Professional Documents

Culture Documents

Notes Experimental Stress Analysis

Uploaded by

Rohit MunaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Notes Experimental Stress Analysis

Uploaded by

Rohit MunaCopyright:

Available Formats

UNIT 1

MEASUREMENTS

www.theo7.co.cc

www.jdrr5.co.cc

Measurement is the estimation of the

magnitude of some attribute of an object, such

as its length or weight, relative to a unit of

measurement.

Measurement usually involves using a

measuring instrument, such as a ruler or scale,

which is calibrated to compare the object to

some standard, such as a meter or a kilogram.

In science, however, where accurate

measurement is crucial, a measurement is

understood to have three parts: first, the

measurement itself, second, the margin of

error, and third, the confidence level -- that is,

the probability that the actual property of the

physical object is within the margin of error.

For example, we might measure the length of an

object as 2.34 meters plus or minus 0.01 meter,

with a 95% level of confidence.

www.theo7.co.cc www.jdrr5.co.cc

Accuracy and precision can not be considered

independently

A number can be accurate and not precise

A number can be precise and not accurate

The use of the number determines the

relative need for accuracy and precision

www.theo7.co.cc www.jdrr5.co.cc

Accuracy can be defined as how close a

number is to what it should be.

Accuracy is determined by comparing a

number to a known or accepted value.

www.theo7.co.cc www.jdrr5.co.cc

The number of decimal places assigned to the

measured number

It is sometimes defined as reproducibility

www.theo7.co.cc www.jdrr5.co.cc

Each of these statements is more accurate

and more precise than the one before it.

Statement two is more accurate and more

precise that statement one.

Statement three is more accurate and more

precise than statement two.

www.theo7.co.cc www.jdrr5.co.cc

How long is a piece of string?

Johnny measures the string at 2.63 cm.

Using the same ruler, Fred measures the string at

1.98 cm.

Who is most precise?

Who is most accurate?

www.theo7.co.cc www.jdrr5.co.cc

You can tell the precision of a number simply

by looking at it. The number of decimal

places gives the precision.

Accuracy on the other hand, depends on

comparing a number to a known value.

Therefore, you cannot simply look at a

number and tell if it is accurate

www.theo7.co.cc www.jdrr5.co.cc

Sensitivity is the study of how the

variation in the output of a model (numerical

or otherwise) can be apportioned,

qualitatively or quantitatively, to different

sources of variation.

www.theo7.co.cc www.jdrr5.co.cc

Range is used to indicate the difference

between the largest and smallest measured

values or set of data.

www.theo7.co.cc www.jdrr5.co.cc

EXTENSOMETERS

www.theo7.co.cc www.jdrr5.co.cc

Extensometer is a device that is used to

measure small/big changes in the length of

an object. It is useful for stress-strain

measurements. Its name comes from

"extension-meter". It was invented by Dr.

Charles Huston who described it in an

article in the Journal of the Franklin Institute

in 1879. Huston later gave the rights to

Fairbanks & Ewing, a major manufacturer of

testing machines and scales

www.theo7.co.cc www.jdrr5.co.cc

Mechanical

Optical

Acoustical

Electrical

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

A thin plastic base supports thin ribbons

of metal, joined in a zig-zag to form one

long electrically conductive strip. The

entire device is typically 10 mm long,

with 16 or more parallel metal bands.

When the plastic is stretched the wires

become longer, and thinner. The

electrical resistance therefore increases.

www.theo7.co.cc www.jdrr5.co.cc

ELECTRICAL RESISTANCE STRAIN GAUGES

www.theo7.co.cc www.jdrr5.co.cc

Electrical Properties of the Resistance

Gage

R=L/A

Where L= Length

= Resistively

A= Cross sectional area

www.theo7.co.cc www.jdrr5.co.cc

Constant Current Circuit

Ballast Circuit

www.theo7.co.cc www.jdrr5.co.cc

The Wheatstone Bridge is the most basic of a

number of useful electrical bridge circuits

that may be used to measure resistance,

capacitance or inductance. It also finds

applications in a number of circuits designed

to indicate resistance changes in transducers

such as resistance thermometers and

moisture gages

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

Temperature Effects in the Cage

Fluctuations in ambient and in operating

temperatures produce the most severe

effects generally dealt with in strain

measuring circuitry

The problems arise primarily from two

mechanisms:

(1) changes in the gage resistivity with

temperature

(2) temperature induced strain in the

gage element

www.theo7.co.cc www.jdrr5.co.cc

Temperature compensation of the strain

gage alone does not generally eliminate

thermal problems entirely.

Such compensation is rarely exact and

the differences must usually be eliminated

by careful configuration of the Wheatstone

Bridge circuit. The ability to make such

compensation is, in fact, one of the more

desirable features of this circuit

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

R

S

= total resistance of lead wires to gage

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

The output from a strain gage bridge is

proportional to changes in resistance of all of the arms.

In most situations, only one or two arms are active and

it is desirable to be able to provide some means of

assurance that the circuit is working properly.

The Wheatstone Bridge circuit is ideally suited for

this purpose because it is relatively easy to affect a

change in resistance in one or more arms that is

proportional to a known physical parameter.

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

Theroy of Photoelasticty

Example 1: Stress Opticon

Example 2: GFP 1000

www.theo7.co.cc www.jdrr5.co.cc

Natural

Light

Linear

Polarizer

Circular

Polarizer

( wave-

length)

Sample

Circular

Polarizer

Linear

Polarizer

Analyzer

Observer

www.theo7.co.cc www.jdrr5.co.cc

Ether Particles Vibration

Light Vector (Amplitude, Direction,

Phase Angle)

Components

www.theo7.co.cc www.jdrr5.co.cc

Nicols Prism:

Double Refraction

o

e

t t i i

n n u u sin sin =

e o

n n =

Calcium

Canada

Balsam

Polaroid:

Energy Loss: damper

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

nl

V

t

|

2

=

e o

n n =

Phase Angle:

2

t

| | =

e o

When

2

t

u | | < =

e o

?

If

Another 1/4

www.theo7.co.cc www.jdrr5.co.cc

When stressed

nl

V

t

|

2

=

V

Wave Length (different for colors)

If no stress

Different color light has different

phase angle, Rainbow appears.

www.theo7.co.cc www.jdrr5.co.cc

Colors

www.theo7.co.cc www.jdrr5.co.cc

Aluminum

Ring

Wrench

GFP 1000 is a strain measurement system based on photoelasticity

www.theo7.co.cc www.jdrr5.co.cc

Theory:

www.theo7.co.cc www.jdrr5.co.cc

c

1

c

1

Tension

Compression

Orientation of ellipse measures direction of c

1

Ellipticity measures magnitude

www.theo7.co.cc www.jdrr5.co.cc

1

2

3

4

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

NON DESTRUCTIVE TESTING

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

Introduction to NDT

Overview of Six Most

Common NDT Methods

Selected Applications

www.theo7.co.cc www.jdrr5.co.cc

The use of noninvasive

techniques to determine

the integrity of a material,

component or structure

or

quantitatively measure

some characteristic of

an object.

i.e. Inspect or measure without doing harm.

www.theo7.co.cc www.jdrr5.co.cc

Visual

www.theo7.co.cc www.jdrr5.co.cc

Flaw Detection and Evaluation

Leak Detection

Location Determination

Dimensional Measurements

Structure and Microstructure Characterization

Estimation of Mechanical and Physical

Properties

Stress (Strain) and Dynamic Response

Measurements

Material Sorting and Chemical Composition

Determination

Fluorescent penetrant indication

www.theo7.co.cc www.jdrr5.co.cc

To assist in product development

To screen or sort incoming materials

To monitor, improve or control manufacturing

processes

To verify proper processing such as heat treating

To verify proper assembly

To inspect for in-service damage

www.theo7.co.cc www.jdrr5.co.cc

Visual

Liquid Penetrant

Magnetic

Ultrasonic

Eddy Current

X-ray

www.theo7.co.cc www.jdrr5.co.cc

Most basic and common

inspection method.

Tools include

fiberscopes,

borescopes, magnifying

glasses and mirrors.

Robotic crawlers permit

observation in hazardous or

tight areas, such as air

ducts, reactors, pipelines.

Portable video inspection

unit with zoom allows

inspection of large tanks

and vessels, railroad tank

cars, sewer lines.

www.theo7.co.cc www.jdrr5.co.cc

A liquid with high surface wetting characteristics

is applied to the surface of the part and allowed

time to seep into surface breaking defects.

The excess liquid is removed from the surface

of the part.

A developer (powder) is applied to pull the

trapped penetrant out the defect and spread it

on the surface where it can be seen.

Visual inspection is the final step in the

process. The penetrant used is often loaded

with a fluorescent dye and the inspection is

done under UV light to increase test

sensitivity.

www.theo7.co.cc www.jdrr5.co.cc

The part is magnetized. Finely milled iron particles coated with a dye

pigment are then applied to the specimen. These particles are

attracted to magnetic flux leakage fields and will cluster to form an

indication directly over the discontinuity. This indication can be

visually detected under proper lighting conditions.

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

The radiation used in radiography

testing is a higher energy (shorter

wavelength) version of the

electromagnetic waves that we

see as visible light. The radiation can

come from an X-ray generator or a

radioactive source.

High Electrical Potential

Electrons

- +

X-ray Generator

or Radioactive

Source Creates

Radiation

Exposure Recording Device

Radiation

Penetrate

the Sample

www.theo7.co.cc www.jdrr5.co.cc

Top view of developed film

X-ray film

The part is placed between the

radiation source and a piece of film.

The part will stop some of the

radiation. Thicker and more dense

area will stop more of the radiation.

= more exposure

= less exposure

The film darkness

(density) will vary with

the amount of radiation

reaching the film

through the test object.

www.theo7.co.cc www.jdrr5.co.cc

www.theo7.co.cc www.jdrr5.co.cc

Conductive

material

Coil

Coil's

magnetic field

Eddy

currents

Eddy current's

magnetic field

www.theo7.co.cc www.jdrr5.co.cc

Eddy current testing is particularly well suited for detecting surface

cracks but can also be used to make electrical conductivity and

coating thickness measurements. Here a small surface probe is

scanned over the part surface in an attempt to detect a crack.

www.theo7.co.cc www.jdrr5.co.cc

High frequency sound waves are introduced into a

material and they are reflected back from surfaces or

flaws.

Reflected sound energy is displayed versus time, and

inspector can visualize a cross section of the specimen

showing the depth of features that reflect sound.

f

plate

crack

0 2 4 6 8 10

initial

pulse

crack

echo

back surface

echo

Oscilloscope, or flaw

detector screen

www.theo7.co.cc www.jdrr5.co.cc

Gray scale image produced using

the sound reflected from the front

surface of the coin

Gray scale image produced using the

sound reflected from the back surface

of the coin (inspected from heads side)

High resolution images can be produced by plotting

signal strength or time-of-flight using a computer-

controlled scanning system.

www.theo7.co.cc www.jdrr5.co.cc

Inspection of Raw

Products

Inspection Following

Secondary Processing

In-Services Damage

Inspection

www.theo7.co.cc www.jdrr5.co.cc

Forgings,

Castings,

Extrusions,

etc.

www.theo7.co.cc www.jdrr5.co.cc

Machining

Welding

Grinding

Heat treating

Plating

etc.

www.theo7.co.cc www.jdrr5.co.cc

Cracking

Corrosion

Erosion/Wear

Heat Damage

etc.

www.theo7.co.cc www.jdrr5.co.cc

Probe

Signals produced

by various

amounts of

corrosion

thinning.

Periodically, power plants are

shutdown for inspection.

Inspectors feed eddy current

probes into heat exchanger

tubes to check for corrosion

damage.

Pipe with damage

www.theo7.co.cc www.jdrr5.co.cc

Electromagnetic devices

and visual inspections are

used to find broken wires

and other damage to the

wire rope that is used in

chairlifts, cranes and other

lifting devices.

www.theo7.co.cc www.jdrr5.co.cc

Robotic crawlers

use ultrasound to

inspect the walls of

large above ground

tanks for signs of

thinning due to

corrosion.

Cameras on

long

articulating

arms are used

to inspect

underground

storage tanks

for damage.

www.theo7.co.cc www.jdrr5.co.cc

Nondestructive testing is used

extensively during the

manufacturing of aircraft.

NDT is also used to find cracks

and corrosion damage during

operation of the aircraft.

A fatigue crack that started at

the site of a lightning strike is

shown below.

www.theo7.co.cc www.jdrr5.co.cc

Aircraft engines are overhauled

after being in service for a period

of time.

They are completely disassembled,

cleaned, inspected and then

reassembled.

Fluorescent penetrant inspection

is used to check many of the parts

for cracking.

www.theo7.co.cc www.jdrr5.co.cc

Sioux City, Iowa, July 19, 1989

A defect that went

undetected in an

engine disk was

responsible for

the crash of

United Flight 232.

www.theo7.co.cc www.jdrr5.co.cc

The failure of a pressure vessel

can result in the rapid release of

a large amount of energy. To

protect against this dangerous

event, the tanks are inspected

using radiography and

ultrasonic testing.

www.theo7.co.cc www.jdrr5.co.cc

Special cars are used to

inspect thousands of miles

of rail to find cracks that

could lead to a derailment.

www.theo7.co.cc www.jdrr5.co.cc

The US has 578,000

highway bridges.

Corrosion, cracking and

other damage can all

affect a bridges

performance.

The collapse of the Silver

Bridge in 1967 resulted in

loss of 47 lives.

Bridges get a visual

inspection about every 2

years.

Some bridges are fitted

with acoustic emission

sensors that listen for

sounds of cracks growing.

www.theo7.co.cc www.jdrr5.co.cc

NDT is used to inspect pipelines

to prevent leaks that could

damage the environment. Visual

inspection, radiography and

electromagnetic testing are some

of the NDT methods used.

Remote visual inspection using

a robotic crawler.

Radiography of weld joints.

Magnetic flux leakage inspection.

This device, known as a pig, is

placed in the pipeline and collects

data on the condition of the pipe as it

is pushed along by whatever is being

transported.

www.theo7.co.cc www.jdrr5.co.cc

Boeing employees in Philadelphia were given the privilege of evaluating the Liberty Bell

for damage using NDT techniques. Eddy current methods were used to measure the

electrical conductivity of the Bell's bronze casing at various points to evaluate its

uniformity.

www.theo7.co.cc www.jdrr5.co.cc

For more PowerPoint presentations, Question

bank, model question papers, two marks with

answers

Visit, www.jdrr5.co.cc

For any help regarding studies contact

Mail id : dineshrajaruban@gmail.com

Mobile no : 9789513519

www.theo7.co.cc www.jdrr5.co.cc

You might also like

- Fatigue 2marks N 16 MarksDocument53 pagesFatigue 2marks N 16 MarksAdrian James90% (10)

- Sudharsan Engineering College: Department of Mechanical EngineeringDocument34 pagesSudharsan Engineering College: Department of Mechanical EngineeringOmar BouledrouaNo ratings yet

- 04a Torsion of ThinWalled StructuresDocument35 pages04a Torsion of ThinWalled StructuresYan NingNo ratings yet

- Flow Zone Indicator Guided Workflows For PetrelDocument11 pagesFlow Zone Indicator Guided Workflows For PetrelAiwarikiaar100% (1)

- Ansys Lab Procedure and Viva QDocument117 pagesAnsys Lab Procedure and Viva QHarshith kumarNo ratings yet

- Subject Code / Name: ME6504 Metrology and Measurements Unit-I Basics of Metrology Part-A (2 Marks)Document4 pagesSubject Code / Name: ME6504 Metrology and Measurements Unit-I Basics of Metrology Part-A (2 Marks)Rohit MunaNo ratings yet

- Shape Functions in Finite Element Method: HandoutsDocument22 pagesShape Functions in Finite Element Method: HandoutssyampnaiduNo ratings yet

- Finite Difference Buckling Analysis of Non Uniform ColumnsDocument8 pagesFinite Difference Buckling Analysis of Non Uniform ColumnsumeshapkNo ratings yet

- Mech Vii Experimental Stress Analysis (10me761) Notes 1Document127 pagesMech Vii Experimental Stress Analysis (10me761) Notes 1Praveen Palthur67% (3)

- Iare Sa-Ii Lecture Notes PDFDocument195 pagesIare Sa-Ii Lecture Notes PDFAkhilesh B.M100% (1)

- Fatigue Failure Is Characterized by Three StagesDocument37 pagesFatigue Failure Is Characterized by Three StagesRohit MunaNo ratings yet

- Maritime Management SystemsDocument105 pagesMaritime Management SystemsAndika AntakaNo ratings yet

- Univ Lab Set - 1 Me8711 Sa LabDocument5 pagesUniv Lab Set - 1 Me8711 Sa LabAsst.Prof MECH100% (1)

- Fea Lab Manual 18mel68 July 2021Document49 pagesFea Lab Manual 18mel68 July 2021md bashirul haqueNo ratings yet

- Experimental Stress Analysis - UnitwiseDocument4 pagesExperimental Stress Analysis - UnitwiseSabik NainarNo ratings yet

- Esa - Unit 1 PDFDocument52 pagesEsa - Unit 1 PDFHarish MathiazhahanNo ratings yet

- Tom New SyllabusDocument13 pagesTom New SyllabusshekhadNo ratings yet

- Question Paper CodeDocument2 pagesQuestion Paper Codesathesh waranNo ratings yet

- Aircraft Structures Lab ManualDocument43 pagesAircraft Structures Lab ManualVinod BalakrishnanNo ratings yet

- SA Lab ManualDocument32 pagesSA Lab ManualAnonymous nSvmh3s67% (3)

- Virtual LaboratoryDocument14 pagesVirtual LaboratoryArie Febry Fardheny, MTNo ratings yet

- AE6601 - Finite Element Method Two MarksDocument5 pagesAE6601 - Finite Element Method Two MarksAravind Phoenix100% (2)

- FinalDocument22 pagesFinalAashis DahalNo ratings yet

- ME8692-Finite Element AnalysisDocument22 pagesME8692-Finite Element AnalysisPrabhu RSNo ratings yet

- 300+ (UPDATED) Strength of Materials Interview QuestionsDocument4 pages300+ (UPDATED) Strength of Materials Interview QuestionsBaydaa QaidyNo ratings yet

- What Is Meant by Lack of Fit in A TrussDocument1 pageWhat Is Meant by Lack of Fit in A TrussTHEJSWI100% (1)

- Experimental Stress Analysis by Sadhu Singh Text P 59a1a3c11723dd234ac96a47Document2 pagesExperimental Stress Analysis by Sadhu Singh Text P 59a1a3c11723dd234ac96a47Markanday Giri33% (3)

- Copyjjjj of Viva Voice QuestionDocument6 pagesCopyjjjj of Viva Voice QuestionVigy BossNo ratings yet

- FEM Notes - IIT KharagpurDocument308 pagesFEM Notes - IIT KharagpurAditya Singh100% (1)

- Cargo Adp-2Document100 pagesCargo Adp-2Adrian James100% (3)

- Experimental Stress Analysis Important QuestionsDocument4 pagesExperimental Stress Analysis Important Questionsmatrixrajiv34No ratings yet

- Ansys Lab Record Experiments-April-2012Document41 pagesAnsys Lab Record Experiments-April-201209gamb4005No ratings yet

- Ae8511 Aircraft Structures LaboratoryDocument2 pagesAe8511 Aircraft Structures Laboratorykarthipriya100% (2)

- Experimental Stress Analysis PDFDocument2 pagesExperimental Stress Analysis PDFKaren0% (4)

- Ce 8381som Lab ManualDocument31 pagesCe 8381som Lab ManualAERO JPR50% (2)

- Model Zeroth Review PPT PhotoDocument14 pagesModel Zeroth Review PPT PhotoLovely Mohan0% (1)

- Structural Analysis II 2marksDocument17 pagesStructural Analysis II 2marksvik1510No ratings yet

- Bcme NotesDocument112 pagesBcme NotesSms RajaNo ratings yet

- Agemp Model 2 ANSWER KEYDocument13 pagesAgemp Model 2 ANSWER KEYAnonymous P0rZmU100% (2)

- Dynamic Analysis FEMDocument9 pagesDynamic Analysis FEMbhanuNo ratings yet

- Dynamics of MachineryDocument92 pagesDynamics of Machinerygkgj100% (1)

- Fluid Power Automation: Unit-IDocument36 pagesFluid Power Automation: Unit-ISelva BabuNo ratings yet

- Experimental Techniques & Instrumentation Unit 1Document94 pagesExperimental Techniques & Instrumentation Unit 1Mohan VikiNo ratings yet

- Exam Paper RGPV MMPD First SemDocument45 pagesExam Paper RGPV MMPD First Semmayuresh_6767No ratings yet

- Catia V5 Questions and AnswersDocument3 pagesCatia V5 Questions and Answerspriyankar007No ratings yet

- Strength of Metirials QUSDocument5 pagesStrength of Metirials QUSraviNo ratings yet

- Needham and Gerarads MethodsDocument3 pagesNeedham and Gerarads MethodsRaj Kumar0% (1)

- Question Paper CodeDocument2 pagesQuestion Paper Codesathesh waranNo ratings yet

- Kinematic Synthesis of MechanismsDocument25 pagesKinematic Synthesis of MechanismsHarshan Arumugam75% (4)

- Propulsion - II 2 Marks by Nambi RajanDocument12 pagesPropulsion - II 2 Marks by Nambi RajanNambi RajanNo ratings yet

- CE8502 Structural Analysis IDocument27 pagesCE8502 Structural Analysis Ishanmugapriyasudhasw100% (1)

- BITSF110 Course HandoutDocument3 pagesBITSF110 Course HandoutultimateNo ratings yet

- Chapter 2-2Document28 pagesChapter 2-2PransuNo ratings yet

- 2 MarksDocument15 pages2 MarksVignesh Durai100% (2)

- Experimental Stress Analysis Two Marks With AnswersDocument24 pagesExperimental Stress Analysis Two Marks With Answersmatrixrajiv34100% (2)

- Finite Element Analysis MCQDocument13 pagesFinite Element Analysis MCQShiva KarthikeyanNo ratings yet

- FEA QuizDocument48 pagesFEA QuizKiran Kumar Yadav100% (1)

- Unit 4 Symmetrical FaultsDocument18 pagesUnit 4 Symmetrical FaultsjayababNo ratings yet

- Unit-III, Advanced Mechanisms PDFDocument41 pagesUnit-III, Advanced Mechanisms PDFvamsi krishnaNo ratings yet

- Design For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringDocument22 pagesDesign For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringjonNo ratings yet

- Strain Measurement MEASUREMENT EXPERIMENT: 1. ObjectDocument7 pagesStrain Measurement MEASUREMENT EXPERIMENT: 1. ObjectKenny KenzoNo ratings yet

- Strain Gauge 1Document26 pagesStrain Gauge 1ULFAT HUSSAINNo ratings yet

- Strain GaugeDocument7 pagesStrain GaugeNicholas Fok0% (5)

- Fi LiDocument17 pagesFi LiFikaduNo ratings yet

- Applications of Quantum and Classical Connections in Modeling Atomic, Molecular and Electrodynamic SystemsFrom EverandApplications of Quantum and Classical Connections in Modeling Atomic, Molecular and Electrodynamic SystemsNo ratings yet

- Lab AlterDocument1 pageLab AlterRohit MunaNo ratings yet

- Em Internal QuestionsDocument3 pagesEm Internal QuestionsRohit MunaNo ratings yet

- BCM Test 2 QuestionsDocument1 pageBCM Test 2 QuestionsRohit MunaNo ratings yet

- P.A. College of Engineering and Technology Palladam Road, Pollachi - 642 002 Department of Mechanical EngineeringDocument26 pagesP.A. College of Engineering and Technology Palladam Road, Pollachi - 642 002 Department of Mechanical EngineeringRohit MunaNo ratings yet

- Emm Question Paper Model ExamDocument4 pagesEmm Question Paper Model ExamRohit MunaNo ratings yet

- Electric Discharge MachiningDocument32 pagesElectric Discharge MachiningRohit MunaNo ratings yet

- Unit II and III Comb CKTDocument35 pagesUnit II and III Comb CKTRohit MunaNo ratings yet

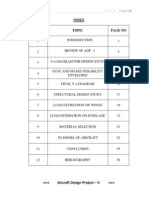

- Aircraft Design Lab - I - Super Jumbo AircraftDocument72 pagesAircraft Design Lab - I - Super Jumbo AircraftRohit MunaNo ratings yet

- Engineering Thermo II ADocument1 pageEngineering Thermo II ARohit MunaNo ratings yet

- My Aircraft Design Project - IDocument132 pagesMy Aircraft Design Project - IRohit MunaNo ratings yet

- Adl 1Document74 pagesAdl 1Rohit MunaNo ratings yet

- CIM Test-10Document1 pageCIM Test-10Rohit MunaNo ratings yet

- Photoelasticity ManualDocument31 pagesPhotoelasticity ManualhimanshusekharpandaNo ratings yet

- Asr IDocument2 pagesAsr IRohit MunaNo ratings yet

- WTTDocument1 pageWTTRohit MunaNo ratings yet

- Adp II Batch III ReportDocument47 pagesAdp II Batch III ReportRohit MunaNo ratings yet

- Aero CollegesDocument3 pagesAero CollegesRohit MunaNo ratings yet

- EsaDocument1 pageEsaRohit MunaNo ratings yet

- Experimental Stress AnalysisDocument18 pagesExperimental Stress AnalysisRohit MunaNo ratings yet

- Experimental Strain AnalysisDocument10 pagesExperimental Strain AnalysisAman BansalNo ratings yet

- Index: Aircraft Design Project - IIDocument56 pagesIndex: Aircraft Design Project - IIRohit MunaNo ratings yet

- Time Table ODDDocument18 pagesTime Table ODDRohit MunaNo ratings yet

- Ae2201 NotesDocument32 pagesAe2201 NotesRohit MunaNo ratings yet

- Shearing and Torsion (And Bending) of Shell Beams: Unit 15Document45 pagesShearing and Torsion (And Bending) of Shell Beams: Unit 15Rohit MunaNo ratings yet

- Textofvideo - Nptel.iitm - Ac.in 112106068 Lec18Document23 pagesTextofvideo - Nptel.iitm - Ac.in 112106068 Lec18Rohit MunaNo ratings yet

- Eg Qbank2008 - MechDocument8 pagesEg Qbank2008 - MechSaranya PandiarajNo ratings yet

- Esterification Oil of WintergreenDocument8 pagesEsterification Oil of WintergreenMaria MahusayNo ratings yet

- Entero SequencesDocument12 pagesEntero SequencesKelvin SueyzyNo ratings yet

- Beastlikebalsam - Muscle BuildingDocument10 pagesBeastlikebalsam - Muscle BuildingBalsam LaaroussiNo ratings yet

- Clinical Biomechanics: Leigh W. Marshall, Stuart M. McgillDocument4 pagesClinical Biomechanics: Leigh W. Marshall, Stuart M. McgillMichael JunNo ratings yet

- Chap 4 - Basic Principles of ElectricityDocument31 pagesChap 4 - Basic Principles of ElectricityAdiseshuMiddeNo ratings yet

- Karl MarxDocument4 pagesKarl Marxeirvine noah isidroNo ratings yet

- Comparative Study On Serial and Parallel Manipulators - ReviewDocument23 pagesComparative Study On Serial and Parallel Manipulators - ReviewShaik Himam SahebNo ratings yet

- V. Jovicic and M. R. Coop1997 - Stiffness, Coarse Grained Soils, Small StrainsDocument17 pagesV. Jovicic and M. R. Coop1997 - Stiffness, Coarse Grained Soils, Small StrainsxiangyugeotechNo ratings yet

- Statics: Vector Mechanics For EngineersDocument39 pagesStatics: Vector Mechanics For EngineersVijay KumarNo ratings yet

- YoungMan EN131 GUIDEDocument16 pagesYoungMan EN131 GUIDErcpawar100% (1)

- 5 Contracting Activity and Technical Staff RequirementsDocument2 pages5 Contracting Activity and Technical Staff RequirementsDaniyar KussainovNo ratings yet

- Orbitol Motor TMTHWDocument20 pagesOrbitol Motor TMTHWRodolfo ErenoNo ratings yet

- Veronte Autopilot Kit DatasheetDocument2 pagesVeronte Autopilot Kit DatasheetEkmedzicNo ratings yet

- Case AnalysisDocument2 pagesCase AnalysisJessa San PedroNo ratings yet

- Chillers VoltasDocument4 pagesChillers Voltasanil shuklaNo ratings yet

- Sap Ewm OverviewDocument11 pagesSap Ewm OverviewsachinNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Document2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Khyle Laurenz DuroNo ratings yet

- 1.1.3.12 Lab - Diagram A Real-World ProcessDocument3 pages1.1.3.12 Lab - Diagram A Real-World ProcessHalima AqraaNo ratings yet

- Chapter 7 - Stress - TransformationsDocument21 pagesChapter 7 - Stress - TransformationsroselleNo ratings yet

- OPTCL-Fin-Bhw-12Document51 pagesOPTCL-Fin-Bhw-12Bimal Kumar DashNo ratings yet

- Line Differential Protection Red670Document8 pagesLine Differential Protection Red670igorsfaceNo ratings yet

- The Practical Reference Guide ForDocument4 pagesThe Practical Reference Guide Forelias667No ratings yet

- Coding DecodingDocument21 pagesCoding DecodingAditya VermaNo ratings yet

- Paper-Czechowski-Slow-strain-rate Stress Corrosion Testing of Welded Joints of Al-Mg AlloysDocument4 pagesPaper-Czechowski-Slow-strain-rate Stress Corrosion Testing of Welded Joints of Al-Mg Alloysjavo0128No ratings yet

- Valdez, Shenny RoseDocument3 pagesValdez, Shenny Roseyeng botzNo ratings yet

- Đề 17Document11 pagesĐề 17Nguyen CuongNo ratings yet

- PANASONIC - WebCam-TQZJ402 - TY-CC20W PDFDocument188 pagesPANASONIC - WebCam-TQZJ402 - TY-CC20W PDF123anthonyNo ratings yet

- Preview: Proquest Dissertations and Theses 2002 Proquest Dissertations & Theses Full TextDocument24 pagesPreview: Proquest Dissertations and Theses 2002 Proquest Dissertations & Theses Full TextFelipe AguilarNo ratings yet