Professional Documents

Culture Documents

938H - JKM - Pi31638 PDF

Uploaded by

diegocatcaseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

938H - JKM - Pi31638 PDF

Uploaded by

diegocatcaseCopyright:

Available Formats

Media Search - REBE4858 - PRODUCT IMPROVEMENT PROGRAM FOR REPL...

Page 1 of 8

Shutdown SIS

Previous Screen

Product: NO EQUIPMENT SELECTED Model: NO EQUIPMENT SELECTED Configuration: NO EQUIPMENT SELECTED

Service Letter

PRODUCT IMPROVEMENT PROGRAM FOR REPLACING THE FUEL PIPE ON CERTAIN 938H WHEEL LOADERS AND IT38H INTEGRATED TOOLCARRIERS

Media Number - REBE4858- 00 Publication Date - 26/02/2009 Date Updated - 26/02/2009

CONFIDENTIAL

REBE4858-00

26Feb2009

U-85 A-75 D-72 O-75

Priority

PRODUCT IMPROVEMENT PROGRAM FOR REPLACING THE FUEL PIPE ON CERTAIN 938H WHEEL LOADERS AND IT38H INTEGRATED TOOLCARRIERS

1274 1261 127A 1252 NOTE:

PI31638

This Program must be administered as soon as possible. When reporting the repair, use "PI31638" as the Part Number and "7751" as the Group Number, "56" as the Warranty Claim Description Code and "T" as the SIMS Description code. Exception: If the repair is done after failure, use "PI31638" as the Part Number, "7751" as the Group Number, "96" as the Warranty Claim Description Code, and "Z" as the SIMS Description Code. The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst. The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date

NOTE:

NOTE:

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 27/2/2009

Media Search - REBE4858 - PRODUCT IMPROVEMENT PROGRAM FOR REPL...

Page 2 of 8

without first contacting your Caterpillar product analyst.

COMPLETION DATE

31Aug2009

TERMINATION DATE

28Feb2010

PROBLEM

There is evidence of twisting of the pipes at the final bend adjacent to the pipe flange. In some instances the twisting can cause a fatigue crack to occur in the pipe.

AFFECTED PRODUCT

Model 938H Identification Number JKM00151-00646, 655, 667, 669, 687, 714, 720-721 LKM00135-00280, 282-346, 352, 393 MJC00047-00506 JNJ00151-00334, 337, 343, 345, 350, 354

IT38H

PARTS NEEDED

Qty 1 1 1 Part Number 6V8397 2784138 3381398 Description SEAL-O-RING PROTECTION KT TUBE PUMP-FILTER

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 40% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

Replace the existing pipe with a similar pipe of new design. Refer to the attached Rework Procedure.

OWNER NOTIFICATION

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 27/2/2009

Media Search - REBE4858 - PRODUCT IMPROVEMENT PROGRAM FOR REPL...

Page 3 of 8

U.S. and Canadian owners will receive the attached Owner Notification.

SERVICE CLAIM ALLOWANCES

Caterpillar Parts % 100% Labor Hrs% 100% Dealer Suggested Parts % 0% Labor Hrs% 0% Customer Suggested Parts % 0% Labor Hrs% 0%

NOTE: This is a 1.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS XYZ Corporation 3240 Arrow Drive Anywhere, YZ 99999 PRIORITY - PRODUCT IMPROVEMENT PROGRAM FOR REPLACING THE FUEL PIPE ON CERTAIN 938H WHEEL LOADERS AND IT38H INTEGRATED TOOLCARRIERS MODELS INVOLVED - 938H Wheel Loaders and IT38H Integrated Toolcarriers Dear Caterpillar Product Owner: The fuel pipe needs to be replaced on the products listed below. The existing pipe can crack. You will not be charged for the service performed. Contact your local Caterpillar dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service. Please refer the dealer to their Service Letter dated 26Feb2009 when scheduling this service. We regret the inconvenience this may cause you, but urge you to have this service performed as soon as possible to prevent unscheduled downtime.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 27/2/2009

Media Search - REBE4858 - PRODUCT IMPROVEMENT PROGRAM FOR REPL...

Page 4 of 8

Caterpillar Inc. Identification #(s)

Attached to 26Feb2009 Service Letter

Rework Procedure

NOTE: Ensure that all adjustments and repairs that are carried out to the fuel system are performed by authorized personnel that have the correct training. Before beginning ANY work on the fuel system, refer to Operation and Maintenance Manual, "General Hazard Information and High Pressure Fuel Lines" for safety information. Refer to System Operation, Testing and Adjusting, "Cleanliness of Fuel System Components" for detailed information on the standards of cleanliness that must be observed during ALL work on the fuel system.

NOTE: Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Dispose of all fluids according to local regulations and mandates. Important Notes: Common rail fuel technology requires a high degree of cleanliness. It is therefore imperative to adhere to all cleanliness requirements within this rework instruction, for example re-using dirty caps will have a detrimental effect on product durability. Parts must be inspected prior to use to ensure capping is intact and parts are clean and undamaged. All new components should remain bagged and capped until immediately before use. Any fuel system components that are removed or exposed should be capped with new, clean caps to prevent dirt ingress, e.g. male connector when low-pressure pipe is removed. Use anti contamination kit part no. 2784138. Before attempting any work on the fuel system ensure that the engine is cleaned of any dirt that might contaminate the fuel system. Clean up any spilt fuel before undertaking further work. Check there is adequate clearance around all low-pressure pipes, and that any clamps are in place and correctly orientated. NO attempt should be made to clean / flush filter elements for re-use. DO NOT PRE-FILL THE FILTERS. Fuel can be hot after running. Care must be taken to ensure hot fuel does not come in contact with exposed skin. Allow engine to cool before undertaking any work.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 27/2/2009

Media Search - REBE4858 - PRODUCT IMPROVEMENT PROGRAM FOR REPL...

Page 5 of 8

1. Open hood. 2. Drain fuel from primary fuel filter into a suitable container for storage or disposal. 3. Disconnect fuel lines and harness at primary fuel filter. Plug/cap fuel lines and ports on filter head.

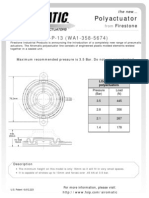

Image1.2.1 4. Remove primary fuel filter.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 27/2/2009

Media Search - REBE4858 - PRODUCT IMPROVEMENT PROGRAM FOR REPL...

Page 6 of 8

Image1.3.1 5. Disconnect fuel lines from secondary fuel filter. Plug/cap fuel lines and ports on filter head. Remove secondary fuel filter assembly.

Image1.4.1 6. Remove secondary fuel filter bracket.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 27/2/2009

Media Search - REBE4858 - PRODUCT IMPROVEMENT PROGRAM FOR REPL...

Page 7 of 8

Image1.5.1 7. Remove low pressure fuel supply tube from connector at fuel injection pump supply port. Install 338-1398 low-pressure fuel supply tube and 6V8397 O-ring seal to connector at fuel injection pump supply port. Tighten swivel nut to torque of 43 +5/-0 N-m.

Image1.6.1

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 27/2/2009

Media Search - REBE4858 - PRODUCT IMPROVEMENT PROGRAM FOR REPL...

Page 8 of 8

8. Install filter mounting bracket and secondary fuel filter assembly. 9. Connect 338-1398 fuel supply tube and 6V-8397 O-ring seal to connector at secondary fuel filter. Tighten swivel nut to torque of 43 +5/-0 N-m. 10. Reconnect fuel lines to secondary fuel filter. 11. Install primary fuel filter and reconnect fuel lines. 12. Connect harness to electric fuel priming pump. Prime the fuel system as describe in 938H/IT38H Operation and Maintenance Manual (Media #REHS8079). 13. Check for leaks and remedy as necessary. 14. Close hood.

Copyright 1993 - 2009 Caterpillar Inc. All Rights Reserved. Private Network For SIS Licensees.

Fri Feb 27 15:06:26 UTC-0300 2009

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sis... 27/2/2009

This document was created with Win2PDF available at http://www.daneprairie.com. The unregistered version of Win2PDF is for evaluation or non-commercial use only.

You might also like

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document24 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Eckard GuendelNo ratings yet

- TH 360-bDocument16 pagesTH 360-bFabian Ariza Ariza100% (1)

- Interactive Schematic ViewerDocument19 pagesInteractive Schematic ViewerFrancisco Alvarado HuenquiaoNo ratings yet

- Cd700 Accugrade For 320D, 322D, Electrical System 323D, 324D, 325D and 330D ExcavatorDocument2 pagesCd700 Accugrade For 320D, 322D, Electrical System 323D, 324D, 325D and 330D ExcavatorFranklin Beaumont100% (1)

- Other Hydraulic Components: Click The Volvo-Logo in The Lower Right Corner To Return To This Menu Main MenuDocument24 pagesOther Hydraulic Components: Click The Volvo-Logo in The Lower Right Corner To Return To This Menu Main MenuGustavo StenzelNo ratings yet

- Plano Electrico de M322CDocument16 pagesPlano Electrico de M322CNeisser Quiroz Grados100% (1)

- Uenr7134uenr7134-03 SisDocument43 pagesUenr7134uenr7134-03 SisMiguel PerezNo ratings yet

- Service Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Document5 pagesService Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Milorad Zelenovic100% (1)

- Esquema Vibro cb22bcDocument16 pagesEsquema Vibro cb22bcgalvis1020No ratings yet

- Ec460b 06Document17 pagesEc460b 06Muhammad Ali IdrisNo ratings yet

- (CLM076) Cat 432E & 442E Product BuletinDocument32 pages(CLM076) Cat 432E & 442E Product BuletinSabito KunnNo ratings yet

- Pavientadora CAT AP500E and BG500EDocument10 pagesPavientadora CAT AP500E and BG500Ealexander_1985100% (1)

- 980H PDFDocument2 pages980H PDFIgnacio Lazo JhsúsNo ratings yet

- 143H and 163H Motor Grader Hydraulic System Ripper AttachmentDocument2 pages143H and 163H Motor Grader Hydraulic System Ripper AttachmentMohamed Harb100% (1)

- Basic Electric & Hydraulic Wiring Diagram Small BulldozerDocument19 pagesBasic Electric & Hydraulic Wiring Diagram Small BulldozerWahab Abdul100% (2)

- Dynapac CA 250 Vibratory Roller Operation Manual/TITLEDocument28 pagesDynapac CA 250 Vibratory Roller Operation Manual/TITLEkikoNo ratings yet

- DocumentoDocument2 pagesDocumentoAlvaro FloresNo ratings yet

- 14M - R9J SchematicDocument6 pages14M - R9J SchematicDiki PurwandiNo ratings yet

- Caterpillar 325 SENR6239Document2 pagesCaterpillar 325 SENR6239Jaime Villalba FlorNo ratings yet

- Plano Hidraulico 980HDocument20 pagesPlano Hidraulico 980HEver Luis Toledo ChancaNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document31 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Richard Haison Chuima Ayvar100% (1)

- Case CX 300CDocument24 pagesCase CX 300CJim Lieb100% (1)

- 980F 3HK, 8CJ, 5XJ1-587Document2 pages980F 3HK, 8CJ, 5XJ1-587Rafa GarciaNo ratings yet

- D5N Track-Type Tractor Hydraulic System Caterpillar: UsageDocument6 pagesD5N Track-Type Tractor Hydraulic System Caterpillar: UsageMohamed WahiebNo ratings yet

- 345b Electrical System Schematic Used in Service Manual Senr1925 Aurora - Cat Machines Electrical SchematicDocument1 page345b Electrical System Schematic Used in Service Manual Senr1925 Aurora - Cat Machines Electrical SchematicAlexNo ratings yet

- 735B and 740B MANUAL DE MANUTENÇÃODocument3 pages735B and 740B MANUAL DE MANUTENÇÃOTom SouzaNo ratings yet

- Service Advisor CF and AG 5.2.201911Document1 pageService Advisor CF and AG 5.2.201911Dio FubyNo ratings yet

- 12M Motorgrader PDFDocument28 pages12M Motorgrader PDFJan HendriksNo ratings yet

- CAT 313 ЭлектросхемаDocument34 pagesCAT 313 Электросхемаmike100% (1)

- Challeger Testeo y AjusteDocument304 pagesChalleger Testeo y AjusteCarlos Irabedra100% (1)

- Salient Features:: Crawler DozerDocument4 pagesSalient Features:: Crawler DozerSAFE EARTHMOVERSNo ratings yet

- TD-25M Extra: Engine CoolingDocument7 pagesTD-25M Extra: Engine CoolingJoshwa SimamoraNo ratings yet

- Cat - Dcs.sis - Controller Cs-663e AefDocument2 pagesCat - Dcs.sis - Controller Cs-663e AefLhsan Rajawi0% (1)

- CX31 Transmision ElectricalDocument16 pagesCX31 Transmision Electricallenny.hutajuluNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document16 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768LuisMarceloNo ratings yet

- SEPD0921-00 New Software Is Now Available To Be Used For M300C MonitorsDocument4 pagesSEPD0921-00 New Software Is Now Available To Be Used For M300C MonitorsOsvaldo Mamani TiconaNo ratings yet

- Volvo L220F HybridDocument7 pagesVolvo L220F HybridForomaquinas100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document31 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768MarcioMartinhoFerreiraNo ratings yet

- Elec Main PDFDocument35 pagesElec Main PDFEl Hadji Malick SyNo ratings yet

- Diagrama CD PDFDocument9 pagesDiagrama CD PDFCarlos AranedaNo ratings yet

- MHL360 Technical DataDocument10 pagesMHL360 Technical DataRonaldo FernandesNo ratings yet

- Pilot Hydraulic System M315CDocument6 pagesPilot Hydraulic System M315CMEULEYE100% (1)

- 320D & 323D Excavator Hydraulic System - Attachment: Top ViewDocument2 pages320D & 323D Excavator Hydraulic System - Attachment: Top ViewTom Souza100% (1)

- Cat 963 CDocument20 pagesCat 963 CA2 BUDNo ratings yet

- Plano Eléctrico - TRACTOR D10T PDFDocument4 pagesPlano Eléctrico - TRACTOR D10T PDFHéctorReyesPinedaNo ratings yet

- 966H Electrical Schematic RENR6332Document4 pages966H Electrical Schematic RENR6332jhonny ysmaelNo ratings yet

- Manuel de Operador GTH4013 EXDocument225 pagesManuel de Operador GTH4013 EXjonny david martinez perezNo ratings yet

- 312B and 312B L Excavator Electrical System: Machine Harness Connector and Component LocationsDocument2 pages312B and 312B L Excavator Electrical System: Machine Harness Connector and Component LocationsomarNo ratings yet

- Diagnostic Trouble Codes: TroubleshootingDocument19 pagesDiagnostic Trouble Codes: TroubleshootingMbahdiro KolenxNo ratings yet

- Final OSB PRIMA - 4038 - 4738 - 3APRIL14Document232 pagesFinal OSB PRIMA - 4038 - 4738 - 3APRIL14sengottaiyanNo ratings yet

- Komatsu PW200-7 Wheeled - ExcavatorDocument16 pagesKomatsu PW200-7 Wheeled - ExcavatorЮлия Дам100% (3)

- 950G - 962G ESQUEMA HIDRAULICO - FlattenDocument12 pages950G - 962G ESQUEMA HIDRAULICO - FlattenAdolfo GarciaNo ratings yet

- Especificações TecnicasDocument20 pagesEspecificações TecnicasDanubio Rocha de LimaNo ratings yet

- 14H (I) PDFDocument20 pages14H (I) PDFSandoval Luis100% (2)

- Pw180-7e0 H55051-Up Disassembly & AssemblyDocument271 pagesPw180-7e0 H55051-Up Disassembly & Assemblydatphuong100% (1)

- Transmission Hydraulic System: Fonctionnement Des SystèmesDocument2 pagesTransmission Hydraulic System: Fonctionnement Des SystèmesEng-AhmedRashad100% (1)

- Pump GP - Main Hydraulic: 325D and 329D Excavator Hydraulic System - AttachmentDocument2 pagesPump GP - Main Hydraulic: 325D and 329D Excavator Hydraulic System - AttachmentDennis OlayaNo ratings yet

- Planetary 789 Salvage ProcedureDocument9 pagesPlanetary 789 Salvage ProcedureAlan GonzalezNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- FENIXGSM Precios Boxs Unlock Argentina Precios ACTUALIZADOSDocument2 pagesFENIXGSM Precios Boxs Unlock Argentina Precios ACTUALIZADOS✔Fenix GSM Oficial - Boxs Unlock en ArgentinaNo ratings yet

- Ce Const2 220kv CB Siemens 2012Document18 pagesCe Const2 220kv CB Siemens 2012erkamlakar2234100% (1)

- Chaderton Barbara AS400Document3 pagesChaderton Barbara AS400Sivakumar RajuNo ratings yet

- A High Performace HMIDocument50 pagesA High Performace HMIAnonymous FFMmIJy100% (1)

- NVOCC Public List as of May 23, 2022Document72 pagesNVOCC Public List as of May 23, 2022anubalanNo ratings yet

- Global Network - Hitachi Construction MachineryDocument19 pagesGlobal Network - Hitachi Construction MachineryluliyangzyNo ratings yet

- CDD Brochure Hospitality 2019 PDFDocument27 pagesCDD Brochure Hospitality 2019 PDFAna BalevaNo ratings yet

- TPM Administration PillarsDocument53 pagesTPM Administration Pillarskingathur26681No ratings yet

- TM2500+ Mobile Gas Turbine Package Technical Scope of SupplyDocument10 pagesTM2500+ Mobile Gas Turbine Package Technical Scope of SupplyMuhammad FazriansyahNo ratings yet

- Resume of Promila - MattuDocument3 pagesResume of Promila - MattuKyle EmersonNo ratings yet

- SAF1-YL SAF2-YL Pneumatic Barrel PumpsDocument20 pagesSAF1-YL SAF2-YL Pneumatic Barrel PumpsSri HariNo ratings yet

- Wheels of Thunder October 2012Document84 pagesWheels of Thunder October 2012Scott RobinsonNo ratings yet

- Packer Shoes Casing Manual Section 7Document22 pagesPacker Shoes Casing Manual Section 7Tong Chaipanyakul100% (1)

- Business Plan Summary for MGVCL FY 2011-16Document160 pagesBusiness Plan Summary for MGVCL FY 2011-16havejsnjNo ratings yet

- Lean Manufacturing Transformation for ShipyardsDocument12 pagesLean Manufacturing Transformation for ShipyardsLukman Tarigan SumatraNo ratings yet

- Wa1 358 5674Document30 pagesWa1 358 5674MROstop.comNo ratings yet

- Qualification of Autoclave & Hot Air OvenDocument26 pagesQualification of Autoclave & Hot Air OvenSharon Dsouza100% (1)

- Procedure for Hydro Testing PipingDocument7 pagesProcedure for Hydro Testing PipingM SaddikinNo ratings yet

- Doc13852681f290020160603122731 SKL User Guide V15 June 2016Document22 pagesDoc13852681f290020160603122731 SKL User Guide V15 June 2016Jose PulidoNo ratings yet

- Chapter 02 KendallDocument9 pagesChapter 02 KendallPaolo BagsicNo ratings yet

- Gabion Wall: Design Information SheetDocument3 pagesGabion Wall: Design Information SheetAnonymous MAQrYFQDzVNo ratings yet

- v1.0 Rishabh Engineering Case Study 25 Piping Stress Analysis For Vacuum Heater Ver23Dec15Document4 pagesv1.0 Rishabh Engineering Case Study 25 Piping Stress Analysis For Vacuum Heater Ver23Dec15JasonChong212No ratings yet

- Cochin Port Traffic - ProcessDocument6 pagesCochin Port Traffic - ProcessdhinakarajjNo ratings yet

- Software Testing Uharc LicenseDocument1 pageSoftware Testing Uharc Licenseaanur1gNo ratings yet

- Essentials of Conversion Optimization by ConversionXLDocument43 pagesEssentials of Conversion Optimization by ConversionXLJohn Sald100% (1)

- As NZS 1865 1997 Aluminium and Aluminium Alloys Drawn Wire Rod Bar and StripDocument7 pagesAs NZS 1865 1997 Aluminium and Aluminium Alloys Drawn Wire Rod Bar and StripYasser Hammad MohamedNo ratings yet

- Foldable Puzzle Mat Game MatDocument36 pagesFoldable Puzzle Mat Game MatAaronNo ratings yet

- PNG Standard Classification (Jan 09)Document124 pagesPNG Standard Classification (Jan 09)Christian BarNo ratings yet

- Hac PresentationDocument14 pagesHac PresentationARC Electrical Safety ConsultingNo ratings yet

- Implementing ISA S88 For A Discrete Process With The Bottom-Up ApproachDocument10 pagesImplementing ISA S88 For A Discrete Process With The Bottom-Up ApproachPaulo Ricardo Siqueira SoaresNo ratings yet