Professional Documents

Culture Documents

Ed M 01.00 I 05

Uploaded by

joseellargoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ed M 01.00 I 05

Uploaded by

joseellargoCopyright:

Available Formats

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 2 of 18

TABLE OF CONTENTS

1. 1.1. 1.2. 2. 2.1. 2.2. 2.3. 2.4. 2.5. 2.6. 3. 3.1. 3.2. 3.3. 3.4. 3.5. 4. 4.1. 4.2. 4.3. 4.4. 4.5. 4.6. 5. 6. 7. 8. 8.1. 8.2. 8.3. 8.4. 9. 10. 10.1. 10.2. 10.3. 11.

GENERAL ..................................................................................................................................................3 Scope .........................................................................................................................................................3 Units of measurement and symbols ............................................................................................................3 MATERIALS ...............................................................................................................................................4 General.......................................................................................................................................................4 Material specifications.................................................................................................................................4 Structural steel............................................................................................................................................4 Bolts ...........................................................................................................................................................4 Checkered plates. .......................................................................................................................................5 Galvanized steel grating (tramex) .............................................................................................................5 CALCULATION OF STEEL STRUCTURES ................................................................................................6 General.......................................................................................................................................................6 Regulations.................................................................................................................................................6 Loads..........................................................................................................................................................6 Stresses and deflections of the structural steel ...........................................................................................6 Calculation of connections ..........................................................................................................................7 DESING OF STEEL STRUCTURE..............................................................................................................10 General design criteria................................................................................................................................10 Connections................................................................................................................................................10 Stairs, platforms y walkways for tanks and recipients (according to PE-M-0100.06 y 07)............................11 Stairs (in accordance with PE-M-0100.02) ..................................................................................................12 Ladders (according to PE-M-0100.03).........................................................................................................12 Handrail (according to PE-M-0100.04) .......................................................................................................13 FIREPROOFING.........................................................................................................................................13 PAINTING...................................................................................................................................................13 PREPARATION FOR SHIPMENT ...............................................................................................................14 DESIGN DOCUMENTS AND RESPONSIBILITIES. ....................................................................................14 General.......................................................................................................................................................14 Calculation report........................................................................................................................................14 Drawings ....................................................................................................................................................15 Responsibilities...........................................................................................................................................15 LOCAL AND NATIONAL SPECIAL REQUIREMENTS. ...............................................................................16 STANDARDS AND SPECIFICATION OF REFERENCE..............................................................................17 Repsol standard and technical specification................................................................................................17 International codes and standards ..............................................................................................................18 Bibliography of reference. ...........................................................................................................................18 TABLES INCLUDED IN THIS SPECIFICATION ..........................................................................................18

TABLE OF CONTENTS

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 3 of 18

1. 1.1.

GENERAL Scope This design specification encompasses design activities for all the steel structures to be erected for the projects performed in Repsol plants. The present document is part of the last issue of technical specifications of Repsol and likewise, refers to the last issue of Codes or Standards which are mentioned and/or applicable, as well as to the indications of the document "Basic Design Data" (B.D.D.) which collects the particular aspects of each project. As a general rule, the requirements of the licensees as well as the local or national codes and regulations, in case they were more restrictive, they shall prevail over this specification. The local particular conditions applicable both in quality as in the types of materials and standard applications are in the applicable addendum listed in paragraph 9 of this specification. The structures object of this specification shall comply, in addition, with the design requirements imposed by the different official codes existing in the place of installation. This specification covers the following typologies of steel structure: Process structures Building structures Platforms Walkways Ladders, stairways, handrails Supporting structures Miscellaneous structures

This specification, together with the calculation report and/or the engineering drawings is part of the material requisition or structural set to be supplied. In case of discrepancy between the documents included in such requisition, the following order of priority shall prevail: Applicable legislation (as long as in the data sheets, in the requisition or in this specification more restrictive criteria are not established than those therein set down). B.D.D. - Basic Design Data Sheet of calculations and/or engineering drawings Material requisition Whatever is established in this design specification Standard drawings

The exceptions, variations or additions which mean some change in such documents shall be communicated in writing to Repsol for their approval. The compliance with the rules and recommendations given in this Specification does not exempt neither partially nor totally the contractor of his responsibilities and contractual guarantees. 1.2. Units of measurement and symbols All the designs, calculations and drawings performed under these specifications must be performed using the International System of Units (I.S.)

1 GENERAL

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 4 of 18

2. 2.1.

MATERIALS General The qualities of the materials to be used for the fabrication and erection of steel structures (section profiles, plates, bolts, nuts, washers, welding materials) must be in agreement with the regulations mentioned in the sections following of this specification. Any change on the specified qualities shall be prior approved by REPSOL. In those countries where there are reference standards mandatory, shall take precedence over those specified in this ED. In those cases where there might not exist regulations in that respect, the following code shall be adopted as reference: AISC, American Institute of Steel Construction, "Manual of Steel Construction" , last issue, with all the standards for quality control of the material of ASTM, American Society for Testing and Materials or equivalent European Codes (EN) where applicable.

2.2.

Material specifications The following codes should serve as reference: European Code (EN):

ENV 1090 - 1 Execution of steel structures. part 1: general rules and rules for buildings.

and standards referenced therein (EN-10025;) Standards US (ASTM - American Society for Testing and Materials):

ASTM A 36 - Standard specification for structural steel ASTM A 123 - Standard specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products ASTM A 325 - Standard specification for High-Strength Bolts for Structural Steel Joints ASTM A 307 - Standard specification for Carbon Steel Bolts and Studs ASTM A 563 - Standard specification for Carbon and Alloy Steel Nuts ASTM A 436 - Standard specification for Hardened Steel Washers

Standards ISO - International Organization for Standardization:

ISO 898 - 1 - Mechanical properties of fasteners made of carbon steel and alloy steel. Part 1: Bolts, screws and studs

2.3.

Structural steel The structural steel material shall be according to the minimum mechanical properties specified in: Specification ASTM A 36 (fy = 253 N / mm ) or European standard EN-10025 type S275J2 (fy = 275 N / mm )

Other qualities differ from those specified may be used in exceptional cases, with the prior approvals of REPSOL. Special attention should be paid to the material resilience when there exists the possibility of low temperatures. 2.4. Bolts In general, steel structures bolted connections should be resolved using common bolts or high strength bolts.

2 MATERIALS

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 5 of 18

The bolts and nuts which are not of high strength shall be according to the ASTM A 307 Grade B (specification in the case of bolts) and according to ASTM A 563 Grade A (specification for the heavy hexagonal nuts). Also the use of bolting (bolts, nuts and washers) in degrees 4.6 or 5.6 shall be acceptable according to norm ISO 898-1. Ordinary bolts shall preferably be used in the connections of structures of smaller importance (secondary) according to are defined in 4.2.b. The high strength bolts shall be according to ASTM A 325 Type 1 (specification for bolts), ASYM A 563 Grade DH (specification for nuts) and ASTM F 436 (specification for washers). Also the use of bolting (bolts, nuts and washers) in degrees 8.8 or 10.9 shall be acceptable according to norm ISO 898-1. High strength bolting shall preferably be used in the connections of structures of greater importance (main) according to are defined in 4.2.b, and obligatorily in that they are designed like resistant joints to the sliding according to Eurocode 3, being due to use in such case prestressed bolts in degree 10.9. Bolting galvanized shall be only used in the connection to realise in galvanized steels. In general, the minimum diameter of the bolts for structure steel connections shall be of 20 mm for main joints or for high strength bolting. For secondary joints when ordinary bolt are used, the minimum diameter should be of 12 mm according to ENV-1090-1. For connections realised with ordinary bolts the use of washers is not required, except in the following cases: a) Washers shall be used in wedge formation when the surfaces are inclined more of 3 with respect to a perpendicular plane to the axis of the bolt. b) Also the use of washers shall be required when the exigency exists to use a greater bolt to maintain its thread outside of the shear plane or out of a calibrated hole. Hardened steel washers of a compatible material with the quality of the material of bolting specified shall be use for connections realised with high strength bolts, in accordance with the criteria and specified recommendations positioning in chapter 8.5 of ENV 1090-1. The non-prestressed bolts shall tighten enough to guarantee the necessary contact between the parts to unite (to see apretado-a-tope according to chapter 8.6 of ENV 1090-1) The prestressed bolt shall be tightened according to ENV 1090-1, chapter 8.7. 2.5. Checkered plates. The steel for checkered plates shall be according to specification ASTM A 36 or according to European Code EN-10025, the minimum thickness shall be 6 mm (thickness of the plate) + 2 mm (checkers). Checkered plates shall be bolted if not otherwise specified. 2.6. Galvanized steel grating (tramex) The galvanized steel grating for slab for platforms or tread of stairs shall comply with the standard of specification ASTM A 36 or the European Code EN-10025. It shall be fabricated with plates of 30 x 30 x 30 x 3 mm galvanized, of denting slip-proof and provided with electro-welded mesh of checkered steel safety, galvanized in the lower surface of each panel, so that it limits the size of maximum opening of the interstices at 8 mm x 8 mm. The spacing plates shall be welded to the top end of the supporting plates. The grating must be hot galvanized according to standard of specification ASTM A 123 or European equivalent. The galvanized steel grating shall be fixed to the steel structure through clamp according to standard REPSOL PE-M-0100.05 or through other accredited systems of fixation (EP HILTI fasteners or similar) prior approval of Repsol.

2 MATERIALS

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 6 of 18

3. 3.1.

CALCULATION OF STEEL STRUCTURES General The design of a steel structure shall consider not only the properties of materials used in construction and stresses calculated in the constituent elements (members) of it (beams, columns, braces, knots, ..) depending loads to which they are subjected but also to see the local environmental conditions and particular requirements of location, construction details, methods of prefabrication, erection and assembly, as well as its effect on cost, order to achieve a safe and economical design. The assumptions adopted in the global analysis of a structure shall be consistent with the expected behaviour of joints between members, depending on the type chosen for them (rigid, semi-rigid, articulated,..). Also, the hypothesis taken in the calculation of the pieces shall be consistent (or be on the side of safety) with the method of global analysis and, of course, with the expected behaviour of the joints

3.2.

Regulations The design of the steel structures, unless required otherwise by national codes or regulation which prevails, shall be carried out according to: ENV 1993-1-1 Eurocode 3 Design of steel structures, last issue, or AISC, American Institute of Steel Construction, Manual of steel Construction, last issue.

3.3.

Loads The loads and combinations of loads to be considered in the design and calculation of all the structures covered by these specifications are indicated in: ED-M-02.00 "Loads for structural design" and the addendum (ED-M-02.0X) corresponding to the country where the project is to be executed.

3.4.

Stresses and deflections of the structural steel

3.4.1. Allowable stresses and deflections: Stresses and strains in structural steel elements, due both to its own weight as live loads, loads derived from equipment or pipes, derivate actions from the wind or the earthquake, or any other either static or dynamic shall be limited as it is indicated in the mentioned codes of design in this specification, in order to fulfill the following verifications: The stability and strength (ultimate limit state "ULS") The aptitude for the service (service limit state SLS.)

3.4.2. Allowable displacements and deflections: Must not exceed the following values: a) Maximum deflections Beams, cantilever beams and slabs:

Beams until 5m splice and floor beams that does not support masonry walls Beams grater than 5m splice that does not support masonry walls Beams and floor beams that support masonry walls

L/300 L/400 L/300

3 Calculation of steel structures

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 7 of 18

Cantilever with deflection measured at free edge Beams or roof slab beam Floor beams without equipment support

L/300 L/250 L/250

Pipe racks

Main beams Combined deflection in intermediate beams and longitudinal beams, tie beams (L=intermediate beam splice)

L/400

L/200

Floor beams supporting equipments:

Operation case Hydraulic test

L/400 L/250

Travelling crane:

Monorail beams and vertical rails beams Monorails beams and horizontal monorails

L/750 L/1500

Unless other rigorous values as per national or local codes should apply. Where: L= splice beam b) Maximum displacements (see note) Structure Maximum horizontal displacements as per wind or earthquake shall no exceed following values, according with structure type and its functionality:

Walkways platforms and roof without travelling crane Building structures with human occupation Maximum displacement between two adjacent floor slabs Pipe racks (combined actions with wind or earthquake loads) Building structures supporting equipments (process structures) Structures with travelling crane

H/150 H/500 H/300 H/250 H/200 H/400

Unless other more strict values are indicated in applicable national or local codes. where: H = Total height of the structure H = difference of elevation between two adjacent levels. Note: In case the earthquake loads, the limits of side displacement specified shall control the displacements resulting from the calculation the latter not being affected by the parameters of "overall" ductility of the structure" which are established in the respective codes of design or earthquake resistant codes (=1 shall be considered when the earthquake loads can be presented into the linear range). 3.5. Calculation of connections

3.5.1. General: The applying rules for the design of joints of steel structures shall be the followings: EN 1993-1-8 Eurocode 3: Design of steel structure - Part 1.8: Design of joints, last issue or AISC American Institute of Steel Construction, Manual of steel Construction, last issue

3 Calculation of steel structures

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 8 of 18

The joints between structural elements (nodes) shall be designed coherent with the overall structure, which supposes a coherent behaviour to the hypotheses assumed in the global analysis, with special emphasis in the consideration of the value of ductility adopted for the calculation of the structure under seismic load and the typology of nodes considered in accordance with the recommendations of the use code or regulations of design and the standards of the good practice Joints shall be verified for resistance (ULS; SLS) according to the verifications required by the design code used. Always shall justify the resistance of connections from concurrent forces of a complete calculation of the structure. In exceptional cases (eg, the calculation of the structure has not been finalized yet) and always with the prior conformity of REPSOL, the resistance of the nodes shall be justified through specific envelope forces" defined from the resistance capacity of the elements forming the connection. Engineering contractor responsible for the general calculation of the structure shall define the envelope forces based on its experience and its knowledge of this structure. More ahead it shall have to demonstrate by a specific study that, in each node, the used envelope forces are more unfavourable than the resulting forces of the calculation. Engineering shall be able to propose formulas of the envelope forces to be considered in the calculation for each case at issue but, unless justified and prior approval of REPSOL, shall satisfy the minimum enveloped formulas specified in the table included below."

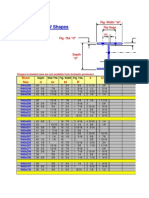

TABLE I MINIMUM FORCES ENVELOPES IN CONNECTIONS CONNECTION TYPE MINIMUM FORCES ENVELOPES (see Notes 2, 3 and 4) 0,4 MU + 0,9 VU or 0,85 MU + 0,55 VU 0,85 MU + 0,85 VU Pinned connection 0,5 VU if l 5 m if l> 5 m. if l > 5 m (see Note 1)

Rigid connection

Rigid connection for cantilever

0,7 VU

0.1 NU +0,5 VU if 5 m.

Pinned connections on longitudinal beam for bracing

0.1 NU+0,7 VU 0,85 NU or 0,45 NU(c) 0,85 NU or 0,45 NU(c)

Pinned connections on beams for vertical bracing

Pinned connections for lattice joints

3 Calculation of steel structures

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 9 of 18

With the notation of ENV 1993-1-1 following: Mu = Wply x fyd Wel x fyd Wef x fyd Vu = Av x fyd / 1,732 Nu = A x fyd Nu(c) = X x A x fyd Notes: 1. In rigid connections beam-column, in the case of being the force smaller than 85% from the resistance at moment in column, the latter should be considered. 2. Stiffeners shall be placed in those rigid connections when required by calculation. 3. Only the methodology of enveloped forces should be able to be used for common structures, regular and simple geometry, such as the structure of a pipe rack formed by cross-braced frames longitudinally. Niether it is to be used for special elements such as a beam rotated, nor may apply this methodology to the base plate that shall always be designed with the whole results of the calculation of the structure. 4. If the complete calculation of the structure was not finalized at the time planned to solicit bids from prefabrication and assembly of the same, the values of the forces obtained from the decided formulas of envelopes to be adopted should be used by the contractor of structures to realise the calculations that allow him to estimate the weight and degree of difficulty of implementation of the connections. However, once the final calculations of structure are completed, both the contractor and the engineering must check the validity of connections with real forces. 3.5.2. Effect of earthquake on the design of the connection. In the case of earthquake resistant structures designed with a dissipative behaviour, where the coefficient of behaviour by ductility is being applied superior or equal to 2, the joints located within the dissipative zones shall be "full-resistance" and shall have an over-resistance of 1.2. Shall be verified, in particular, the criteria and the rules defined in section 3.5 of EN 1998-1-3 Eurocode 8 Part 1.3: Specific rules for different materials and elements. TABLE II OVER-RESISTENCE CRITERIA IN CONNECTIONS CONNECTION TYPE Rigid connection Pinned connection Pinned connections on beams for vertical bracing Pinned connections for lattice joints With the notation of ENV 1993-1-1 following: Mu = Wply x fyd Wel x fyd Wef x fyd Vu = Av x fyd / 1,732 Nu = A x fyd for classes 1 y 2 for class 3 for class 4 OVER-RESISTENCE CRITERIA 1,2 MU or 1,2 V U 1,2 (0,5 VU + 0,15 NU) or 1,2 V U 1,2 NU 1,2 NU for classes 1 y 2 for classes 3 for classes 4

3 Calculation of steel structures

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 10 of 18

3.5.3. Anchor bolts and base plate The design of these elements of connections shall be realised according to section. 4.3 of the specification EDQ-01.00 Concrete structures and foundations

4. 4.1.

DESING OF STEEL STRUCTURE. General design criteria a) The design and detailing of structural elements shall comply with the requirements of regulation or applicable design code as well as in paragraph 8 of this specification. In those cases where may not be applicable regulations, AISC, American Institute of Steel Construction, "Manual of Steel Construction", latest edition, or the equivalent European standard, last issue shall be adopted as reference. b) In general, all the structures shall be welded at the workshop to the maximum extent to allow a comfortable and safe erection of it. Connections at field shall generally be bolted. c) For both of the welding or execution of drills (separation, allowed forms of execution, etc.), the established norms of good practice in the design code shall be followed or regulates applicable to be selected. d) In the case of structures to be installed inside units in operation, the latter are designed so that the welds are made at the workshop prefabrication and assembly is executed in the field by means of bolting, meccano type, taking into account the function to perform and potential interference with other elements. The structures of platforms and ladders attached to columns or vessels, if their size and weight do not condition or penalized erection operations shall be assembled on the floor and hoisted all at once. e) The design of structures, both pipe racks and support of equipments, shall be designed maximizing the use of braced frames, whenever this is possible, taking into account the layout of equipment and pipe supports and adjacent. In the frames, it shall be checked that the placing of tie beams does not prevent access to equipment and vessels located at operation levels neither it makes difficult to the circulation of mobile equipment used for lifting and transportation maintenance work, nor prevents or it conditions the passage of pipes. f) Structural steel beams supporting pipes shall not carry the round pipe support bar, except for slope pipes where they may be placed with the prior approval of Repsol g) Rolled standardized profiles shall be used (preferably in the country of location of the project or in its area of influence), unless the circumstances (special designs, economy or difficulties of storing) advise the opposite. The proposal of using of non-standardized profiles shall be communicated to REPSOL for its joint approval with the design bases. h) Holes for draining shall be provided in all the elements where water could accumulate.

4.2.

Connections. a) The connections subjected to moments of any type shall be designed maximizing the bolting details in the field and the shop welding. The quantity of connections welded in the field shall be minimized, reduced exclusively to those cases where it becomes necessary. b) The connections may be classified by type of importance, using the following criteria:

Connections of less importance (secondary): It is considered as secondary connections, those connections between elements which are not of particular complexity of implementation to ensure continuity in the structure (simple beam-beam connections, beam-pillar, pillar-strut ,..), subject exclusively to forces from static, these forces are expected to be much lower than those that should limit the resistance capacity of its members (<50%) under conditions of permanent loads and ordinary variables (overload of use, wind, snow ,..). This classification may include all connections between members of auxiliary structures (operational platforms and / or maintenance, stairs, handrails, etc..

4 DESING OF STEEL STRUCTURE.

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 11 of 18

Connections of high importance (main): It is considered as main connections those connections can not be included in the previous section, i.e., connections between elements under considerable strain, either from static or dynamic, and investment are likely to experience stress, or those that are screwed designed as slip resistant. Including in this category connections shall be designed under the criteria of verification "full strength", such as the nodes of structures located in seismic zone when required by regulations (eg, the Spanish code NCSE - 02 S). (See section. 3.5.2 of this specification) For bolted connections designed under the criteria of "shear strength" with prestressed high-strength bolts, the current requirements and recommendations in this regard established by the applicable design code, especially regarding the resistance calculation bolts and slip resistant capacity of the contact surfaces, according to the class (A, B, C or D) that is in accordance with Eurocode 3. Classes of stiffness surfaces for prestressed bolted connections: : stiffness coefficient: = 0,2 surfaces classes D = 0,3 surfaces classes C = 0,4 surfaces classes B = 0,5 surfaces classes A Surfaces classes A: blast cleaned surfaces of grit or sand, with removal of any rust and no pitting or aluminum metallized projected Surfaces classes B: surfaces cleaned with grit or sand blasting, and painted with an alkaline zinc silicate producing a layer of thickness 50-80 m. Surfaces classes C: surfaces cleaned with a wire brush or cleaning with flame, removing rusted. Surfaces classes D: untreated surfaces.

4.3.

Stairs, platforms y walkways for tanks and recipients (according to PE-M-0100.06 y 07) a) All the platforms with levels superior to 1 m shall be provided of handrail of 1100 mm height and skirting of 150 mm height. b) The main working platforms shall have a minimum useful width of 1250 mm. The crossing platforms shall be of a minimum useful width of 1000 mm. For platforms of vertical equipment see PE-M-0100.06 and for platforms and stairs in tanks see PE-M-0100.07 (This standard drawing is indicated as an orientation, since the design of the stair shall be carried out specifically in each case). c) The platform sections which are removable must be limited to a weight of 1.50 kN. d) The platform and walkway floor shall generally be of hot galvanized steel grating according to what is specified in 2.6 (for fixing details see PE-M-0100.05). It should also be of another slip-proof metallic type (for instance: of checkered or embossed plate as specified or of perforated plate), with the previous approval of Repsol and as long as the essential requirement insofar as size of maximum opening of the holes (8 mm). e) Sufficient strength shall be provided in overhead platforms of service for heat exchangers in order to have the covers or the bottoms of these equipment items resting in any place of them, when disassembled during maintenance. f) If the floor can be under heavy live-loads during maintenance tasks (such as supporting larges pieces of equipment), a solution should be the execution of a concrete slab supported by steel beams, if this solution is more economic. g) All the cuts given to the grating for its adjustment shall be cold galvanized. h) All the openings in the floor of platforms for crossing of pipes or equipment which are not protected shall be protected with a skirting made up of a plate of 150 x 4 mm as maintenance protection. i) The ramps must have a maximum slope of 12% when their length is less than 3 meters, of 10% when the length is less than 10 meters or of 8% in the rest of cases.

4 DESING OF STEEL STRUCTURE.

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 12 of 18

j) The overhead platforms in nearby equipment must be communicated with each other, independently of the stairs or ladders which may be required by them to communicate with other platforms or with the ground floor. The zones or points to be communicated shall be agreed upon with the piping specialist. k) The spans of removable platforms require for maintenance and/or access for operation, shall be duly indicated on the drawings in the design phase and will be agreed upon with the piping specialists. 4.4. Stairs (in accordance with PE-M-0100.02) a) These ladders should be used preferentially to provide access to equipment or structures that support teams, which require frequent care and maintenance attention. b) The stairs shall have a minimum useful width of 1000 mm. c) Each span shall have a level difference exceeding 3600 mm. d) The depths of the intermediate platforms shall be as a minimum of 1000 mm. e) All the steps, in general, shall have the type of galvanized grating of 30 x 33 x 30 x 3 of slip-proof denting with galvanized clips and they shall be provided of electro-welded safety mesh of striated galvanized steel limiting the size of the opening to a maximum of 8 mm x 8 mm. They shall also be acceptable prior approval of Repsol, other options mentioned for platform floors of 4.3.d) of this specification. f) The steps, excluding the projecting ones, shall have a net step of 255 mm and the riser of 200 mm height. The width and height shall remain constant in each stair. See standard drawing PE-M-0100.02. g) The grating of the intermediate platforms (landing) shall carry the same slip-proof element in the edge as the rest of the standard steps. h) The sleepers or longitudinal stringers of the stairs which end at the ground level shall rest on a concrete base. See standard drawings PE-M-0100.02 and PE-Q-0100.03. i) For constructive details of spiral stairs for tanks, see standard drawing PE-M-0100.07. 4.5. Ladders (according to PE-M-0100.03) a) Outside of units, ladders shall not be installed of height exceeding 9.0 meters with respect to the ground level. Inside the units, ladders will not be installed of height exceeding 6.0 meters. Resting platforms shall be installed every 9.0 and 6.0 meters or fraction respectively, changing the location of the ladder so that it may be necessary to pass by the platform in order to have access to the following span. b) The minimum usable width of the vertical scales shall be of 410 mm and steps shall be constructed of flat or round corrugated steel (to be selected according to background information contained in the standard PE-M-0100.03), 20 mm in diameter, welded at 300 mm. For projects to be undertaken in Argentina, the minimum useful width shall be 450 mm s / Decree 351 of that country. c) Safety cages shall be installed in all the ladders which start in platforms or working levels above the floor (level 0.00) and in those which starting at the floor, have a length exceeding 3000 mm. The cage shall start at 2400 mm from the ground or starting level. d) The accesses to ladders from platforms shall be provided with safety movable handrails or with chains, if it is not possible to erect the movable handrail. e) Ladders shall be provided in all overhead work levels with access through stair on the opposite side to it, in order to allow an alternative escape in case of emergency and in all the overhead work levels so that distances exceeding 15.00 m do not have to be walked. f) The ladders shall end without skirting on the ground, unless otherwise specified. g) Ladders which go up to a platform and do not continue the rods shall be extended 1550 mm above such platform. h) The ladders and the cages must be free of obstructions. i) In the ladders starting from a platform, which width between ladder and handrails is less than 1200 mm, the vertical plates of the safety cage must be extended up to the handrail of the platform. (See standard drawing PE-M-0100.03).

4 DESING OF STEEL STRUCTURE.

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 13 of 18

j) The spacing between ladders and walls or obstacles on their upper part shall not be, in any case, of less than 200 mm. 4.6. Handrail (according to PE-M-0100.04) a) Banister are composed of:

Handrail Tubes 1-1/4" Sch. 40 Middle bar PL 50 x 6 Baseboard PL 150 x 6 Maximum Space between fences1500 mm Total height above ground 1100 mm Fences (for circular handrails) L 80.8 Fences (for straight handrails)L 80.8

b) Handrails shall project 150 mm from the front or riser of the first step c) The handrail height, from the theoretical line (line highlight of any step or grid level), is 1,100 mm. (See standard drawing PE-M-0100.04)

5.

FIREPROOFING Those structures that they require to be fireproofed according with the obtained conclusions of the potential fire areas layout, shall be marked on the structure drawing so that the manufacturer of the same can foresee the installation of the corresponding nuts or clips of fireproof fastening. The drawing of the structures to be fireproofed shall make reference to their specific fireproofing detail drawing in which the fireproofing scope, time of fire resistance, materials and other details regarding to the fireproofing shall be established according to the specification ED-N-02.00, Passive fire protection of structures, equipment and cable trays.

6.

PAINTING Regarding the finishing of the fabrication, in general, all the structural steel surfaces, including those that have to be fireproofed shall be treated in accordance with specified in the section and the corresponding table of specification ED-B-06.00 Paintings. Contact surfaces of all the connection to be performed in the field shall be painted according to the demands of the project. Special attention shall be paid to those surfaces of difficult access for the painting, once erected. The contact surfaces of the connections by friction (with tightening of the elements which join them) with high strength bolts, considered of critical sliding, shall not be painted; they shall only be blasted at the workshop according to the approved procedure. The surfaces which should be fireproofed, shall also receive the treatment specified in the ED-B-06.00 for the case in question. Before applying the corrosion-proof protection, all the sharp edges, burrs (including burrs from drill holes for bolts), welding projections, slab, milling barbs and other strange elements shall be eliminated from the surfaces. The galvanized bolts shall be used for the galvanized steel structure connections and the bolts without surface treatment for the rest of the steel works. The bolts, once placed, shall be painted in the same manner as the steel structure.

5 FIREPROOFING

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 14 of 18

It is required that all these activities be performed at the workshop, outside the Repsol installations. The finishing paint layer, in general, and for bolted structures in particular, shall also be applied at the workshop.

7.

PREPARATION FOR SHIPMENT Follow the indications in the specification ED-B-01.00, Preparation for the transportation of equipment and materials.

8. 8.1.

DESIGN DOCUMENTS AND RESPONSIBILITIES. General In general terms shall apply the requirements set out in ENV 1090-1 and ENV 1993-1 -1, concerning the required documentation for a project to supply, prefabrication and erection of steel structure as the delineation of responsibilities for the parties to the project (Engineering and Contractor) Independent of the previous thing and with particular character, also the requirements indicated in the following sections to be applied:

8.2.

Calculation report The calculations shall be performed according to this design specification and it will be presented as a calculation report with all the references for its checking, explanatory notes and Annexes that consider for their understanding and checking. The calculation reports shall be presented in the Spanish language and, in general, will be made up as follows: a) Cover page with Contract title and number/reference, with the name of author, the one who checks it and the one who approves it. b) Document table of contents (report). c) General notes and references. d) Structure description and its characteristics. e) Structural diagram. f) Load analysis g) Load combinations h) Stress analysis, indicating and describing clearly the applied formulas, symbols, units and references (bibliography and technical documentation), procedures of the software program, diagrams of acting forces in the different elements of the structure and the stress calculation. i) Analysis of deformations. j) Checking the state of stresses and deformations in accordance with the limitations established in the design code used and in this specification. k) Typology of joints and detail sketch of the connections. l) Typology of considered knots and sketch of detail of the special connections m) Annexes (if available and/or clarifies and/or it is necessary)

Inputs and outputs of data from the computer with clear references. description of the procedures of software programs used

7 PREPARATION FOR SHIPMENT

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 15 of 18

Single line drawings or the supplier, etc. Compiling of photocopies with technical documentation of unusual references.

8.3.

Drawings The drawings performed shall comply with the indications in the specification ED-A-10.00 and its addendum (former standard NRM-540) "Requirements for detail and FEL engineering drawings and documents- general part", and especially the Notes related in the G.3 Annexes and G.4 of the mentioned ED. The provider drawings (Contractor) shall be realised according to stipulated in specification ED-A-09.00 (the former standard NRM-542) Requirements for suppliers drawings and documentation.

8.4.

Responsibilities

8.4.1. Engineering responsibilities a) Engineering shall draft the following documents:

Single line drawings of the structures, with identification of the typology of joints (blocked or articulated) to consider in the design of each one of the connections, as well as the specific details (connection with requirements of expansion, special motherboards of pillars, joints, etc.) that considers necessary to in sequence facilitate to guarantee the due correspondence with the considered hypotheses of design. Calculation of the structure with specific indication of the loads and live loads considered, used norm, method of used calculation, calculation of the forces that act on the joints, as well as the analyses of stresses and deflections (Calculation Report) Documentation for offer request and subsequent supply and/or erection of this material, including the Conditions Documents which are deemed necessary (Requisition).

In the case of considering the purchase as a supply order and prefabrication, it shall carried out the corresponding purchasing requisition. In the case of considering as a contract of supply, prefabrication and assembly (preferable case) it shall perform the descriptive memory and compliments the corresponding list of prices. In both cases, it shall be measured or estimated the quantities of each one of the materials to be supplied (section profiles, handrails, grating, steps, etc.).

b) Engineering shall check and approve the construction workshop drawings presented by the Contractor of structures. c) Engineering shall check and approve the construction workshop drawings presented by the Contractor of structures, in what refers to its agreement with the delivered Engineering drawings and to the fulfilment with the settled down special requirements in the same, as well as far as the validation of the details of execution by this one developed. d) This checking shall not reduce in any case the Contractor's responsibility with respect to the fabricated material and/or supplied by itself, which shall resist the stresses and loads indicated by Engineering. e) The materials shall be inspected and approved by Engineering in accordance with the mentioned standards and with the requirements stated in the construction specification EC-M-52.00, whether the supply and prefabrication are awarded as an order or if it is performed inside of an erection contract. f) In those countries or autonomic communities in which the competent authority shall require the presentation of an official structural project, this shall be the responsibility of Engineering, having to be signed by a competent professional and certified by the official college or authorized organism. 8.4.2. Structure contractor responsibilities: a) The Contractor who is awarded the supply, pre-fabrication and erection of the structure shall apply all the requirements collected in the construction specification EC-M-52.00. b) Before starting any prefabrication work, the Contractor must:

8 Design documents and responsibilities.

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 16 of 18

To realise the design of the joints in accordance with the surrounding formulas of forces and the calculations facilitated by Engineering. It shall be able to use its own standard of connections according to typology, previously whenever they have been validated by Engineering and the requirements and special details facilitated by this one consider. Perform dimensional checks of the parts detailed by Engineering and immediately notify in case they find that some part has not been suitably designed. Prepare the construction drawings fully detailed and submit them to Engineering for their revision and/or approval.

c) Supply extension Contractor shall supply the profile sections, plates, bolts and nuts for the pre-fabrication and the erection of all the structures which have been ordered and which appear in Engineering single line drawings (stairs, inclined stairs, vertical stairs (ladders), safety cages, anchors bolts of the equipment to the structures, handrails, stringers, grating steps and skirting, grating floors, davits, railings for travelling cranes, beams for monorails, rolling tracks for travelling cranes, columns and beams for the construction of crane structures, etc. All the accrediting documentation of the conformity of the materials provided with the norm and contractual specifications (certificates of materials) All the accrediting documentation of the quality of the execution of the works according to the norm, specifications and sheets of contractual conditions (certificates of the used materials of contribution in the manufacture, welding procedures and homologations, assayer's certificates, x-rays, etc.) (Quality dossier). Edit "as-built drawings for prefabrication and assembly The following materials, unless otherwise indicated, will not be included in the supply of the Contractor:

Travelling crane. Shear legs for davits, travelling cranes, winches for monorails and any other lifting equipment. Anchor bolts (to anchoring concrete).

9.

LOCAL AND NATIONAL SPECIAL REQUIREMENTS. This paragraph refers to all the mandatory requirements, legal references, codes and statistic data relevant and applicable to the main countries where the firm acts, as well as to the special situation referring to the particular conditions of the country, without considering the information provided by the geotechnical study of the ground. Prior to starting the design activities, Engineering shall check that the last revisions or additions of all the reference documents on the codes and on the standards are available. The requirements of the country, legal references, codes and special data (such as technical specifications for materials locally applicable and allowable calculation stresses, safety coefficients and similar) shall be taken into account in accordance with the specifications of: ED-M-02.01 ED-M-02.02 ED-M-02.03 Loads for structural design. Addendum for Spain. Loads for structural design. Addendum for Argentina. Loads for structure design. Addendum for Peru

9 LOCAL AND NATIONAL SPECIAL REQUIREMENTS.

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 17 of 18

10.

STANDARDS AND SPECIFICATION OF REFERENCE

10.1. Repsol standard and technical specification This design specification shall apply together with the following Repsol specifications: 10.1.1.Design specifications ED-A-09-00 ED-A-10-00 ED-B-01.00 ED-B-06.00 ED-M-02.00 ED-N-02.00 ED-Q-01.00 ED-Q-01.01 ED-Q-01.02 ED-Q-01.03 ED-Q-02.00 ED-Q-02.01 ED-Q-03.00 Requirements for suppliers drawings and documentation. Requirements for detail and FEL engineering drawings and documents- general part. Preparation for transportation of equipment and materials Painting Loads for structural design Passive fire protection of structures equipment and cable trays Concrete Structures and Foundations Concrete Structures and Foundations. Addendum for deep foundations by piles and micropiles. Concrete Structures and Foundations. Addendum for reinforced concrete pipe racks Concrete Structures and Foundations. Addendum for design of concrete floor slabs Pavements and trenches. Pavements and trenches. Addendum for off-site roads and streets. Tanks bases and bounded areas

10.1.2.Construction specifications EC-M-52.00 Steel structures

Note: Due to the fact that on the issue date of this specification, some construction specifications may not have been updated in accordance with the new codes, as indicated in this document, here below is the correspondence existing between the new and the previous code: New code EC-M-52.00 10.1.3.Standards drawings PE-M-0100.01 PE-M-0100.02 PE-M-0100.03 PE-M-0100.04 PE-M-0100.05 PE-M-0100.06 PE-M-0100.07 PE-Q-0100.08 Steel structure - symbols Steel structure - stairway type A and B (3 sheets) Steel structure - vertical stairs (4 sheets) Steel structure - handrail in stairways (3 sheets) Steel structure - grating fastenings Platforms in vertical vessels (3 sheets) Circular stairways and platforms in tanks (4 sheets) Typical pedestals on pavement for stairs and ladders Old code EC-M52

10 STANDARDS AND SPECIFICATION OF REFERENCE

Document cod:

Design specification:

ED-M-01.00-I-05

Engineer Division Technical Department

STEEL STRUCTURES

STEEL STRUCTURES JANUARY 2010 Page 18 of 18

Note 1: Every REPSOL specification available in English language is identified in the REPSOL index of technical specifications ED-A-00.00 with the letter "I" as indicated in the following example: ED-Y-XX.XX ED-Y-XX.XX-I Spanish language. English language.

10.2. International codes and standards All the codes, standards and reference documents mentioned in their last revision, shall be considered as an integral part of this specification, as well as all the appendices, updating and reference documents therein included. In general all the standards, the rules, the codes and the special local and/or national requirements shall be complied with and shall prevail over others, if they are more restrictive than this specification or that the standard drawings of reference. The greater part of the local or national references is listed in the specifications addenda mentioned in paragraph 9 of this specification. In those situations neither covered by this specification nor by the other codes of reference, the internationally recognized and accepted codes shall also be applied. Generally, where it is applicable, is preferable to use European standards for design activities such as Eurocodes, ISO. In particular, the following shall be considered: Al least the following may be considered: Eurocode Eurocode 3 Desing of steel structures

AISC, American Institute of Steel Construction, latest edition of

Manual of steel Construction ASD, allowable stress design. Specification for the Design, Fabrication and Erection of Structural Steel for Building. Codes and Standards practice for steel buildings and bridges. Specification for structural joints using ASTM-A-325 or ASTM-A-490 bolts.

AWS, American Welding Society: Standard D.11 Structural Welding Code , latest edition. International Society of Building Officials: UBC Uniform Building Code.

10.3. Bibliography of reference. For those particular cases neither covered by this specification nor by the other codes of reference, the internationally well-known methods obtained of books shall have to be applied/technical documents and manuals. In this case, in the calculation memory, it must indicate clearly the author, the title and the edition. A photocopy of the compiling of the technical documentation which is not usually used should be attached to the calculation.

11.

TABLES INCLUDED IN THIS SPECIFICATION Table I Table II Minimum forces envelopes at connections Over-resistance criteria at connections

11 TABLES INCLUDED IN THIS SPECIFICATION

You might also like

- Codes Standards For YANBU ProjectDocument7 pagesCodes Standards For YANBU ProjectBehçet Serdal CanbazNo ratings yet

- 4C-01-02 Rev 2Document5 pages4C-01-02 Rev 2Christian Martínez G.No ratings yet

- (DS2-010112) Y:/Proyecto/2090/PLANOS/04-Piping/Estandares/En Trabajo/4C/4C-01.03 C Rev-0Document3 pages(DS2-010112) Y:/Proyecto/2090/PLANOS/04-Piping/Estandares/En Trabajo/4C/4C-01.03 C Rev-0Christian Martínez G.No ratings yet

- 1824 000 PI SPC 0003 - 7 - IFP - CleanedDocument22 pages1824 000 PI SPC 0003 - 7 - IFP - CleanedJudith HidalgoNo ratings yet

- Projects Engineering Department Engineering Standard: BES-L001Document42 pagesProjects Engineering Department Engineering Standard: BES-L001Fox Alpha DeltaNo ratings yet

- Dimensional & Material Standards For Piping ComponentsDocument3 pagesDimensional & Material Standards For Piping ComponentsaasattiNo ratings yet

- Configure SPM 2012 On Windows 7 LaptopDocument7 pagesConfigure SPM 2012 On Windows 7 Laptopcgf_arNo ratings yet

- Ed Q 01.00 I 02Document22 pagesEd Q 01.00 I 02joseellargoNo ratings yet

- AbrivationsDocument1 pageAbrivationsArkhan KhanNo ratings yet

- IFD - Issued For DesignDocument26 pagesIFD - Issued For DesignCristhian Solano BazalarNo ratings yet

- Piping Specification: Piping Class: A2ADocument30 pagesPiping Specification: Piping Class: A2AAbhijeet WayaseNo ratings yet

- 1 Engg DBD PP 010Document19 pages1 Engg DBD PP 010sanketNo ratings yet

- Guia de Linhas EUROPEAN PLASTICS WELDERDocument25 pagesGuia de Linhas EUROPEAN PLASTICS WELDERFernanda ChavesNo ratings yet

- BOA Group Axial Expansion JointsDocument24 pagesBOA Group Axial Expansion JointsA_ValsamisNo ratings yet

- Enhanced IsometricsDocument28 pagesEnhanced IsometricsGerry100% (1)

- Standards in The Valve IndustryDocument2 pagesStandards in The Valve IndustryessnelsonNo ratings yet

- Estandar de SoporteriaDocument74 pagesEstandar de SoporteriaRuth Tecsi TCNo ratings yet

- PIPES AND FITTINGS CATALOGUEDocument44 pagesPIPES AND FITTINGS CATALOGUEANV100% (1)

- Piping Material Class Comparison ChartDocument5 pagesPiping Material Class Comparison ChartAbu Akhmad BusanaNo ratings yet

- AB-031A Minimum Required Information Form The Submitter For Pressure Vessels Heat Exchangers and BoilersDocument1 pageAB-031A Minimum Required Information Form The Submitter For Pressure Vessels Heat Exchangers and BoilersTrung NguyenNo ratings yet

- AsmeDocument1 pageAsmesimplexmNo ratings yet

- Standards Scope PDFDocument6 pagesStandards Scope PDFaravindhcamNo ratings yet

- ISCO HDPE Product Catalogo-Fittings Section PDFDocument72 pagesISCO HDPE Product Catalogo-Fittings Section PDFJorge Santos RomeroNo ratings yet

- PIPING CODES AND STANDARDS GUIDEDocument299 pagesPIPING CODES AND STANDARDS GUIDENaresh Sharma0% (1)

- Welding Carbon Steel Piping StandardDocument3 pagesWelding Carbon Steel Piping StandardandhucaosNo ratings yet

- Advanced Isometric Configuration in AutoCADPlant3DDocument49 pagesAdvanced Isometric Configuration in AutoCADPlant3DRoobens SC Lara100% (1)

- PP Lined Pipe PDFDocument27 pagesPP Lined Pipe PDFNILADRI BHATTACHARYYANo ratings yet

- Asme B16.36 Int PDFDocument3 pagesAsme B16.36 Int PDFRuben Dario Mamani ArellanoNo ratings yet

- Solder Metal: Standard Specification ForDocument11 pagesSolder Metal: Standard Specification Foranurag yadavNo ratings yet

- Sec 05100 - Structural SteelDocument10 pagesSec 05100 - Structural Steeltiju2005hereNo ratings yet

- AP-NozzleTutorial R01 PDFDocument31 pagesAP-NozzleTutorial R01 PDFbalumagesh1979No ratings yet

- How To Create A Reinforcing Pad in Branch Table PDFDocument1 pageHow To Create A Reinforcing Pad in Branch Table PDFnirgaNo ratings yet

- Anexo I - Típicos de Soportes Metálicos PDFDocument174 pagesAnexo I - Típicos de Soportes Metálicos PDFAngely CanalesNo ratings yet

- Piping EngineeringDocument224 pagesPiping EngineeringMed RjebNo ratings yet

- Alias Isogen Text PosDocument5 pagesAlias Isogen Text PosBhartendu Patni100% (1)

- Lecture Notes Part 1 EN v331 Rev 0Document77 pagesLecture Notes Part 1 EN v331 Rev 0JackobNo ratings yet

- Onis Brochure GB 2015Document16 pagesOnis Brochure GB 2015r_chulinNo ratings yet

- Mechanical Piping and FittingsDocument19 pagesMechanical Piping and FittingsPinak ProjectsNo ratings yet

- Piping Material Class for Oman SRIP ProjectDocument1,507 pagesPiping Material Class for Oman SRIP ProjectMidhun K ChandraboseNo ratings yet

- Combining Spatial Components in Seismic DesignDocument11 pagesCombining Spatial Components in Seismic DesignjemanuelvNo ratings yet

- Cyclone Separator Removes Dust From Industrial AirDocument15 pagesCyclone Separator Removes Dust From Industrial AirChandra Sekar RNo ratings yet

- GB015 Disc Check Valve Technical Specifications and Performance DataDocument2 pagesGB015 Disc Check Valve Technical Specifications and Performance DataJessicalba LouNo ratings yet

- 6877-SM-LM-99-00-09014-A1A7 Document Number: Merlin Version 2.2 11-JAN-05 15:46:38 Detailed ReportDocument12 pages6877-SM-LM-99-00-09014-A1A7 Document Number: Merlin Version 2.2 11-JAN-05 15:46:38 Detailed ReportSalimNo ratings yet

- 347 Stainless Steel Class 2500 Piping SpecificationDocument3 pages347 Stainless Steel Class 2500 Piping SpecificationTrevor KanodeNo ratings yet

- The in Uence of The Bourdon Effect On Pipe Elbow: September 2016Document11 pagesThe in Uence of The Bourdon Effect On Pipe Elbow: September 2016araz_1985No ratings yet

- Pms Eil BPCLDocument79 pagesPms Eil BPCLManjunatha VNo ratings yet

- PFI ES 24 Pipe Bending and TollerancesDocument12 pagesPFI ES 24 Pipe Bending and TollerancesArcadio DuranNo ratings yet

- An Article On Tank Bulging Effect or Bulging Effect of Tank ShellsDocument4 pagesAn Article On Tank Bulging Effect or Bulging Effect of Tank ShellsiaftNo ratings yet

- PV Elite 2007 - Training On Oct-2014 HLDocument45 pagesPV Elite 2007 - Training On Oct-2014 HLmechanical engineeringNo ratings yet

- 01CB1S01Document5 pages01CB1S01raobabar21No ratings yet

- Gaurav Chudasama ContentDocument11 pagesGaurav Chudasama ContentDevashish JoshiNo ratings yet

- Piping Support Standard Specification (163-189)Document49 pagesPiping Support Standard Specification (163-189)Emilio HuertasNo ratings yet

- MS-6.1 Piping SupportsDocument19 pagesMS-6.1 Piping SupportsLe Thanh HaiNo ratings yet

- Pip STS05130 2018Document14 pagesPip STS05130 2018Syarief NahdiNo ratings yet

- PIP STF05501 Fixed Ladders Fabrication DetailsDocument24 pagesPIP STF05501 Fixed Ladders Fabrication Detailslashara100% (1)

- Pip Ars13120-2020Document29 pagesPip Ars13120-2020d-fbuser-93320248100% (1)

- SPECDocument24 pagesSPECnavinzhereNo ratings yet

- STF05521Document15 pagesSTF05521lingoalvaNo ratings yet

- 0000 15 DCR 0001 - eDocument52 pages0000 15 DCR 0001 - eTumboo TumbooNo ratings yet

- PIP STF05121 Anchor Fabrication and Installation Into ConcreteDocument6 pagesPIP STF05121 Anchor Fabrication and Installation Into Concretecarrimonn11No ratings yet

- PDExportToSP3D PDFDocument1 pagePDExportToSP3D PDFjoseellargoNo ratings yet

- Ibm Ds3400Document156 pagesIbm Ds3400Ivo MayerNo ratings yet

- Formulas Calculo Valv - Control PDFDocument3 pagesFormulas Calculo Valv - Control PDFjoseellargoNo ratings yet

- Ed G 01.03 I 01Document13 pagesEd G 01.03 I 01joseellargoNo ratings yet

- ReadmeDocument18 pagesReadmejoseellargoNo ratings yet

- PRN0124 - A DCTools 1-12-14Document3 pagesPRN0124 - A DCTools 1-12-14joseellargoNo ratings yet

- Manual EB 2512 de SAMSON PDFDocument2 pagesManual EB 2512 de SAMSON PDFjoseellargoNo ratings yet

- Gasket Design Criteria PDFDocument58 pagesGasket Design Criteria PDFjoseellargoNo ratings yet

- Release Notes 170 EnuDocument68 pagesRelease Notes 170 EnujoseellargoNo ratings yet

- HD G 0103.01 I 01Document4 pagesHD G 0103.01 I 01joseellargoNo ratings yet

- Ed Q 01.00 I 02Document22 pagesEd Q 01.00 I 02joseellargoNo ratings yet

- Autodesk Navisworks Simulate 2012 - Manual Del UsuarioDocument834 pagesAutodesk Navisworks Simulate 2012 - Manual Del UsuarioLeon HernandezNo ratings yet

- Ed D 02.00 I 01Document25 pagesEd D 02.00 I 01joseellargoNo ratings yet

- Storage Sphere Data SheetDocument1 pageStorage Sphere Data SheetjoseellargoNo ratings yet

- Programa Perfiles Estructurales SteelBookDocument232 pagesPrograma Perfiles Estructurales SteelBookAlberto Avendaño AguirreNo ratings yet

- PDMS EquipmentDocument53 pagesPDMS EquipmentPrasanta Kumar Behera100% (2)

- Hysys 3-2 User Guide 2 PDFDocument478 pagesHysys 3-2 User Guide 2 PDFMaycol SuárezNo ratings yet

- M05 Piping DesignDocument46 pagesM05 Piping DesignAnbalagan PrabhuNo ratings yet

- ASME B16.5 - Pipe Flanges PDFDocument157 pagesASME B16.5 - Pipe Flanges PDFRoniero BarrosoNo ratings yet

- M20 Advanced Drawing ProductionDocument180 pagesM20 Advanced Drawing ProductiondienhtNo ratings yet

- Training Manual: Basics & FunctionsDocument129 pagesTraining Manual: Basics & FunctionsRamesh KumarNo ratings yet

- 07-Sundyne Presentation Fs OringsDocument26 pages07-Sundyne Presentation Fs Oringsjoseellargo0% (1)

- 08-Sundyne Presentation - Fs Installation1Document15 pages08-Sundyne Presentation - Fs Installation1joseellargo100% (1)

- 09-Sundyne Presentation Fs ImprovementDocument39 pages09-Sundyne Presentation Fs Improvementjoseellargo100% (2)

- 04 Sundyne Presentation Fscontrol SystemDocument27 pages04 Sundyne Presentation Fscontrol SystemjoseellargoNo ratings yet

- 06-Sundyne Presentation Fs SealsDocument74 pages06-Sundyne Presentation Fs Sealsjoseellargo88% (8)

- 05-Sundyne Presentation Fs NPSHDocument35 pages05-Sundyne Presentation Fs NPSHjoseellargoNo ratings yet

- DeltaValve 2010 Customer VersionDocument97 pagesDeltaValve 2010 Customer VersionjoseellargoNo ratings yet

- University of Toronto Astronomy 101 Midterm Test QuestionsDocument6 pagesUniversity of Toronto Astronomy 101 Midterm Test QuestionsTrash RowzanNo ratings yet

- Understanding the Process of OogenesisDocument52 pagesUnderstanding the Process of OogenesisBharat ThapaNo ratings yet

- Greek MathemaDocument6 pagesGreek MathemaSebastian GhermanNo ratings yet

- CP I-O Modules PDFDocument91 pagesCP I-O Modules PDFVlad ChioreanNo ratings yet

- Mathematics: Full Marks Zero Marks: 0 in All Other CasesDocument31 pagesMathematics: Full Marks Zero Marks: 0 in All Other CasesAbhishek KumarNo ratings yet

- E5971 m4n68t-m Series ManualDocument0 pagesE5971 m4n68t-m Series ManualcamiloelosadaNo ratings yet

- NPC PrintPlay DeckDocument19 pagesNPC PrintPlay DeckBenjamin Pappa Bach FossumNo ratings yet

- Ajhgaa English O6Document28 pagesAjhgaa English O6dhirumeshkumarNo ratings yet

- Interpretation of Static Load Tests On The Burj Khalifa's FoundationDocument9 pagesInterpretation of Static Load Tests On The Burj Khalifa's FoundationMALIKNo ratings yet

- RUDDER PLATING DIAGRAMDocument1 pageRUDDER PLATING DIAGRAMMuhammad Ilham AlfiansyahNo ratings yet

- 21734Document67 pages21734Jeef100% (4)

- Compression Molding of Gypsum Blocks Using Ecological Brick MachinesDocument11 pagesCompression Molding of Gypsum Blocks Using Ecological Brick Machinessami fanuaelNo ratings yet

- FM200 Clean Agent System Installation GuideDocument6 pagesFM200 Clean Agent System Installation Guidehazro lizwan halimNo ratings yet

- BSC Ag Syllabus 5th DeanDocument150 pagesBSC Ag Syllabus 5th Deansaurabh rNo ratings yet

- Assignment 1 Systems Analysis - EME5601Document7 pagesAssignment 1 Systems Analysis - EME5601Travis GrantNo ratings yet

- 2G Call FlowDocument71 pages2G Call Flowm191084No ratings yet

- Solving Problems Involving Kinds of Propotion StudentDocument18 pagesSolving Problems Involving Kinds of Propotion StudentJohn Daniel BerdosNo ratings yet

- BCTG Guide-Love in The Time of CholeraDocument21 pagesBCTG Guide-Love in The Time of CholeraBernard MasiphaNo ratings yet

- Megger FORMDocument1 pageMegger FORMCOSMOPOLITAN M&ENo ratings yet

- TOEFL Module 1 - ReadingDocument65 pagesTOEFL Module 1 - ReadingImam NurviyantoNo ratings yet

- MA 102 Tutorial Sheet No. 2 on Limits and ContinuityDocument1 pageMA 102 Tutorial Sheet No. 2 on Limits and ContinuityKanan KumarNo ratings yet

- Olympian Generator Brochure 26-200 KvaDocument7 pagesOlympian Generator Brochure 26-200 KvaJawad RazaNo ratings yet

- WozairDocument4 pagesWozairRajakumar Bajji SubburamanNo ratings yet

- Lab 7 Activities Sheet Winter 2020Document7 pagesLab 7 Activities Sheet Winter 2020Mareline MendietaNo ratings yet

- 3 1Document4 pages3 1HakanNo ratings yet

- Diversification in Flavoured Milk: A ReviewDocument6 pagesDiversification in Flavoured Milk: A ReviewInternational Journal of Clinical and Biomedical Research (IJCBR)No ratings yet

- Comp7 - Answer Key - Dec. Exam - 1st SetDocument2 pagesComp7 - Answer Key - Dec. Exam - 1st SetHazel Joy LusellaNo ratings yet

- Bep Rev.c-New 20 MLD WTP, NathavaliDocument380 pagesBep Rev.c-New 20 MLD WTP, NathavaliAnonymous 7l8AIyq2No ratings yet

- TTBR 10 January 2024 LDocument22 pagesTTBR 10 January 2024 Lfossil.tractor0sNo ratings yet

- PLOTINUS: On Beauty (Essay On The Beautiful)Document12 pagesPLOTINUS: On Beauty (Essay On The Beautiful)Frederic LecutNo ratings yet