Professional Documents

Culture Documents

The Frame Analysis and Testing For Student Formula

Uploaded by

SaugatoDuttoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Frame Analysis and Testing For Student Formula

Uploaded by

SaugatoDuttoCopyright:

Available Formats

AbstractThe objective of this paper is to study the analysis and

testing for determining the torsional stiffness of the student formulas

space frame. From past study, the space frame for Chulalongkorn

University Student Formula team used in 2011 TSAE Auto Challenge

Student Formula in Thailand was designed by considering required

mass and torsional stiffness based on the numerical method and

experimental method. The numerical result was compared with the

experimental results to verify the torsional stiffness of the space frame.

It can be seen from the large error of torsional stiffness of 2011 frame

that the experimental result can not verify by the numerical analysis

due to the different between the numerical model and experimental

setting. In this paper, the numerical analysis and experiment of the

same 2011 frame model is performed by improving the model setting.

The improvement of both numerical analysis and experiment are

discussed to confirm that the models from both methods are same.

After the frame was analyzed and tested, the results are compared to

verify the torsional stiffness of the frame. It can be concluded that the

improved analysis and experiments can used to verify the torsional

stiffness of the space frame.

KeywordsSpace Frame, Student Formula, Torsional Stiffness,

TSAE Auto Challenge

I. INTRODUCTION

SAE Auto Challenge Student Formula [1] is the student

formula competition of Thailand under formula SAE

international rules [2] organized by society of engineers

Thailand. In order to participate in this competition, the formula

car was formulated by considering many parts using the

engineering skills. The frame is one of the most important parts

that integrated the other parts together. The best frame is the

frame with less mass but still have high torsional rigidity. To

design frame, the analysis of torsional stiffness of the frame and

verify this results by using the torsional stiffness test became

more important [3][5].

There are many types of frame been used in Student Formula

Competition for example: Space Frame, Monocoque, and

Ladder Frame [6], [7]. A space frame, as shown in Fig. 1, is a

truss-like, lightweight rigid structure constructed from

interlocking struts in a geometric pattern. Space frames are a

series of tubes which are joined together to form a structure that

connects all of the necessary components together. Space frame

is simple and cheap when compared to the other twos. Therefore

it can be seen commonly in student level competition.

Tanawat Limwathanagura, Chartree Sithananun, and Teekayu

Limchamroon are with the Automotive Design and Manufacturing Engineering,

Chulalongkorn University, Phayathai, Pathumwan, Bangkok, 10330, Thailand.

Thanyarat Singhanart is with the Departments of Mechanical Engineering,

Chulalongkorn University, Phayathai, Pathumwan, Bangkok, 10330, Thailand

(e-mail: fmetsn@eng.chula.ac.th).

Fig. 1 Space frame

In advance level of racing, Monocoque, as shown in Fig. 2, is

more popular. Monocoque is a construction technique that

supports structural load by using an objects exterior. It is

generally made as one piece. The use of composite materials in

monocoque skins allows strength, stiffness and flexibility to be

controlled in different directions. With the used of composite

material, Monocoque are significantly higher in cost but the

performance is worth investing. The last one isnt much seen, it

is the ladder frame. The ladder frame is a shorthand description

of a twin-rail chassis. It is typically made from round or

rectangular tubing similar to space frame. Ladder frame can use

straight or curved members, connected by two or more cross

members. Body mounts are usually integral outriggers from the

main rails, and suspension points can be well or poorly

integrated into the basic design.

Fig. 2 Monocoque

The space frame was chosen for 2011 Auto Challenge

Student Formula. From previous research [5], the torsional

stiffness of the 2011 frame was designed by considering

required mass and torsional stiffness with the usage of the

numerical and experimental methods. The numerical result of

Tanawat Limwathanagura, Chartree Sithananun, Teekayu Limchamroon, Thanyarat Singhanart

The Frame Analysis and Testing for Student Formula

T

World Academy of Science, Engineering and Technology 65 2012

1008

torsional stiffness was verified by using experiment. It can be

seen that the error between numerical result and experimental

result is large due to many mistakes when setting the

experiments. In this paper, the improvement of the numerical

model and experiment is the interested topic that has to be

carefully considered. Therefore, the objective of this paper is to

study the analysis and testing for determining the torsional

stiffness of the student formulas space frame.

II. THE ANALYSIS ANDEXPERIMENT OF 2011 FRAME [5]

The 2011 frame of Chulalongkorn University team for 2011

Auto Challenge Student Formula is shown in Fig. 3. The frame

was designed under SAE international rules with many concepts

such as

1) Lower the center of gravity by using the curve beam

2) Use the triangular mesh at the rear to improve the torsional

stiffness of the frame

3) Use removable member at the end to provide the space for

attaching the engine, etc.

Additionally, the frame was designed under the requirements

of mass less than 30kg and torsional stiffness of the whole car

more than 1200Nm/deg.

The Model for FEM analysis is shown in Fig. 4. The frame is

fixed at one end and the torque is applied at the other end. From

Fig. 4, the deflections at point 1, 2, 3, and 4, which located at the

rear part of the frame, are determined when fixed at the front.

The analysis was also performed when fixed at the rear and

torque is applied at the front to determine the deflections at

point 5, 6, 7, and 8, which located at the front part of the frame.

The torsional stiffness of the frame is from the lowest value

which occurred from point 7 when fixed at the rear. The

torsional stiffness from numerical analysis is found to be

1270Nm/deg.

Fig. 3 The 2011 frame for 2011-2012 Auto Challenge student formula

Fig. 4 Model for FEM analysis

The torsional stiffness test was performed as shown in Fig. 5

and 6. The steel rod is used to connect to the eight points at the

front which can be considered to be fixed end. At the other end,

the frame is connected to the steel beam that lied on the pivot

point. The load is applied at one end of the steel bar and

produced the torque to the frame as shown in Fig. 7. The torque

applied on the frame can be determined from

( )

1 2

T mgL F F w = = +

(1)

Where m is the end mass and L is the distance between end mass

and pivot point.

The deflections of point 1, 2, 3, and 4 as shown in Fig. 4 are

collected corresponding to the increasing load. The deflections

of point 5, 6, 7, and 8 can be determined with the rear part fixed

and torque applied to the front. The angle of rotation as shown

in Fig. 8 can be calculated from

1

tan

a b

L

=

(2)

The torsional stiffness from experiment can be determined

from

T =

. The experimental results show that the

torsional stiffness of the frame is 787Nm/deg. By comparing the

numerical and experimental results, the error is found to be

38.0% which is considered to be large.

The errors may come from many parts that will be discussed

in next section. After the source of error is identify, the

improvement of the experiments and numerical analysis can be

clearly obtained.

Fig. 5 Model for experiment setup

s:--. --a

c----:.-,

:- :-- a-

s:--. --a

-..-: ,-.-:

-.-+

--.-:s

/,,..-+

:-|a-

World Academy of Science, Engineering and Technology 65 2012

1009

(a)

(b)

Fig. 6 Experimental setup for torsional stiffness tests

Frame

Steel Beam

1

F

2

F

mg

L

2w

Fig. 7 Free body diagram of separated frame and steel beam

1

F

2

F

Frame

w

a

b

Fig. 8 The angle of twist

III. THE DISCUSSIONONTHE PAST RESEARCH

In the experiment, the connection points between the test rig

and the frame at the rear are joined by welding two steel

columns to the frame as shown in Fig. 5 or 6(a). It can ensure the

lock between the frame and the test rig however, caused by

welding these two members, the two part acting like one body.

As the result of this action, the point where load was distributed

into the frame has much error and fails to simulate the driven

condition. The process of holding the frame where the loads will

be applied should be improved to gain better result for the

torsional stiffness.

As can see in Fig. 5 and 6(a), the front part was fixed by

welding eight rods to frame. The torque applied will cause the

frame integrated with eight rods to rotate, then if the angle of

twist is calculated from the absolute deflections at the rear, this

value will represent the angle of twist of the whole system but

not only the frame. To ensure that only the frame rotates with

fixed support at the front, the improvement of the fixed points

has to be considered. It would be more accurate to ensure that

the fixed parts dont have any movement. The defection at the

fixed part must be measured and subtracted from the deflection

at the rotating end to get the displacement from frame rotation

only. Also, in measuring the deflection, suitable equipment

should be selected to measure distance a and b.

IV. THE IMPROVEDANALYSIS

In the finite element analysis the method for applying load is

changed as shown in Fig. 9. The force was distributed equally

into all four point of the frame on each side (point 1, 2, 3, 4)

when the rear was fixed at point 5, 6, 7, and 8. This model

verifies the condition to be the most related to the real

experiment.

Fig. 9 The improve analysis (The red points are the applied load points

while the purple are the construction points)

.z

.s

s:--. --a

-..-: ,-.-:

(/-,.- s:--.,

World Academy of Science, Engineering and Technology 65 2012

1010

V. THE IMPROVEDEXPERIMENT

For improving of the experiment first of all the way to

connect the frame and the test rig was changed. Instead of

welding the frame and the test rig together by a steel beam or

steel rods, new propose was introduced. In order to simulate the

closed situation in real driving, the force should distribute

through the frame passed by the wheel. Therefore not only the

frame, A-arms and wheel base were attached to the frame as

shown in Fig. 10. The new test rig is designed by connecting the

wheel base both at the front and at the rear to the test rig.

Fig. 10 The new test rig

This new test rig can be locked with wheel base by

combination of nuts and washers as shown in Fig. 11(a) and

11(b). The hold fitting object (Green part) minimize the

clearance between the hold and the wheel base. Due to the

inclination of the wheel base (Blue part) the different numbers

of washer (Red part) were added. Therefore the locker is

possible to position vertically with the test rig. After that

washers and nuts (Black part) are used to lock at the outer side.

This ensures the limitation of vertical movement and dont

allow the locker to slip out. One thing to consider is the number

of washer used. Washer usage is depending on how the wheel

base aligned with respect to the test rig. The front part of the test

rig can freely rotate by using the pin support as can see in Fig.

11(a).

(a) The locker

Wheel base

Washer

Hole Filling Object

Nut

Locker

(b) Side view of the locker

Fig. 11 Locker setting

For more accuracy of the experiment result the dial gauge and

vernier height gauge are used to measure deflection at the fixed

end and at the rotating end, respectively. The dial gauges with

0-25.0mm / 1.0 range and resolution 0.03mm/0.0012 are used

to measure the deflection at the fixed end. At the rotating end the

vernier height gauge will be installed to observe the deflection

at both sides. Actually dial gauges are used for checking

whether the fixed part has movement or not, if there is the

measurement gained, it will be subtracted from the rotating end

to ensure the exact displacement.

VI. RESULTS

The model when fixed at the front and the torque applied at

the rear was performed and the result from point 7 is used to

compare with past experiment as shown in Table I. The

improved experimental results for point 1, 2, 3, 4, 5, 6, 7, and 8

can be found to be 1371, 1104, 1251, 1060, 1143, 1483, 955,

and 1122, respectively. The results from the torsional stiffness

test and FEM analysis are presented in Table II. With these two

values of torsional stiffness the percentage of error can be

determined.

VII. DISCUSSION

From the previous experiment the error between the FEM

analysis and the experiment was 38.0% which is considered

being unacceptable and failing to verify the numerical result.

With the improvement presented in this paper, the result from

the improvement version has acceptable error between the FEM

analysis and the experiment. It shows a good way of improving

and proves that the improving of the analytical model and

experimental setting significantly affect the result. Therefore,

the numerical result is verified and can be used in design process.

However some change could be made to achieve more and make

both FEM analysis and exact test more precise.

FEM analysis can be used to predict the torsional stiffness in

order to design the new frame. The torsional stiffness of the

candidate frames based on the FEM analysis are compared and

selected for the best performance frame. However the exact

torsional stiffness test is required for the final frame design

anyway.

World Academy of Science, Engineering and Technology 65 2012

1011

VIII. CONCLUSIONS

The improved analysis and experiment are presented and

discussed in this paper. It can be seen that this improvement has

succeed to model the real situation of load applied to the frame

that can see from the small error between analytical and

experimental results. From now FEM analysis can be used as an

effective tool for designing a frame.

However lots of improvements are expected to be done in

order to enhance it to the next level. More designs are possible

to help improving this test rig to become more accurate and

flexible.

REFERENCES

[1] Auto Challenge Student Formula, Available at

www.tsae.or.th/autochallenge.html, Accessed on 20, Mar 2012

[2] Student Formula Rules and Regulations 2011, Available at

http://www.jsae.or.jp/formula/en/background.html, Accessed on 20, Mar

2012

[3] Abrams, R., Formula SAE Race Car Analysis: Simulation & Testing of

the Engine as a Structural Member, in FISITA 2008 World Automotive

Congress, Munich, Germany, 2008

[4] William B. Riley and Albert R. George, Design, Analysis and Testing of

a Formula SAE Car Chassis, in SAE International, Proceedings of the

2002 SAE Motorsports Engineering Conference and Exhibition,

Indianapolis, Indiana, 2002

[5] Sithananun C., Leelaphongprasut C., Baitiang C., Rungpipatphol N.,

Noomwongs N., Singhanart T., SAE Student Formula Space Frame

Design and Fabrication, in The second TSME International Conference

on Mechanical Engineering, Krabi, Thailand, 2011

[6] Edmund, F. Gaffney III and Anthony, R. Salinas, Introduction to

Formula SAE Suspension and Frame Design, SAE International, 1997

[7] Why Our Chassis Looks the Way It Does, Available at:

http://www.erareplicas.com/misc/stress/deslogic.html, Accessed on 20,

Mar 2012

TABLE I

COMPARISON BETWEEN IMPROVED AND PREVIOUS RESULTS

Torsional Stiffness [Nm/deg]

Comparison

FEM Experiment

Previous

Experiment

1270 780 38.0%

Improved

Experiment

1006 955 5.3%

TABLE II

IMPROVED TORSIONAL STIFFNESS FROM POINT 1-8

Point

Torsional Stiffness[Nm/deg]

Comparison

FEM Experiment

1 1371 1427 4.1%

2 1104 1157 4.8%

3 1251 1329 6.2%

4 1060 1129 6.5%

5 1143 1209 5.8%

6 1483 1547 4.3%

7 955 1006 5.3%

8 1122 1165 3.9%

World Academy of Science, Engineering and Technology 65 2012

1012

You might also like

- Xiu-Chun WU, Wen-Qiang ZHENG, Pan Zhou: Topology Optimization Design of Bus Body Structure Based On Altair-OptistructDocument6 pagesXiu-Chun WU, Wen-Qiang ZHENG, Pan Zhou: Topology Optimization Design of Bus Body Structure Based On Altair-OptistructHaile SolomonNo ratings yet

- Experimental and Finite Element Stress Analysis of Three Wheeler Front FenderDocument7 pagesExperimental and Finite Element Stress Analysis of Three Wheeler Front FenderNithin SunnyNo ratings yet

- Development of A Lightweight Tubular Space FrameDocument7 pagesDevelopment of A Lightweight Tubular Space FrameJony M. TemnikarNo ratings yet

- Space Frame DesignDocument5 pagesSpace Frame DesignAmeer ShNo ratings yet

- M Jayakumar Paper (17142691331)Document12 pagesM Jayakumar Paper (17142691331)N V DhandapaniNo ratings yet

- Methods To Determine Torsional Stiffness in A Semi-Trailer Chassis FrameDocument9 pagesMethods To Determine Torsional Stiffness in A Semi-Trailer Chassis Frameognen88No ratings yet

- Development of A Test Stand For Determining The Torsional Rigidity of A Formula Sae Space FrameDocument20 pagesDevelopment of A Test Stand For Determining The Torsional Rigidity of A Formula Sae Space FrameAmiljkovicviNo ratings yet

- Stress Analysis of Automotive Chassis With Various ThicknessesDocument6 pagesStress Analysis of Automotive Chassis With Various ThicknessesRtdpDinuNo ratings yet

- Stress Behaviour Improvement of Automobile Flywheel Under High Centrifugal ForcesDocument6 pagesStress Behaviour Improvement of Automobile Flywheel Under High Centrifugal ForcesParag NaikNo ratings yet

- Syehan 2019 IOP Conf. Ser. Mater. Sci. Eng. 494 012088Document10 pagesSyehan 2019 IOP Conf. Ser. Mater. Sci. Eng. 494 012088Mehul ChauhanNo ratings yet

- Comparison of Analytical and Numerical Models On Torque and Hookload CalculationDocument7 pagesComparison of Analytical and Numerical Models On Torque and Hookload Calculationsaeed65No ratings yet

- Re Design of A Failed Clutch Fork UsingDocument7 pagesRe Design of A Failed Clutch Fork UsingShafier KhanNo ratings yet

- Frame Optimization by Means of Algorithm - MaestrelliDocument16 pagesFrame Optimization by Means of Algorithm - MaestrelliPlinio GuzmanNo ratings yet

- Simulation and Test Correlation of Wheel Impact TestDocument8 pagesSimulation and Test Correlation of Wheel Impact Testesmaeel ghafariNo ratings yet

- OSA Poster Design Improvement SigmaConsultancyDocument6 pagesOSA Poster Design Improvement SigmaConsultancySanchit GuptaNo ratings yet

- 60b7d5156166b47d4c PDFDocument6 pages60b7d5156166b47d4c PDFAnkush_1No ratings yet

- ReviewDocument4 pagesReviewAnonymous 7eSIXWYMNo ratings yet

- Matecconf Eureca2020 03001Document13 pagesMatecconf Eureca2020 03001Putra JokoNo ratings yet

- Fatigue Analysis of An Automotive Stabilizer BarDocument4 pagesFatigue Analysis of An Automotive Stabilizer BarAbhay KhotNo ratings yet

- Static Analysis of Mobile Launch PedestalDocument6 pagesStatic Analysis of Mobile Launch PedestalinventionjournalsNo ratings yet

- Failure Analysis of A Re-Design KnuckleDocument9 pagesFailure Analysis of A Re-Design Knuckleali soydaşNo ratings yet

- Irjet V8i4487Document13 pagesIrjet V8i4487Saravanan SolutionsNo ratings yet

- Impact Analysis of Mini BajaDocument6 pagesImpact Analysis of Mini Bajayashvirsingh21No ratings yet

- Analysis and Validation of Eicher 11.10 ChassisDocument4 pagesAnalysis and Validation of Eicher 11.10 ChassisdessaivipulNo ratings yet

- Numerical Estimation of The Torsional Stiffness CHDocument14 pagesNumerical Estimation of The Torsional Stiffness CHKiran ShetNo ratings yet

- Motorcycle Tyre Crash AnalysisDocument9 pagesMotorcycle Tyre Crash Analysistovinny14159No ratings yet

- Analytical Study of End-Plate Connection On CrucifDocument6 pagesAnalytical Study of End-Plate Connection On CrucifMohamed GamalNo ratings yet

- Artigo - Study On Bridge Structure of Bridge Crane - ICCET 2015 - Li Hai-Ying and Wu Hua-Iiang PDFDocument4 pagesArtigo - Study On Bridge Structure of Bridge Crane - ICCET 2015 - Li Hai-Ying and Wu Hua-Iiang PDFKaique CavalcanteNo ratings yet

- Design Analysis of Barrel CouplingDocument5 pagesDesign Analysis of Barrel CouplingBruno SantosNo ratings yet

- Sae Technical 2008-36-0253 Paper Series: Design and Optimization of A Space Frame ChassisDocument11 pagesSae Technical 2008-36-0253 Paper Series: Design and Optimization of A Space Frame ChassisCharlie TejNo ratings yet

- Design and Optimization of Bulkhead Laminated With Palmyra and Epoxy Composite Materials Using FemDocument6 pagesDesign and Optimization of Bulkhead Laminated With Palmyra and Epoxy Composite Materials Using FemVadivel AeroNo ratings yet

- Failure Prediction of Propeller-Shaft Prototype Using Finite Element AnalysisDocument4 pagesFailure Prediction of Propeller-Shaft Prototype Using Finite Element AnalysisRajendra PraharajNo ratings yet

- Astm A227Document5 pagesAstm A227Diganta KonerNo ratings yet

- 05 Ijetmr19 A01 612 PDFDocument8 pages05 Ijetmr19 A01 612 PDFShahnewaz BhuiyanNo ratings yet

- Wu 2018Document14 pagesWu 2018Rayhan Fajar SatrioNo ratings yet

- Ijfatigue S 07 00263Document40 pagesIjfatigue S 07 00263ekremNo ratings yet

- Analysis of The Results of Theoretical and Experimental Studies of Freight Wagon FalsDocument8 pagesAnalysis of The Results of Theoretical and Experimental Studies of Freight Wagon FalscolletrialNo ratings yet

- The Seismic Behavior of An Asymmetric Exterior Precast Beam-Column ConnectionDocument10 pagesThe Seismic Behavior of An Asymmetric Exterior Precast Beam-Column ConnectionlangxuzengNo ratings yet

- The Seismic Behavior OfAnAsymmetric ExteriorPrecastDocument10 pagesThe Seismic Behavior OfAnAsymmetric ExteriorPrecastAhmed DhyiaaNo ratings yet

- Fatigue Life Estimation of Chassis Frame FESMDocument7 pagesFatigue Life Estimation of Chassis Frame FESMRtdpDinuNo ratings yet

- Ali 2015Document10 pagesAli 2015sai rajeshNo ratings yet

- Nonlinear Finite Element Analysis of An RC FrameDocument12 pagesNonlinear Finite Element Analysis of An RC Framearash250100% (1)

- Fatigue Analysis of An Automobile Wheel Rim: AbstractDocument10 pagesFatigue Analysis of An Automobile Wheel Rim: AbstractSagar ANo ratings yet

- Fatigue Strength Analysis On The Automobile Stabilizer BarDocument5 pagesFatigue Strength Analysis On The Automobile Stabilizer BarSantiago UrgilesNo ratings yet

- 002-Steering Knuckle Made With TO AM MetalDocument15 pages002-Steering Knuckle Made With TO AM MetalMarcofNo ratings yet

- Stress Distribution Analysis of Rear Axle Housing by Using Finite Elements AnalysisDocument10 pagesStress Distribution Analysis of Rear Axle Housing by Using Finite Elements AnalysisrubantoNo ratings yet

- Expt 4b.flexure TestDocument5 pagesExpt 4b.flexure TestVishwasVerma100% (1)

- Design Considerations For Automobile Chassis For Prevention of Rolling Over of A VehicleDocument10 pagesDesign Considerations For Automobile Chassis For Prevention of Rolling Over of A VehicleIsha FauzanNo ratings yet

- Design, Analysis and Simulation of A Composite BulkheadDocument5 pagesDesign, Analysis and Simulation of A Composite BulkheadThota Sri K HarithaNo ratings yet

- BAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogieDocument7 pagesBAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogiePPNNo ratings yet

- Design For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringDocument22 pagesDesign For Fatigue and Simulation of Glass Fibre Epoxy Composite Automobile Leaf SpringjonNo ratings yet

- 1Document4 pages1johnNo ratings yet

- Optimization of Car Rim Using OptiStructDocument6 pagesOptimization of Car Rim Using OptiStructsujaydsouza1987No ratings yet

- Strength Analysis of Diesel Engine Crankshaft Based On PRO/E and ANSYSDocument3 pagesStrength Analysis of Diesel Engine Crankshaft Based On PRO/E and ANSYSMaiman LatoNo ratings yet

- Virtual Design Conception of Fatigue SpecimenDocument6 pagesVirtual Design Conception of Fatigue Specimen赵怀瑞No ratings yet

- Analysis of Fly WheelDocument5 pagesAnalysis of Fly Wheelfsilassie8012No ratings yet

- Development of Theoretical Framework of Ultimate Fashion and Textile Design Process ModelDocument24 pagesDevelopment of Theoretical Framework of Ultimate Fashion and Textile Design Process ModelSaugatoDutto0% (1)

- Case Tesla Motors Part IDocument16 pagesCase Tesla Motors Part ISaugatoDutto100% (2)

- LS-DYNA Theory ManualDocument811 pagesLS-DYNA Theory ManualSaugatoDuttoNo ratings yet

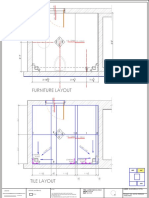

- Design and Drawing of Water TankDocument38 pagesDesign and Drawing of Water TankSaugatoDutto67% (3)

- Nasa Aprop1Document22 pagesNasa Aprop1SaugatoDuttoNo ratings yet

- Notes of F.MDocument159 pagesNotes of F.Mnidhalsaada100% (1)

- A Case Study On Arav in D Eye Care SystemsDocument4 pagesA Case Study On Arav in D Eye Care SystemsSaugatoDuttoNo ratings yet

- Tabelas Tubos MecanicosDocument6 pagesTabelas Tubos MecanicosCristhian GraefNo ratings yet

- Courtney Love Science 101 Electricity and HeatDocument41 pagesCourtney Love Science 101 Electricity and HeatCourtney Love Arriedo OridoNo ratings yet

- Principles of LED - The Mesopic Vision - John Rooymans, CroDocument35 pagesPrinciples of LED - The Mesopic Vision - John Rooymans, Cromark78goNo ratings yet

- Property Printable Listing-20171110Document18 pagesProperty Printable Listing-20171110chek86351No ratings yet

- Airport Transit Escalator Design Standards (051910)Document35 pagesAirport Transit Escalator Design Standards (051910)J Ganesh KumarNo ratings yet

- BREEAM Assessing Health and Wellbeing in BuildingsDocument16 pagesBREEAM Assessing Health and Wellbeing in BuildingspcastrorNo ratings yet

- Diamond Baru-Paving BlockDocument10 pagesDiamond Baru-Paving BlockBudi SetiawanNo ratings yet

- MCD Officials Delhi (Mail IDs)Document11 pagesMCD Officials Delhi (Mail IDs)mydearg50% (2)

- Open Channel APHDocument2 pagesOpen Channel APHponmanikandan1No ratings yet

- Machine Room-Less (MRL)Document13 pagesMachine Room-Less (MRL)rishi070881No ratings yet

- Design of A Ground Level Storage TankDocument8 pagesDesign of A Ground Level Storage TankcamagnacNo ratings yet

- Frequently Asked QuestionsDocument3 pagesFrequently Asked QuestionsGuru SwamyNo ratings yet

- Gombrich - EstiloDocument6 pagesGombrich - EstiloRoxana CortésNo ratings yet

- Application To Polly Biddut SamityDocument4 pagesApplication To Polly Biddut SamityMahibul HasanNo ratings yet

- Basic Structure of ComputersDocument26 pagesBasic Structure of ComputersLyn-Jo Chris SarmientoNo ratings yet

- Chillers CatalogueDocument42 pagesChillers CatalogueAlaa FaiqNo ratings yet

- Zeus - Technical Specification - Eng - v101 - PP PDFDocument70 pagesZeus - Technical Specification - Eng - v101 - PP PDFgalih santosoNo ratings yet

- Script Dancing With DeathDocument8 pagesScript Dancing With Deathapi-443233873No ratings yet

- Industrial Insulation Applications: Green Engineering-1 Insulation Spreadsheets - ContentDocument55 pagesIndustrial Insulation Applications: Green Engineering-1 Insulation Spreadsheets - ContentRashel HasanNo ratings yet

- Pitched Roof PergolaDocument4 pagesPitched Roof PergolaNdahiro Gordon JamesNo ratings yet

- Pre-Chamber RegulatorDocument3 pagesPre-Chamber RegulatorfahadullahNo ratings yet

- Goyal Terrace - A61 - Toilet Layouts - 20-12-2022 - Rutuja PDFDocument6 pagesGoyal Terrace - A61 - Toilet Layouts - 20-12-2022 - Rutuja PDFRutuja RajurwarNo ratings yet

- LMUKA11510 Reliability EngineerDocument4 pagesLMUKA11510 Reliability EngineerInaya GeorgeNo ratings yet

- Underground PlanDocument1 pageUnderground PlansuliamnNo ratings yet

- Designing Combined Standpipe and Sprinkler SystemDocument3 pagesDesigning Combined Standpipe and Sprinkler SystemMohammed Abdul MoiedNo ratings yet

- DebugDocument3 pagesDebugAriefENstNo ratings yet

- Patient Label and Test Tube Preparation System BC ROBO-888 TCP/IP Interface Protocol ManualDocument9 pagesPatient Label and Test Tube Preparation System BC ROBO-888 TCP/IP Interface Protocol ManualrahulbordeNo ratings yet

- L-1, L-2 & L-3 ScheduleDocument8 pagesL-1, L-2 & L-3 ScheduleShariful islamNo ratings yet

- Literature Review For Wheel ChairDocument22 pagesLiterature Review For Wheel ChairShakil MalikNo ratings yet