard-to-form, ED coating, electroplating

API 5CT J55U

HR steel coils with low S,P elements to improve toughness & weldability, applicable to API 5CT

J 55 oil well casing, and API 5CT N80Q grade after customers proper heat treatment, having this

option will promote customers operation performance

EN10025-2 S355J0

HR steel coils with low carbon equivalent & strength of 50 kgf possessing excellent low

temperature toughness & weldability, that are best used in steel pipe pile for bridge, underwater

tunnel, coastal wall, breakwaters

PA Steels

HR PA steel coils high-medium carbon, low alloy, tool steel grade as basis and through lowering

their hardness and variance of mechanical properties will promote formability and mold life,

applicable to tube making, blanking, bending, that are best used in cold-drawn bicycle tube,

hydraulic tube, washers, knives, cold re-rolling

PAS Steels

HR PAS steel coils having HR PA steel coils excellent features and spheroid carbides in addition,

enabling high-medium carbon, low alloy, tool steel grade suitable for fine blanking, shaving, finish

blanking, cold forging, hole expansion, drawing, that are best used in tooth plate, slider, starter gear,

bearing rings, sewing machine needle plates

- 3 -

)$ ;| ,z;|;[;z|z [[V ,z;|;[;z|z

)$ ;| ,z;|;[;z|z [,Q ,z;|;[;z|z

- 4 -

$(/|$ (949 ,z;|;[;z|z $( 900 ,z;|;[;z|z

- 7 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3. Specification

The contents of this catalog are for reference only. Customers are urged to consult the specifications

published by the corresponding associations. Information of the available CSC steel grades, as shown herein

may be updated without notice to comply with actual production situations.

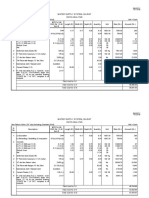

3.1 Chemical Compositions and Mechanical properties.

3.1.1 CSC ACR-TEN Superior Atmospheric Corrosion Resistance Hot-Rolled Steel Plates, Sheets and Strip

Grade

Chemical Composition %

Applicable

thickness

range (mm)

Tensile Test Bendability

C Si Mn P S

Yield

Strength

N/mm

2

Tensile

Strength

N/mm

2

Elongation Angle

of

bending

Inside

Diameter

Test

Piece

Test

Piece

%

ACR-TEN

A

0.12

max.

0.25

0.55

0.20

0.50

0.070

0.150

0.025

max.

1.5

12.7

345

min.

480

min.

No.5

in

Rolling

direction

25

min

180

thickness

1.0

No.1

in

Rolling

direction

ACR-TEN

AF

0.08

max.

0.15

0.45

0.15

0.45

1.5

12.7

285

min.

410

510

Remark1.The values specified shall not apply to the irregular portions at both ends of steel strip.

2. To improve the atmospheric corrosion resistant steel material properties, adding appropriate

amount of Cu, Ni and other alloying elements.

3.1.2 CSC Cr-B-V Alloy steel

Grade

Applicable

thickness range

(mm)

Chemical Composition %

C Mn P S Cr B V

CSC 50BV30 2.205.00

0.27

0.33

0.70

1.00

0.025

max.

0.015

max.

0.30

min.

0.0005

min.

0.10

min.

3.1.3 CSC HM-690T (high strength steel)

Grade

Applicable

thickness

range (mm)

Chemical Composition %

Tensile Test Bendability

Yield

Strength

N/mm

2

Tensile

Strength

N/mm

2

Elongation %

(transverse to

rolling direction )

Angle

of

bending

Inside

Diameter

Test Piece

, [ $ $;

z,5

(Test Piece) thickness

|

qq

thickness|

qq

,0

|

,3

,3

|

(,3

(,3

|

,7

|

(,0

(,0

|

,$,

[-(90|

0

0,0

max.

,00

max.

0,03

max.

0,05

max.

0,(0

max.

550

min.

(90

min.

5

min.

(

min.

;

min.

;0

z

3,0| 4,0|

No.3

rolling

direction

- 8 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.1.4 CSC HC 1085 (hot-rolled high carbon tool steel with thermostable coating)

Grade

Chemical Composition %

C Mn P S Si

CSC HC 1085

0.80

0.90

0.10

0.50

0.02

max.

0.03

max.

0.08

max.

RemarkSupply hot-rolled pickled and annealing(spheroidizing) coil. only guaranteed chemical composition.

3.1.5 CSC HC 15B22 (hot-rolled high-strength B-Mn steel)

Grade

Chemical Composition %

C Mn P S Si Al B

CSC HC 15B22

0.19

0.25

1.05

1.35

0.020

max.

0.010

max.

0.15

0.25

0.075

max.

0.0005

0.0030

RemarkOnly guaranteed chemical composition.

3.1.6 JIS G3101 Rolled Steel for General Structure

Grade

Chemical Composition

%

Tensile Test

Bendability

C Mn P S

Yield Point

or

Yield Strength

N/mm

2

Tensile

Strength

N/mm

2

Elongation % %

Angle

of bending

Inside radius

Test

Piece

No.5

Test Piece

No.1A

Test Piece

thickness

tmm thicknesst

mm

thicknesst

mm

t5 5t16

SS330

0.050

max.

0.050

max.

205 min 330 - 430

26

min

21

min

180

0.5 t

No.1

SS400 245 min 400 - 510

21

min

17

min

1.5 t

SS490 285 min 490 - 610

19

min

15

min

2.0 t

SS540

0.30

max.

1.60

max.

0.040

max.

0.040

max.

400 min 540 min

16

min

13

min

2.0t

Remarks1. Alloy elements other than those shown in the above table may be added necessary.

2. t is the thickness of material.

3. The bend test may be omitted*. However, when the purchaser designates, the test shall be

performed.

* It means that the test may be omitted by the manufacturers decision, but it means that the

bendability shall satisfy the specification.

- 9 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.1.7 JIS G3106 Rolled Steel for Welded Structure

Grade

Chemical Composition % Tensile Test Impact Test

C Si Mn P S

Yield

Point

or Proof

Strength

N/mm

2

Tensile

Strength

N/mm

2

Elongation %

Test

Temperature

Charpy

Absorbed

Energy

J

Test

Piece

No.5 Test Piece

No.1A

Test Piece

Thickness(t)mm Thickness(t)mm

t5.00 t16.00 5.00t16.00

SM400A

0.23

max.

2.5C

min.

0.035

max.

0.035

max.

245

min.

400-510

23

min.

18 min.

No.4

in

rolling

direction

SM400B

0.20

max.

0.35

max.

0.60

|

1.50

0 27min.

SM400C

0.18

max.

0.60

|

1.50.

0 47min.

SM490A

0.20

max.

0.55

max.

1.65

max

325

min.

490-610

22

min.

17 min.

SM490B

0.18

max.

0 27min.

SM490C 0 47min.

SM490YA

0.20

max.

365

min.

490-610

19

min.

15min.

SM490YB 0 27min.

SM520B

0.20

max.

365

min.

520-640

19

min.

15min.

0 27min.

SM520C 0 47min.

SM570

0.18

max.

1.70

max

460

min.

570-720

19

min.

-5 47min.

Remarks1. Alloy elements other than those shown in the above table may be added necessary.

2. Impact test is applicable to thickness over 12.0mm of steel.

3.1.8 JIS G3113 Hot-Rolled Steel Plates, Sheets and Strip for Automobile Structural Uses

Grade

Chemical

Composition

%

Tensile Test Bendability

Tensile

Strength

N/mm

2

Yield Point

N/mm

2

Elongation % (rolling direction)

Angle

of

bending

Inside radius

Test

piece

No.5 Test Piece

P S

Thickness (t) mm Thickness (t) mm

Thickness (t)

mm

t6.0

6.0t

8.0

8.0t

14.0

1.6

t2.0

2.0

t2.5

2.5

t3.15

3.15

t4.0

4.0

t6.3

t6.3 t2.0

t

2.0

SAPH

310

0.040

max.

0.040

max.

310

min.

(185)

min.

(185)

min.

(175)

min.

33

min.

34

min.

36

min.

38

min.

40

min.

41

min.

180

Flat on

itself

1.0 t

No.3

transverse

to rolling

direction

SAPH

370

370

min.

225

min.

225

min.

215

min.

32

min.

33

min.

35

min.

36

min.

37

min.

38

min.

0.5 t

1.0 t

SAPH

400

400

min.

255

min.

235

min.

235

min.

31

min.

32

min.

34

min.

35

min.

36

min.

37

min.

1.0 t

1.0 t

SAPH

440

440

min.

305

min.

295

min.

275

min.

29

min.

30

min.

32

min.

33

min.

34

min.

35

min.

1.0 t

1.0 t

Remark1. Values in parentheses mean reference values.

2. The values specified shall not apply to the irregular portions at both ends of steel strip.

- 10 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.1.9 JIS G3116 Steel Sheets, Plate and Strip for Gas Cylinders

Grade

Chemical Composition % Tensile Test Bendability

C Si Mn P S

Yield Point

or Proof

Stress

N/mm

2

Tensile

Strength

N/mm

2

Elongation

%

Test

Piece

Angle

of

bending

Inside radius

Thickness (t)

mm

Test

Piece

SG255

0.20

max.

0.30

min.

0.030

max.

0.030

max.

255min. 400min. 28min.

No.5

in

rolling

direction

180

1.0 t

No.3

in

rolling

direction

SG295

0.35

max.

1.00

max.

295min. 440min. 26min.

1.5 t

SG325

0.55

max.

1.50

max.

325min. 490min. 22min.

1.5 t

SG365 365min. 540min. 20min.

1.5 t

RemarkThe values specified shall not apply to the irregular portions at both ends of steel strip.

3.1.10 JIS G3125 Superior Atmospheric Corrosion Resisting Rolled Steels

Grade

Thickness

(t) mm

Chemical Composition % Tensile Test Bendability

C Si Mn P S Cu Cr Ni

Yield

Point or

Proof

Stress

N/mm

2

Tensile

Strength

N/mm

2

Elongation

Angle

of

bending

Inside

radius

Thickness

(t) mm

Test

Piece

Test

Piece

%

SPA-H

t6.0

0.12

max.

0.20

0.75

0.60

max.

0.070

0.150

0.035

max.

0.25

0.55

0.30

1.25

0.65

max.

355

min.

490

min.

No.5

22

min.

180

0.5 t

No.1

in

rolling

direction

t6.0 No.1A

15

min.

1.5 t

RemarkAlloy elements other than those shown in the above table may be added necessary.

3.1.11 JIS G3131 Hot-Rolled Mild Steel Plate, Sheets and Strip

Grade

Chemical Composition

%

Tensile Test Bendability

Tensile

Strength

N/mm

2

Elongation % (Rolling direction)

Test

Piece

Angle

of

bending

Inside radius

Test

Piece

C Mn P S

Thickness (t) mm Thickness (t) mm

1.2t

1.6

1.6t

2.0

2.0t

2.5

2.5t

3.2

3.2t

4.0

t4.0 t3.2 t3.2

SPHC

0.12

max.

0.60

max.

0.045

max.

0.035

max.

270

min.

27

min.

29

min.

29

min.

29

min.

31

min.

31

min.

No.5

rolling

direction

180

Flat on

itself

0.5 t

No.3

in

rolling

direction

SPHD

0.10

max.

0.45

max.

0.035

max.

0.035

max.

30

min.

32

min.

33

min.

35

min.

37

min.

39

min.

SPHE

0.08

max.

0.40

max.

0.030

max.

0.030

max.

31

min.

33

min.

35

min.

37

min.

39

min.

41

min.

SPHF

0.08

max.

0.35

max.

0.025

max.

0.025

max.

37

min.

38

min.

39

min.

39

min.

40

min.

42

min.

Remark1. Grade SPHF is manufactured by a special process, such as made of killed steel to improve drawability.

2. The values specified shall not apply to the irregular portions at both ends of steel strip.

3. The bend test may be omitted*.However, when the purchaser designates, the test shall be performed.

* It means that the test may be omitted by the manufacturers decision, but it means that the bendability

shall satisfy the specification.

- 11 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.1.12 JIS G3132 Hot-Rolled Carbon Steel Strip for Pipes and Tubes

Grade

Chemical Composition %

Tensile Test Bendability

Tensile

Strength

N/mm

2

Elongation %

Test

pieces

Angle

of bending

Inside radius

Test

Piece C Si Mn P S

Thickness (t)mm Thickness (t) mm

1.2t

1.6

1.6t

3.0

3.0t

6.0

t6.0

13.0

t3.0

3.0t

13.0

SPHT1

0.10

max.

0.35

max.

0.50

max.

0.040

max.

0.040

max.

270

min.

30

min.

32

min.

35

min.

37

min.

No.5

in

rolling

direction

180

Flat on

itself

0.5 t

No.3

in

rolling

direction

SPHT2

0.18

max.

0.35

max.

0.60

max.

340

min.

25

min.

27

min.

30

min.

32

min.

1.0 t 1.5 t

SPHT3

0.25

max.

0.30

0.90

410

min.

(20

min).

22

min.

25

min.

27

min.

1.5 t 2.0 t

SPHT4

0.30

max.

0.30

1.00

490

min.

(15

min).

18

min.

20

min.

22

min.

1.5 t 2.0 t

Remarks1. The Si content of SPHT1 can be modified to 0.04% max. upon agreement.

2. Values in parentheses mean reference values.

3. The values specified shall not apply to the irregular portions at both ends of steel strip.

4. The bend test may be omitted*. However, when the purchaser designates, the test shall be performed.

* It means that the test may be omitted by the manufacturers decision, but it means that the bendability

shall satisfy the specification.

3.1.13 JIS G3134 Hot-Rolled High Strength Steel Sheets with Improved Formability for Automobile Structural

Uses

Grade

Tensile

Strength

N/mm

2

Yield Point

or Proof

Stress

N/mm

2

Elongation % Bendability

Thickness(t) mm

Test

Piece

Angle

of

bending

Inside radius

Thickness(t) mm

Test

Piece 1.6t

2.0

2.0t

2.5

2.5t

3.25

3.25t

6.0

1.6t

3.25

3.25t

6.00

SPFH 490 490min. 325min. 22min. 23min. 24min. 25min.

No.5

Transverse

to rolling

direction

180

0.5 t 1.0 t

No.3

transverse

to rolling

direction

SPFH 540 540min. 355min. 21min. 22min. 23min. 24min. 1.0 t 1.5 t

SPFH 590 590min. 420min. 19min. 20min. 21min. 22min. 1.5 t 1.5 t

SPFH 540Y 540min. 295min. 24min. 25min. 26min. 1.0 t 1.5 t

SPFH 590Y 590min. 325min. 22min. 23min. 24min. 1.5 t 1.5 t

Remarks1. The chemical composition shall be agreed upon by the purchaser and supplier, if necessary.

2. The bend test may be omitted*. However, when the purchaser designates, the test shall be performed.

* It means that the test may be omitted by the manufacturers decision, but it means that the bendability

shall satisfy the specification.

3.1.14 JIS G3136 Rolled Steels for Building Structure

Grade

Chemical Composition %

Carbon

Equivalent

%

Yield Point or

Proof Stress

N/mm

2

Tensile

Strength

N/mm

2

Yield Ratio %

Elongation %

Test Piece

No.1A

C Si Mn P S

Thickness

mm

6.00mmt

12.0mm

12.0mmt

16.0mm

6.0mmt

12.0mm

12.0mmt

16.0mm

6.0mmt

16.0mm

SN400A

0.24

max.

0.050

max.

0.050

max.

235min. 235min.

400-510

17min.

SN400B

0.20

max.

0.35

max.

0.60

1.50

0.030

max.

0.015

max.

0.36

max.

235min. 235-355 80max. 18min.

SN490B

0.18

max.

0.55

max.

1.65

max.

0.44

max.

325min. 325-445 490-610 80max. 17min.

Remarks1. Impact test for SN400B & SN490B is applicable to thickness over 12.0mm of steel. Test temperature at

0, charpy absorption energy is 27J min. , test piece is No.4 in rolling direction.

2. Carbon Equivalent =C

Mn

Si

Ni

Cr

Mo

V

6 24 40 5 4 14

- 12 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.1.15 Carbon Steels for Machine Structural Use

)$ (405

$,[

Chemical Composition Chemical Composition

Grade , $; [ $ Grade , $; [ $

0,5

0,35

0,030

q,

0,035

q,

00

()

0,00,04

0,35 q,

0,030

q,

0,050

q,

003

()

0,00,0( 0,35 q,

004

()

0,00,0; 0,35 q,

005

()

0,0( q, 0,35 q,

00(

() (3)

0,0; q, 0,50,40

007

()

0,00,0 0,50 q,

00;

() (3)

0,0 q, 0,300,50

009 0,5 q, 0,(0q,

$0, 0,0;0,3 0,300,(0 00 0,0;0,3 0,300,(0

$, 0,00,5 0,300,(0 0 0,00,5 0,300,(0

$5, 0,30,; 0,300,(0 05 0,30,; 0,300,(0

0( 0,30,; 0,(00,90

$7, 0,50,0 0,300,(0 07 0,50,0 0,300,(0

0; 0,50,0 0,(00,90

09 0,50,0 0,70,00

$0, 0,;0,3 0,300,(0 00 0,;0,3 0,300,(0

0 0,;0,3 0,(00,90

$, 0,00,5 0,300,(0 0 0,;0,3 0,70,00

03 0,00,5 0,300,(0

$5, 0,0,; 0,300,(0 05 0,0,; 0,300,(0

$;, 0,50,3 0,(00,90 0( 0,0,; 0,(00,90

$30, 0,70,33 0,(00,90 030 0,;0,34 0,(00,90

$33, 0,300,3( 0,(00,90 033 0,300,3( 0,70,00

$35, 0,30,3; 0,(00,90 035 0,30,3; 0,(00,90

037 0,30,3; 0,70,00

$3;, 0,350,4 0,(00,90 03; 0,350,4 0,(00,90

$40, 0,370,43 0,(00,90 040 0,370,44 0,(00,90

04 0,400,47 0,(00,90

$43, 0,400,4( 0,(00,90 043 0,400,47 0,70,00

044 0,430,50 0,300,(0

$45, 0,40,4; 0,(00,90 045 0,430,50 0,(00,90

04( 0,430,50 0,70,00

$4;, 0,450,5 0,(00,90

049 0,4(0,53 0,(00,90

$50, 0,470,53 0,(00,90 050 0,4;0,55 0,(00,90

$53, 0,500,5( 0,(00,90 053 0,4;0,55 0,70,00

$55, 0,50,5; 0,(00,90 055 0,500,(0 0,(00,90

$5;, 0,550,( 0,(00,90

0(0 0,550,(5 0,(00,90

0(5 0,(00,70 0,(00,90

070 0,(50,75 0,(00,90

55 0,30,; ,0,40 0,030 q, 0,050 q,

54 0,90,5 ,35,(5 0,030 q, 0,050 q,

55 0,470,55 ,0,50 0,030 q, 0,050 q,

430

(4)

0,;0,33 0,50,35 0,400,(0 0,030 q, 0,040 q,

Note1. Ultra low carbon, interstitial free stabilized and nonstablized steel shall not be supplied for these grades.

2. Ultra low carbon, interstitial free stabilized and nonstablized steel may be supplied for these grades.

3. MANGANESEFor grades G10060 and G10080 applicable to Structural Shapes, Plates, Strip, Sheets and

Welded Tubing, the manganese limit is 0.45% maximumand 0.50% maximum, respectively, with no minimum.

4. SAE4130, Cr0.80-1.10%Mo0.15-0.25%Cu0.35% max.Ni0.25% max.

- 13 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.1.16 SAE J1392 High Strength Steel

Grade

Chemical

Composition

Yield

Strength

N/mm

2

Tensile

Strength

N/mm

2

Elongation

Test

Piece

Bendability

C Mn

Angle

of

bending

Inside Radius

Thickness(t) mm

Test Piece

t4.55mm 4.55mmt

050XLF

0.13

max.

0.90

max.

340

min.

410

min.

22min.

In

rolling

direction

90 1.0t 2.0t

Transverse to

rolling direction

060XLF

410

min.

480

min.

20min.

070XLF

0.13

max.

1.65

max.

480

min.

550

min.

17min.

080XLF

550

min.

620

min.

14min.

3.1.17 JIS G4053 Cr-Mo Steel

Grade

Chemical Composition

C Si Mn P S Ni Cr Mo

SCM415 0.13~0.18

0.15 ~0.35

0.60~0.90

0.030max. 0.030max.

0.25max

0.90~1.20

0.15~0.25

SCM418 0.16~0.21

SCM420 0.18~0.23

SCM421 0.17~0.23 0.70~1.00

SCM425 0.23~0.28 0.60~0.90

0.15~0.30

SCM430 0.28~0.33 0.60~0.90

SCM432 0.27~0.37 0.30~0.60 1.00~1.50

SCM435 0.33~0.38

0.60~0.90 0.90~1.20

SCM440 0.38~0.43

RemarkAs impurities, Cu shall not exceed 0.30% throughout all classes.

3.1.18 ASTM A36A283 Carbon Steel for Structural Use

ASTM No

(Description)

Chemical Composition % Tensile Test

C Si Mn P S

Yield Point

ksi(N/mm

Tensile Strength

ksiN/mm

Elongation

Gage Length

in. (mm)

%

min

A36

Structural Quality

0.25

max.

0.40

max.

0.04

max.

0.05

max.

36250

min.

58~80

400~550

8(200) 20

2(50) 23

A283

Low and

Intermediate

Tensile

Strength

Grade A

0.14

max.

0.40

max.

0.90

max.

0.035

max.

0.04

max.

24165

min.

45~60

310~415

8(200) 27

2 (50) 30

Grade B

0.17

max.

27185

min.

50~65

345~450

8(200) 25

2 (50) 28

Grade C

0.24

max.

30205

min.

55~75

380~515

8(200) 22

2 (50) 25

Grade D

0.27

max.

33230

min.

60~80

415~550

8(200) 20

2 (50) 23

RemarkCu is 0.20% min. when specified.

- 14 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.1.19 ASTM A1011 Carbon, structural, High-Strength Low-Alloy Steel and High-Strength Low-Alloy with

Improved Formability.

Grade

Chemical Composition %

C Mn P S Al Cu Ni Cr Mo V Nb Ti

CS Type A 0.10max.

0.60max.

0.030max

0.035max

.

0.20max 0.20max.

*1

0.15max.

0.06max.

0.008max

.

0.008max

.

0.025max

.

CS Type B 0.02/0.15

CS Type C 0.08max. 0.10max

CS Type D 0.10max. 0.70max. 0.030max

0.008max

.

DS Type A 0.08max.

0.50max. 0.020max 0.030max 0.01min.

0.025max

. DS Type B 0.02/0.08

SS Gr. 30

0.25max.

0.90max.

0.035max.

0.040max

.

0.15max.

0.025max

.

SS Gr. 33

SS Gr. 36 Type 1

SS Gr. 36 Type 2 1.35max.

SS Gr. 40 0.90max.

SS Gr. 45 Type 1

1.35max.

SS Gr. 50

SS Gr. 55

SS Gr. 60

SS Gr. 70

SS Gr. 80

HSLAS Gr.45 C1ass 1 0.22max.

1.35max.

0.040max.

0.005min. 0.005min. 0.005min.

HSLAS Gr.45 C1ass 2 0.15max.

HSLAS Gr.50 C1ass 1 0.23max.

HSLAS Gr.50 C1ass 2 0.15max.

HSLAS Gr.55 C1ass 1 0.25max.

HSLAS Gr.55 C1ass 2 0.15max.

HSLAS Gr.60 C1ass 1 0.26max.

1.50max.

HSLAS Gr.60 C1ass 2 0.15max.

HSLAS Gr.65 C1ass 1 0.26max.

HSLAS Gr.65 C1ass 2 0.15max.

HSLAS Gr.70 C1ass 1 0.26max.

1.65max.

0.16max.

HSLAS Gr.70 C1ass 2 0.15max.

HSLAS-F Gr.50

0.15max. 0.020max

0.025max

.

0.16max.

HSLAS-F Gr.60

HSLAS-F Gr.70

0.16max.

HSLAS-F Gr.80

Remark1. Cr is 0.25% maximum when C0.05%. Ti is permitted for SS designations to the lesser of 3.4N+1.5S

or 0.025%, when C0.02%.

2. Nb, Ti and V is 0.005% min. when specified.

- 15 -

S

p

e

c

i

f

i

c

a

t

i

o

n

Grade

Tensile

Strength

MPa

Yield Strength

Mpa

Elongation G.L.=2 inch

Test Piece

Bend Test

Inside Radius

Test Piece

t<6.0mm t<1.6mm 1.6mmt<2.5mm t=2.5mm

2.5mm<t

<6.0mm

t<6.0mm

CS Type A 205/340 25min. 25min. 25min. 25min.

in

rolling

direction

Transverse

to rolling

direction

CS Type B 205/340 25min. 25min. 25min. 25min.

CS Type C 205/340 25min. 25min. 25min. 25min.

CS Type D 205/340 25min. 25min. 25min. 25min.

DS Type A 205/310 28min. 28min. 28min. 28min.

DS Type B 205/310 28min. 28min. 28min. 28min.

SS Gr. 30 340min. 205min. 21min. 24min. 25min. 25min. 1.0t

SS Gr. 33 360min. 230min. 18min. 22min. 23min. 23min. 1.0t

SS Gr. 36 Type1 365min. 250min. 17min. 21min. 22min. 22min. 1.5t

SS Gr. 36 Type2 400/550 250min. 16min. 20min. 21min. 21min. 2.0t

SS Gr. 40 380min. 275min. 15min. 20min. 21min. 21min. 2.0t

SS Gr. 45 410min. 310min. 13min. 18min. 19min. 19min. 2.0t

SS Gr. 50 450min. 340min. 11min. 16min. 17min. 17min. 2.5t

SS Gr. 55 480min. 380min. 9min. 14min. 15min. 15min. 3.0t

SS Gr. 60 520min. 410min. 8min. 13min. 14min. 14min. 3.5t

SS Gr. 70 585min. 480min. 7min. 12min. 13min. 13min. 4.0t

SS Gr. 80 620min. 550min. 6min. 11min. 12min. 12min. 4.0t

HSLAS Gr.45 C1ass 1

410min. 310min. 23min. 23min. 23min. 25min. 1.5t

HSLAS Gr.45 C1ass 2

380min. 310min. 23min. 23min. 23min. 25min. 1.5t

HSLAS Gr.50 C1ass 1

450min. 340min. 20min. 20min. 20min. 22min. 2.0t

HSLAS Gr.50 C1ass 2

410min. 340min. 20min. 20min. 20min. 22min. 1.5t

HSLAS Gr.55 C1ass 1

480min. 380min. 18min. 18min. 18min. 20min. 2.0t

HSLAS Gr.55 C1ass 2

450min. 380min. 18min. 18min. 18min. 20min. 2.0t

HSLAS Gr.60 C1ass 1

520min. 410min. 16min. 16min. 16min. 18min. 2.5t

HSLAS Gr.60 C1ass 2

480min. 410min. 16min. 16min. 16min. 18min. 2.0t

HSLAS Gr.65 C1ass 1

550min. 450min. 14min. 14min. 14min. 16min. 3.0t

HSLAS Gr.65 C1ass 2

520min. 450min. 14min. 14min. 14min. 16min. 2.5t

HSLAS Gr.70 C1ass 1

585min. 480min. 12min. 12min. 12min. 14min. 3.5t

HSLAS Gr.70 C1ass 2

550min. 480min. 12min. 12min. 12min. 14min. 3.0t

HSLAS-F Gr.50 410min. 340min. 22min. 22min. 22min. 24min. 1.0t

HSLAS-F Gr.60 480min. 410min. 20min. 20min. 20min. 22min. 1.5t

HSLAS-F Gr.70 550min. 480min. 18min. 18min. 18min. 20min. 2.0t

HSLAS-F Gr.80 620min. 550min. 16min. 16min. 16min. 18min. 2.0t

Remarkst is the thickness of material.

- 16 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.1.20 ASTM A1018 Heavy-thickness for Carbon, Commercial, drawing, structural steelHigh-Strength

Low-Alloy, and High-Strength Low-Alloy Steel with Improved Formability

Grade C Mn P S Cu Ni Cr Mo V Nb Ti N

SS Gr. 30

0.25max.

1.50

max.

0.035

max.

0.04

max.

0.20

max.

0.20

max.

0.15

max.

0.06

max.

0.008

max.

0.008

max.

0.025

max.

0.014

max.

SS Gr. 33

SS Gr. 36

SS Gr. 40

HSLAS Gr.45 C1.1 0.22max.

1.50

max.

0.040

max.

0.005

min.

0.005

min.

0.005

min.

HSLAS Gr.45 C1.2 0.15max.

HSLAS Gr.50 C1.1 0.23max.

HSLAS Gr.50 C1.2 0.15max.

HSLAS Gr.55 C1.1 0.25max.

HSLAS Gr.55 C1.2 0.15max.

HSLAS Gr.60 C1.1 0.26max.

HSLAS Gr.60 C1.2 0.15max.

HSLAS Gr.65 C1.1 0.26max.

HSLAS Gr.65 C1.2 0.15max.

HSLAS Gr.70 C1.1 0.26max.

1.65

max.

0.16

max.

HSLAS Gr.70 C1.2 0.15max.

HSLAS-F Gr.50

0.15max.

1.65

max.

0.025

max.

0.035

max.

0.06

max.

HSLAS-F Gr.60

HSLAS-F Gr.70

0.16

max.

HSLAS-F Gr.80

Remarks1. CuNiCrMo0.50

2. Nb, Ti and V is 0.005% min. when specified.

- 17 -

S

p

e

c

i

f

i

c

a

t

i

o

n

Grade

Tensile

Strength

MPa

Yield Strength

Mpa

Elongation G.L.=2

Test Piece

Bend Test

Inside

Radius Test Piece

t25mm

G.L.=2

t25mm

G.L.=8

t25mm

t25mm

SS Gr. 30 340min. 205min. 22min. 17min.

Transverse

to rolling

direction

1.0t

Transverse

to rolling

direction

SS Gr. 33 360min. 230min. 22min. 16min. 1.0t

SS Gr. 36 365min. 250min. 21min. 15min. 1.5t

SS Gr. 40 380min. 275min. 19min. 14min. 2.0t

HSLAS Gr.45 C1.1 410min. 310min. 22min. 17min. 1.5t

HSLAS Gr.45 C1.2 380min. 310min. 22min. 17min. 1.5t

HSLAS Gr.50 C1.1 450min. 340min. 20min. 16min. 2.0t

HSLAS Gr.50 C1.2 410min. 340min. 20min. 16min. 1.5t

HSLAS Gr.55 C1.1 480min. 380min. 18min. 15min. 2.0t

HSLAS Gr.55 C1.2 450min. 380min. 18min. 15min. 2.0t

HSLAS Gr.60 C1.1 520min. 410min. 16min. 14min. 2.5t

HSLAS Gr.60 C1.2 480min. 410min. 16min. 14min. 2.0t

HSLAS Gr.65 C1.1 550min. 450min. 14min. 12min. 3.0t

HSLAS Gr.65 C1.2 520min. 450min. 14min. 12min. 2.5t

HSLAS Gr.70 C1.1 590min. 480min. 12min. 10min. 3.5t

HSLAS Gr.70 C1.2 550min. 480min. 12min. 10min. 3.0t

HSLAS-F Gr.50 410min. 340min. 22min. 16min. 1.0t

HSLAS-F Gr.60 480min. 410min. 16min. 14min. 1.5t

HSLAS-F Gr.70 550min. 480min. 12min. 10min. 2.0t

HSLAS-F Gr.80 620min. 550min. 12min. 10min. 2.0t

Remarks t is the thickness of material.

- 18 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.1.21 ASTM A572 Gr. 50 TYPE1 High-Strength Low-Alloy Steel

(;,z

Chemical Composition %

Tensile Test

Yield

Strength

N/mm

2

Tensile

Strength

N/mm

2

Elongation %

(in rolling

direction)

, [ $ $; Nb

ASTM A572

GR.50 TYPE1

0,3

q,

,35

q,

0,04

q,

0,05

q,

0,40

q,

0.005

0.050

345

mi n.

450

mi n.

18

mi n.

3.1.22 EN 10149-2 Hot-rolled flat products made of high yield strength steels for cold forming

Remarks1. NbVTi0.22.

2. The S content can be modified to 0.010% max. upon agreement.

Grade Steel No.

Tensile Strength

N/mm

2

Yield Strength

N/mm

2

Elongation% (in rolling direction) Bend Test

Inside Diameter

thickness(t) mm

t3

G.L.=80mm

3t

G.L.=

0

65 . 5 S

Transverse to

rolling direction

S315MC 1.0972 315min. 390-510 20min. 24min. Flat on itself

S355MC 1.0976 355min. 430-550 19min. 23min. 0.5t

S420MC 1.0980 420min. 480-620 16min. 19min. 0.5t

S460MC 1.0982 460min. 520-670 14min. 17min. 1.0t

S500MC 1.0984 500min. 550-700 12min. 14min. 1.0t

S550MC 1.0986 550min. 600-760 12min. 14min. 1.5t

S600MC 1.8969 600min. 650-820 11min. 13min. 1.5t

S650MC 1.8976 650min. 700-880 10min. 12min. 2.0t

S700MC 1.8974 700min. 750-950 10min. 12min. 2.0t

Remarks1. S

0

: Test piece section area.

2. t8mm, yield strength of S650MC and S700MC can be lower by 20 N/mm

2

.

.

Grade Steel No.

Chemical Composition %

C Mn Si P S

(2)

Al

total

Nb

(1)

V

(1)

Ti

(1)

Mo B

S315MC 1.0972

0.12

max.

1.30

max.

0.50

max.

0.25

max.

0.020

max.

0.015

min.

0.09

max.

0.20

max.

0.15

max.

S355MC 1.0976

1.50

max.

S420MC 1.0980

1.60

max.

0.015

max.

S460MC 1.0982

1.60

max.

S500MC 1.0984

1.70

max.

S550MC 1.0986

1.80

max.

S600MC 1.8969

1.90

max.

0.22

max.

0.50

max.

0.005

max.

S650MC 1.8976

2.00

max. 0.60

max.

S700MC 1.8974

2.10

max.

- 19 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.1.23 API 5L

Type of

pipe

Level Grade

Chemical Composition % Tensile Test

C

max.

Mn

max.

Si

max.

P

max.

S

max.

Yield Strength

psiMPa

Tensile Strength

psiMPa

Welded

PSL 1

A 0.22 0.90

0.030 0.030

30500210min. 48600335min.

B

0.26

1.20

35500245min. 60200415min.

X42 1.30

42100290min. 60200415min.

X46

1.40

46400320min. 63100435min.

X52

52200360min. 66700460min.

X56

56600390min. 71100490min.

X60

60200415min. 75400520min.

X65 1.45

65300450min. 77600535min.

X70 1.65

70300485min. 82700570min.

PSL2

BM

0.22

1.20

0.45 0.025 0.015

3550065300245450 60200~110200415~760

X42M

1.30

4210071800290~495 60200~110200415~760

X46M

46400~76100320~525 63100~110200435~760

X52M

1.40

52200~76900360~530 66700~110200460~760

X56M

56600~79000390~545 71100~110200490~760

X60M

0.12

1.60

60200~81900415~565 75400~110200520~760

X65M

65300~87000450~600 77600~110200535~760

X70M 1.70

70300~92100485~635 82700~110200570~760

Remarks1. For each reduction of 0.01 below the specified maximum for carbon, an increase of 0.05 above the

specified maximum for manganese is permissible, up to a maximum of 1.65 for gradesL245 or B,

but L360 or X52up to maximum of 1.75 for grades L360 or X52, but L485 or X70up

to a maximum of 2.00 for grades L485 or X70, but L555 or X80.

2. For Grade B X70 and Grade X52M X70M, the sum of the Nb, V, Ti contents shall not exceed 0.15%.

3. For Grade BM X46M, Nb/ V/ Ti contents shall not exceed 0.05%/0.05%/0.04% seperately.

4. The purchase order shall include type of pipe.

3.1.24 API 5CT

Grade

Chemical Composition (%) Tensile Test

C Mn

P

max.

S

max.

Yield Strength

MPa

Tensile Strength

MPa

J 55 0.030 0.030 379-552 517 min.

RemarksThe purchase order shall include type of pipe.

- 20 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.2 Dimensional Tolerance

3.2.1 JIS G3113 Thickness Tolerances of Hot-Rolled Plates, Sheets and Coils Unitmm

Width(w)

Thickness(t)

w1200 1200w1500 1500w1800 1800w1880

1.60t2.00 0.16 0.17 0.18

2.00t2.50 0.17 0.19 0.21

2.50t3.15 0.19 0.21 0.24

3.15t4.00 0.21 0.23 0.26

4.00t5.00 0.24 0.26 0.28 0.29

5.00t6.00 0.26 0.28 0.29 0.31

6.00t8.00 0.29 0.30 0.31 0.35

8.00t10.0 0.32 0.33 0.34 0.40

10.0t12.5 0.35 0.36 0.37 0.45

12.5t14.0 0.38 0.39 0.40 0.50

Remarks1. The positions where the thickness is to be measured shall be as follows:

(A) For mill-edged products, any point 25mm and over inward from the edge.

(B) For cut-edged products, any point 15mm and over inward from the edge.

2. The values specified shall not apply to the irregular portions at both ends of steel coils.

3.2.2 JIS G3116 Thickness Tolerances of Hot-Rolled Steel Plates, Sheets and Coils Unitmm

Width(w)

Thickness(t)

600w1200 1200w1500 1500w1800 1800w1880

1.60t2.00 0.16 0.17 0.18 0.21

2.00t2.50 0.17 0.19 0.21 0.25

2.50t3.15 0.19 0.21 0.24 0.26

3.15t4.00 0.21 0.23 0.26 0.27

4.00t5.00 0.24 0.26 0.28 0.29

5.00t6.00 0.26 0.28 0.29 0.31

t =6.00 0.29 0.30 0.31 0.35

Remarks1. The above table applies to SG255 and SG295.

2. Thickness shall be measured at any point of 20mm and over inside the edges.

3. The values specified shall not apply to the irregular portions at both ends of steel coils.

- 21 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.2.3 JIS G3131 Thickness Tolerances of Hot-Rolled Steel Plates,Sheets and Coils Unitmm

Width(w)

Thickness (t)

w1200 1200w1500 1500w1800 1800w1880

t1.60 0.14 0.15 0.16*1

1.60t2.00 0.16 0.17 0.18 0.21

2.00t2.50 0.17 0.19 0.21 0.25

2.50t3.15 0.19 0.21 0.24 0.26

3.15t4.00 0.21 0.23 0.26 0.27

4.00t5.00 0.24 0.26 0.28 0.29

5.00t6.00 0.26 0.28 0.29 0.31

6.00t8.00 0.29 0.30 0.31 0.35

8.00t10.0 0.32 0.33 0.34 0.40

10.0t12.5 0.35 0.36 0.37 0.45

12.5t14.0 0.38 0.39 0.40 0.50

Remarks1. The above table applies to SPHC, SPHD, SPHE and SPHF grades.

2. Thickness shall be measured at any point of 20mm and over inside the edges.

3. The values specified shall not apply to the irregular portions at both ends of steel coils.

Note * 1. The value shall be applied to the steel strip under 1600mm in width.

3.2.4 JIS G3132 Thickness Tolerances of Hot-Rolled Steel Coils (SPHT1~ SPHT3) unitmm

Width(w)

Thickness (t)

w1200 1200w1500 1500w1800 1800w1880

t1.60 (0.14)

*2

0.15 0.16

*1

1.60t2.00 0.16 0.17 0.18 0.21

2.00t2.50 0.17 0.19 0.21 0.25

2.50t3.15 0.19 0.21 0.24 0.26

3.15t4.00 0.21 0.23 0.26 0.27

4.00t5.00 0.24 0.26 0.28 0.29

5.00t6.00 0.26 0.28 0.29 0.31

6.00t8.00 0.29 0.30 0.31 0.35

8.00t10.0 0.32 0.33 0.34 0.40

10.0t12.5 0.35 0.36 0.37 0.45

12.5t13.0 0.38 0.39 0.40 0.50

Remarks1. The above table applies to SPHT1~3 and CSC ACR-TEN grades.

2. Thickness shall be measured at any point 20mm and over inside the edges.

3. The values specified shall not apply to the irregular portions at both ends of steel coils.

Note * 1. The value shall be applied to the steel strip under 1600mm in width.

* 2. Values in parentheses mean reference values.

- 22 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.2.5 JIS G3132 Thickness Tolerances of Hot-Rolled Steel Coils (SPHT4) unitmm

Width(w)

Thickness (t)

w1200 1200w1500 1500w1800 1800w1880

t1.60 (0.14)

*2

0.15 0.16

*1

1.60t2.00 0.16 0.19 0.20

2.00t2.50 0.18 0.22 0.23 0.25

2.50t3.15 0.20 0.24 0.26 0.29

3.15t4.00 0.23 0.26 0.28 0.30

4.00t5.00 0.26 0.29 0.31 0.32

5.00t6.00 0.29 0.31 0.32 0.34

6.00t8.00 0.32 0.33 0.34 0.38

8.00t10.0 0.35 0.36 0.37 0.44

10.0t12.5 0.38 0.40 0.41 0.49

12.5t13.0 0.41 0.44 0.45

0.54

Remark1. The above table applies to SPHT4 and CSC ACR-TEN grades.

2. Thickness shall be measured at any point 20mm and over inside the edges.

3. The values specified shall not apply to the irregular portions at both ends of steel coils.

Note* 1. The value shall be applied to the steel strip under 1600mm in width.

* 2. Values in parentheses mean reference values.

3.2.6 JIS G3134 Hot-Rolled High Strength Steel Sheets with Improved for Formability for Automobile

Structural Uses Unitmm

Width(w)

Thickness (t)

w1200 1200w1500 1500w1800 1800w1880

1.60t2.00 0.16 0.19 0.20

*1

2.00t2.50 0.18 0.22 0.23

*1

2.50t3.15 0.20 0.24 0.26

*1

3.15t4.00 0.23 0.26 0.28 0.30

4.00t5.00 0.26 0.29 0.31 0.32

5.00t6.00 0.29 0.31 0.32 0.34

t =6.00 0.32 0.33 0.34 0.38

Remarks1. The positions where the thickness is to be measured shall be as follows:

(A) For mill-edged products, any point 25mm and over inward from the edges.

(B) For cut-edged products, any point 15mm and over inward from the edges.

2. The values specified shall not apply to the irregular portions at both ends of steel coils.

Note *1. The values are applicable to the steel sheets and coils under 1600 mm in width.

- 23 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.2.7 JIS G3136 Thickness tolerances of Rolled Steel for Building Structure Unitmm

Width(w)

Thickness (t)

w1600 1600w1880

6.00t6.30

+0.70

-0.30

+0.90

-0.30

6.30t10.0

+0.80

-0.30

+1.00

-0.30

10.0t16.0

+0.80

-0.30

+1.00

-0.30

Remarks1. The above table applies to SN400A,SN400B,and SN490B grades.

2. The positions where the thickness is to be measured shall be as follows:

(A) For mill-edged products, any point 25mm and over inward from the edges.

(B) For cut-edged products, any point 15mm and over inward from the edges.

3.2.8 JIS G3193 Thickness Tolerances of Hot-Rolled Steel Plates, Sheets and Coils Unitmm

Width(w)

Thickness (t)

w1600 1600w1880

t1.25 0.16

1.25t1.60 0.18

1.60t2.00 0.19 0.23

2.00t2.50 0.20 0.25

2.50t3.15 0.22 0.29

3.15t4.00 0.24 0.34

4.00t5.00 0.45 0.55

5.00t6.30 0.50 0.60

6.30t10.0 0.55 0.65

10.0t16.0 0.55 0.65

16.0t20.0 0.65 0.75

Remarks1. The above table applies to SS,SM,SCM,SPA-H, and SXXC grades.

2. The positions where the thickness is to be measured shall be as follows

(A) For mill-edged products, any point 25mm and over inward from the edges.

(B) For cut-edged products, any point 15mm and over inward from the edges.

3. Tolerance given in the table may be limited to either plus side or minus side upon the agreement

between the purchaser and the supplier. The total tolerance range in this case shall be equal to

that given in this table.

- 24 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.2.9 JIS G3193 Width Tolerances of Hot-Rolled Steel Plates, Sheets and Coils Unitmm

Width (w) Thickness (t)

Tolerance

Mill edge Cut edgeby ordinary cutting

max. min. max. min.

630w1000 1.20t20.0 25 0 10 0

1000w1250

t6.00

30 0

10

0

6.00t20.0 15

1250w1600

t6.00

35 0

10

0

6.00t20.0 15

1600w1880

t6.00

40 0

10

0

6.00t20.0 20

3.2.10 JIS G3193 Length Tolerances of Hot-Rolled Steel Plates and Sheets Unitmm

Length L

Tolerances

by ordinary cutting

max. min.

L4000 20 0

4000L6000 30 0

6000L8000 40 0

3.2.11 JIS G3193 Camber Tolerances of Hot-Rolled Steel Strip Unitmm

Width (w) Maximum value

w250 5 in any 2000 length

- 25 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.2.12 JIS G3193 JIS G3193 Maximum Flatness of Hot-Rolled Steel Plates and Sheets Unitmm

Width(w)

Thickness (t)

w1250 1250w1600 1600w1880

t1.60 18max. 20max.

1.60t3.15 16max. 18max. 20max.

3.15t4.00 16max.

4.00t5.00 14max.

5.00t8.00 13max.

8.00t15.00 12max.

Remarks1. The table is not applicable by the plate and sheet leveling done after leveling machine.

2. Values in this table shall be applied to any 2000 mm length. For the steel plate and sheet under 2000

mm in length, the values shall be applied to the full length. For the steel plate and sheet over 2000 mm

in wave pitch, the values in this table shall be applied to any pitch of the wave. For those over4000

mm in wave pitch, however, the above values shall be applied to any 4000 mm length.

3. Unless otherwise specified, 1.5 times the maximum deviation from flatness specified in this table shall

be applied to the steel plate and sheet of which the lower limit of yield point or proof strength in

tensile test is at least 460N/mm

2

, or chemical position on hardness is equivalent thereto, or quenched

and tempered.

4. Measurement of flatness, as a rule, shall be made on a flat surface plate.

5. The table does not apply to rolled edge (mill edge) steel plate.

6. This table also applies to CSC ACR-TEN.

3.2.13 The Applicable Size Ranges of ASTM A6, A568 and A635 Unitmm

Width(w)

Thickness (t)

720w1220 1220w1650

1.2t4.58 coilA568

sheetA568

4.58t5.85 coilA635

plateA6 5.85t12.7

Remarks 1. A568 applies to A1011, A1018 specifications.

2. A635 applies to the heavy thickness coils of A1011, A1018 specifications.

3. A6 applies to A36 and A1011 specifications.

3.2.14 ASTM A568 Thickness Tolerances of Hot-Rolled Steel Sheets and Coils (Carbon Steel) Unitmm

Width(w)

Thickness (t)

508w1016 1016w1220 1220w1524 1524w1829 1829w

1.2t1.30 0.10 0.10

1.30t1.45 0.10 0.11 0.11 0.12

1.45t1.81 0.11 0.11 0.12 0.12

1.81t2.49 0.12 0.12 0.12 0.15 0.15

2.49t4.58 0.12 0.15 0.15 0.15 0.15

4.58t5.84 0.15 0.17

0.19 0.20 0.22

Remarks1. The above table applies to ASTM A1011and A1018 specifications.

2. The values in the above table are converted from inch-pound units.

3. Thickness shall be measured at any point across the width not less than 9.5mm from a cut edge and not

less than 19mm from a mill edge.

4. The above table does not apply to the uncropped ends of mill-edged coils.

- 26 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.2.15 ASTM A568 Thickness Tolerances of Hot-Rolled Steel Sheets and Coils (High-Strength Low-Alloy Steel)

Unitmm

Width(w)

Thickness(t)

509w813

813w

1017

1017w

1220

1220w

1525

1525w

1830

1830w2032

1.2t1.30

0.11 0.11 0.11

1.30t1.50

0.11 0.11 0.12 0.12

1.50t1.78

0.12 0.12 0.12 0.12 0.15

1.78t2.09

0.12 0.12 0.12 0.12 0.15 0.15

2.09t2.49

0.12 0.15 0.15 0.15 0.17 0.17

2.49t4.58

0.15 0.15 0.19 0.19 0.20 0.22

4.58t5.84

0.17 0.17 0.19 0.19 0.20 0.22

Remarks1. The above table applies to ASTM A1011and A1018 specifications.

2. The values in the above table are converted from inch-pound units.

3. Thickness shall be measured at any point across the width not less than 9.5mm from a cut edge and

not less than 19mm from a mill edge.

4. The above table does not apply to the uncropped ends of mill-edged coils.

3.2.16 ASTM A568 Width Tolerances of Hot-Rolled Steel Sheets and Coils Unitmm

Width(w)

Tolerance

Mill edge

Cut Edge

Carbon Steel High-Strength Low-Alloy Steel

720w763

23

0

28

0

3.1

0

763w890

28

0

28

0

4.7

0

890w1220

28

0

31

0

4.7

0

1220w1270

28

0

31

0

6.3

0

1270w1525

38

0

38

0

6.3

0

1525w1651

38

0

41

0

7.9

0

1651w1778

38

0

44

0

7.9

0

1778w1981

38

0

47

0

7.9

0

Remarks1. The above table applies to ASTM A1011 and A1018 specifications.

2. The values in the above table are converted from inch-pound units.

3. The above table does not apply to the uncropped ends of mill-edged coils.

- 27 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.2.17 ASTM A568 Length Tolerances of Hot-Rolled Steel Sheets Unitmm

Length(L) 763L1525 1525L3049 3049L3963 3963L4877 4877L6096 6096L

Tolerance

12.7

0

19.0

0

25.4

0

31.7

0

38.1

0

44.4

0

Remarks1. The above table applies to A1011 and 1018 specifications.

2. The values in the above table are converted from inch-pound units.

3.2.18 ASTM A635 Thickness Tolerances of Hot-Rolled Steel Sheets Unitmm

Width(w)

Thickness(t)

509w1017 1017w1220 1220w1525 1525w1830 1830w

5.84t7.96 0.20 0.22 0.22 0.25 0.27

7.96t9.53 0.22 0.25 0.26 0.27 0.30

9.53t12.7 0.26 0.26 0.27 0.30 0.34

Remarks1. The above table applies to ASTM A1011 and A1018 specifications.

2 .The values in the above table are converted from inch-pound units.

3. Thickness shall be measured at any point across the width not less than 9.5mm from a cut-edge and

not less than 19mm from a mill-edge.

4. The above table does not apply to the uncropped ends of mill-edged coils.

- 28 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.2.19 ASTM A635 Width Tolerances of Hot-Rolled Heavy-Thickness Carbon Steel Coils Unitmm

Width (w)

Tolerance

Mill Edge Cut Edge

720w763

28

0

3.1

0

763w890

4.7

0

890w1220

31

0

1220w1271

6.3

0

1271w1525

+38

0

1525w1652

41

0

7.9

0

1652w1779

44

0

1779w2032

47

0

Remarks 1. The above table applies to ASTM A1011, A1018 specifications.

2. The values in the above table are converted from inch-pound units.

3. The above table does not apply to the uncropped ends of mill-edged coils.

3.2.20 ASTM A36 Thickness Tolerances of Hot-Rolled Steel Plates Unitmm

Width(w)

Thickness(t)

720w2132

t25.4

0.76

0.25

Remarks 1. The above table applies to ASTM A36 and A1011 specifications.

2. The values in the above table are converted from inch-pound units.

3. Thickness shall be measured at any point across the width 9.5 to 20 mm from the longitudinal edge .

4. For thickness measured at any location other than that specified in remark 3,the

permissible maximum over tolerance shall be increased by 75%.

- 29 -

S

p

e

c

i

f

i

c

a

t

i

o

n

3.2.21 ASTM A6 Width and Length Tolerances of Hot-Rolled Steel Plates Unitmm

Length (L) Width (w)

Width Tolerance Length Tolerance

Mill Edge Cut Edge

t9.53 9.53t15.87 t9.53 9.53t15.87

762L3048

720w889

28

0

9

6

11

6

12

6

15

6

889w1270

31

0

1270w1524

38

0

1524w1651

41

0

11

6

12

6

15

6

17

6

1651w1778

44

0

1778w2031

47

0

3048L6096

720w889

28

0

9

6

12

6

19

6

22

6

889w1270

31

0

1270w1524

38

0

1524w1651

41

0

12

6

15

6

1651w1778

44

0

1778w2031

47

0

6096L7620

720w889

28

0

9

6

12

6

25

6

28

6

889w1270

31

0

1270w1524

38

0

1524w1651

41

0

12

6

15

6

1651w1778

44

0

1778w2031

47

0

Remarks1. The above table applies to ASTM A36 specification.

2. The values in the above table are converted from inch-pound units.

3. t is the thickness of material.

- 30 -

P

r

o

d

u

c

t

A

v

a

i

l

a

b

i

l

i

t

y

4. Product Availability

4.1 Product Types and Mass Range

Item Product Type Mass Range

Plate and Sheet

HR Plate and Sheet, Mill Edge

2 t min.Pack

HR Plate and Sheet, Cut Edge

1

Coil

HR Coil, Mill edge

6~32t Coil

HR Coil, Pickled and Oiled, Mill Edge

HR Coil, Pickled and Oiled, Cut Edge

1

HR Coil, Pickled and Annealed-Spheroidized, Cut Edge

HR Coil, Pickled and Annealed, Cut Edge

HR Band

Note 1These product types will be produced when a customer has no special requirements.

4.2 Available Sizes

4.2.1 General Size Unit : mm

HR Product Thickness Range Mill Edge Cut Edge

Length Range/

Inside Diameter

Sheet 1.50~5.99

860~1545 760~6096

Plate

6.00~12.7 860~1524 1500~7620

Coil

1.50~6.50 720~1855

Inside Diameter 762 6.51~7.99 850~1560

8.00~9.50 850~1250

Pickled and

Oiled Coil

1.30~6.50 800~1560 800~1550 Inside Diameter 610

Band

2.00~10.0 740~1855

Inside Diameter 762

10.01~20.0 740~1560

Pickled and Annealed 2.0~6.5 800~1550 Inside Diameter 610

Pickled and

Annealed-Spheroidized

2.0~6.5 800~1550 Inside Diameter 610

Note 1Refer to the size range classified by strength in tables 4.2.2.

- 31 -

P

r

o

d

u

c

t

A

v

a

i

l

a

b

i

l

i

t

y

4.2 2 Size Range Classified by Strength

(1) 300N/mm

2

(30kgf/mm

2

)Class-Commercial Quality Unitmm

Mill Edge

Cut Edge

Thickness

720~1000

720~990

795

~1100

~1090

~1135

~1125

~1205

~1195

~1220

~1210

~1250

~1240

~1305

~1295

~1410

~1400

~1560

~1550

~1860

~1850

Typical

Specification

1.20~ JIS G3131 SPHC

JIS G3132

SPHT1

JIS G3113

SAPH310

SAE 1006

SAE 1008

SAE 1010

JFS A1011

JSH270C

1.30~

1.40~

1.50~

1.60~

1.75~

1.85~

2.00~

2.30~

2.50~

2.80~

3.00~

3.20~

3.50~

3.60~

4.00~

4.50~

5.00~

6.00~

6.51~7.99

8.00~10.0 1300

850 1250

(2) 300N/mm

2

(30kgf/mm

2

) Class-Drawing Quality Unitmm

Mill Edge

Cut Edge

Thickness

720~1000

720~990

~1135

~1125

~1205

~1195

~1220

~1210

~1250

~1240

~1305

~1295

~1410

~1400

~1560

~1550

~1630

~1620

~1860

~1850

Typical

Specification

1.50~ JIS G3131 SPHD

JFS A1011

JSH270D

1.60~

1.75~

1.86~

2.00~

2.30~

2.50~

2.80~

3.00~

3.20~

3.50~

3.60~

4.00~

4.50~

5.00~

6.00~

6.51~7.99

8.00 ~10.0 1300

850 1250

- 32 -

P

r

o

d

u

c

t

A

v

a

i

l

a

b

i

l

i

t

y

(3) 350N/mm2 (35kgf/mm

2

) Class Unitmm

Mill Edge

Cut Edge

Thickness

720~1000

720~990

~1100

~1090

~1135

~1125

~1205

~1195

~1220

~1210

~1250

~1240

~1305

~1295

~1410

~1400

~1560

~1550

~1860

~1850

Typical

Specification

1.50~ JIS G3101 SS330

JIS G3132

SPHT2

JIS G3113

SAPH370

ASTM A1011 SS

Gr.30

ASTM A1011 SS

Gr.33

SAE 1012

1.60~

1.75~

1.86~

2.00~

2.30~

2.50~

2.80~

3.00~

3.20~

3.50~

3.60~

4.00~

4.50~

5.00~

6.00~

6.51~7.99

8.00 ~10.0 1300

850 1250

(4) 400N/mm2 (40kgf/mm2) Class Unitmm

Mill Edge

Cut Edge

Thickness

720~1000

720~990

~1135

~1125

~1205

~1195

~1220

~1210

~1250

~1240

~1305

~1295

~1410

~1400

~1560

~1550

~1630

~1620

~1860

~1850

Typical

Specification

1.50~ JIS G3136

SN400A

JIS G3136

SN400B

JIS G3101 SS400

JIS G3106

SM400A

JIS G3106

SM400B

JIS G3132 SPHT3

JIS G3113

SAPH400

JIS G3116 SG255

ASTM A36

ASTM A1011 SS

Gr.40

ASTM A1011 SS

Gr.45

SAE 1015-1019

API 5L GR.B

1.60~

1.75~

1.86~

2.00~

2.30~

2.50~

2.80~

3.00~

3.20~

3.50~

3.60~

4.00~

4.50~

5.00~

6.00~

6.51~7.99

8.00 ~10.0 1300

850 1250

- 33 -

P

r

o

d

u

c

t

A

v

a

i

l

a

b

i

l

i

t

y

(5) 400N/mm2 (40kgf/mm2) Class (ACR-TEN AF) Unitmm

Mill Edge

Cut Edge

Thickness

720~1000

720~990

~1135

~1125

~1205

~1195

~1220

~1210

~1250

~1240

~1305

~1295

~1410

~1400

~1560

~1550

~1630

~1620

~1860

~1850

Typical

Specification

1.50~ CSC ACR-TEN AF

1.60~

1.75~

1.86~

2.00~

2.30~

2.50~

2.80~

3.00~

3.20~

3.50~

3.60~

4.00~

4.50~

5.00~

6.00~

6.51~7.99

8.00~10.0 1300

850 1250

(6) 450N/mm2 (45kgf/mm2) Class Unitmm

Mill Edge

Cut Edge

Thickness

720~1000

720~990

~1135

~1125

~1205

~1195

~1220

~1210

~1250

~1240

~1305

~1295

~1410

~1400

~1560

~1550

~1630

~1620

~1860

~1850

Typical

Specification

1.60~ JIS G3113 SAPH440

JIS G3116 SG295

ASTM A1011 SS

Gr.50

SAE 1020-1023

API 5L X46/X46M

1.75~

1.86~

2.00~

2.30~

2.50~

2.80~

3.00~

3.20~

3.50~

3.60~

4.00~

4.50~

5.00~

6.00~

6.51~7.99

8.00~10.0

1300

850 1250

- 34 -

P

r

o

d

u

c

t

A

v

a

i

l

a

b

i

l

i

t

y

(7) 500N/mm2 (50kgf/mm2)Class Unitmm

Mill Edge

Cut Edge

Thickness

720~1000

720~990

~1135

~1125

~1205

~1195

~1220

~1210

~1250

~1240

~1305

~1295

~1410

~1400

~1560

~1550

~1630

~1620

~1860

~1850

Typical

Specification

2.00~ JIS G3136 SN490B

JIS G3101 SS490

JIS G3106 SM490A

JIS G3106 SM490B

JIS G3106 SM490C

JIS G3106

SM490YA

JIS G3132 SPHT4

JIS G3134

SPFH540

JIS G4051 S40C

ASTM A1011 SS

Gr.55

SAE 1025-1043

API 5L X52/X52M

API 5CT J55

2.30~

2.50~

2.80~

3.00~

3.20~

3.50~

3.60~

4.00~

4.50~

5.00~

6.00~

6.51~7.99

8.00~10.0 1300

850 1250

(8) 500N/mm2 (50kgf/mm2) Class (ACR-TEN ASPAH) Unitmm

Mill Edge

Cut Edge

Thickness

720~1000

720~990

~1135

~1125

~1205

~1195

~1220

~1210

~1250

~1240

~1305

~1295

~1410

~1400

~1560

~1550

~1630

~1620

~1860

~1850

Typical

Specification

1.50~ CSC ACR-TENA

J IS G3125 SPAH

1.60~

1.75~

1.86~

2.00~

2.30~

2.50~

2.80~

3.00~

3.20~

3.50~

3.60~

4.00~

4.50~

5.00~

6.00~

6.51~7.99

8.00~10.0 1300

850 1250

- 35 -

P

r

o

d

u

c

t

A

v

a

u

l

a

b

i

l

i

t

y

(9) 600N/mm

2

(60kgf/mm

2

)Class Unitmm

Mill Edge

Cut Edge

Thickness

720~1000

720~990

~1135

~1125

~1205

~1195

~1220

~1210

~1250

~1240

~1305

~1295

~1410

~1400

~1560

~1550

~1630

~1620

~1860

~1850

Typical

Specification

2.30~ API 5L X60

API 5L X65

J IS G3134 SPFH590

CSC HM-690T

2.50~

2.80~

3.00~

3.20~

3.50~

3.60~

4.00~

4.50~

5.00~

6.00~

6.51~7.99

8.00~10.0 1300

850 1250

(10) 600N/mm2 (60kgf/mm2) Class (S45CS50C) Unitmm

Mill Edge

Cut Edge

Thickness

720~960

720~950

~1035

~1025

~1065

~1055

~1215

~1205

~1250

~1240

~1305

~1295

~1410

~1400

~1560

~1550

~1630

~1620

~1860

~1850

Typical

Specification

1.75~ J IS G4051 S45C

J IS G4051 S50C

J IS G4051 S55C

SAE 1045

SAE 1050

SAE 4130

1.86~

2.00~

2.30~

2.50~

2.80~

3.00~

3.20~

3.50~

3.60~

4.00~

4.50~

5.00~

6.00~

6.51~7.99

8.00~10.0

1300

850 1250

- 36 -

M

a

r

k

i

n

g

&

P

a

c

k

i

n

g

5.1 Marking

(1) Label MarkTwo labels are affixed to each coil pack

5.2 Packing

(1) Hot-rolled steel coil for domestic packing (2) Pickled and Oiled hot-rolled steel coil for export

packing

Circumferential and Eye/Trans Strapping VCI paper+Metal Protector+Metal Edge

Protector+Circumferential Strapping

5. Marking and Packing

- 37 -

A

p

p

l

i

c

a

t

i

o

n

E

x

a

m

p

l

e

s

Containers

Rims and Discs Bicycle Sprocket

Re-rolling Coil

Oil Drums

6. Application Examples

6. ApplicationExamples

A

p

p

l

i

c

a

t

i

o

n

E

x

a

m

p

l

e

s

- 38 -

Steel Pipe

Trailer Chassis

Line Pipes

- 39 -

U

n

i

t

C

o

n

v

e

r

s

i

o

n

T

a

b

l

e

7. Unit Conversion Table

Length

ft in. mm m

1 12 304.8 0.3048

0.08333 1 25.4 0.0254

0.003281 0.03937 1 0.001

Weight 1kg=2.20462 lb

Force 1kgf=9.80665 N

Stress

ksi=1000psi psi kgf/mm

2

N/mm

2

(MPa)

1 1000 0.703070 6.89476

0.001 1 0.70307010

-4

6.8947610

-3

1.42233 1422.33 1 9.80665

0.145038 145.038 0.101972 1

Absorbed

Energy

ft-lbf kgf-m N-m=J oule

1 0.138255 1.35582

7.23301 1 9.80665

0.737562 0.101972 1

- 40 -

O

r

d

e

r

I

n

f

o

r

m

a

t

i

o

n

8. Ordering Information

For prompt and proper processing of your inquiries and orders, please furnish complete details of items as shown in

the box below.

Required Ordering Data Example

1

Product

Name

HR Pl ate

HR Pickled and Annealed/

Annealed-Spheroidized Coil

HR Coi l

HR Cut Length HR Pi ckl ed and Oi l ed Coi l

HR Coi l HR Band

2

Specification and Designation of Grade J IS G3131 SPHC

3

Cut Edge or Mill Edge Mill Edge

4

Size (Thickness width Length or Coil) 1.6

mm

1219

mm

Coil

5

Inside and Outside Diameter ID 762

mm

OD 1700

mm

max.

6 Mass

Maximum Mass 10t

Order Mass 150t

7

Application and Fabricating Methods Hot-dipped ERW Pipe

8

Special Requirements(if Required)

I The contents of this catalog are for reference only. Customers are urged to consult the specifications published by

the corresponding Associations.

II Information on the available steel grades, size, marking and packing as shown herein may be updated without

notice to comply with actual production situations.

III We invite you to contact our Head Office should you have any questions concerning steel specifications or ordering

requirements.

Phone numbers are listed below for your convenience-Numbers of our international Offices are shown on the back

cover.

1. Sales services

CHINA STEEL GLOBAL TRADING CORPORATION

Address: 31F, NO. 8, MING-CHUAN 2ND ROAD, KAOHSIUNG 806, TAIWAN

Tel: 886-7-3322168

Fax: 886-7-3356411

E-mail:csgtb12@mail.csc.com.tw

CSGT JAPAN CO., LTD.

Address: 2F, Osaka U2 Bldg., 4-7 Uchihonmachi 2-Chome,Chuoku, Osaka 540-0026, J apan)

Tel: 002-81-6-6910-0850

Fax: 002-81-6-6910-0851

E-mail: csgtjpn@pop21.odn.ne.jp

CSGT HONG KONG LIMITED

Address: ROOM 1407,14/F, WORLD WIDE HOUSE, 19 DES VOEUX ROAD, CENTRAL, HONG KONG

Tel: 852-25231488

Fax: 852-25234748

E-mail: admin@csgthk.com.hk

CSGT (SHANGHAI) CO.,LTD.

Address: 21F, NO.1468 NAN J ING WEST RD., SHANGHAI 200040, CHINA

TEL86-21-62896898

FAX86-21-62896678

E-mail: pcliu@csgtsha.com

CSGT (SINGAPORE) PRIVATE LIMITED

Address: 10 SHENTON WAY #14-01, MAS BLDG., SINGAPORE 079117

Tel: 65-62238777~8

Fax: 65-62256054

E-mail: cscsin@singnet.com.sg

2. Metallurgical Department

Technical Service Section-Metallurgy: 886-7-8021335

Metallurgical Specification and Testing Section: 886-7-8021111 Ext. 3261, 2207, 2208

You might also like

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- China Steel PDFDocument38 pagesChina Steel PDFKalpeshNo ratings yet

- Bdip 16Document40 pagesBdip 16Lee Tin YanNo ratings yet

- Cdip16 PDFDocument35 pagesCdip16 PDFpeter wongNo ratings yet

- Rock BoltsDocument17 pagesRock BoltsayubpasombaNo ratings yet

- Pile Foundations: Driven Piles of Ductile Cast IronDocument8 pagesPile Foundations: Driven Piles of Ductile Cast IronqawsderNo ratings yet

- ASDO Anchors For Marine Structures GB 2015Document15 pagesASDO Anchors For Marine Structures GB 2015jmm100% (1)

- Schwing SPB BrochureDocument6 pagesSchwing SPB BrochureEdiNo ratings yet

- Gold Sun: DemonstrationDocument63 pagesGold Sun: DemonstrationMk3No ratings yet

- Segment Design - RETC 2003-From CD - Kramer Et Al-LDocument14 pagesSegment Design - RETC 2003-From CD - Kramer Et Al-Lprotal7351100% (1)

- FEM Reporting Guidelines-2014Document5 pagesFEM Reporting Guidelines-2014rch_ngNo ratings yet

- Promat Structural Steel Fire ProtectionDocument76 pagesPromat Structural Steel Fire ProtectionEdward LeungNo ratings yet

- Armador Bored Piling Tools 2010 PDFDocument30 pagesArmador Bored Piling Tools 2010 PDFjovanangelssNo ratings yet

- Plastic Section Moduli For I.S. Rolled Steel Beam Sections Zpy About Y-Y AxisDocument8 pagesPlastic Section Moduli For I.S. Rolled Steel Beam Sections Zpy About Y-Y AxisIJRASETPublicationsNo ratings yet

- Sdip 16Document38 pagesSdip 16Lee Tin YanNo ratings yet

- Anvita SharmaDocument45 pagesAnvita SharmaJay MehtaNo ratings yet

- Tunelling in Soft SoilsDocument14 pagesTunelling in Soft SoilsPiyush BhatiaNo ratings yet

- Sads DemoDocument63 pagesSads DemoMr LamNo ratings yet

- Technical English: Engineer. Sánchez Espinoza Edwin Student. Torres Mendoza Juan Carlos Theme. Mining SupportDocument28 pagesTechnical English: Engineer. Sánchez Espinoza Edwin Student. Torres Mendoza Juan Carlos Theme. Mining SupportJeferson Israel TORRES MENDOZANo ratings yet

- Dywidag Systems International - Mechanical Anchors and Rebar Rock Bolts (DSI, 2013)Document16 pagesDywidag Systems International - Mechanical Anchors and Rebar Rock Bolts (DSI, 2013)sandycastleNo ratings yet

- KEMROC-Products ENDocument27 pagesKEMROC-Products ENMina TadrosNo ratings yet

- Powder CoatDocument130 pagesPowder CoatAlonso IbarraNo ratings yet

- Composite Beam IIDocument27 pagesComposite Beam IIStefan-Raluca AsavoaeNo ratings yet

- What Are The Differences Between Rock Dowels and Rock BoltsDocument1 pageWhat Are The Differences Between Rock Dowels and Rock BoltsnirajlamichhaneNo ratings yet

- Elastomeric Bearing Pads and Strips Brochure 2010Document4 pagesElastomeric Bearing Pads and Strips Brochure 2010Anton Husen PurboyoNo ratings yet

- Superslim RMD Kwikform Hong Kong 16751 LowDocument21 pagesSuperslim RMD Kwikform Hong Kong 16751 Lowtmg016No ratings yet

- AnchoringDocument20 pagesAnchoringjack21abNo ratings yet

- A Jetplus IndeDocument13 pagesA Jetplus IndeMelissa MorganNo ratings yet

- Q1 - Testing, Design, and Field Implementation of GFRP RC Soft-Eyes For Tunnel ConstructionDocument17 pagesQ1 - Testing, Design, and Field Implementation of GFRP RC Soft-Eyes For Tunnel ConstructionJhoshep SaavedraNo ratings yet

- Deep Soil MixingDocument8 pagesDeep Soil MixingsuvraNo ratings yet

- DSI Bonded PT System Strands enDocument32 pagesDSI Bonded PT System Strands enElvisyuriNo ratings yet

- 12o Ton TelescopicDocument1 page12o Ton TelescopicmohamedNo ratings yet

- Underground-Sprayed Concrete BrochureDocument12 pagesUnderground-Sprayed Concrete BrochureEngTamerNo ratings yet

- Dsi Info 22 en PDFDocument172 pagesDsi Info 22 en PDFMauricio GutierrezNo ratings yet

- Cumulative Standard Normal TableDocument1 pageCumulative Standard Normal TableDian Paul100% (1)

- Multi-Mode and Variable Density TBMs Latest Trends in DevelopmentsDocument13 pagesMulti-Mode and Variable Density TBMs Latest Trends in DevelopmentsAyman SobhyNo ratings yet