Professional Documents

Culture Documents

H1000e K FJ

Uploaded by

Syarif HidayatullahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H1000e K FJ

Uploaded by

Syarif HidayatullahCopyright:

Available Formats

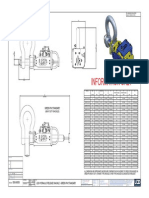

FJ SERIES HYDRAULIC CYLINDER

FJ Series General Purpose Hydraulic Cylinder

Features

qStandard series that conforms with JIS standards (JIS B8354-1985) A high level of general compatibility and interchangeability, plus very stable performance and quality.

30 to 250 1000ST 7, 14MPa

wAll component parts are completely standardized for quick delivery and easy parts replacement, maintenance, and inspection.

eSpecially selected materials used in tubes, rods, packing, bolts and all other parts ensures durability. In a tough environment.

For details see catalog number 9214.

Specifications

Item Maximum Working Pressure Withstand Pressure Minimum Operating Pressure Load Pressure Coefficient Allowable Maximum Speed Allowable Minimum Speed Cylinder Inside Diameter (mm) Stroke Rod Diameter Operating Fluid and Fluid Temperature Paint Color 7MPa{71.4kgf/cm2}Series 7MPa{71.4kgf/cm2} 10.5MPa{107kgf/cm2} 0.3MPa{3.06kgf/cm2} 18m/min 0.3m/min 30, 40, 50, 63, 80, 100, 125, 140 150, 160, 180, 200, 224, 250 Standard up to 1000mm. See JIS B8354 Table 5, Series B and C. Operating Fluid : Mineral oil hydraulic fluid Oil Temperature : 10C to 80C Mancel No 5B 6/3 Melamin No. 51 14MPa{143kgf/cm2}Series 14MPa{143kgf/cm2} 21MPa{214kgf/cm2} 0.3MPa{3.06kgf/cm2} Remarks When using a meter out inhibitor, take care that pressure generated in the rod side cylinder chamber does not exceed the limits shown to the left.

At least 95%

See page K-2 for strokes greater than 1000mm. Fire resistant hydraulic fluid is also handled as standard products. Contact your agent for more information. Or red rust-resistant paint

Note) Contact your agent for non-standard requirements. The following series are also available. FH Series (21MPa) FJS Series (with switch) FL Series (3.5MPa) FJM Series (Mill)

Cylinder Specifications (Major Characteristics Calculated Values)

K

Hydraulic Cylinder

Note) 1.Non-cushion (N) is standard for inside diameter 30. Contact your agent for information about cushions. 2.Speed ratio and out output specifications are theoretical values based on a JIS B8354 rod diameter.

K-1

Understanding Model Numbers

FJ FA N 1 J 100 B 1000 T R 21

Cylinder name Mounting Axial right-angle foot type Axial foot type

L

Design number Cushion, air bleeder position Port position

Cover

Rod side flange type Head side flange type Rear clevis type Rod side trunnion type Intermediate trunnion type

2

R L U R U

Cushioning N H R B None Head side cushioning Rod side cushioning Both side cushioning

Pressure classification 1 2 Maximum operating pressure: 7MPa{71.4kgf/cm 2 } Maximum operating pressure: 14MPa{143kgf/cm 2 }

Bellows Conex Silicon Nylon/tarpaulin (standard) Neoprene None Cylinder I.D.

K

Hydraulic Cylinder

Rod diameter sequence (B, C) Cylinder stroke

Stroke up to 1000mm is standard. See the following table for strokes greater than 1000mm.

Series Inside diameter 7MPa{71.4kgf/cm2} 14MPa{143kgf/cm }

2

30 40 1500 1500

50 to 150 2000 2000 Tie Rod 1500 0800

180 to 250 1501 to 2000 801 to 2000 Screw In Flange

Cover Fixing System

Note) 1.Use a Nomograph to determine rod buckling. 2.With the screw in flange system, the tube and flange are fixed by being screwed in.

Handling

Note the following installation and handling precautions to get the most out of cylinder performance and to obtain the long service life for which cylinders are designed. zCylinders are designed for rigidity. Be sure to secure them in place with bolts. xInstall cylinders in a location that allows their easy removal, maintenance, and inspection.

cWhen installing a cylinder in a location where the air quality is poor, or where there are large amounts of dust, metal powder, or other contaminants, install dust covers on the rod and shell to protect them. vWhen installing a cylinder, align it with the center of the slide, and make sure it is not subjected to lateral or rotational force by the piston or rod. When lateral force is

unavoidable, make sure it does not exceed 1/100 of cylinder maximum output. bWhen coupling the piston rod and machinery, adjust so there is no unnecessary force applied to the piston rod sliding bush. nFor other details, see catalog number 9214.

K-2

Nomograph

(Operation Conditions, Load, Rod, Stroke)

Back Ring Safety Factor 4 According to Euler Equation

Cylinder diameter mm

A

250 200 150 125 100 80 63 50 40 30

Maximum pressure

MPa {kgf/cm2}

0.7

2.1 3.5

14 21

B

7.1 21 36 71 143 214

1 .05 .1

2 .2

3 4 5 .3 .4 .5

10 .75 1

20 1.5 2

30 3

50 4 5

100 10

200 15 20 30

500 50 100 150 250

TYPE LA. LB. FA. FB(When there is complete load guide) Mounting Auxiliary Line

D

1 2 3 4 5 TYPE LA. LB. TA. FA. FB(When there is complete load guide is not possible)

When there is concern about unbalanced load caused by rod tip freedom

TYPE TC. CA Auxiliary Line

TYPE LA. LB. FA. FB(When load guide is unstable)

Rod O.D. mm

F

500 250 180 150 125 100 80 60 50 40 30 25 20 16

Stroke mm (4000)

G

(2500) (2000) (1500) 1000 500 300 250

K

Hydraulic Cylinder

Note) TC type is intermediate trunnion type

(3000)

Nomograph Application Example Determining Maximum Stroke The maximum stroke under the following operating conditions can be easily determined as shown below. Operating Environment Cylinder I.D. : 100mm Maximum Working Pressure: 14MPa{143kgf/cm2} Mounting Method : FA type (Rod Side Flange) Load Guide Condition : Unstable Piston Rod Diameter : 56mm Determining Maximum Stroke zDraw a line through 100mm on Line A (Cylinder I.D.) and 14 on Line B (Maximum Pressure), and extend it to Line C (Output). The point of intersection on Line C is at 110kN. xDraw a line from 100kN on Line C to point 3 (FA type, unstable load guide) on Line D (Mounting Type Auxiliary Line), and then extend the line until it intersects with Line E.

cDraw a line from the point of intersection on Line E to 56mm on Line F (Rod Diameter) and then extend the line until it intersects with Line G (Stroke). This indicates a maximum stroke of about 630mm.

K-3

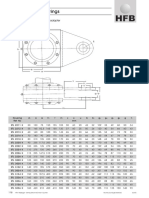

Installation Dimension Drawings

LA Type

7MPa{71.4kgf/cm2}14MPa{143kgf/cm2}

LB Type

7MPa{71.4kgf/cm2}

FA Type

7MPa{71.4kgf/cm2}

FB Type

7MPa{71.4kgf/cm2}

CA Type

7MPa{71.4kgf/cm2}.14MPa{143kgf/cm2}

TA Type

7MPa{71.4kgf/cm2}14MPa{143kgf/cm2}

TC Type

7MPa{71.4kgf/cm2}14MPa{143kgf/cm2}

K

Hydraulic Cylinder

FY Type

7MPa{71.4kgf/cm2}14MPa{143kgf/cm2}

FZ Type

7MPa{71.4kgf/cm2}14MPa{143kgf/cm2}

K-4

Hydraulic Cylinder

Unit : mm

K-5

Unit : mm

: Specify when GH dimensions are different from those shown above. Note) 1.ST is stroke. 2.The overall length dimensions are B Series dimensions. For Series C, Dimension A is different, so overall length is also different. 3.S and T rows marked with an asterisk (*) are FY type typical values. See FY Type for other types of mounting.

Weight Table

Unit : kg

K

Hydraulic Cylinder

Note) Cylinder weight is the total of the zero stroke weight plus the stroke weight.

K-6

Rod Cover Mounting Method

Inside diameter Symbol W1 Rod diameter W2 W3 ST is stroke. Note) 1.The decimal part of the W3 dimension is rounded down. 2.This diagram shows dimensions for nylon tarpaulin (Standard: 80C max. heat resistance), neoprene (130C max. heat resistance), silicon (220C max. heat resistance), and conex (300C max. heat resistance), which are used with the standard FJ cylinder. Heat resistance does not indicate constant temperature, but maximum temperature within a short period. Asbestos/aluminum (400C max. heat resistance) and other materials are also available, and using such materials changes the W3 dimension. Contact your agent for more information. 3.Use a heat wall when there is particularly intense heat radiation due to ambient temperature. Also avoid high temperatures due to heat conduction. 4.When a rod cover is required, specify with the symbol described in the section that explains model numbers. B C 30 50 20 ST 45 + 3.5 40 50 50 20 ST 45 + 3.5 50 60 50 20 ST 45 + 3.5 63 70 60 30 55 + ST 4 80 80 70 30 55 + ST 4 100 100 80 30 55 + ST 4 125 120 100 40 65 + ST 5 140 130 120 40 65 + ST 5 150 140 130 40 65 + ST 5 160 140 40 65 + ST 5 180 150 40 65 + ST 5 200 170 40 65 + ST 5 224 180 50 80 + ST 6 250 200 50 80 + ST 6

Packing Type List

Note)O-ring 1A/B-** refers to JIS B2401-1A/B.

Rod Diameter Series B

Part No. Cylinder I.D. 30 40 50 63 80 100 125 140 150 160 180 200 224 250

1 Cushion Valve Nominal Diameter Screw Seat Packing (Fujikoshi)(Qty : 2) M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M16P1.5 4.5 M16P1.5 4.5 M16P1.5 4.5 M16P1.5 4.5 M16P1.5 4.5 1 Cushion Valve Nominal Diameter Screw Seat Packing (Fujikoshi)(Qty : 2) M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5 M10P1.5 3.5

2 Dust Seal SDR Type I.D. O.D. Height (Qty : 1) 18 26 4.5 6 22.4 30.4 4.5 6 28 36 4.5 6 35.5 43.5 5 6.5 45 53 5 6.5 56 64 5 6.5 71 81 6 8 80 90 6 8 85 95 6 8 90 100 6 8 100 110 6 8 112 122 6 8 125 138 7 9.5 140 153 7 9.5 2 Dust Seal SDR Type I.D. O.D. Height (Qty : 1) 18 26 4.5 6 22.4 30.4 4.5 6 28 36 4.5 6 35.5 43.5 5 6.5 45 53 5 6.5 56 64 5 6.5 63 71 5 6.5 67 75 5 6.5

3 Gland Packing SKY Type I.D. O.D. Height (Qty : 1) 18 26 5 22.4 30 5 28 35.5 5 35.5 45 6 45 55 6 56 66 6 71 80 6 80 90 6 85 100 9 90 105 9 100 115 9 112 125 8.5 125 140 9 140 155 9 3 Gland Packing SKY Type I.D. O.D. Height (Qty : 1) 18 26 5 22.4 30 5 28 35.5 5 35.5 45 6 45 55 6 56 66 6 63 73 6 67 77 6

4 Gland Bush Nominal Diameter (Qty : 1) 1A-G30 1A-G30 1A-G35 1A-G45 1A-G55 1A-G65 1A-G80 1A-G90 1A-G95 1A-G105 1A-G115 1A-G125 1A-G140 1A-G155 4 Gland Bush Nominal Diameter (Qty : 1) 1A-G30 1A-G35 1A-G45 1A-G55 1A-G65 1A-G80 1A-G90 1A-G95

5 Cover Nominal Diameter (Qty : 2) 1B-G25 1B-G35 1B-G45 1B-G58 1B-G75 1B-G95 1B-G120 1B-G135 1B-G145 1B-G150 1B-G170 1B-G190 1B-G214 1B-G240 5 Cover Nominal Diameter (Qty : 2) 1B-35 1B-45 1B-58 1B-75 1B-95 1B-120 1B-135 1B-145 6 Piston I.D. Nominal Diameter (Qty : 1) 1A-P15 1A-P20 1A-G25 1A-P32 1A-G35 1A-G45 1A-G50 1A-G55

6 Piston I.D. Nominal Diameter (Qty : 1) 1A-P14 1A-P15 1A-P20 1A-G25 1A-P32 1A-G35 1A-G45 1A-G50 1A-G55 1A-G60 1A-G70 1A-G80 1A-G90 1A-G100 7 Piston Packing SKY Type I.D. O.D. Height (Qty : 2) 30 40 6 40 50 6 53 63 6 71 80 6 85 100 9 112 125 8.5 125 140 9 136 150 8.5

7 Piston Packing SKY Type I.D. O.D. Height (Qty : 2) 22.4 30 5 30 40 6 40 50 6 53 63 6 71 80 6 85 100 9 112 125 8.5 125 140 9 136 150 8.5 145 160 9 165 180 9 180 200 12 204 224 12 230 250 12 8 Bush Nominal Diameter (Qty : 1) 1A-G35 1A-G45 1A-G55 1A-G65 1A-G75 1A-G80

K

Hydraulic Cylinder

Rod Diameter Series C

Part No. Cylinder I.D. 40 50 63 80 100 125 140 150

K-7

Tip Cap

FJI 40 B 10

Design number Rod sequence Inside diameter

1-Fork Tip Cap

Inside diameter Symbol IA IC ID Common IE IF IG 30

0.1

40

0.1

50

0.1

63

0.1

80

0.1

100

0.1

125

0.1

140

0.1

150

0.1

25

0.4

25

0.4

31.5

0.4

40

0.4

40

0.4

50

0.4

63

0.4

80

0.6

80

0.6

50 20 16 35 25 15 M8 2 27 M16 P1.5

55 20 16 35 25 15 M8 2 32 M20 P1.5 27 M16 P1.5

65 25 20 45 32 15 M8 2.5 37 M24 P1.5 32 M20 P1.5

92 40 31.5 65 40 15 M8 2.5 47 M30 P1.5 37 M24 P1.5

107 40 31.5 65 40 15 M8 2.5 62 M39 P1.5 47 M30 P1.5

135 50 40 85 55 20 M10 3 78 M48 P1.5 62 M39 P1.5

168 63 50 105 68 20 M10 3 98 M64 P2 78 M48 P1.5

210 80 63 130 85 20 M10 4 113 M72 P2 83 M56 P2

215 80 63 130 85 20 M10 4 118 M76 P2 88 M60 P2

Tip fitting 1 thread: FJI 2 thread: FJY

1-Fork Tip Cap

L M Q Series B Series C IB K IB K

Rod diameter

2-Fork Tip Cap

Inside diameter Symbol YA YC 30

+0.4

40

+0.4

50

+0.4

63

+0.4

80

+0.4

100

+0.4

125

+0.4

140

+0.6

150

+0.6

25

+0.1

25

+0.1

31.5

+0.1

40

+0.1

40

+0.1

50

+0.1

63

+0.1

80

+0.1

80

+0.1

50 20 16 12.5 66 15 M8 27 M16 P1.5

55 20 16 12.5 66 15 M8 32 M20 P1.5 27 M16 P1.5

65 25 20 16 80 15 M8 37 M24 P1.5 32 M20 P1.5

92 40 31.5 20 101 15 M8 47 M30 P1.5 37 M24 P1.5

107 40 31.5 20 101 15 M8 62 M39 P1.5 47 M30 P1.5

135 50 40 25 126 20 M10 78 M48 P1.5 62 M39 P1.5

168 63 50 31.5 153 20 M10 98 M64 P2 78 M48 P1.5

210 80 63 40 192 20 M10 113 M72 P2 83 M56 P2

215 80 63 40 192 20 M10 118 M76 P2 88 M60 P2

2-Fork Tip Cap (With Pin)

Common

YD YE YF YG L M

Rod diameter

Series B Series C

YB K YB K

K

Hydraulic Cylinder

Locknut Type Description (Example)

FJN 28 10

Design number Rod diameter Tip lock nut

Locknut (For FJ)

Rod diameter Symbol a b c H 18 M16 P1.5 24 27.7 10 22.4 M20 P1.5 30 34.6 12 28 M24 P1.5 36 41.6 14 35.5 M30 P1.5 46 53.1 18 45 M39 P1.5 60 69.3 23 56 M48 P1.5 75 86.5 29 63 M56 P2 85 98.1 34 67 M60 P2 90 104 36 71 M64 P2 95 110 38 80 M72 P2 105 121 42 85 M76 P2 110 127 46

K-8

You might also like

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- TS 1600-140 - Datenblatt - V3Document2 pagesTS 1600-140 - Datenblatt - V3Ulfah Fauziyyah0% (1)

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFDocument8 pagesCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- Conveyor CapacityDocument3 pagesConveyor Capacityx30patelNo ratings yet

- Powder Cooler - BrochureDocument4 pagesPowder Cooler - BrochureAnonymous Cxriyx9HIX100% (1)

- Beam Deflection CalculationDocument2 pagesBeam Deflection CalculationAriful IslamNo ratings yet

- Soportes Take UP STL Series - Rodamientos SmilovicDocument4 pagesSoportes Take UP STL Series - Rodamientos SmilovicAlejandro SmilovicNo ratings yet

- Standard Specification For Hot Insulation Piping EquipmentDocument62 pagesStandard Specification For Hot Insulation Piping EquipmentAri SupramonoNo ratings yet

- Automatic Samplers: Proven & DependableDocument6 pagesAutomatic Samplers: Proven & DependableHarish KumarNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNo ratings yet

- Expandable MandrelsDocument3 pagesExpandable Mandrelsali-masoodNo ratings yet

- Brochure - Slide Gate Valve - Pubc-0502-SvDocument2 pagesBrochure - Slide Gate Valve - Pubc-0502-SvedgarspalaciosNo ratings yet

- Conventional JacketsDocument4 pagesConventional JacketskayeNo ratings yet

- En - Iso - 14890 (2013)Document3 pagesEn - Iso - 14890 (2013)Hà Khểnh0% (1)

- Dunlop Conveyor Belt Design Manual. Page 2 PDFDocument17 pagesDunlop Conveyor Belt Design Manual. Page 2 PDFMuthuvel VivekNo ratings yet

- Gate ValvesDocument2 pagesGate Valves@sssNo ratings yet

- Bucket ConveyorDocument20 pagesBucket ConveyorHoras Nies100% (1)

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- Helix Delta-T6 Sample Report01Document29 pagesHelix Delta-T6 Sample Report01Khaleel PashaNo ratings yet

- Conveyor PulleyDocument4 pagesConveyor Pulleyprashant mishraNo ratings yet

- CasoEstudio PervaporaciónDocument17 pagesCasoEstudio PervaporaciónValentina SánchezNo ratings yet

- Pin Bush CouplingDocument1 pagePin Bush CouplingVinod Kumar VermaNo ratings yet

- 07 Elevators Deep Buckets DIN 15234 02Document1 page07 Elevators Deep Buckets DIN 15234 02mkiani2No ratings yet

- Unit-5 Design of Belt DrivesDocument39 pagesUnit-5 Design of Belt DrivesCHANDRASEKARANNo ratings yet

- Ramdas Osborne Ortt 1980 PDFDocument10 pagesRamdas Osborne Ortt 1980 PDFSebastian PinzonNo ratings yet

- Dekoron Data Sheet2Document6 pagesDekoron Data Sheet2MarioNo ratings yet

- Belt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldDocument1 pageBelt Conveyor Capacity Calculation Form: Remarks Selelct / Insert Values in Orange FieldManoj ThakurNo ratings yet

- Conductix Wampfler Crane Cables Festoon Systems CatalogueDocument60 pagesConductix Wampfler Crane Cables Festoon Systems Cataloguehino_kaguNo ratings yet

- CEMA 6 Belt Conveyors Belt AlignmentDocument2 pagesCEMA 6 Belt Conveyors Belt Alignmentali kajbafNo ratings yet

- ABB CatalogueDocument6 pagesABB CatalogueNavneet SinghNo ratings yet

- Rotary Valves Airlocks Rotolok UsaDocument6 pagesRotary Valves Airlocks Rotolok UsagallowdrNo ratings yet

- Power Calculations PPDocument3 pagesPower Calculations PPbashok20No ratings yet

- Screw Conveyor RatingDocument6 pagesScrew Conveyor RatingPereiraeNo ratings yet

- Reference Notation Description: 1.bottom Plate ThicknessDocument6 pagesReference Notation Description: 1.bottom Plate ThicknessSakib RafeeNo ratings yet

- Shrink Disc TAS SchaeferDocument20 pagesShrink Disc TAS SchaeferFernando Tapia GibsonNo ratings yet

- Carbon Steel Tee Rails: Standard Specification ForDocument7 pagesCarbon Steel Tee Rails: Standard Specification ForAAYNo ratings yet

- Motive Power Calculation Sheet For Transfer CarDocument2 pagesMotive Power Calculation Sheet For Transfer Carmech_abhiNo ratings yet

- Is 8531 1986Document6 pagesIs 8531 1986Srini KumarNo ratings yet

- Belt Conveyor: Designer's ChoiceDocument4 pagesBelt Conveyor: Designer's ChoiceAmeu CostaNo ratings yet

- Hitachi Conveyor ChainDocument176 pagesHitachi Conveyor ChainFatkhur Rochman Barot100% (1)

- Oriental Engineering Works PVTDocument20 pagesOriental Engineering Works PVTDarshan DhimanNo ratings yet

- Rotary Airlock FeedersDocument28 pagesRotary Airlock Feederslhphong021191No ratings yet

- Questionnaire Troughed Belt ConveyorDocument1 pageQuestionnaire Troughed Belt ConveyorhadimarviNo ratings yet

- Bucket Elevator CatalogDocument20 pagesBucket Elevator CatalogLeonardo De la CruzNo ratings yet

- Fenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesDocument22 pagesFenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesSubramanian ChidambaramNo ratings yet

- Iso 3684 1990Document8 pagesIso 3684 1990joaquin fuentealba moralesNo ratings yet

- Bag Filter & GasometerDocument9 pagesBag Filter & GasometerPoovanaan Sathiya SeelanNo ratings yet

- Green Pin Standard Hydraulic ShackleDocument1 pageGreen Pin Standard Hydraulic ShackleAthox QhurienNo ratings yet

- Bonfiglioli Reductoare C A F SDocument582 pagesBonfiglioli Reductoare C A F SAgache ValentinNo ratings yet

- Foundations For Auto Shredders : - Hammer / / / / / / / / / IDocument6 pagesFoundations For Auto Shredders : - Hammer / / / / / / / / / ISandraNo ratings yet

- VT Range 40-75HPDocument6 pagesVT Range 40-75HPQco MyNo ratings yet

- Helix Dynamic Sample Conveyor CV202 Tail End Transition DistanceDocument1 pageHelix Dynamic Sample Conveyor CV202 Tail End Transition DistancethiemxmcpNo ratings yet

- Mechanical Specifications For Fiberbond ProductDocument8 pagesMechanical Specifications For Fiberbond ProducthasnizaNo ratings yet

- Iso 2406-1974 PDFDocument5 pagesIso 2406-1974 PDFmarcos crisostoNo ratings yet

- DFC Install MaintDocument40 pagesDFC Install MaintAvinash Gamit100% (1)

- The Turning Movement of a Particle About the Axis of Rotation is Called the Angular Momentum of the Particle and is Measured by the Product of the Linear Momentum and the Perpendicular Distance of the Line of Action From the AxDocument24 pagesThe Turning Movement of a Particle About the Axis of Rotation is Called the Angular Momentum of the Particle and is Measured by the Product of the Linear Momentum and the Perpendicular Distance of the Line of Action From the AxSURAJ MAHATONo ratings yet

- WWTFSludge Thickener No 2 RehaDocument28 pagesWWTFSludge Thickener No 2 RehamhreteabNo ratings yet

- SEW Eurodrive Industrial Gear UnitsDocument15 pagesSEW Eurodrive Industrial Gear UnitsSteve IpNo ratings yet

- Continuous Disc Dryer: Use and FunctionDocument4 pagesContinuous Disc Dryer: Use and FunctionDouglas TondelloNo ratings yet

- DAC40 X 100Document16 pagesDAC40 X 100Ốt Xì ÀNo ratings yet

- (CRC Industries LTD) Ados Food Grade Silicone Sealant Translucent H3590 24-11-2015Document6 pages(CRC Industries LTD) Ados Food Grade Silicone Sealant Translucent H3590 24-11-2015Syarif HidayatullahNo ratings yet

- 151 Hardox 400 Uk Data SheetDocument2 pages151 Hardox 400 Uk Data SheetArief TirtanaNo ratings yet

- 15.P.sathIYA 2009 Optimization of Friction Welding Parameters UsingDocument9 pages15.P.sathIYA 2009 Optimization of Friction Welding Parameters UsingSyarif HidayatullahNo ratings yet

- 18.SAHIN 2009 Characterization of Properties in Plastically Deformed Austenitic-Stainless Steels Joined by Friction WeldingDocument10 pages18.SAHIN 2009 Characterization of Properties in Plastically Deformed Austenitic-Stainless Steels Joined by Friction WeldingSyarif HidayatullahNo ratings yet

- VV SATYANARAYANA 2005 Dissimilar Metal Friction Welding of Austenitic-Ferritic Stainless SteelsDocument10 pagesVV SATYANARAYANA 2005 Dissimilar Metal Friction Welding of Austenitic-Ferritic Stainless SteelsSyarif HidayatullahNo ratings yet

- Loker BlueScopeDocument2 pagesLoker BlueScopeSyarif HidayatullahNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Math Academy AppDocument4 pagesMath Academy Appkisame1357No ratings yet

- Understand Concept of Multi-Rate Signal Processing: (Autonomous College Affiliated To University of Mumbai)Document2 pagesUnderstand Concept of Multi-Rate Signal Processing: (Autonomous College Affiliated To University of Mumbai)nicO neeNo ratings yet

- 3681 113533 1 SM - , mutasiCVKaroseriLaksanaDocument14 pages3681 113533 1 SM - , mutasiCVKaroseriLaksanataufiq hidayatNo ratings yet

- AnovaDocument17 pagesAnovaIshan ShahNo ratings yet

- Evolution of C-Si: PV Cell TechnologiesDocument52 pagesEvolution of C-Si: PV Cell TechnologiesFábio VelôzoNo ratings yet

- 17.alekhya Research ArticleDocument8 pages17.alekhya Research ArticleBaru Chandrasekhar RaoNo ratings yet

- Assigment Sheet Tast 2 Aina MardianaDocument10 pagesAssigment Sheet Tast 2 Aina MardianaAina MardianaNo ratings yet

- Pega Interview PreperationDocument35 pagesPega Interview PreperationPramodh SSNo ratings yet

- Functions Equations Question BankDocument101 pagesFunctions Equations Question BankParth DesaiNo ratings yet

- Chapter 20 Surface Area and Volume of A Right Circular ConeDocument19 pagesChapter 20 Surface Area and Volume of A Right Circular ConeMann GosarNo ratings yet

- Dawood University of Engineering & Technology Karachi Department of Basic Sciences & HumanitiesDocument4 pagesDawood University of Engineering & Technology Karachi Department of Basic Sciences & HumanitiessamadNo ratings yet

- Paper I & 11 Answer All Questions: (E) Explain The Use of Correlation and Regression Studies in Busainess?Document5 pagesPaper I & 11 Answer All Questions: (E) Explain The Use of Correlation and Regression Studies in Busainess?Suthaharan PerampalamNo ratings yet

- Process Cooling System Chiller and Tower Sizing FormualsDocument2 pagesProcess Cooling System Chiller and Tower Sizing FormualsChuen Hau TanNo ratings yet

- Synchro CheckDocument4 pagesSynchro CheckAdhyartha KerafNo ratings yet

- ErrorsDocument498 pagesErrorsIsmael DiasNo ratings yet

- FREE EthnicKnittingBookPattern HeadbandDocument4 pagesFREE EthnicKnittingBookPattern HeadbandriyuuhiNo ratings yet

- Base Tree PropertyDocument17 pagesBase Tree PropertyMario Jardon SantosNo ratings yet

- DLP in Law of SineDocument4 pagesDLP in Law of SineRed DeverraNo ratings yet

- 02a-2 V-Can2 Xlrteh4300g033850Document1 page02a-2 V-Can2 Xlrteh4300g033850Daniel PricopNo ratings yet

- Horizontal Vessel Support: Vertical Saddle ReactionsDocument12 pagesHorizontal Vessel Support: Vertical Saddle ReactionsSanket BhaleraoNo ratings yet

- CBCS Revised BCA 5 and 6 Sem-FinalDocument38 pagesCBCS Revised BCA 5 and 6 Sem-FinalIrfan AhmedNo ratings yet

- DBMS Practice QueestionsDocument2 pagesDBMS Practice QueestionsAbhibhava Bhatt VIII [E] 4No ratings yet

- Gear Manufacturing ProcessDocument30 pagesGear Manufacturing ProcessSanjay MehrishiNo ratings yet

- Lerdge-Gcode List V3.0.5Document108 pagesLerdge-Gcode List V3.0.5osman perez vidalNo ratings yet

- Department of Mechanical Engineering Question Bank Subject Name: Heat & Mass Transfer Unit - I Conduction Part - ADocument3 pagesDepartment of Mechanical Engineering Question Bank Subject Name: Heat & Mass Transfer Unit - I Conduction Part - AkarthikNo ratings yet

- Asmi-52: 2/4-Wire SHDSL ModemDocument4 pagesAsmi-52: 2/4-Wire SHDSL ModemManuel FreireNo ratings yet

- FSU Electronics PrelabDocument7 pagesFSU Electronics Prelabcamaguey5No ratings yet

- ReportDocument1 pageReportDrew DacanayNo ratings yet

- Industrial Organization (Theory and Practice) - 184-189Document6 pagesIndustrial Organization (Theory and Practice) - 184-189kurniaNo ratings yet

- Test For CarbohydratesDocument15 pagesTest For CarbohydratesKevin SangNo ratings yet