Professional Documents

Culture Documents

M08 Simulation Paper

Uploaded by

Pushkar FegadeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M08 Simulation Paper

Uploaded by

Pushkar FegadeCopyright:

Available Formats

DYNAMIC SIMULATION OF A SINGLE CYLINDER DIESEL ENGINE

Vidhate Yogesh Deoram Galande Prashant Arjun T.E.Mech S.N.D.COE.YEOLA Contact:-9623479147,976683369 E-!a"#:-yvidhate47@gmail.com prashantgalande@gmail.com

Abstract: he recent drive to reduce emissions and improved e!!iciency means that there is real need !or improved models !or the simulation o! direct-injection diesel engines. "ith a vie# to improving the transient !uel control$ a model o! the non-linear transient dynamics o! a generic direct-injection single cylinder diesel engine is developed in order to predict the instantaneous engine speed and tor%ue. he model can &e used as an engine simulator to aid diesel engines control system design and !ault diagnostics. he model does not use any empirical inputs$ and accurately predicts in-cycle variations o! engine parameter during transient response. he model treats the cylinder stro'es and the mani!old as thermodynamic control volume &y using the !illing and emptying method( solving energy and mass conservation e%uations #ith su& models !or com&ustion$ heat trans!er$ instantaneous !riction and dynamic analysis. )nertia variations and piston pin o!!set are ta'en into considerations. )n-cycle calculations are per!ormed at each cran' angle$ so the correct cran' angle o! ignition$ speed variations$ amount o! !uel and the air as #ell as the !uel-&urning rate are predicted. he model #ould &e implemented in *A +A,-.)*/+)01$ and simulation results o! &oth transient and steady state dynamics #ould &e presented.

Introduction: he modeling o! diesel engine has received much research attention. he models have &een used !or engine simulation and design. )n addition$ #ith the recent rapid advance it o! has microprocessor technology$

and the method o! 8haracteristics. hese thermodynamic engine models have &een developed !or engine design and per!ormance predictions$ and !e# have &een developed !or diesel engine control. he model consists o! several empirical alge&raic and !irst order di!!erential e%uations in order to achieve real time implementation. empirical electronic developed. test he main dra#&ac' o! data to !it model are this type o! model is the re%uirement o! e%uations. Diesel engine models !or control development he in-cylinder com&ustion

&ecome !easi&le to use these models !or real time applications$ such as state estimation$ control and !ault diagnostics. 2o#ever$ there needs to &e !urther research in modeling techni%ues$ to improve predictive accuracy$ &e!ore models can &e used !or estimation and control tas's. .everal investigators have studied diesel engine thermodynamic modeling. categories3 i4 +inear engine models relying on empirical steady-state data. hese models lin' data e5perimental he investigations can &e divided !or t#o

process is included &y using a single 9one model$ and a !illing emptying modeling techni%ue. )n several modi!ications to the model are proposed to cut do#n computational time and commercial rate cost. is not suita&le !or hese models diagnostic provide a tool !or engine simulation &ut !ormulations and in-cycle cran'sha!t angular speed variation predictions.

representing engine thermodynamics and gas !lo#s$ #ith simple dyanamic models o! the mechanical components. he major disadvantage o! such %uasi-linear models is their heavy reliance on e5perimental data. 6urthermore$ they poorly represent o! the transient response o! the engine. ii4 0on linear engine simulation models using the 6illing and 7mptying *ethod$

)nstruments to measure the 'ey per!ormance parameters A4 he tor%ue is measured &y a tor%ue sensor <6ig :4

Diesel 7ngine .imulation is needed in order to3 :. 8onduct diesel engine per!ormance optimi9ation ne# engine on or computer$ improving reduce engine development time and cost in designing per!ormance ;. As a part o! the vehicle simulation pac'age$ diesel engine model provide po#er to the vehicle simulation$ investigating the interaction &et#een engine and vehicle )n this project$ the simulation is done !or a .ingle 8ylinder and a heavy duty tur&ocharged multicylinder engine.

6ig :. ,4 )nstantaneous engine speed is

measured &y a hollo# sha!t encoder <6ig ;4$

84 2ollo# sha!t encoder <6ig. =4$

74 ur&ocharger speed is measured &y tur&ocharger speed sensor( e5haust emission is measured &y 6ast response 6)D. (OSC) #ass !o* s$nsor <6ig. >4 is used to measure inta'e air mass !lo# rate.

6ig =. D4 he gas pressure in each o! the si5 cylinders measured &y #ater-cooled !us" #ount$d in%c&!ind$r 'r$ssur$ transduc$r <6ig. 44

6ig>.

6ig 4.

Si#u!ation 8omputer program are developed to simulate the engine thermodynamics$ auto ignition and com&ustion. engine via. *atla&-.imulin'$ *atla&-.imulin'=$ !ig.a$&$c4 *atla&-.imulin';$ <as sho#n in he program is integrated !or the #hole

6ig c.

6ig a.

6ig &.

Co#'arison he simulation is done !or di!!erent engine operating modes. Predicted results$ ;$ =$ 4$ >$ have per!ect match #ith the e5perimental data.

8omparison &et#een predicted < ??? 4 and measured < ----4 cylinder pressure under !iring.

8omparison &et#een predicted < ??? 4 and measured < ----4 instantaneous cran'sha!t angular velocity under !iring.

R$ $r$nc$s: :4 he *ath#or'$ )nc.$ *A$ /.A *A +A,3 $e%e&ence '(")e$ :@@@. ;4 he *ath#or'$ )nc.$ *A$ /.A .)*/+)013 A *&o+&a! %o& S"!(#at"n+ D,na!"c S,-te!-$ :@@@. =4 A#eiri Y.2.$ "hid&orne B.6.$ and .eneviratne +.D. A mathematical transient model !or the dynamics o! a single cylinder diesel engine.)n .&oc. S"!(#at"onC@D$ pages :4>-:>:$ Yor'$ /1$ .ep.:@@D. 44 A#eiri Y.2.$ "hid&orne B.6.$ and .eneviratne +.D. 8omplete analytical model o! a single-cylinder diesel engine !or non-linear control and estimation$ :@@@. >4 2ey#ood B.,. /nte&na# co!0(-t"on En+"ne 1(n)a!enta#-. *cGra#-2ill$ 0e# Yor'$ ;EE4.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

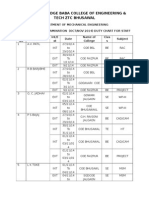

- Shri Sant Gadge Baba College of Engineering & Tech ZTC BhusawalDocument3 pagesShri Sant Gadge Baba College of Engineering & Tech ZTC BhusawalPushkar FegadeNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Bract's VIT Mechanical Engineering Course Structure and SyllabusDocument164 pagesBract's VIT Mechanical Engineering Course Structure and SyllabusPushkar FegadeNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Teaching Plan FM 2013-14Document3 pagesTeaching Plan FM 2013-14Pushkar FegadeNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Application of Cad in RP TechnologyffDocument13 pagesApplication of Cad in RP TechnologyffPushkar FegadeNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Mechanical Engineering TYDocument25 pagesMechanical Engineering TYShailendrasingh DikitNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Be Syllabus AutoDocument1 pageBe Syllabus AutoPushkar FegadeNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Sr. No. Name of Students Mobile Number RemarksDocument1 pageSr. No. Name of Students Mobile Number RemarksPushkar FegadeNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- P G ChaudharyDocument2 pagesP G ChaudharyPushkar FegadeNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Sr. No. Name of Students Mobile Number RemarksDocument1 pageSr. No. Name of Students Mobile Number RemarksPushkar FegadeNo ratings yet

- Teaching Plan: Automobile EnggDocument2 pagesTeaching Plan: Automobile EnggPushkar FegadeNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 16 Ivg Engfuelreg 11 hb130 FinalDocument24 pages16 Ivg Engfuelreg 11 hb130 FinalPushkar FegadeNo ratings yet

- Project On Bid ProcessDocument13 pagesProject On Bid ProcessPushkar Fegade100% (1)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Mech-Time Table First Sem Mech 13-14 Second Shift Legal DisplayDocument1 pageMech-Time Table First Sem Mech 13-14 Second Shift Legal DisplayPushkar FegadeNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Auto Teaching Plan NbaDocument4 pagesAuto Teaching Plan NbaPushkar FegadeNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Be Syllabus AutoDocument1 pageBe Syllabus AutoPushkar FegadeNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 2007-08 TE Engg MechDocument35 pages2007-08 TE Engg Mechmspiso2000No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- References: Jianhui Chen and Ning ZhongDocument2 pagesReferences: Jianhui Chen and Ning ZhongPushkar FegadeNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- CGDocument1 pageCGPushkar FegadeNo ratings yet

- Texomech14: Department of Mechanical EngineeringDocument1 pageTexomech14: Department of Mechanical EngineeringPushkar FegadeNo ratings yet

- Robo SoccerDocument1 pageRobo SoccerPushkar FegadeNo ratings yet

- AbbreviationDocument2 pagesAbbreviationPushkar FegadeNo ratings yet

- MCADocument19 pagesMCARajasekaran ChNo ratings yet

- 2 AbstractDocument1 page2 AbstractPushkar FegadeNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SE Thermodynamics Exam QuestionsDocument2 pagesSE Thermodynamics Exam QuestionsPushkar FegadeNo ratings yet

- 04oct Dec 2012Document8 pages04oct Dec 2012Pushkar FegadeNo ratings yet

- 01jan March 2011Document8 pages01jan March 2011Pushkar FegadeNo ratings yet

- Practical Internal Combustion Engine Laser Spark Plug: DevelopmentDocument5 pagesPractical Internal Combustion Engine Laser Spark Plug: DevelopmentPushkar FegadeNo ratings yet

- M16 - New Heat Exchanger Design Allows Improved CoolingDocument9 pagesM16 - New Heat Exchanger Design Allows Improved CoolingPushkar FegadeNo ratings yet

- m34 Shiv SanvedDocument9 pagesm34 Shiv SanvedPushkar FegadeNo ratings yet

- Hydrogène Internal Combustion Engine: MR - Yusuf Mulani Ms. Tejashri Khochare Collège of Engineering, PandharpurDocument11 pagesHydrogène Internal Combustion Engine: MR - Yusuf Mulani Ms. Tejashri Khochare Collège of Engineering, PandharpurPushkar FegadeNo ratings yet

- PIA and EmiratesDocument20 pagesPIA and EmiratesAyima AyimiNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- A Database For Handwritten Text Recognition ResearchDocument5 pagesA Database For Handwritten Text Recognition Researchtweety492No ratings yet

- ArWrt 2010Document10 pagesArWrt 2010Ratheesh KumarNo ratings yet

- ) Power System Analysis Toolbox (Document29 pages) Power System Analysis Toolbox (Mustadir Darusman B100% (1)

- Getting Started With Energyplus: Basic Concepts ManualDocument31 pagesGetting Started With Energyplus: Basic Concepts ManualMajdi Abdeljawad FlahNo ratings yet

- Using Pof Models To Predict System Reliability Considering Failure CollaborationDocument8 pagesUsing Pof Models To Predict System Reliability Considering Failure CollaborationKarthik KarunanidhiNo ratings yet

- City CarDocument4 pagesCity CarAkshay DixitNo ratings yet

- International Journal of Computer Science and Security (IJCSS), Volume (1), IssueDocument101 pagesInternational Journal of Computer Science and Security (IJCSS), Volume (1), IssueAI Coordinator - CSC JournalsNo ratings yet

- Combined Marine Propulsion Systems PDFDocument20 pagesCombined Marine Propulsion Systems PDFMerrelNo ratings yet

- Luger 2018 Redesign MMF ModelDocument28 pagesLuger 2018 Redesign MMF Modelcatur rizky rahmanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Creo Mold Flow AnalysisDocument2 pagesCreo Mold Flow AnalysisKishore KNo ratings yet

- Assessment CentresDocument42 pagesAssessment CentresnsnitinNo ratings yet

- Aspen Flare System Analyzer/ Flarenet: Gautham S Process EngineerDocument13 pagesAspen Flare System Analyzer/ Flarenet: Gautham S Process EngineerShamsMohdNo ratings yet

- Lammps Users ManualDocument1,191 pagesLammps Users ManualLuis Maria Pizarro Etchegoyen0% (1)

- Referencia Salama API Rp14Document138 pagesReferencia Salama API Rp14Silvina ZúñigaNo ratings yet

- ADAMS - BASIC - TRAINING - and - EXAMPLES - B5Document172 pagesADAMS - BASIC - TRAINING - and - EXAMPLES - B5dragishaNo ratings yet

- DLL in Agricrops 8Document3 pagesDLL in Agricrops 8Nelfa Plaza67% (3)

- S7-Plcsim Advanced Function Manual en-US en-USDocument399 pagesS7-Plcsim Advanced Function Manual en-US en-USaling alingNo ratings yet

- Heart Failure Simulation Reflection Rubric: Exceptional (100%) Proficient (50%) No Credit (0%) Content (10 Points)Document2 pagesHeart Failure Simulation Reflection Rubric: Exceptional (100%) Proficient (50%) No Credit (0%) Content (10 Points)clarimerNo ratings yet

- ResFrac Introduction HFTC Feb 2022Document23 pagesResFrac Introduction HFTC Feb 2022kumar abhishek singhNo ratings yet

- Final Syllabus 3rd & 4th Semester MBADocument58 pagesFinal Syllabus 3rd & 4th Semester MBASamir PandaNo ratings yet

- Design of Thermal Systems A Lost CourseDocument10 pagesDesign of Thermal Systems A Lost CourseviniciusschwabNo ratings yet

- Policy Analysis Survey and Simulation MethodsDocument18 pagesPolicy Analysis Survey and Simulation MethodsVaishnavi SuthraiNo ratings yet

- Reading Material - BIM Tools Matrix 2Document5 pagesReading Material - BIM Tools Matrix 2AhmadjakwarNo ratings yet

- Tools for Tour GuidingDocument44 pagesTools for Tour Guidingleonardo vidal tovarNo ratings yet

- Brochure SAEDocument20 pagesBrochure SAEKartavya BhagatNo ratings yet

- SPE 62917 Advances in Multilayer Reservoir Testing and Analysis Using Numerical Well Testing and Reservoir SimulationDocument14 pagesSPE 62917 Advances in Multilayer Reservoir Testing and Analysis Using Numerical Well Testing and Reservoir SimulationhusseinhshNo ratings yet

- Aspen Plus OptionsDocument2 pagesAspen Plus OptionsUmeshKumarSharmaRamamoorthiNo ratings yet

- AOCMF Brochure ISS5 A4 04 LRDocument16 pagesAOCMF Brochure ISS5 A4 04 LRDea Alberta SNo ratings yet

- Kingston University Wireless Communications Coursework GuideDocument2 pagesKingston University Wireless Communications Coursework GuideOntime BestwritersNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsFrom EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNo ratings yet

- ASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersFrom EverandASE A1 Engine Repair Study Guide: Complete Review & Test Prep For The ASE A1 Engine Repair Exam: With Three Full-Length Practice Tests & AnswersNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)