Professional Documents

Culture Documents

HEMM-Wheel Loader01

Uploaded by

miningnova2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HEMM-Wheel Loader01

Uploaded by

miningnova2Copyright:

Available Formats

w

Non-mechanic’s guide to appraising a loader H

E

WHEEL loaders come in 2WD, 4WD, E

rigid frame, articulated frame, L

powershift transmission and hydro- An Earthmover &

static transmission, etc, etc. Civil Contractor L

The largest-selling configuration is special feature O

the 4WD articulated loader, and for the A

purpose of this exercise we will as- D

sume the loader in question is of that

E

type.

“Loaders load”. How’s that for an

R

over-simplification? What we mean is S

that they can load from a stockpile,

load and carry, or actually dig material.

It’s important to try and find out

exactly what use the loader has been

put to. For example, load and carry

introduces a different set of wear

characteristics in comparison to stock-

pile loading, and loading corrosive

material such as fertiliser causes more

wear and tear than loading sand and

gravel. Don Shewring, of used equipment specialist

In appraising wheeled loaders, you

should not accept the number of hours

Consolidated Crane & Tractor, continues his “non-

shown on the meter as 100% accurate. mechanic’s” guide to appraising used equipment:

Investigate, check service history, etc, this time around, we’re looking at wheel loaders.

as many loaders work double shifts —

do your best to verify the hours worked.

Remember our criteria from previ- your closest major dealer. the stud holes to elongate, which causes

ous non-mechanic’s guides to inspect- Once you have the serial number, the wheel to keep coming loose.

ing machines: you can verify the year of manufacture, Brakes

1 Time is important. We have to be using excellent publications put out by

quick and, bearing in mind that we International Equipment Exchange Ltd, If outboard discs are fitted, carry out a

don’t have X-ray vision, as efficient or enquire at the local distributor. visual inspection of callipers, pads,

as possible within the time avail- Moving around the loader, check discs and hydraulic lines at this time.

able. Allow an hour (or if you are the fluids in the radiator, transmission, Remember, if discs are scored they

paying a fitter to do the inspection, engine, batteries; also lights, wiring, can be skimmed back to flat at least

he is going to want about four hours etc. once. Replacement discs are expen-

plus travelling time). Tyres sive.

2 What still works, what doesn’t and If they are inboard discs, testing can

how much will it cost to make it Check the size, approximate life re- be done when operating the machine,

work? maining, whether they have been as per the procedure for testing out-

3 50% life remaining (give or take relugged, recapped, or have cuts. board discs.

10%) is fair enough in the world of Pay special attention to the inside of Axle mountings and hubs

used equipment. the tyres, as this is where the cuts and

Ground level inspection damage usually get hidden. Check for loose bolts, or welded cracks

If possible, the machine should be where axle joins frame.

Walk around the machine at least twice, on a level surface, with all tyres inflated Check the rear axle oscillation pin

taking in the appearance, from which to the same pressure. and bush at this time by putting a jack

much can be learned, and taking note Uneven tyre wear is not desirable, under the axle and jacking the axle up,

of oil leaks, damaged tin work, doors, as it gives each wheel a different cir- which will show wear or, if this is not

glass, tyres, radiator, bucket and loader cumference, causing adverse wear in possible, get under and have a look.

frame, etc. the driveline components. This visual inspection will discover

I call this “absorbing the image”. Ideally, tyres should be same size, excessive wear in the pin and bush.

Now take your photos, and plenty of same pattern and around the same Check planetaries for leaks.

them. This is insurance against “memory wear (life remaining). Diffs and drivelines

fade”, which becomes more intense as Wheels

we get older. If you jack the back of the machine up

We should start our inspection at the Check rims for damage, inside and out, to check for wear in the oscillation

unit serial number and, if possible, use and examine wheel nuts and studs for

a prepared check sheet. Get one from evidence that loose nuts have allowed

July 1998 The Earthmover & Civil Contractor

w

Non-mechanic’s

H

E guide to appraising

Step-by-step appraisal

E When the editor called for a guide to

L a loader loader appraisals, wouldn’t you know

it, the Consolidated Crane & Tractor

L cupboard was bare of a suitable unit.

O trunnion, you can at this time turn the Fortunately, the courtesy of Ray

A rear driveshaft by hand to check the Murphy, of Brisbane used equipment

D universal joint for wear and the differ- dealer Topline Machinery, gave us ac-

E ential for backlash. Often you can hear cess to one of his stock units.

excess play in the planetaries at this We appraised a 1994 model Cater- Walking down the left side of the loader,

R time. pillar 970F with a 5 m3 light material

S we note that the steps are in very good

The front can be checked by jacking bucket, air-conditioned ROPS cabin, condition, the tyres (almost a separate

up on the bucket and following the with 7800 hours on the clock. study item, just like different machines)

same procedure. Owner: Used equipment dealer have an average 40-45% life remaining

Frame Asking price: $200,000 plus sales tax and are 26.5x25 tubeless steel-belted

if applicable (22%) radials in good overall condition.

It is the structural and less obvious Initial impression: very clean and

areas that should be scrutinised most tidy. The unit shows evidence of good

carefully, as such faults as misalign- repair and maintenance practices. If I

ment and fractures in one area can was asked to hazard a guess at its

result in major failures in another. previous use, I would think woodchips

Check the points at which super- or sand because of the very clean

structure members are welded (includ- appearance, no nicks and cuts on the

ing engine and transmission mounts) tyres, and very little abrasion on the

for cracks. If a repair has been made, bucket and loader arms.

is it a professional job? Take note of all the numbers and

Has the inside of the frame been symbols on the side of the tyre. Your

repaired, or plated, as well as the local distributor for that brand can tell

outside to minimise recurrence of the you what they are most suitable for.

failure? Don’t forget to thoroughly check the

Loader frame inside of each tyre and rim for faults.

Did you know that each tyre has its own

This is the front attachment which unique serial number? Keep a note of it;

enables the bucket to dig, crowd, lift, it could help identify a stolen loader.

discharge and return to dig.

Check the sidearms (boom) for

cracks in welded areas and where As always, have the machine on good

bosses are fitted. Check ram mounting level ground. The cleaner the

points for cracks. hardstand the better, because to do the

Visually inspect all pins and bushes job properly, you are going to have to

for obvious signs of excessive wear. “get down and dirty”. Go around the

Check that grease actually goes into machine at ground level first, making

the pin. It’s a good idea to borrow a observations and taking notes. Check all rims (particularly on older

grease gun and spot check that the machines) for cracks, damage, broken

pins and bushes will take grease, par- studs, elongated holes, etc. Brakes are

ticularly the bottom bucket pins. inboard oil-immersed discs and will

Obviously, on any loader worth its be checked during the operational test.

salt there will be wear; if this is within

reason, it need not deter us, but exces-

sive loader frame wear costs a lot to

rectify, so check closely.

If repairs have been made, apply

checks as for the main chassis.

We look at the loader frame again Head straight for the serial number

during the actual testing of the loader, plate. The serial number 7PL00173

which comes next. indicates it was made in Japan in Open up the left-hand engine covers.

In-yard test 1994. The diamond-shaped plate is the These are beauties. Just look at the

“certificate of new machine for export” accessibility. You can see the turbo,

Jump up into the cab. Is it ROPS (very from the Construction Equipment muffler, alternator, air-conditioning

important), are there any certification Manufacturers Association of Japan. It compressor, fuel filters, etc. Visually

indicates that the unit is an export check belts and for leaks or anything

model. else untoward.

The Earthmover & Civil Contractor July 1998

w

H

E

E

L

L

Slipping under the tractor again, we O

Coming around the back, open the look up at the front of the rear diff, the A

Check all mounts, engine,

radiator grill. Radiators are becoming oscillation bearing trunnion mount D

transmission, etc. Make sure none are

quite sophisticated and often contain broken or damaged. If they are, they

and back driveshaft and universal E

heat exchangers, transmission coolers, can cause extensive damage to those

bearing. Put a bar into the universal R

etc. Inspect carefully. The reverse gear and check for wear. In this case, we S

components and possibly to the

alarm can be seen at the bottom left of didn’t jack up the rear axle; if we did

driveline. As you can see, these are

the enclosure. we could check for backlash in the diff.

perfect.

Open up the battery boxes on the left This photo shows the hydraulic tank,

and right rear of the loader. Check that transmission dipstick and filler (check

they are of sufficient CCA (cold transmission fluid level with motor

cranking amps), the right physical running) and steering ram. Check all

Dip the engine stick, taking note of the hoses and wiring in articulation joint,

and, importantly, that they are

level and condition of the oil. Don’t be check transmission mounts and

properly retained.

afraid to feel and smell the oil. Look visually inspect the driveline.

for signs of water or anything that

shouldn’t be there.

Hop under the rear of the loader and This shot, taken from the right (we

inspect the underside. Check brake always talk left and right as if sitting

lines, grease lines, etc. Note the rear of in the operator’s seat) shows top and

the back diff and the trunnion bearing bottom artic pins, front driveshaft and

which allows the rear axle to oscillate. Look closely at the back of the radiator front rear universals, steering ram

All is in good operating order and for “sandblasting” wear. In this case, anchoring point and all the spaghetti

seems commensurate with the 8000- we also check the air-conditioning running through the articulation

odd operating hours. radiator, inspect all coolant hoses and joint. It all looks good.

clamps. Be alert for engine oil leaks.

Back under the machine, we are

looking forward at the front driveshaft

and differential. Inspect the axle

Get those right-hand engine covers mounting bolts, hydraulic hoses and

open and carefully check the inner and Moving forward down the right side of fittings, and look for anything

outer air filters, the housing and our loader, we check the inside of the “bodgie”, oil leaks, etc. This is clean

connections to engine intake. Dusting tyre and rim, as well as the steering and tidy and very original.

an engine is an expensive piece of ram anchor point, the hydraulic tank

mostly avoidable “bad luck”. and mounts. All is as it should be. pics continued next page

July 1998 The Earthmover & Civil Contractor

w

H

E

Step-by-step appraisal

E

L

L

O

A

D

E

R Here we are at the pointy end. Very

S carefully go over the bucket for cracks, Are the seat, controls, pedals, etc in

distortion and excessive wear on the condition we would expect for

bottom and sides. In the operating 8000 hours’ use? Is the seat

test, we can check the bottom of the mechanism tight, does it work

bucket and for wear in the mounting properly? It’s more than your life is

points, especially the bottom pins. worth today to supply a machine to an

operator with anything faulty which

may cause an accident. In this case, all

is well.

Stepping over the engine cowling on

the way to checking the radiator fluid,

we find a cover for a small toolbox

This is standing in front looking back

and the windscreen washer bottle.

into the bucket. See the 600 mm crack

Have a good look inside and inspect

in the back of the bucket. There were

everything within. Clean, isn’t it?

several other small cracks in the

bucket — not anything to be too

concerned about; probably a day’s Check all switches and gauges. See the

work for a boilermaker. hour meter? Note the holder for a

drink left of shot, and holder for

thermos flask right of photo.

Now enter “the office”. Make sure that

it’s the best it can be. It’s most

Jump up onto the loader. Always open important to you or your operator that

every hatch and have a look. In this if you are going to spend your working

case, it is the filler hole for the fuel day here, it is comfortable and

tank right in front of you as you climb functional.

up the left side. Everything is clean,

with no adverse signs.

Now start the machine. Be sure that

Checking the interior of the cabin, once you have checked the radiator for

make sure that the light works, that bubbles you replace the cap. Note the

the mirrors are fitted. Also note the external mirrors. Make sure the lights,

Some people say an air-cooled engine is excellent radio, cassette player and, wipers, washers, etc work. Operate the

one that ran out of fluid. Don’t run air- an added bonus, a load indicator loader for at least 15 minutes to heat

cooled, always check the fluid level and mounted between the internal all the fluids to operating

look for unwanted contaminants in the mirrors. This device weighs each load temperature. Check the underside of

coolant. Leave this open until you run and keeps a running total of the the bucket. Test the transmission,

the engine so you can check for bubbles. amount of material handled. brakes. Does it load correctly, etc?

The Earthmover & Civil Contractor July 1998

w

Non-mechanic’s H

E

guide to appraising E

a loader L

continued from page 40

L

plates, is it air-conditioned, and does it O

work? A

Make sure that the control levers work Wether you are the operator or you D

Bucket mounting pins and bushes are are going to supply this loader to an

and, when you are operating the E

good, eg 60% or better life remaining operator, “the office” should be in the

loader, make certain that the boom, R

— more than enough to satisfy our best possible condition, with lights,

kick-out and automatic return to dig

used equipment criteria. wipers, gauges, switches, doors, seat,

S

on the bucket both work.

glass all in top buckle.

Now gentlemen, start your engines.

Engine

We should accept that engine repairs

are costly, but their condition is easily

checked and the methods of doing so

are universally known. Suffice it to say,

if it starts easily and runs sweetly, it’s

okay.

When the machine is hot, hop down So there you have it. We walked In our quick assessment, we are

and check the engine crankcase filler around it (at least twice), we climbed looking for signs of problems which

for excessive blow-by or heavy under it, we climbed on it, we climbed we can call the professionals in to

breathing or “slobbering”, as it is into it, we operated it, we took notes, investigate. Look for the following:

known. Excessive blow-by usually we took photographs — all in a • bubbles or oil in radiator

means at least new pistons and rings. planned, methodical fashion. In this • coolant in engine oil

instance, we found virtually no faults, • blue exhaust smoke, indicating ex-

but if faults are there, this method cessive oil usage

will find them. • white exhaust smoke, indicating

moisture in oil

• excessive black smoke, indicating

So what’s this excessive fuel (fuel injection prob-

lems)

machine worth? • slobbering (excessive breathing)

Quite obviously, this loader would from crankcase breather, indicating

Put the bucket on the ground and use not appeal to the buyer who has to excessive piston and ring wear.

downward force and crowd the bucket to pay sales tax. As you warm the engine up, check

discover wear in the loader frame, These loaders retail new for that the gauges work and that they are

hydraulic cylinder mounts and bucket around $350,000, give or take. There- “in the green” during operation.

mounting points. There are a lot of fore, an asking price in the range of

bearing points in a modern loader $200,000 to $240,000 would, in my Transmission

frame and they can cost a lot of money if opinion, be a “fair cop”. Work the loader in “a heap” for at least

worn. Jack the front axle up off the Given that the machine we in- 15 minutes to test the transmission.

ground to check for front driveline wear. spected was a 1994-manufactured If the loader won’t push at the heap,

unit (it could well have been put into it’s odds on to be that the torque

service later) and it had only 7800 converter needs resealing or that the

hours on the clock, I would suggest clutch pack in that range has given up

that the asking price is at the bottom the ghost.

end of the scale and represents ex- Like the engine, if there are no

cellent value for money. obvious faults (leaks, noises, etc) and

If it were me trying to purchase the transmission does what it is sup-

the loader, my negotiations would posed to and the gauges work and are

With the bucket on the ground, jiggle centre on a good GP loader bucket in the green during operation, then the

the steering wheel from side to side to in the price in lieu of a discount, transmission is serviceable and will do

discover any lateral movement in the unless the light material bucket ex- us.

loader frame and wear in the steering actly suited my purpose. If in doubt, call the dealer to do a

ram mounts. In this instance, the pins Then I would be going for a tad pressure test in all ranges and/or buy

and bushes at both ends of the steering extra — freight to site might be the the loader with an allowance for a

rams are starting to show wear. right sweetener.

Replace in 1000 hours.

July 1998 The Earthmover & Civil Contractor

w

Non-mechanic’s Bucket

H

guide to appraising While you lift the E

bucket to full height, E

a loader check wear on the L

underside and for

damage to the back. L

transmission rebuild. Check the cutting O

If the loader has a hydrostatic trans- edge, teeth and A

mission, which usually consists of an adaptors, if fitted. D

engine driving into a hydraulic pump Check for a “bowed”

E

driving a hydraulic motor into a simple bottom on the

high-low reduction gearbox, then if bucket and for ex-

R

there is a problem you really have to cessive wear at

S

call the dealer and have the hydraulic bucket mounting

components tested. Eight out of 10 points, particularly

times, it’s the pump. bottom pins and bushes.

going through the procedures we have

Brakes The bucket is the real “pointy end” to

just outlined.

this ship and cops a lot of punishment.

Test the brakes; if they work well, Check for cracks in all areas of the Good loader appraising.

that’s very good. If not, try and see why bucket.

— for example, outboard discs might

show worn pads.

Bucket repairs are not too tricky —

generally a simple boilermaking exer-

Special offer

If the brakes are inboard discs and cise — but they cost money and can Would you like:

won’t work, it’s generally a large and get into really big bucks when replace- • a reprint of this article and the

expensive job to remove the axles com- ment cutting edges, adaptors and teeth pictorial appraisal?

pletely or the diffs, planetaries and brakes. come into the equation. • a copy of the appraisal form used

The saving grace with these types of If a 4-in-1 bucket is fitted, you will by Don Shewring?

brakes is that they last a long time and also have to check that the clam pivot • a copy of an ownership declara-

are virtually maintenance free. pins and rams are okay, that the back tion form?

of the bucket is not bent and that the • a copy of an authority to release

Final drives payout information?

back cutting edges are good, as well as

Let your ears be the judge. We are the above-mentioned things. Don Shewring will be pleased to

listening for excessive noise or obvi- send you the information free of

Articulation joint charge. To obtain copies, fax or write

ous malfunction from the diffs or

planetaries. Excessive wear here requires new top to Don Shewring at Consolidated

Overheating of planetary cases is a and bottom pins and bushes. If the Crane & Tractor Pty Ltd, PO Box 632,

sure sign something is wrong. Check wear is let go too far, a built-up with Albion, Queensland 4010. Fax (07)

the oil level. If the planetary cases are weld and line bore procedure is neces- 3256 3300. State your name, com-

hot, you can also insert a magnet and sary, and that’s expensive. pany name, phone and fax number.

fish for metal pieces, a sure sign some- To test, lift the front off the ground Free valuation

thing is amiss. and have someone check the move- If you would like a free valuation of

Loader frame ment in the artic pins and bushes. your loader, contact Don Shewring

Jiggling the wheel from side to side on ph 018 788 856, fax (07) 3256 3300.

Put the bucket on the ground and use also gives an indication of articulation This service is not available over

bucket crowd and lower to indicate the wear, as well as steering ram pin and the phone. An information sheet re-

level of pin and bush wear in the bush wear. questing details about your machine

loader frame. Sometimes it pays to find out ex- will be faxed or posted to you. Re-

In some worn loader frames, the actly what type of articulation bearing turn the completed information sheet

movement is quite dramatic, as the the loader you are inspecting has, with photos (if possible), and a “cur-

frame bangs and crashes about due to straight pins and bushes or spherical rent market valuation” will be faxed

excessive clearances. bearings, etc. Can it be adjusted or not? or posted to you at no charge.

Now turn steering from right to left General

several times with the bucket firmly on

the ground. This will indicate lateral If you are being offered a “little-used”

movement of the loader frame. DON SHEWRING is managing director of

loader, just have a quick look and your

Brisbane-based used

Lift the bucket to full height, paying instincts will guide you.

equipment specialist Con-

special attention that the bucket re- If the cab has sloppy controls, well-

solidated Crane & Tractor.

mains parallel to the ground and that worn foot pedals, worn seat cover,

He has been involved in

the lift arms and torque tube are not worn and rattly seat, it’s a sure indica-

buying, selling and evalu-

bent or twisted. tion that it has had a very active life and

ating used equipment for

Check that automatic kick-out and has done a good 8000-10,000 hours.

more than 20 years.

return to dig devices are fitted and You can glean this just from an

You can contact him on phone 018 788 856.

working. investigation of the cabin, let alone

July 1998 The Earthmover & Civil Contractor

w

H

E

Komatsu loader scores a perfect year

E A KOMATSU WA500-3 wheel loader

L has done a year’s work with maximum

reliability.

L The 235 kW Komatsu WA500-3 is

O the sales loader at CSR Readymix’s

A Castlereagh site, in Sydney’s west.

D It was commissioned in August

E 1997 and has logged more than 2500

hours.

R CSR Readymix’s process improve-

S ment manager for Sydney quarries,

Jason Ferguson, said the Komatsu

WA500-3 loads 80,000-100,000 t of prod-

uct a month.

“It’s the first machine I can remem-

ber where we have never had one

issue with it,” he said.

“It loads a lot of tonnes and the

operator, Merv Bratby, is just rapt.”

“He likes the comfort and conven-

ience of the cabin and controls, and he

prefers the Komatsu’s linear-assist

power-steering characteristics.”

CSR Readymix subjected the

Komatsu WA500-3 to field trials by its

operators against a competitor’s ma-

chine, before commissioning the ma- The Komatsu WA500-3 in action at CSR Readymix’s Castlereagh quarry.

chine.

CSR Readymix’s Richard Savage said

then that the machine had to meet the It is also suitable for forestry appli- and fast hydraulic cycle times when

company’s specific site requirements cations, and medium to large civil loading.

and measure up against the competi- contractor requirements. With an operating weight of nearly

tion in field trials. A major feature is the automatic shift 29 t, it is powered by a Komatsu

“The operators found the Komatsu transmission facility for the powershift S6D140E diesel rated at 235 kW.

machine more to their liking, particu- transmission, enabling the operator to Bucket capacities range from 4.3 to

larly its stability and control system,” switch from automatic to manual at the 6 m3, bucket breakout is 27,000 kgf

he said. flick of a switch. and static tipping load at full turn is

Komatsu’s WA500-3, launched in The automatic transmission, com- 18,600 kg.

1997, is used in Australian quarries bined with Komatsu’s unique Dual Further information: NS Komatsu

as both a production and sales Speed Hydraulics, provides maximum Pty Ltd, ph (02) 9795 8222, fax (02)

loader. rim pull when pushing into a stockpile, 9795 8244.

The Earthmover & Civil Contractor July 1998

w

Two new loaders from JCB H

E

JCB used the recent Bauma ’98 show to launch two new E

wheel loaders — one coming in at the top end of its range, L

plus a special purpose bulk handling model.

The high-end JCB 446B is available in HT (four ram L

geometry) and ZX (Z bar) variants and has an operating O

weight of 15 t. A

Both models have the same high torque Cummins C D

series engine, which is rated at 127 kW and will be used with

E

a 2.6 m3 shovel as standard.

The ZX has a breakout of 16,500 kgf and dump height of

R

2985 mm, while the HT has a dump height of 2968 mm and S

breakout of 14,300 kgf.

Both machines feature a four-speed powershift transmis-

sion with top road speed of 38 km/h.

Rear-mounted cabs are designed to offer comfort, ease of

operation and good safety standards, with large glass areas

optimising visibility.

The 446B HT also has a quick hitch option available, JCB’s 446B wheel loader is now the largest in its range.

allowing use of attachments such as forks, log grabs, dozer

blades and crane jibs. changeover.

JCB’s new bulk handling unit is the 411B ZX, a hydrostatic Powered by a 67 kW Perkins 1000 series engine, the 411B

drive unit fitted with a 1.2 m3 shovel. ZX brings to five the number of compact wheeled loading

It features Z-bar loader geometry, giving high bucket shovels in the JCB range.

breakout forces and good roll back and dump angles, The 411B ZX weighs in at 7.3 t, has a loadover height of

together with a parallel lift capacity for safe handling of 3.27 mm, minimum ground clearance of 428 mm and

palletised loads when optional pallet forks are fitted. breakout force of 7500 kgf.

An extensive range of attachments is available for the new Further information: JCB Sales Ltd, ph 0800 581761, fax

machine, with its quick hitch system allowing swift (03) 9841 0600.

July 1998 The Earthmover & Civil Contractor

w

H

Extended reach

Case 621B XT High-power

E

E

loader working

at Leppington

compact

L Pastoral Kubota loaders

Company’s

L Bringelly KUBOTA’S new R520 wheel loader

complements the increased horse-

O operation.

power of the recently introduced R420,

A so that Kubota now offers two of the

D most powerful machines in their class.

E The R520 has an operating weight

R of 3.64 t, is powered by a 36 kW

S Kubota V2203-RP diesel and has a

bucket capacity of 0.57 m3, while the

R420 is a 3.05 t unit powered by a 32

kW Kubota D1503 -T-RP1 turbo diesel

and has a bucket capacity of 0.4 m3.

Extended reach units load faster The new designs retain some fea-

tures of previous models and incorpo-

AFTER experiencing good perform- Already having an extensive range rate many innovations designed to

ance with its Case 721B XT wheel of Case agricultural and construction make them easier to manoeuvre, bet-

loader, the Leppington Pastoral Com- equipment, LPC could see many ben- ter in handling and providing an unob-

pany recently decided to add two more efits in adding more Case models to structed field of vision for the operator.

Case XT wheel loaders to its extensive their fleet, including common parts Powered by Kubota’s low emission

equipment fleet. and continuing to deal with the back- E-TVCS diesel engines, both models

The company has just bought two up support of Sydney dealer Case are balanced and power matched for

621B Extended Reach tool carrier ver- Equipment Sales. performance, suiting them to a range

sions. The model 621B XT is powered by of applications in construction, waste

Leppington Pastoral (LPC), owned a 92.5 kW turbocharged Case 6T-590 management, materials handling, hor-

and operated by Tony and Ron Perich, CDC engine. With external compo- ticulture and agriculture.

bought a Case 721B XT in July last year nents incorporated into the integral A newly adopted parallel circuit

to work at their dairy and fertiliser design of the block, there is less wear valve allows simultaneous operation

manufacturing operation in Bringelly, and fewer moving parts, for increased with the service port, during lifting or

south-west of Sydney. reliability, lower operating cost and bucket operation. A standard Kubota

The loader arms were modified reduced maintenance. backhoe attachment is also available

slightly to provide the extra reach An autoshift function was specially for both models.

capability required to clear the 180 cm fitted to LPC’s new units, providing the The R-20 series wheel loaders fea-

high sides of transporters when load- ability to automatically shift from sec- ture Kubota’s load sensing transmis-

ing the raw materials at their opera- ond gear to the highest speed selected sion (LST), which automatically changes

tions. on the shifter. from high speed/low torque to low

Speed was critical in this operation, The Case Auto Shift system allows speed/high torque, as load conditions

where the unit is often working around operators to tailor the transmission vary.

the clock. shifting mode to suit their preference A column-mounted electric shuttle

According to LPC, after the intro- and the requirements of the site. shift is claimed to make directional

duction of the Case 721B XT, loading Further information: Case Corpora- changes smoother and easier, simply

times were substantially reduced and tion, ph (02) 9833 6000, fax (02) 9833 shifting the control lever forward or

operations became more efficient. 1128. Website www.casecorp.com. reverse to accelerate.

The Earthmover & Civil Contractor July 1998

w

Tilly’s takes on Chinese loader range H

E

TILLY’S Crawler Parts, E

based in Toowoomba, L

Queensland, has been

appointed Australian L

distributor for the Chi- O

nese-built Changling, A

Liugong and Weili D

loader ranges.

E

According to com-

pany director Hugh

R

Tilly, Changling works S

closely with Komatsu.

Limited slip differential ensures trac- Also available

tion on slippery road surfaces and through Tilly’s is the

difficult worksites, so that operators Liugong range of load-

can exploit the loaders’ 4WD capabili- ers. These loaders use

ties. some Caterpillar design, Changling wheel loaders coming off the production

The “low hold” travel speed-limit- with some models fit- line at the factory in China.

ing switch has been relocated to the ted with Cummins en-

top of the loader control lever, so that gines and ZF transmissions and axials. their investment.

changes up or down can be made with The third loader range available Tilly said his company has also

a one-touch, right-handed operation, from Tilly’s, Weili, is very popular in made it a priority to ensure a quick and

while maintaining steering control with China, according to Tilly. reliable parts back-up service is pro-

the left hand. A major selling feature is what Hugh vided for these machines.

Both models feature Kubota’s cen- Tilly described as “a surprisingly low Having recently returned from a

tre shaft oscillation and articulation price tag”. visit to China, he said the message was

joint, designed for smooth operation Complementing the loader range, that loaders from that country were

and stability. Tilly’s distributes a range of Chinese- now meeting international standards.

Other standard features include elec- built dozers, graders and rollers. He visited a number of loader facto-

tric park brake, enclosed hydrostatic When it comes time to sell or trade ries which he said had quality assur-

wet brake, wide industrial tyres, dual one of the Chinese machines, the com- ance systems in place and were serious

inching brake pedals, extra large muf- pany offers a minimum buyback or about producing well-built, reliable

fler, automatic bucket levelling system, trade-in price, based on the unit’s years machines.

ROPS/FOPS canopy, retractable of operation and hours used. In many cases, the design and tech-

seatbelt, safety starting system, and Contractors have told Tilly they have nology had been purchased from es-

control lever locks. been able to get the same hire rate for tablished names in this field, said Tilly.

Further information: Kubota Tractor these low-priced machines as they do Further information: Tilly’s Crawler

Australia Pty Ltd, ph (03) 9279 2000, fax for one costing twice the price, and Parts Pty Ltd, ph 1800 076 280, fax (07)

(03) 9279 2010. have only half the interest to pay on 4633 1702.

July 1998 The Earthmover & Civil Contractor

O

U

R

New mid-sized Cat G-series loaders

CATERPILLAR has updated its wheel

C loader range, with the 17 t 950G replac-

O ing the 950F Series II, and the 18 t 962G

V as an advance on the 960F loader.

E Improvements and innovations in-

R corporated into the new loaders were

designed to boost productivity in truck

or hopper loading, hard bank digging

or general utility work.

Both new loaders are powered by a

Cat 3126 engine producing 134 kW in

the 950G and 149 kW in the 962G.

Compared to previous designs, the

G-Series front linkage has greater lift

and breakout force, as well as greater

reach and dump height.

According to the manufacturer, the The new Cat 950G wheel loader.

units have a more powerful and re-

sponsive engine, and increased hy- Implement hydraulic power is good penetration into the pile.

draulic flow for faster implement matched to torque converter power Both loaders can be equipped with

speeds. demands to help balance cycles and one of two operator control configura-

The planetary powershift transmis- improve loader productivity. tions. Conventional steering produces

sion has four forward and four reverse In the 950G, an externally mounted pilot hydraulic flow when the operator

gears and, in addition to powershift spin-on hydraulic oil filter is used to rotates the steering wheel, and also has

and autoshift, it has electronic clutch improve filtration and make service pilot hydraulic bucket controls.

pressure control for smooth shifts. The more convenient. Command Control steering incor-

microprocessor-based control also Cat’s Ride Control System is an porates hydraulic and a mechanical

serves as a diagnostic point. optional attachment, with a nitrogen feedback system which directly links

Fully hydraulic brake controls elimi- oil accumulator in the hydraulic lift steering wheel position to the articula-

nate the need for a compressed air circuit acting as a shock absorber for tion angle. Nearly quarter-turn steering

system, and a new brake wear indica- the bucket. (72° each direction) is provided with

tor simplifies monitoring and improves General purpose, rock or material this option.

serviceability. The oscillating rear axle handling buckets can be handled by Transmission controls are integrated

helps ensure four-wheel ground con- the loaders, in sizes ranging from 2.5 to into the Command Control steering

tact. 3.3 m3 for the 950G and from 2.9 to 3.8 wheel for one-hand operation in all

The hydraulic system uses separate m3 for the 962G. steering positions. This arrangement

circuits for steering and bucket con- The radius of the material handling also includes electro-hydraulic bucket

trols. Increased hydraulic flow in the buckets has been opened for easier controls.

implement circuit improves lift arm loading and better material flow, and The control pod is mounted on the

and bucket speeds. the bucket floor is longer and flat for end of the adjustable right armrest,

with in-cab adjustable lift, lower and

bucket kick-outs providing program-

mable stops for faster cycle times, and

electronically controlled, cushioned

stops.

Status of key controls and functions

is displayed on the monitoring sys-

tem’s three instrument clusters, and a

three-level warning system alerts the

operator to any impending or immedi-

ate problems.

The G-Series cab offers 20% more

space than its predecessor and in-

creased viewing through 50% more

glass area.

New designs open up access for

maintenance and make maintenance

and inspections easier.

Further information: Caterpillar of

Australia Ltd, ph (03) 9339 9333, fax

The 962G replaces the 960F loader. (03) 9335 3366.

The Earthmover & Civil Contractor July 1998

w

How to get more from your mid-size wheel loader H

E

THE mid-size wheel loader’s speed E

and manoeuvrability makes it an ideal L

choice for a wide range of loading and

material handling applications, such as L

building and maintaining stockpiles, O

loading trucks and rail wagons, trim- A

ming ship’s holds and feeding hoppers D

and crushers.

E

Good machine selection is essential

if the machine is to achieve its full

R

performance potential. S

Having first established the produc-

tion rates the machine has to achieve,

the most important thing to consider

when selecting a mid-size wheel loader

is the application.

This can have a major impact on the

way a machine is configured. Key

variables include the material density

and loading characteristics, ground

conditions, the type and size of the

loading target, and the distance be-

tween the loading and discharge areas. What are the key points to look for when buying a

Once you have collected and ana-

lysed this information, the next task is mid-size wheel loader (defined as having an

to establish which loader best suits engine power of between 90 kW and 225 kW)? Ben

your production and operational needs. Lister, Caterpillar of Australia’s wheel loader

This is done by comparing the ma-

chines’ key specifications and design product manager, gives a few tips.

features.

Engine and driveline tem is essential on a mid-size wheel and job-matched attachments.

loader. It should produce high breakout The type of bucket you need will

Most mid-size wheel loader users like and lift forces, and be able to raise a also depend on the application. You

a high torque rise engine that provides fully loaded bucket to its full dump may, however, find that a bucket such

a quicker response and increased height in around six seconds. as a materials handling bucket will

rimpull for faster acceleration and more Peak power makes more horse- meet the majority of your require-

aggressive loading. power available to the powertrain and ments, particularly when most of the

You should also look for an auto- loader hydraulics when the engine work involves rehandling loose, free-

matic powershift transmission that al- lugs down for faster acceleration and flowing materials.

lows on-the-go speed and direction increased penetration into the pile. Other points to consider here in-

changes; and features a kick-down Load-sensing steering only takes clude selecting the right types of cut-

facility to speed up downward shifting power from the engine when it is ting edge and teeth, and the importance

for faster cycle times and increased needed. of a good dump clearance and reach

bucket fill factors. Frame when you are loading into high-sided

Other features to look for include trucks.

• an adjustment-free wet disc braking The frame should provide a rugged While the above points are all fun-

system platform for the engine and powertrain; damental to good machine selection, it

• some form of traction control which and the stability to operate the loader always pays to think of your operator

automatically activates and does not with the largest possible buckets. when you select a mid-size wheel

affect manoeuvrability This should be achieved without loader.

• a system to improve machine stabil- the machine having an unnecessarily You should, therefore, ensure the

ity during high-speed travel. large turning circle or excessive machine provides a comfortable and

The durability and robustness of amounts of counterweight. efficient working environment with

key components such as the engine, Loading equipment low in-cab noise levels, good all-round

transmission and axles should always visibility and easy to use controls.

be considered, particularly when the The type of loader linkage you choose Good serviceability should also not

machine is to be used in production will usually depend on the application. be forgotten, so look out for features

applications. Choose a Z-bar layout for production such as ground-level daily maintenance,

Hydraulic system loading applications, and a parallel lift grouped greasing points, computer-

arrangement when you need to oper- ised monitoring/diagnostic systems,

A powerful and efficient hydraulic sys- ate the loader with a variety of buckets and a tiltable engine enclosure.

July 1998 The Earthmover & Civil Contractor

w

H

E

The bum-biting loader

E rangement did not stay with us. I

L By Don Shewring

daresay the reality of two worn artic

Boys, you can win money at the pub pins and bearings together with eight

L with this one. worn steering ram locating pins and

O Start out with something like, “Does bushes might have been enough to

A anyone remember Yale loaders which make the loader snap around and bite

D were manufactured by Eaton, Yale & its own bum.

E Towne, who also made Trojan loaders? So you say to the guys in the pub,

R They then became Eaton, who made “Bet you have never seen a double

S Timberjack log skidders.” articulated loader,” and you proceed to

The loader we are looking at is the suck ’em in from there.

Trojan 8000 dual pivot articulated Beware the old bugger over 60. He

loader or, as we might sometimes be would have been in his prime in 1965

wont to say, the articulated, articu- and might remember, thus bringing the

lated loader. whole scheme undone.

The Trojan 8000 was powered by a While we’re on this subject, does

361 kW Cummins and weighed 46 t, anyone else have old specifications or

which puts it into the Cat 988F-Series 2 photographs of disastrous events?

class. Please send them in, with a short note

When you consider that this loader describing what makes them signifi-

was produced in the middle to late cant.

1960s, the concept becomes all the Send them to Don Shewring c/- this

more remarkable. magazine. We’ll make sure you get

Needless to say, the dual pivot ar- them back.

Here’s what the manufacturer had to say about the Trojan 8000 Dual-Pivot wheel

loader:

The Trojan Dual-Pivot model 8000 tractor shovel provides the speed and manoeu-

vrability of a conventional articulated machine, yet possesses all the stability of

rigid-frame construction. This stability does not depend on excessive width; it is

accomplished by Trojan’s exclusive dual-pivot articulation, an entirely new

design concept.

The Trojan 8000 is built in three sections and articulates in two places. The centre

section weighs over six tons; it acts as a laterally sliding counterbalance, shifting

its weight to the outside on every turn. This counterbalanced, dual-pivot action

results in unprecedented stability, greater reliability, and longer machine life.

Other features include servocontrols, variable-rate steering, demand hydraulics,

and fail-safe brakes — every one Trojan engineered for maximum operator

efficiency and safety.

The Trojan Dual-Pivot Model 8000 tractor shovel is the giant workhorse with small-

machine finesse, your unbeatable production combination.

The Earthmover & Civil Contractor July 1998

You might also like

- Learner's Book Answers: Unit 1 CellsDocument31 pagesLearner's Book Answers: Unit 1 CellsLyaz Antony91% (91)

- 10 Yrs Mine FatalityDocument20 pages10 Yrs Mine FatalityChiranjib BanerjeeNo ratings yet

- Tyre Modelling - Pacejka '96 Model: Links To Page 133 of Race Car Design by Derek SewardDocument5 pagesTyre Modelling - Pacejka '96 Model: Links To Page 133 of Race Car Design by Derek SewardahmadNo ratings yet

- VFL 26.11.2021 Mines OperationDocument2 pagesVFL 26.11.2021 Mines OperationSubhashree dipali muduliNo ratings yet

- Information Bulletin - MAC 25 Allowable Wind SpeedDocument1 pageInformation Bulletin - MAC 25 Allowable Wind SpeedStuart EdwardsNo ratings yet

- Tread Cuts: Damage Code NoDocument33 pagesTread Cuts: Damage Code NojorgegachaNo ratings yet

- Student Camps 2022 - Grade 6 Science Curriculum Based Test BookletDocument58 pagesStudent Camps 2022 - Grade 6 Science Curriculum Based Test Bookletthank you GodNo ratings yet

- HEMM Excavator01Document9 pagesHEMM Excavator01miningnova2No ratings yet

- HEMM Dumper25Document28 pagesHEMM Dumper25miningnova2No ratings yet

- Louis Berger S.A.: 805. Equipment in WorkshopDocument7 pagesLouis Berger S.A.: 805. Equipment in Workshoprelu1986No ratings yet

- Safety and Maintenance of Haual RoadDocument42 pagesSafety and Maintenance of Haual RoadajaykumarprasadNo ratings yet

- Safety Futures HEMMDocument48 pagesSafety Futures HEMMkhan sabNo ratings yet

- HEMM Dumper16Document8 pagesHEMM Dumper16miningnova2No ratings yet

- Problems Associated With Tyres and Their RemediesDocument5 pagesProblems Associated With Tyres and Their RemediesAnuj SharmaNo ratings yet

- Introduction Od Dump Truck Model HD785-7Document4 pagesIntroduction Od Dump Truck Model HD785-7AbdulKarimAbbasNo ratings yet

- Patria Light Vessel HD 785-7Document9 pagesPatria Light Vessel HD 785-7bayu enasoraNo ratings yet

- Dumper ManualDocument10 pagesDumper Manual2692rimmi5902No ratings yet

- Panhard RodDocument2 pagesPanhard RodHarjot SinghNo ratings yet

- Training Manual For: MechanicsDocument78 pagesTraining Manual For: MechanicsepsaNo ratings yet

- LMV Tyre SafetyDocument19 pagesLMV Tyre SafetykarvadNo ratings yet

- Hemm - Present and Future TrendDocument19 pagesHemm - Present and Future TrendDhiraj PatilNo ratings yet

- Mining Trucks Terex MT 3300acDocument8 pagesMining Trucks Terex MT 3300acmoxmoNo ratings yet

- Tire and Tire WearDocument45 pagesTire and Tire WearLe DuNo ratings yet

- Forklift PDFDocument17 pagesForklift PDFANKUSHNo ratings yet

- 773DDocument24 pages773DGabo Gabo100% (1)

- 10 Crane Tyre Crawler Check ListDocument1 page10 Crane Tyre Crawler Check Listjohn rajNo ratings yet

- MainteMaintenance Guide For Earthmover Tyres - Tyre Inspectionnance Guide For Earthmover Tyres - Tyre InspectionDocument5 pagesMainteMaintenance Guide For Earthmover Tyres - Tyre Inspectionnance Guide For Earthmover Tyres - Tyre InspectionAlex JordánNo ratings yet

- Automatic Fire Detection and Suppression SystemDocument2 pagesAutomatic Fire Detection and Suppression SystemProdip SarkarNo ratings yet

- Hw300 AssembleDocument111 pagesHw300 AssembleAndreiNo ratings yet

- Specifications: 797F Off-Highway Truck Suspension CylinderDocument12 pagesSpecifications: 797F Off-Highway Truck Suspension CylinderManuel Alejandro Silva VeraNo ratings yet

- OTR Tyre Management Overview PDFDocument2 pagesOTR Tyre Management Overview PDFjorge dazaNo ratings yet

- Fifth Wheel Coupling and Uncoupling ProceduresDocument3 pagesFifth Wheel Coupling and Uncoupling ProceduresAbrar HussainNo ratings yet

- Margin of Safety Formula - Guide To Performing Breakeven AnalysisDocument4 pagesMargin of Safety Formula - Guide To Performing Breakeven AnalysisGerald HandersonNo ratings yet

- Working With The MachineDocument9 pagesWorking With The MachineYeny CatzinNo ratings yet

- Speech On Road SafetyDocument2 pagesSpeech On Road Safetyraytcg100% (1)

- HEMM Dumper24Document15 pagesHEMM Dumper24miningnova2No ratings yet

- As 4457.1-2007 Earth-Moving Machinery - Off-The-road Wheels Rims and Tyres - Maintenance and Repair Wheel AssDocument7 pagesAs 4457.1-2007 Earth-Moving Machinery - Off-The-road Wheels Rims and Tyres - Maintenance and Repair Wheel AssSAI Global - APACNo ratings yet

- Skills Standards: Heavy Equipment Maintenance: Heavy Equipment MechanicDocument17 pagesSkills Standards: Heavy Equipment Maintenance: Heavy Equipment MechanicRohit Om TiwariNo ratings yet

- Tata Steel Iron Ore Tailing Dams Safety DisclosureDocument103 pagesTata Steel Iron Ore Tailing Dams Safety DisclosureSappidi Manoj KumarNo ratings yet

- MN2-51-24790 Tyre Handler - 50231 - ROTASIDocument48 pagesMN2-51-24790 Tyre Handler - 50231 - ROTASITyas Wulandari100% (1)

- Wa500 6RDocument20 pagesWa500 6RYulius PurnamaNo ratings yet

- OTR DatabookDocument91 pagesOTR DatabookSamuel Hendra Sinaga100% (2)

- TractorsDocument58 pagesTractorsSteven Ztifler RoccoNo ratings yet

- Michelin RegroovingDocument28 pagesMichelin Regroovingkaber89100% (1)

- Operating Manual Maxtrailer N enDocument35 pagesOperating Manual Maxtrailer N enFeraru Valentin0% (1)

- Forklift Truck/Powered Indutrial Truck: I. ObjectiveDocument4 pagesForklift Truck/Powered Indutrial Truck: I. ObjectiveprinceNo ratings yet

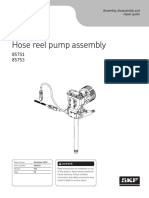

- Hose Reel Pump Assembly: Assembly, Disassembly and Repair GuideDocument18 pagesHose Reel Pump Assembly: Assembly, Disassembly and Repair GuideВиталий КозловскийNo ratings yet

- All Otr Tires by SizeDocument4 pagesAll Otr Tires by SizeMuhammad Sharif JanjuaNo ratings yet

- Development of Tipper Unloading MechanismDocument4 pagesDevelopment of Tipper Unloading MechanismAnonymous kw8Yrp0R5rNo ratings yet

- UNIT-1: Vehicle Structure and EnginesDocument69 pagesUNIT-1: Vehicle Structure and Enginessrihari_bhadabhagniNo ratings yet

- Case Study On Bullet Driven SantiDocument23 pagesCase Study On Bullet Driven Santiurvish_soniNo ratings yet

- 2018 Otr Global Product Catalog PDFDocument120 pages2018 Otr Global Product Catalog PDFRaul CraciunNo ratings yet

- Road Safety Report-74 PagesDocument74 pagesRoad Safety Report-74 PagesMinatiBindhaniNo ratings yet

- OTR Tyre Standard Operating ProceduresDocument19 pagesOTR Tyre Standard Operating ProceduresAnbarasan100% (1)

- Dgms All Circular 2004Document35 pagesDgms All Circular 2004Hari PidikitiNo ratings yet

- Euro Truck Simulator ManualDocument28 pagesEuro Truck Simulator ManualTeodor CimpocaNo ratings yet

- Appraising A Used Dozer: An Earthmover & Civil Contractor Special FeatureDocument12 pagesAppraising A Used Dozer: An Earthmover & Civil Contractor Special Featureminingnova2100% (2)

- HEMM Excavator04Document16 pagesHEMM Excavator04miningnova2No ratings yet

- Sample: Excavator Safety TrainingDocument61 pagesSample: Excavator Safety Trainingvega f ankaNo ratings yet

- Towability Guide2008Document60 pagesTowability Guide2008Adam KrugNo ratings yet

- Wheeltalk PDFDocument4 pagesWheeltalk PDFizmitlimonNo ratings yet

- Unit 3 EquipmentDocument97 pagesUnit 3 EquipmentDon Stidarmam100% (2)

- Mining Constn EquipmentDocument55 pagesMining Constn EquipmentPiyush KatakwarNo ratings yet

- MinMach HomePage09Document8 pagesMinMach HomePage09miningnova2No ratings yet

- MinMach HomePage15Document46 pagesMinMach HomePage15miningnova2No ratings yet

- MinMach HomePage14Document25 pagesMinMach HomePage14miningnova2100% (1)

- Compressor Types: The Basic Principals of Air or Gas CompressionDocument22 pagesCompressor Types: The Basic Principals of Air or Gas Compressionminingnova2100% (1)

- MinMach HomePage08Document8 pagesMinMach HomePage08miningnova2No ratings yet

- Contamination, Leakage and Use of Wrong FluidDocument43 pagesContamination, Leakage and Use of Wrong Fluidminingnova2100% (1)

- MinMach HomePage11Document99 pagesMinMach HomePage11miningnova2100% (1)

- Maintenance Performance Management: The Need of The Hour For The Mechanized Mining IndustryDocument5 pagesMaintenance Performance Management: The Need of The Hour For The Mechanized Mining Industrycologne99No ratings yet

- MinMach HomePage05Document10 pagesMinMach HomePage05miningnova2No ratings yet

- MinMach HomePage06Document7 pagesMinMach HomePage06miningnova20% (1)

- MinMach HomePage07Document5 pagesMinMach HomePage07miningnova2No ratings yet

- Frequency Control System For Improving Efficiency of Conventional Coal Mine Hauler EfficiencyDocument5 pagesFrequency Control System For Improving Efficiency of Conventional Coal Mine Hauler Efficiencyminingnova2No ratings yet

- Van Dyk 2006Document2 pagesVan Dyk 2006ashpaxNo ratings yet

- Machinery Selection-Books23Document78 pagesMachinery Selection-Books23miningnova2No ratings yet

- Machinery Selection-Books22Document277 pagesMachinery Selection-Books22miningnova2100% (1)

- User'S Handbook: A Guide To Using Roller Cone Rock Bits in MiningDocument43 pagesUser'S Handbook: A Guide To Using Roller Cone Rock Bits in Miningminingnova2100% (1)

- MinMach HomePage01Document18 pagesMinMach HomePage01miningnova2No ratings yet

- MinMach HomePage16Document7 pagesMinMach HomePage16miningnova2100% (1)

- RCMDocument96 pagesRCMLuis Alberto Silva NavarroNo ratings yet

- Machinery Selection-Books14Document16 pagesMachinery Selection-Books14miningnova2No ratings yet

- Machinery Selection-Books21Document71 pagesMachinery Selection-Books21miningnova2100% (1)

- O&M CompressorDocument116 pagesO&M Compressorantidote_deNo ratings yet

- GearologyDocument132 pagesGearologyRyley McCarthyNo ratings yet

- Machinery Selection-Books04Document53 pagesMachinery Selection-Books04miningnova2100% (1)

- Army WeldingDocument757 pagesArmy WeldingKenn FerroNo ratings yet

- Machinery Selection-Books06Document146 pagesMachinery Selection-Books06miningnova2100% (1)

- Basic Hydraulic Systems and ComponentsDocument67 pagesBasic Hydraulic Systems and Componentsnareshkumaran100% (8)

- Machinery Selection-Books01Document43 pagesMachinery Selection-Books01miningnova2100% (2)

- AbstractDocument1 pageAbstractJignesh PrajapatiNo ratings yet

- As 4587-1999 Water Mist Fire Protection Systems - System Design Installation and CommissioningDocument10 pagesAs 4587-1999 Water Mist Fire Protection Systems - System Design Installation and CommissioningSAI Global - APAC100% (1)

- 13 y 14. Schletter-SingleFix-V-Data-SheetDocument3 pages13 y 14. Schletter-SingleFix-V-Data-SheetDiego Arana PuelloNo ratings yet

- Acm 003Document5 pagesAcm 003Roan BNo ratings yet

- DLPDocument2 pagesDLPEunice Junio NamionNo ratings yet

- 4 MFL67658602 00 160519 1Document329 pages4 MFL67658602 00 160519 1Cédric MorisotNo ratings yet

- AquaMapPublic v202Document26 pagesAquaMapPublic v202engfeupNo ratings yet

- De Cuong On Thi HK2 Tieng Anh 10Document5 pagesDe Cuong On Thi HK2 Tieng Anh 10hoangtouri2512No ratings yet

- Management Information Systems and Corporate Decision - Making: A Literature ReviewDocument5 pagesManagement Information Systems and Corporate Decision - Making: A Literature Reviewvaaz205No ratings yet

- Overseas Assignment 18thseptDocument6 pagesOverseas Assignment 18thseptSuresh VanierNo ratings yet

- Lecture 12 Public Administration and Development 2017Document23 pagesLecture 12 Public Administration and Development 2017Raheel Joyia100% (1)

- Basic - Concepts - in - Pharmaceutical - Care CLINICAL PHARMACYDocument17 pagesBasic - Concepts - in - Pharmaceutical - Care CLINICAL PHARMACYPrincess RonsableNo ratings yet

- Tavistock PrimerDocument13 pagesTavistock PrimerSharon Schaff100% (1)

- Third Space Learning Ratio GCSE WorksheetDocument11 pagesThird Space Learning Ratio GCSE WorksheetDrichy Obi-EmelonyeNo ratings yet

- Thesis StoryboardDocument5 pagesThesis StoryboardJill Brown100% (2)

- Ass AsDocument2 pagesAss AsMukesh BishtNo ratings yet

- UT Dallas Syllabus For Math3303.501.10f Taught by Phillip Kisunzu (pxk091000)Document7 pagesUT Dallas Syllabus For Math3303.501.10f Taught by Phillip Kisunzu (pxk091000)UT Dallas Provost's Technology GroupNo ratings yet

- An Automated Test and Measurement System For Calibration of Industrial FlowmetersDocument2 pagesAn Automated Test and Measurement System For Calibration of Industrial FlowmetersfredpintoNo ratings yet

- H5P Active Learning Guide: HERDSA Workshop MaterialDocument7 pagesH5P Active Learning Guide: HERDSA Workshop Materialgeorgemarian_manea100% (1)

- Asl Scroll Wuxi 2hp - 8hp 2930719180Document142 pagesAsl Scroll Wuxi 2hp - 8hp 2930719180Roy MokNo ratings yet

- Acc Inter 3 AtsiriDocument9 pagesAcc Inter 3 AtsiriZania Putri100% (1)

- Important Questions - BlockchainDocument1 pageImportant Questions - BlockchainHarsh Varshney100% (1)

- Recent Advances in Second Generation Bioethanol Production An Insight To Pretreatment, Saccharification and Fermentation ProcessesDocument11 pagesRecent Advances in Second Generation Bioethanol Production An Insight To Pretreatment, Saccharification and Fermentation ProcessesBryant CoolNo ratings yet

- CNSB Bypass Separator Commissioning and Maintenance Guide: Conder® Tanks Covered by This GuideDocument4 pagesCNSB Bypass Separator Commissioning and Maintenance Guide: Conder® Tanks Covered by This GuidesterlingNo ratings yet

- MP35N K Tube Technical Data SheetDocument2 pagesMP35N K Tube Technical Data Sheetstrip1No ratings yet

- Rack Interface Module 3500 20SDocument71 pagesRack Interface Module 3500 20SmaheshNo ratings yet

- Indian Council of Medical ResearchDocument6 pagesIndian Council of Medical Researchram_naik_1No ratings yet

- NC1 AC Contactor, 9 95A: Contactors ContactorsDocument2 pagesNC1 AC Contactor, 9 95A: Contactors ContactorsYamendra GurungNo ratings yet