Professional Documents

Culture Documents

Uhde Brochures PDF en 18

Uploaded by

geocottonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uhde Brochures PDF en 18

Uploaded by

geocottonCopyright:

Available Formats

3

ThyssenKrupp Uhde

C

P

3

1

0

/

1

5

0

0

e

0

1

/

2

0

1

2

U

/

T

K

P

M

/

P

r

i

n

t

e

d

i

n

G

e

r

m

a

n

y

Competence and

know-how by tradition

A new dimension in

cokemaking technology

Table of contents

2

1. Company profle 3

2. Competence and know-how by tradition 4

3. Slot type coke oven batteries 6

4. Heating systems 8

5. Heating-up burners 9

6. High stability and gas tightness 10

7. Coke oven doors 11

8. Environmental protection 12

9. Coke oven machinery 14

10. Charging and pushing 15

11. Quenching and door service 16

12. Coke transfer and pushing emissions control 17

13. Heat-recovery cokemaking and related machinery 18

14. Coke oven gas treatment 20

15. Condensation and tar separation 21

16. Removal and treating of by-products 22

17. Tar refning 24

18. Alternative use of coke oven gas 25

19. Coke cooling 26

20. Coke plant automation 28

21. Technology services 30

3 3

1. Company profle

With its highly specialised workforce of more than 4,800 employees

and its international network of subsidiaries and branch ofces, Uhde,

a Dortmund-based engineering contractor, has to date successfully

completed over 2,000 projects throughout the world. Uhdes inter-

national reputation has been built on the successful application of

its motto Engineering with ideas to yield cost-efective high-tech

solutions for its customers. The ever-increasing demands placed

upon process and application technology in the felds of chemical

processing, energy and environmental protection are met through a

combination of specialist know-how, comprehensive service pack-

ages, top-quality engineering and impeccable punctuality.

In 2004 Uhdes portfolio was expanded to include coke plant tech-

nologies. The synergies created by the integration of a company

which had combined the activities of Krupp Koppers and Thyssen

Still Otto into one have immensely benefted customers in terms

of technical know-how and experience in coke plant technologies

coupled with the international sales and engineering presence of a

company with high competence in executing demanding projects.

Uhde now provides a wide range of solutions in the feld of coke-

making technologies, from complex hot repairs for batteries to

revamps or the complete new construction of battery and gas

treatment sections. A major achievement is the worldwide imple-

mentation of our high-capacity coke production plants which com-

prise coke ovens with net chamber volumes of up to 93m

3

and

single-stream gas treatment plants for approximately 200,000m

3

of raw gas per hour. Our portfolio also includes servicing machines

equipped with high-level automation and drive technology. As these

enable production units for up to 2.6 million tonnes of coke to be

operated by one team per shift, they make a major contribution to

cost-efective environmentally friendly steel production.

4

2. Competence and know-how by tradition

A global leader for more than 130 years

Uhde's coke plant technologies division is proud

to offer the entire range of technologies and know-

how from the most famous names in coke plant

engineering.

The origin of the division can be traced back to

the company Dr. C. Otto & Comp. which was

founded in the year 1872. Carl Still and Heinrich

Koppers, both employed as junior engineers by

Dr. C. Otto, then formed their own companies in

1898 and 1901, respectively, and enjoyed great

success for many decades. In the 70's and 80's

the companies founded by these cokemaking

pioneers were taken over by the groups Krupp

(Koppers) and Thyssen (Still, Otto and Didier).

Ultimately, the merger of the groups Thyssen and

Krupp resulted in the combination of all coke-

making technology activities into ThyssenKrupp

EnCoke GmbH in 1999, followed by the integra-

tion into Uhde GmbH.

"Zeche Holland" coke plant

in the Ruhr area, Germany, 1895

Dr. C. Otto Heinrich Koppers Carl Still

5

Integrated in the ThyssenKrupp group with

its global spectrum of activities Uhde has

assumed the task of continuous improve-

ment, building on the decades of accumu-

lated know-how and maintaining the tradi-

tion of quality established by its founders.

With state-of-the-art technologies and

know-how proven through the construction

of over 100,000 coke ovens and associ-

ated gas treatment facilities and service

machines worldwide, Uhde offers its cus-

tomers a palette of systems and processes

from which the optimum solution to their

operational requirements can be provided.

Along with know-how and experience in

building new coke plants, Uhde has a long

and successful history of providing com-

prehensive technologies for modernising

and repairing entire plants or individual

plant components. We work jointly with the

customer to develop the most cost-effective

solution to satisfy specific needs.

"Kwangyang" coke plant,

South Korea, 1992

6

3. Slot-type coke oven batteries

More than 100,000 times worldwide

Uhde has been designing and building coke

oven plants for more than 130 years, mak-

ing it the longest established coke plant

engineering company in the world. Our com-

petence and know-how gained through

the construction of more than 100,000 coke

ovens worldwide are embodied in numer-

ous inventions and developments which

are today recognised standards in modern

cokemaking technology: for example multi-

stage heating. Uhde has always been a front

runner in the technical development of coke

oven plants.

Among these inventions and developments

are the principle of regenerative heating,

the introduction of compound ovens and

the gradual enlargement in chamber height

to well over 8 m and in oven volume to over

90 m

3

.

Linked to an increase in the net volume of

oven chambers, the oven width has also

been expanded from the conventional

450 mm to typically 590 mm. This develop-

ment began in the mid-80s and has become

a technically matured solution. Fewer pro-

duction cycles per day and oven, accompa-

nied by higher shrinkage values of the coal,

Battery front of 8.4 m ovens at the

Schwelgern coke plant, Germany

GLD, Detroit, USA

7

result in a major reduction in thermal and

mechanical stresses, which helps to protect

the battery structure and prolong its lifetime.

The principle of multi-stage heating nowa-

days standard technology for heating coke

ovens was introduced by Carl Still as early

as 1926. Uhde can now supply the opti-

mum heating concept to meet any specific

demand: COMBIFLAME

and TWINFLUE for

compound ovens of either the gun-flue or

underjet type, and MULTISTAGE for purely

rich gas ovens.

The increasing heights of oven chambers

and the associated stability requirements for

maintaining the refractory materials demand

fully effective oven bracing systems. Over

the course of approximately 30 years Uhde

has developed the CONTROLPRESS

system

based on intensive research and develop-

ment, accompanied by data from practical

experience.

Fugitive emissions at coke oven batteries have

been drastically reduced by well proven seal-

ing systems for oven doors and other oven

closures. Depending on the application, Uhde

offers either FLEXZED

or FLEXIT

oven doors.

The PROven

system for the individual

control of oven chamber pressure has been

developed to a technically matured status

within a period of approximately 10 years.

It marks a new generation with virtually

emission-free battery operation during cok-

ing and charging. Since its first application

at the Schwelgern coke plant in 2003, al-

most all batteries installed and commis-

sioned by Uhde have been equipped with

PROven

. The system has also been in-

stalled in existing batteries as well.

In total almost 2,000 ovens have been

equipped with this system.

Top view of the battery at Schwelgern,

ThyssenKrupp Stahl AG, Germany

COKE TRANSFER CAR

COKE SIDE

BATTERY

PUSHER SIDE

QUENCH CAR

COKE WHARF

COAL CHARGING CAR

PUSHER MACHINE

Battery cross-section

Battery front of 6.2 m ovens at

the GLD coke plant, Detroit, USA

8

4. Heating systems

Optimised heat distribution low NO

X

The COMBIFLAME

heating system for low-NO

X

com-

bustion, which was specially designed for large ovens,

is equipped with a two or three-stage air supply sys-

tem. About half the combustion air enters the bottom of

the heating zone through the air duct, while the other

half enters the heating zone through air ports positioned

at higher elevations in the binder wall. The regenerator

chambers are divided longitudinally in order to permit

individual control of the bottom air and wall air flows.

In combination with an internal flue gas recirculation

system this results in an optimum vertical temperature

distribution over the heating walls while reducing the

NO

X

content of the exhaust gas to a very low level.

COMBIFLAME

heating system with internal

waste gas recirculation and staged air supply

Lean gas

Air

Waste gas

9

5. Heating-up burners

Smooth commissioning with perfect results

Uhde has developed a high-performing, well

proven procedure for heating-up batteries

by means of external fan burners. These

are proven standard industrial units, spe-

cially selected and equipped for the task.

The high overall volume flow of flue gas

produced by the fan burners generates a

positive pressure in the entire oven block

from the very beginning of heat-up, accom-

panied by optimum heat transfer through-

out the system. Since the hot flue gas is

generated outside of the coke oven cham-

ber, local overheating in the area behind the

coke oven door is ruled out. Dutch ovens

are no longer needed to protect the brick-

work. Flame safety is provided by automatic

burner management systems, eliminating

the manpower formerly required for this

purpose.

The increased flow of heating gas from the

start allows the heating-up time to be re-

duced by 2 3 weeks.

These burners are not only applied for the

heating-up of new batteries. They have also

been successfully used in refractory hot

repairs, where certain areas of the batteries

have to be kept at a minimum temperature

level.

Batteries installed and commissioned by

Uhde since 2000 are being successfully

heated up by means of this technology. Our

long reference list bears witness to our ex-

perience and competence.

Heating-up curve:

excellence compliance

between set point and

actual values

Heating-up burners alongside a battery

Design temperature

Actual temperature

10 20 30 40 50 60

900

800

700

600

500

400

300

200

100

0

Heating-up day

T

e

m

p

e

r

a

t

u

r

e

i

n

C

10

6. High stability and gas tightness

Prerequisites for safe operation and long service life

Oven roof

protection

plate

Oven roof

protection

plate

Oven roof bracing

Wall

protection

plate

Sliding joint

COMBIFLAME

heating wall

Buckstay

Wall protection plate

Pressure springs for

wall protection plate

Regenerator

protection plate

Pressure elements

for regenerator

protection plate

Regenerator bracing

Bottom cross tie rods

The refractory construction, oven bracing, heating

equipment, oven door design and every individual

detail bear out the extensive experience gained by our

engineers over the years. Heating walls are designed

and built so as to safely withstand the lateral coking

pressure.

The CONTROLPRESS

bracing system provides the re-

quired pre-stressing of heating walls, thus protecting the

refractory block from uncontrolled forces. This system

was developed especially for application in tall coke

ovens with large chamber volumes and is today stand-

ard cokemaking technology. The high level of wall sta-

bility and bracing system reliability in all stages of oper-

ation provide for the long service life of our coke ovens.

Heating fue arrangement during bricking-up

CONTROLPRESS

bracing system

11

7. Coke oven doors

Lasting tightness

The FLEXIT

and FLEXZED

coke oven doors developed by Uhde

ideally suit today's requirements for an environmentally responsible

and low-maintenance door system.

The large gas escape channels at the door plug reduce the gas

pressure at the door seal an important prerequisite for the avoid-

ance of door emissions. The seals of these coke oven doors auto-

matically adapt to the door jamb contour, with the required sealing

forces being provided by springs acting on the sealing strips. The

FLEXIT

coke oven door with its flexible stainless steel membrane

and door body made of ductile cast iron is particularly suitable for

coke ovens with a large chamber height and chamber width.

Its high elasticity results in a excellent capacity to compensate for

the bending of sealing surfaces, ensuring maximum gas tightness.

Hence it comes as no surprise that the tallest and largest coke ovens

worldwide are equipped with FLEXIT

coke oven doors.

The standard door for all oven sizes is the FLEXZED

door, which

has been installed in thousands of coke ovens worldwide over the

decades. With its adjustable Z-sealing strip and its robust cast-iron

door body this door has proved extremely reliable in withstanding

the severe requirements of coke oven operation. Its special features

are a high level of gas tightness, a robust structure and low main-

tenance requirements.

Installed

oven doors

Cross section of a coke oven door.

6. High stability and gas tightness

Prerequisites for safe operation and long service life

12

8. Environmental protection

Innovation at the battery

Single-chamber pressure control

The innovative PROven

system for single-

chamber pressure control allows the pres-

sure in each individual oven chamber to be

adjusted as a function of the actual raw gas

generation rate, thus providing the optimum

pressure level for the given coking condition.

The gas collecting main itself is operated

under suction, and the pneumatically actu-

ated PROven

valve controls the back-pres-

sure in the chamber. The control system is

based on adjustment of the water level in-

side the PROven

valve, providing variation

of the valve port area through which the raw

gas flows.

A low chamber pressure is set at the begin-

ning of the coking time so that the large raw

gas quantities generated in this phase are

discharged without high gas pressures at

the oven doors. Door and oven top emis-

sions are thus prevented almost entirely.

PROVen

system under construction

Pressures in the conventional raw gas and PROVen

system

-30

-25

0

10

20% 40% 60% 80% 100%

20

30

mmWG

Collecting main under suction

Pressure in standpipe

Pressure at foot of door

Pressure at foot of door

Lines in red = conventional raw gas system Lines in blue = PROven

system

Pressure in collecting main

Suction during charging

Coking time

13

Pressure measurement line

Pressure

controller

Pneumatic

cylinder

Control valve

Fix Cup-valve: H~P

NH

3

-water

Standpipe

Oven roof

Gas collecting space

GC-main

Charging with PROven

As coking proceeds, the chamber pres-

sure is gradually increased in line with the

reduction in the gas generation rate inside

the oven. When the amount of generated

gas declines at the end of the coking pro-

cess, the pressure in the oven is raised to

the point where no air can be drawn in at

the doors. This protects the refractory walls

from combustion in the end zone of the

chambers, thus prolonging the service life

of the ovens.

Reduction of charging-gas emissions

The PROven

system also ensures that the

charging gases are retained within the raw

gas system because the standpipes and,

consequently, the oven chambers are under

suction when charging takes place. Coke

oven doors with an efficient sealing system

and water-sealed standpipe lids round off

the means for preventing battery emissions.

PROven

arrangement

schematic

14

9. Coke oven machinery

Comprehensive systems

The increasing dimensions of oven cham-

bers and the demand for high-performance

operation have spurred the development of

complex oven machinery.

Nowadays, where there may be up to 150

oven cycles per day, so-called single-spot

operation of the machines which involves

no additional travelling is the standard op-

eration for each cycle.

The drivers cabins are fully air-conditioned

and equipped with modern control units,

e.g. touch-screen monitors. Comprehensive

PLC systems, which are connected to the

monitoring and control units of the plant,

ensure safe operation.

Travelling and all related operation steps

are designed to allow for fully automated

operation based on the COKEMASTER

system for battery automation. This system,

among other things, controls and adjusts

the pushing schedule.

The machines are equipped with state-of-

the-art emission control systems that are

designed to meet the most stringent envi-

ronmental regulations.

Moreover, installations, such as automatic

cleaners for oven closures, benches, etc., ob-

viate the need for helpers during operation.

Years of development work ensure that

Uhdes coke oven machines, whether for

conventional or heat-recovery technology,

meet the highest standards. We also hold

a number of patents to protect all of this

know-how.

Approximately 2,000 machines have been

supplied to date.

15

10. Charging and pushing

Safe operation that meets

all environmental requirements

Coal charging car

Single-spot coke pusher machine

Coal charging cars

Uhde coal charging cars are equipped

with horizontal screw feeders and gas-tight

telescopic pipes. The coal is charged at

as high a rate as possible to minimise the

charging cycle time and the amount of gas

generated. Efficient exhaust systems are

provided to ensure gas removal, and thus

emission-free charging. These are particu-

lary effective in combination with the

PROven

system.

Coke pushing machines

The coke pushing machines are equipped

with door extractors, mechanical door clean-

ers, and jamb cleaners. Emissions during

door extraction are collected by a retract-

able hood and fed to the pushing emissions

exhaust system.

The levelling operation is also smoke-free

due to the tight seal provided by the leveler-

bar sleeve.

16

11. Quenching and door service

Hot coke transport and oven front maintenance

Coke quenching cars

The red-hot coke is discharged to the coke quenching

car and conveyed to the quenching tower for wet cool-

ing. Uhde single-spot quenching cars provide optimum

emission control during the pushing operation. In

conjunction with the Uhde combined sump and spray

quenching system the single-spot quenching car is

ideal for producing stabilised blast furnace coke with a

moisture content that may be as little as 2%.

Door Service Car

Single-spot quench car

The service machine

Uhde has developed a service machine which travels

along the battery face on the coke and pusher sides.

This small machine is ideal for maintenance work on

oven doors, the bracing system and refractory structure.

17

12. Coke transfer and pushing emissions control

Advanced combination of operational needs

and environmental control

Capture and transfer of pushing

emissions from the hood and

sampling duct to the stationary

bag flter house

The complete, comprehensive coke transfer and push-

ing emissions control system features a transfer car

with an integrated suction hood. This transfer car is

connected via a machine-mounted belt tripper car to

the emissions sampling duct, which conducts the dust-

loaded air to a stationary bag filter house.

Combined with a single-spot quenching car, the system

is so efficient that hardly any emissions can be detect-

ed at the hood during pushing. Added to this, the most

stringent environmental regulations are also met at the

outlet of the bag filter house.

Coke transfer machine with integrated suction hood

18

13. Heat-recovery cokemaking and related machinery

Coke, power, environmental protection

The Uhde heat-recovery cokemaking technology pro-

vides an attractive alternative to conventional coke pro-

duction in those cases in which power generation is

required alongside coke. The technology was wide-

spread in Europe and America prior to the introduction

of by-product coke ovens.

In heat-recovery ovens, the complete gas produced

from coal carbonisation is combusted directly inside the

coke oven, thus creating the heat needed for carboni-

sation. In contrast to the slot-type oven, the coal charge

for a heat-recovery oven has a flat-bed characteristic

with typical dimensions of approx. 1 m in height, 4 m

in width and 15 m in length.

As the coal charge is not restrained between heating

walls, the lateral coking pressure of the coal blend is

far less significant than in horizontal chamber ovens.

Coals which develop a higher coking pressure and are

thus unsuitable for carbonisation in horizontal chamber

ovens can therefore be carbonised safely in heat-

recovery ovens.

The crude gas produced from the coal is first partially

combusted in the free space above the coal charge.

The generated mixture of waste gas and crude gas is

led through vertical ducts in the side walls (downcom-

ers) into the heating flue system under the oven sole.

Here, the combustion is completed with the staged

supply of air so that the coal layer is evenly heated

from the top and bottom.

Heat-recovery coke oven

Negative

pressure

(suction)

Direct

heat transfer

from top

Indirect

heat transfer

from bottom

Slot-type coke oven

Positive

pressure

Indirect

heat transfer

from sides

Flat-bed quench car

19

The hot waste gas can be used to generate steam,

which can then be used for power generation. Assuming

an annual coke production of 1 million tons, approx.

80MW of electric power can be generated, depending

on the properties of the coal.

As the ovens are operated under suction, there are no

battery emissions during carbonisation and almost no

emissions during charging. The waste gas from the

ovens is dedusted, desulphurised and then discharged

into the atmosphere through suction fans and a stack.

A proven technology is used to charge the ovens with

compacted coal. The coal cakes are of a uniform height

and do not require levelling. The increased density of

this type of coal charge improves the oven throughput,

so fewer ovens are required for a given coke produc-

tion rate. In addition, fewer charging emissions can be

expected.

A flat bed quench car minimises coke pushing emissions

by keeping the coke cake in a cohesive mass. This

eliminates the need for pollution control systems on the

coke side and their associated baghouses. A moveable

cover and filter over the coke mass in the car can also

be provided. This has been adapted from the flatbed

pushing system used successfully for many years at

the non-recovery coke plants operated by Illawarra Coke

Company Pty. Ltd., Australia.

The heat-recovery cokemaking technology is a virtually

emission-free process with comparably low demands

on operating crews. It represents a technically and eco-

nomically lucrative alternative to classical cokemaking.

Combination of a coal cake loading machine

and a fat-bed coke pushing machine

Raw gas

Steam

Methanol Ammonia Hydrogen Clean gas

Steam

Technical oils

Ammonium

sulphate

Ammonia

Benzol

Special pitch

Pure C

10

H

8

Flushing liquor

Methanol

synthesis

Methanol

distillation

Ammonia

synthesis

H

2

separation

Benzol removal

Benzol recovery

C

10

H

8

removal

Sulphur production

H

2

SO

4

production

Sulphur production

H

2

SO

4

production Desulphurisation

Partial oxidation

Flushing liquor Tar distillation

Primary cooling

Tar removal

Ammonium

sulphate

production

Ammonia

recovery

Ammonia

destruction

HT-CO

conversion

20

14. Coke oven gas treatment

Proftable and environmentally responsible

Palette of possible processes

for coke oven gas treatment

The significance of coke oven gas and its constituents

has changed substantially over the past decades. Today,

the foremost task of a modern coke oven gas treatment

facility is to convert crude gas into an environmentally

compatible fuel as economically as possible.

To this effect crude gas is cooled, compressed and

freed from constituents that might entail hazards to the

environment or plant. Apart from the cleaned coke oven

gas, the only by-products produced in modern plants

are crude tar, crude benzol, and sulphur. The necessary

process steps and equipment are chosen to eliminate

gaseous emissions and minimise the level of contami-

nants in the waste water.

Uhde offers the full palette of possible process steps

for the economical cleaning of coke oven gas and the

environmentally responsible processing of by-products

and waste water streams.

The array of processes developed in-house and our

proven detailed know-how make us the global leader

in this field.

A few examples are:

CYCLASULF

process for the desulphurisation of

coke oven gas and removal of ammonia

VACASULF

process for the desulphurisation of

ammonia-lean coke oven gas

COMBICLAUS

, MONOCLAUS

and COMBACID

processes for the production of elementary sulphur

or sulphuric acid in simultaneous combination with

ammonia cracking

The many types, combinations and configurations of

available by-product recovery processes mean that we

can provide a flexible solution to meet specific require-

ments.

21

15. Condensation and tar separation

Sound basis for further process steps

The condensation system, which consists of the primary

coolers and electrostatic tar precipitators, frees the coke

oven gas from tar and condensate. The exhausters then

compress the gas to the pressure needed for the down-

stream process units. In most gas treatment plants the

disposal of tar sludge is carried out manually using

equipment that is more or less open to the atmosphere.

In order to reduce environmental pollution and simplify

the handling of the tar sludge, a completely closed sys-

tem has been developed. A centrifuge separates out

the tar sludge, which is then pumped back to the feed

coal of the batteries by a high-pressure pump.

COG from ovens Downcomer COG to primary cooling

Centrifuge

Coal water

tank

Tar

decanter

Gorator

Tar sludge

Solid pump

Crude tar

Coal water Flushing liquor

Primary coolers and electrostatic precipitators at

Schwelgern coke plant, Germany

Tar separation with tar sludge removal

22

16. Removal and treating of by-products

Comprehensive cleaning processes

Removal of H

2

S, NH

3

and BTX

The well-known CYCLASULF

process for

the removal of H

2

S and NH

3

has undergone

many detailed improvements. By using

structured packing, instead of expanded

metal packing, for the scrubbers and parts

of the desorber, the dimensions of the col-

umns have been reduced significantly. This

allows the H

2

S and the NH

3

scrubbers, as

well as the deacifier and the fixed and free

ammonia stills, to be combined into single

columns. The amount of mechanical equip-

ment and associated investment costs can

therefore be reduced drastically. The coke

oven gas processed in these purification

units can be used as underfiring gas for the

coke oven batteries or for applications in

the blast furnace.

VACASULF

process

The standard process for the desulphurisa-

tion of ammonia-lean coke oven gas is the

VACASULF

process, which uses potash

solution as an absorbent. The absorbed

hydrogen sulphide is recovered as sour gas

through regeneration under partial vacuum.

The partial vacuum in the H

2

S stripper allows

the use of very low-temperature heating

media. The heat required for regeneration

of the potash solution is supplied indirectly.

The heat requirement can be provided either

by sensible heat from the hot water gener-

ated at the top of the primary cooler, by

sensible heat from the flushing liquor before

it enters the collecting main of the coke

oven battery or by latent heat using low-

pressure steam. Most of the equipment is

fabricated from carbon steel, with a negligi-

ble portion of stainless steel.

Sulphur recovery

The sour gas vapours released from the

H

2

S and NH

3

desorption system are further

treated in the sulphur recovery unit. Many

coke plants have adopted the CLAUS pro-

cess with simultaneous NH

3

destruction to

produce liquid sulphur. In order to reduce

investment and operating costs, a modified

MONOCLAUS

-process has been developed

by Uhde.

Contrary to the usual CLAUS-process the kiln

is positioned horizontally, the process gas

cooler and sulphur condenser are combined

in a common unit and only one CLAUS reac-

tor is used for the catalytic conversion. In

this way the costs for piping, steelwork and

instrumentation can be reduced by about

30%. The tail gas is recycled to the raw coke

oven gas so that no emissions occur.

Depending on specific requirements other

H

2

S processing technologies can be pro-

vided, such as conversion to sulphuric acid

for use in combination with ammonium sul-

phate production.

VACASULF

coke plant,

Frstenhausen, Germany

23

Gas treatment unit at

Schwelgern coke plant, Germany

BTX recovery

BTX and/or naphthalene components can

be removed from the coke oven gas using

two main types of wash oil. The normal

degradation of petroleum-based wash oil

makes it more suited to once-through oper-

ation, whereas tar-based wash oil can be

successfully regenerated and recirculated to

the BTX removal process. The recovered

BTX fraction has a typical boiling range of

95% at 180C.

Biological treatment

The waste water effluent from the H

2

S/NH

3

regeneration unit comprises the water pre-

sent as the coal moisture, the water released

during coking and the condensed direct

stripping steam. The total concentration of

NH

3

in the waste water is less than 100 mg/l.

Biological treatment can be used to condi-

tion the waste water before it is discharged

from the plant if this is required by local

regulations.

LP-steam

Tail gas

Sulfur

Claus reactor

Process gas cooler

Sulphur condenser

Claus kiln

Air

H

2

S/NH

3

vapors

MONOCLAUS

process

24

17. Tar refining

Huge variety of products

The feedstock of the tar refining plant is

typically the crude tar recovered in the coke

oven by-product plant. A wide range of prod-

ucts can be separated from the crude tar.

The state of the art for primary distillation

consists of two alternative systems. The

first is complete vacuum distillation, the

second a combination of atmospheric and

vacuum distillation.

In order to reduce operational problems,

solids are separated from the crude tar using

a centrifuge. This is followed by neutralisa-

tion to reduce the corrosion hazard. The sep-

aration of tar fractions with individual boiling

ranges uses a system of distillation columns

with direct heaters and an efficient heat re-

covery system. The main products of the

primary distillation are the light oil, naph-

thalene oil, wash oil and anthracene oil-

fractions and a normal pitch as the residue.

Typical tar distillation

P

r

i

m

a

r

y

d

i

s

t

i

l

l

a

t

i

o

n

Naphthalene

crystallisation

Light-/Carbolic oil Phenole

Pure naphthalene

Phenol

extraction

Oil mixing

Crude tar Special oilstar

Anthraquinone

Special pitch

Anthracene

crystallisation

Pitch

reforming

Anthraquinone

oxidation

Tar distillation process

25

18. Alternative use of coke oven gas

Hidden treasures

With the emphasis on increasing coke pro-

duction and less on by-products, the use

of coke oven gas for alternative purposes

is becoming more and more attractive. The

high hydrogen-content of coke oven gas

makes it suitable for direct use as a synthe-

sis gas (see table below).

Proven technologies can be applied, such

as methanol or ammonia synthesis or H

2

separation. In order to meet the require-

ments of the synthesis processes, Uhde

has developed and diversified the standard

gas treatment process.

Partial

oxidation

Collecting

main

Naphthalene

crystallisation

Clausplant

Waste-heat

recovery

Desulfuri-

sation

Tar + Water

Raw gas

Flushing liquor

Tail gas

H

2

S

Tar

Sulfur Methanol,

Ammonia, H

2

Composition %

H

2

: 63.26%

CO : 29.22%

CO

2

: 5.17%

H

2

O : tr.

CH

4

: 0%

N

2

: 2.35%

Methanol plant

Gas composition

Treatment of coke oven raw gas and tar

for generation of synthesis gas

Vol.-% Coke oven Direct Methanol- NH

3

-

gas reduction synthesis synthesis H

2

-gas

gas gas gas

H

2

63 66 69 75 > 99.5

CO 8 27 22 < 0.1

CO

2

3 3 8 - -

CH

4

21 - 0.5 0. 1 -

N

2

5 3.6 0.5 25 < 0.4

H

2

S < 0.02 < 0.02 - - -

26

19. Coke cooling

A wet quenching trendsetter

Coke Stabilisation Quenching (CSQ)

Two main components characterise the

CSQ wet quenching process. One is the

quenching car prepared for a combined

feed of quench water from the top and

bottom of the hot coke. The other is the

quench tower itself, prepared for this type

of quenching but additionally equipped

with installations for thorough removal of

particulate emissions as generated dur-

ing the quenching process. The quenching

procedure features a very high water feed

rate and a very short quenching time. The

specially developed single-spot quenching

car has a coke bed depth of approx. 4 m.

The combined top and bottom quench-

ing procedure develops flash steam which

agitates the coke intensively, ensuring the

entire coke charge is stabilised and evenly

moistened.

Because of its uniform grain size, high sta-

bility and reduced moisture content of only

approx. 2%, coke quenched by the CSQ

process is particularly suitable for tall blast

furnaces run on high pulverized coal or high

oil injection rates per tonne of hot metal.

CSQ quenching tower,

Schwelgern plant, Germany

CSQ quenching car

27

CSQ emission control

The quenching process with a combined top and

bottom supply of water works in connection with the

reduction of particulate emissions. The dust-loaded

steam generated during the quenching passes through

several stages inside the quench tower.

Two baffle systems are installed, both serving as

impact separators for the particulates by redirecting the

flow of the plume. The lower one is made of stainless

steel material to withstand higher temperatures while

the second system is equipped with polypropylene

plates which are arranged more closely to each other

than the stainless steel units, thus allowing even the

finest particulates to be seperated out. The top baffle

arrangement is cleaned after each quenching cycle by

a water spray. This scrubbing uses clean service water

only not quenching water which at the same time

compensates for part of the loss due to evaporation.

Additional dust removal is provided by two plume

spraying devices, one positioned directly above the top

quenching level, the second one above the lower baffle

system. This dust removal process is characterised by

partial condensation of the plume in that the intensive

stream of droplets emitted by the scrubbers mixes with

the rising steam, so forming bigger drops. A substan-

tial part of the quenching plume is thus condensed at

an early stage and the particles are absorbed by the

water droplets. The upper plume sprayer also serves

for cleaning of the lower baffle system. The particulate

emissions associated with this technology are as low as

emissions generated by Coke Dry Quenching (CDQ).

CSQ quenching process, diagramm

baffle cleaner

upper baffle

plume sprayer

lower baffle

plume sprayer

top quench

bottom quench

19. Coke cooling

A wet quenching trendsetter

28

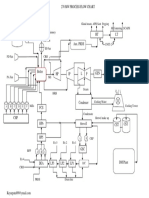

The challenge

To be able to operate a coke oven plant at optimum

efficiency, it has to be equipped with state-of-the-art

automation technology. The aim of automating the

process sequences is to facilitate the long-term ad-

justments required to meet environmental protection

requirements.

The engineering

Uhde has been successfully engaged in the auto-

mation of coke-oven plants since 1980. The auto-

mation systems supplied by Uhde are tailored to

the customer's specific requirements in each case.

The modular design of the automation systems

facilitates this.

The results

To meet the challenge, the following system struc-

ture has been developed under the umbrella of the

COKEMASTER

automation architecture:

The AutoTherm

TM

measuring system uses its six infra-

red sensor heads to measure the surface temperatures

of the two heating walls at three different levels dur-

ing each coke pushing operation. In other words, the

heating walls are thermally scanned, allowing an exact

overview of the temperature distribution in each heating

wall. The aim is to keep the temperature distribution in

the heating walls as uniform as possible and to detect

any changes.

The ManuTherm

TM

system is an infrared pyrometer with

integral data memory for taking manual measurements

at the heating flues. Its main job is to measure heating

flue temperatures when no Autotherm

TM

measurements

are available, for instance when no coke pushing is tak-

ing place for operational reasons. Also, detailed spot

measurements can be taken where heating problems

have been detected by AutoTherm

TM

. These tempera-

ture measurements can be fed into the computer sys-

tem and used for further calculations and evaluations.

The BatControl

TM

system calculates the amount of heat

required for the battery, taking into account all relevant

operating parameters such as coal quality, coal mois-

ture, coke pushing schedule, etc. The heating situation

is controlled automatically and the heat input is cor-

rected immediately upon detecting a fault, such as a

delay in production or a change in temperature.

The PushSched

TM

system is an automatic pushing and

charging schedule calculation program designed to as-

sist operating crews. The production plan is recalculated

ManuTherm

TM

Heating fue

temperatures

Heating fue

temperatures

Oven wall

temperatures

Pushing

forces

Operator

station

control room

Coordination PCL for oven machines

Handheld

pyrometer

Pusher machine

Coke

transfer

car

Coal

quench

car

Coal

charging

car

PushSched

TM

Scheduling of

oven machines

Scheduling of

oven machines

AutoTherm

TM

Oven wall

temperatures

RamForce

TM

Pushing

forces

BatControl

TM

Heat quantity

control

DCS

Process

data

Heat quantity

control

Level 2 process computer/battery

20. Coke plant automation

Flexible solutions with COKEMASTER

Automation system

for battery operation

29

continuously after every coke pushing operation, taking

into account special operating conditions such as "oven

with extended coking time" or "oven out of service". The

resulting production schedule is transmitted to the ma-

chines. Confirmations received from the oven machines

are forwarded to the BatControl

TM

system so that the

heating can be corrected automatically.

The GasControl

TM

system is a process model for gas

treatment plants. The process model consists of the

CHEMCAD commercial simulator for chemical plants

plus extension modules developed by Uhde for individ-

ual coke-oven-specific machinery and equipment. The

GasControl

TM

process model uses chemical and ther-

modynamic mass equilibria and streams to rate each

individual gas treatment unit and determines the input

and output streams, interlinking them in accordance

with the plant flowsheet. The model is supplied with the

relevant on-line process variables from the plant instru-

mentation in real-time mode (via the process control

system) and the process model is calculated dynami-

cally. By varying the control parameters (e.g. steam

rate, water rate, etc.) in this virtual plant it is possible to

optimise the operating results. The control parameters

that deliver the best operating results are retransmitted

to the plant instrumentation to set the local controllers

in the "real" plant. All important data can be displayed

on screens, reports and trend charts. This model is not

only a powerful tool for plant optimisation and automa-

tion it can also be used in an off-line simulation mode

as a training tool for operators.

Operator

station

control room

Process

data base

Copying of actual data

Set simulation

scenario

Exchange of data

Laboratory

data

SimuGas

TM

Process simulator

Gas Treatment

TM

Process optimization

model

DCS

Process

data

Process

control

Level 2 process computer/gas treatment

Automation system

for gas treatment

plant operation

MainControl

TM

SimuGas

TM

GasControl

TM

PushSched

TM

AutoTherm

TM

ManuTherm

TM

SimuCoke

TM

BatControl

TM

CokeControl

TM

CoalControl

TM

CokEmASTER

30

21. Technology services

Successful plant operation over the entire life cycle

Would you like your plant to be operating optimally and

successfully throughout its entire lifetime?

Market conditions, feedstock, product quality, environ-

ment, plant lifetime, safety things are becoming in-

creasingly dynamic and challenging these days.

Uhdes Coke Plant Technology Services team can help

you to master these challenges on a competent, reli-

able and customised basis.

Our service portfolio comprises:

Performance Improvement and Revamp

Coke oven, gas treatment plants and service machines

all require modernisation and continous optimisation to

ensure the most reliable and efficient plant operation.

Examples:

Installation of gas-tight coke oven doors

Revamp of the gas collection system including

PROven

implementation

Modernisation of the bracing system

Revamp of absorption/desorption columns

with structured packing

Implementation of process automation

Inspection, Training, Troubleshooting

Uhdes service team analyses customers problems

on an interdisciplinary basis and provides them with

specific solutions.

Examples:

Studies on extending the useful plant life

Preventive or incident-based inspections (bracing

system, refractory, heating system, machines).

Process-related consulting (coke oven operation, gas

treatment, heating system, machine coordination)

Training for operating teams and maintenance

personnel (new employees or refreshment)

Helpline/Teleservice/Troubleshooting

Coke oven door survey

Broad inspection services and trouble shooting

31

Hot repair

Hot repairs are the best option when the battery struc-

ture has deteriorated to such an extent that preventa-

tive maintenance will not meet expectations in terms of

battery lifetime and economic considerations.

Examples:

End flue repair up to through-wall repair

Oven roof repair

Provision of sophisticated know-how (logistics,

design of interface between new and old brickwork,

precise investigation of conditions for construction/

commissioning)

Components and spare parts

With Uhdes technical experience and market knowl-

edge specific components/spares requirements of our

customers can be fulfilled.

Examples:

Procurement of both proprietary and standard

equipment based on our comprehensive archive

and database

Engineering and procurement of alternative spare

parts for obsolescent equipment

Procurement of process-specific consumables

Utilisation of Uhdes excellent supply contacts

Thanks to many years of experience backed up by cor-

responding references, we can provide in whatever kind

of technology service you need.

Some of the required tasks may be highly complex and

in need of an integrated approach. Thus, where appro-

priate, Uhdes Coke Plant Technology Services collabo-

rates closely with all relevant in-house departments and

subsidiaries in the global Uhde service network.

The team Uhde Coke Plant Technology Services can

be contacted quickly and easily by email

(Cokeplant-support.uhde@thyssenkrupp.com),

fax or phone.

Typical battery revamp measures

Oven sole

Standpipe

Charging hole Oven roof Cross tie rod

Collecting

main

Bracing

Doors

End fues or

complete walls

Regenerator

Oven roof repair

Helpline/teleservice

2

Thyssen Krupp Uhde GmbH

Friedrich-Uhde-Strasse 15 44141 Dortmund Germany

Phone +49 231 547-0 Fax +49 231 547-3032

www.uhde.eu

C

P

3

1

0

/

1

5

0

0

e

0

1

/

2

0

1

2

U

/

T

K

P

M

/

P

r

i

n

t

e

d

i

n

G

e

r

m

a

n

y

You might also like

- By Product PlantDocument7 pagesBy Product PlantPratyush RanjanNo ratings yet

- Thermax - NTPC PresentationDocument57 pagesThermax - NTPC PresentationPiyush MalviyaNo ratings yet

- Techint Group Brochure 2013Document100 pagesTechint Group Brochure 2013MD AFROZ RAZANo ratings yet

- Boiler Efficiency CalculationDocument44 pagesBoiler Efficiency CalculationgARRYNo ratings yet

- Lab: Introduction to Control Apparatus and PLC Control of Asynchronous MotorDocument11 pagesLab: Introduction to Control Apparatus and PLC Control of Asynchronous MotorMuhammad J SherwaniNo ratings yet

- Centrifugal Pump Types (API-610)Document4 pagesCentrifugal Pump Types (API-610)Иван РадевNo ratings yet

- 02 Cokemaking Process (54 Slides)Document54 pages02 Cokemaking Process (54 Slides)karinzzinhaNo ratings yet

- WP 17Document34 pagesWP 17Tyndall Centre for Climate Change Research100% (2)

- Mechanical Topics - Skive ProjectsDocument15 pagesMechanical Topics - Skive ProjectsJithin V KNo ratings yet

- CO&CCPDocument23 pagesCO&CCPApoorva RamagiriNo ratings yet

- Uses and Applications of AmmoniaDocument5 pagesUses and Applications of AmmoniaSohail Asghar100% (2)

- As 4264.5-1999 Coal and Coke - Sampling Guide To The Inspection of Mechanical Sampling SystemsDocument6 pagesAs 4264.5-1999 Coal and Coke - Sampling Guide To The Inspection of Mechanical Sampling SystemsSAI Global - APACNo ratings yet

- Temperature Sensors CAT1667Document36 pagesTemperature Sensors CAT1667damienwckNo ratings yet

- Oisd 159Document37 pagesOisd 159Ritika VermaNo ratings yet

- Boiler Industry Pack April 2020 Rev2Document33 pagesBoiler Industry Pack April 2020 Rev2Jagdish SinhaNo ratings yet

- Coal ChemicalDocument71 pagesCoal ChemicalKiran KumarNo ratings yet

- 2 ERG 401 2015 Energy Performance Analysis of BOILERDocument57 pages2 ERG 401 2015 Energy Performance Analysis of BOILERnaveenNo ratings yet

- Asme B16.47 - 2011Document120 pagesAsme B16.47 - 2011Guido KünstlerNo ratings yet

- Tata Steel ProjectDocument12 pagesTata Steel Projectsp32483No ratings yet

- Municipal Solid Waste Project SKTGDocument3 pagesMunicipal Solid Waste Project SKTGDevanSandrasakerenNo ratings yet

- 147 20 Safe Practices Guide For Cryogenic Air Separation PlantsDocument86 pages147 20 Safe Practices Guide For Cryogenic Air Separation PlantsJose ChiriNo ratings yet

- Nioec SP 00 10Document7 pagesNioec SP 00 10Amirhossein DavoodiNo ratings yet

- Coke Oven Life Prolongation - A Multidisciplinary ApproachDocument31 pagesCoke Oven Life Prolongation - A Multidisciplinary ApproachJorge MadiasNo ratings yet

- Report @NTPCDocument34 pagesReport @NTPCme11727100% (1)

- Drive Failure and Interruption in SCP Machines of Battery 567, Coke PlantDocument37 pagesDrive Failure and Interruption in SCP Machines of Battery 567, Coke Plantnarendramaharana39No ratings yet

- Coke Oven Gas Purification and Cooling ProcessDocument3 pagesCoke Oven Gas Purification and Cooling Processshishir18No ratings yet

- Instrumentation Fittings, Valves & Accessories GuideDocument12 pagesInstrumentation Fittings, Valves & Accessories GuideGloria HamiltonNo ratings yet

- Main Combustion ChamberDocument31 pagesMain Combustion Chambershaliq28No ratings yet

- Pipeline Safety and Public Awareness - Spectra EnergyDocument2 pagesPipeline Safety and Public Awareness - Spectra EnergyElisa CanoNo ratings yet

- Handling HydrogenDocument51 pagesHandling HydrogenShabin Shabi100% (1)

- Power Plant Process Flow Chart PDFDocument1 pagePower Plant Process Flow Chart PDFFikriHidayatullahNo ratings yet

- Company Profile - PATDocument78 pagesCompany Profile - PATmahendra_kolheNo ratings yet

- Complete Package For Cokemaking Stamping TechnologyDocument10 pagesComplete Package For Cokemaking Stamping TechnologyJJNo ratings yet

- Steinmueller Broschuere 1Document46 pagesSteinmueller Broschuere 1andri.motoGNo ratings yet

- SCR PresentationDocument85 pagesSCR PresentationariyaNo ratings yet

- Enquiry Specification For BOD PlantDocument94 pagesEnquiry Specification For BOD PlantBanerjee SuvranilNo ratings yet

- SURFACE COAL GASIFICATION EXPERIENCE FROM TALCHER FERTILIZER PROJECTDocument37 pagesSURFACE COAL GASIFICATION EXPERIENCE FROM TALCHER FERTILIZER PROJECTAlfin A. N.No ratings yet

- Your Global Engineering PartnerDocument4 pagesYour Global Engineering PartnerN TanejaNo ratings yet

- Industrial Watertube BrochureDocument12 pagesIndustrial Watertube Brochuregonzaracing84No ratings yet

- Fired Heaters: Esteem Projects Pvt. Ltd. The Fired Heater CompanyDocument21 pagesFired Heaters: Esteem Projects Pvt. Ltd. The Fired Heater CompanySoumitra GuptaNo ratings yet

- Project Oxygen DocumentationDocument38 pagesProject Oxygen DocumentationGoda KondapallyNo ratings yet

- Topology OptimizationDocument11 pagesTopology OptimizationSagar Gawde100% (1)

- Unit Operations of Bokaro Steel Plant and Their Environmental AspectsDocument52 pagesUnit Operations of Bokaro Steel Plant and Their Environmental AspectsGopalSingh100% (2)

- MPR September 2019Document13 pagesMPR September 2019Pradipt DasNo ratings yet

- Globe Valve Bs 1873 and Api 602: ASME B16.10Document7 pagesGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNo ratings yet

- From prototype to serial production of hydrogen fuelling stationsDocument24 pagesFrom prototype to serial production of hydrogen fuelling stationsmessiNo ratings yet

- Gas Holders Risk AssessmentDocument48 pagesGas Holders Risk AssessmentRonak MotaNo ratings yet

- Report on Industrial Training at BHEL HyderabadDocument74 pagesReport on Industrial Training at BHEL Hyderabadvijayk23060% (1)

- Advances in Oxy Fuel Fired Glass Melting TechnologyDocument17 pagesAdvances in Oxy Fuel Fired Glass Melting TechnologytedmozbiNo ratings yet

- Boiler: Ir. SadaniDocument50 pagesBoiler: Ir. SadaniAldy Bagus PratamaNo ratings yet

- Sps Engineering SolutionsDocument10 pagesSps Engineering Solutionssaumya.nanda5567No ratings yet

- Books: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsDocument1 pageBooks: Cryogenic Engineering, 2 Edition Distillation Theory and Its Application To Design of Separation UnitsRaul tejadaNo ratings yet

- II 1/2G Ex DB IIC T4 Ga/Gb: Internally/externally EPL Internally/externallyDocument2 pagesII 1/2G Ex DB IIC T4 Ga/Gb: Internally/externally EPL Internally/externallyDhananjay BhaldandNo ratings yet

- Vuthpala. Chaitanya Krishna: Engineering Manager - Operation & Maintenance - Power / Desalination PlantDocument2 pagesVuthpala. Chaitanya Krishna: Engineering Manager - Operation & Maintenance - Power / Desalination PlantVuthpalachaitanya KrishnaNo ratings yet

- Model 4WI 100-800 HP Boilers Provides Low NOx Emissions and High EfficiencyDocument56 pagesModel 4WI 100-800 HP Boilers Provides Low NOx Emissions and High EfficiencyShafqat AfridiNo ratings yet

- A New Dimension in Cokemaking Technology: Competence and Know-How by TraditionDocument28 pagesA New Dimension in Cokemaking Technology: Competence and Know-How by Traditionvinay1999No ratings yet

- GasifikasiDocument29 pagesGasifikasiMartha GamalNo ratings yet

- Cryo Quip Web BrochureDocument16 pagesCryo Quip Web BrochuresppramNo ratings yet

- Carbolite Furnace (Leading Heat Technology)Document100 pagesCarbolite Furnace (Leading Heat Technology)Anonymous Wi2Pd2UgPINo ratings yet

- Heat Recovery Steam Generators: Capability BrochureDocument20 pagesHeat Recovery Steam Generators: Capability BrochureMartin Olowe100% (1)

- Sheppard 1986 Ethylbenzene Dehydrogenation ReaDocument4 pagesSheppard 1986 Ethylbenzene Dehydrogenation ReageocottonNo ratings yet

- Simulation and Optimization of an Existing Ethylbenzene Dehydrogenation ReactorDocument5 pagesSimulation and Optimization of an Existing Ethylbenzene Dehydrogenation ReactorÉrico CavalcantiNo ratings yet

- Jae Lee-2008-Ethylbenzene Dehydrogenation IntoDocument12 pagesJae Lee-2008-Ethylbenzene Dehydrogenation IntogeocottonNo ratings yet

- Factura ENEL NR 4MF1227636 06.02.2014 PDFDocument4 pagesFactura ENEL NR 4MF1227636 06.02.2014 PDFgeocottonNo ratings yet

- Uhde Brochures PDF en 17Document20 pagesUhde Brochures PDF en 17geocottonNo ratings yet

- A.Volkov Biorefinery PDFDocument28 pagesA.Volkov Biorefinery PDFgeocottonNo ratings yet

- To Mass TransferDocument28 pagesTo Mass TransfergeocottonNo ratings yet

- Factura ENEL NR 4MF1227636 06.02.2014 PDFDocument4 pagesFactura ENEL NR 4MF1227636 06.02.2014 PDFgeocottonNo ratings yet

- Group-Contribution Method for Predicting Activity CoefficientsDocument14 pagesGroup-Contribution Method for Predicting Activity Coefficientsm_adnane_dz3184No ratings yet

- Uhde Brochures PDDF en 16Document36 pagesUhde Brochures PDDF en 16geocottonNo ratings yet

- Chapter 11Document36 pagesChapter 11Sunmoon Al-HaddabiNo ratings yet

- Biodiesel Synthesis On Solid CatalystsDocument1 pageBiodiesel Synthesis On Solid CatalystsgeocottonNo ratings yet

- A Solar-Powered Reverse Osmosis System For High Recovery of FreshwaterDocument8 pagesA Solar-Powered Reverse Osmosis System For High Recovery of FreshwatergeocottonNo ratings yet

- RST4Document47 pagesRST4geocottonNo ratings yet

- HYSYS Distillation Column Simulation TutorialDocument7 pagesHYSYS Distillation Column Simulation Tutorialcmlim100% (2)

- Haber Process For AmmoniaDocument9 pagesHaber Process For AmmoniarafcobosNo ratings yet

- Energetics of Adsorption and DesorptionDocument28 pagesEnergetics of Adsorption and DesorptionWaheed MiranNo ratings yet

- Brick 3Document7 pagesBrick 3mah0809No ratings yet

- Aalterpaint - Galva Wash - 02 - enDocument2 pagesAalterpaint - Galva Wash - 02 - enAnitha Grey'sNo ratings yet

- GSTC Industry Criteria For Hotels With Indicators Dec 2016Document11 pagesGSTC Industry Criteria For Hotels With Indicators Dec 2016Alejo VargasNo ratings yet

- 01-HAZOP Worksheet Formaldehyde - (Corrosion)Document8 pages01-HAZOP Worksheet Formaldehyde - (Corrosion)Muhammad Zarif Amir100% (1)

- IDYLLIC BEACH LIFE ANYWHEREDocument6 pagesIDYLLIC BEACH LIFE ANYWHEREPro-arquit Daniel Morales LopezNo ratings yet

- Food and Beverage Services in HotelDocument20 pagesFood and Beverage Services in HotelJay Lord Santos SalvadorNo ratings yet

- Separating Mixtures Through FiltrationDocument11 pagesSeparating Mixtures Through Filtrationchona redillasNo ratings yet

- SW (Adventure Edition) Deadlands - Lost Colony - WidowmakerDocument32 pagesSW (Adventure Edition) Deadlands - Lost Colony - WidowmakerJacobo Cisneros100% (1)

- Sources & Uses of Water Lesson PlanDocument7 pagesSources & Uses of Water Lesson PlanPatria Hence GabuyaNo ratings yet

- R-2A Agar: Intended Use: CompositionDocument3 pagesR-2A Agar: Intended Use: CompositionABDO ELJANo ratings yet

- Material Safety Data SheetDocument16 pagesMaterial Safety Data Sheetaya sofiaNo ratings yet

- Determination of The Anti-Inflammatory Property of Tannins From The Rind of Calamansi (Citrus Microcarpa, Rutaceae)Document1 pageDetermination of The Anti-Inflammatory Property of Tannins From The Rind of Calamansi (Citrus Microcarpa, Rutaceae)DBNo ratings yet

- Indonesian Journal On Geoscience: A Case of Erelu Dam, Southwestern NigeriaDocument10 pagesIndonesian Journal On Geoscience: A Case of Erelu Dam, Southwestern NigeriaAZKY RAMANIYA SUKARDINo ratings yet

- Web-Based Lesson PlanDocument6 pagesWeb-Based Lesson PlanScarlette Beauty EnriquezNo ratings yet

- John Deere Tractor 5103, 5103S & 5203 Technical Manual TM2041 PDFDocument31 pagesJohn Deere Tractor 5103, 5103S & 5203 Technical Manual TM2041 PDFEquipment ManualsNo ratings yet

- Bsi Bs 903 A1Document8 pagesBsi Bs 903 A1Wyllton CandidoNo ratings yet

- Groundwater - : Reservoir For A Thirsty Planet?Document16 pagesGroundwater - : Reservoir For A Thirsty Planet?CODEP100% (2)

- English and Filipino Gened QuestionsDocument25 pagesEnglish and Filipino Gened QuestionsGelo JarabeNo ratings yet

- Soal Cause Effect 3Document9 pagesSoal Cause Effect 3Syarmidah Maknya AldiraNo ratings yet

- Project Profile On White and Black PhenylDocument7 pagesProject Profile On White and Black PhenylSyedNo ratings yet

- Potassium Hydroxide PDFDocument4 pagesPotassium Hydroxide PDFMartiNo ratings yet

- Plans and Policies 2080 81englishDocument52 pagesPlans and Policies 2080 81englishYagya Raj BaduNo ratings yet

- Birkosit - MSDS (2017) PDFDocument10 pagesBirkosit - MSDS (2017) PDFSuresh MuruganNo ratings yet

- Décret 21-261.englilsh VersionDocument14 pagesDécret 21-261.englilsh Versionqa/qcNo ratings yet

- Design of Circular Type of Sedimentation Tank: Div-B Civil Engineering Department Guided by - Prof. Nitin SawalkarDocument17 pagesDesign of Circular Type of Sedimentation Tank: Div-B Civil Engineering Department Guided by - Prof. Nitin SawalkarPRASADNo ratings yet

- Self Inspection Check ListDocument73 pagesSelf Inspection Check ListOsama Mahmoud100% (2)

- LEED Gold Certified Island City Center in MumbaiDocument34 pagesLEED Gold Certified Island City Center in MumbaiPERVEZ AHMAD KHANNo ratings yet

- First Summative TestDocument3 pagesFirst Summative TestNini VillezaNo ratings yet

- Food and Beverage ServiceDocument20 pagesFood and Beverage Serviceniceta kingeNo ratings yet

- SUG514 - Hydrographic Surveying - Run Line Vs Cross Line CalculationDocument2 pagesSUG514 - Hydrographic Surveying - Run Line Vs Cross Line Calculationmruzainimf100% (4)