Professional Documents

Culture Documents

Prof. K. Narasimhan: Case Study Report On

Uploaded by

Rajveer FandanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prof. K. Narasimhan: Case Study Report On

Uploaded by

Rajveer FandanCopyright:

Available Formats

CASE STUDY REPORT ON ECONOMIC LOAD DISPATCH

GUIDE

Prof. K. NARASIMHAN

RAJVEER SINGH FANDAN (133110021)

Metallurgical Engineering & Materials Science Department INDIAN INSTITUTE OF TECHNOLOGY BOMBAY

INTRODUCTION: A good business practice is the one in which the production cost is minimized without sacrificing the quality. This is not any different in the power sector as well. The main aim here is to reduce the production cost while maintaining the voltage magnitudes at each bus. In an early attempt at economic operation it was decided to supply power from the most efficient plant at light load conditions. As the load increased, the power was supplied by this most efficient plant till the point of maximum efficiency of this plant was reached. With further increase in load, the next most efficient plant would supply power till its maximum efficiency is reached. In this way the power would be supplied by the most efficient to the least efficient plant to reach the peak demand. Unfortunately however, this method failed to minimize the total cost of electricity generation. We must therefore search for alternative method which takes into account the total cost generation of all the units of a plant that is supplying a load. Economic Distribution of Loads between the Units of a Plant To determine the economic distribution of a load amongst the different units of a plant, the variable operating costs of each unit must be expressed in terms of its power output. The fuel cost is the main cost in a thermal or nuclear unit. Then the fuel cost must be expressed in terms of the power output. Other costs, such as the operation and maintenance costs, can also be expressed in terms of the power output. Fixed costs, such as the capital cost, depreciation etc., are not included in the fuel cost. The fuel requirement of each generator is given in terms of the Rupees/hour. Let us define the input cost of an unit- i , F(Pgi) in Rs./h and the power output of the unit as Pgi . Then the input cost can be expressed in terms of the power output as F(Pgi) = aiPgi2 + biPgi + ci Rs./h

The operating cost given by the above quadratic equation is obtained by approximating the power in MW versus the cost in Rupees curve. The

incremental operating cost of each unit is then computed as Rs./MWh

Economic Load Dispatch

Minimize: F(Pgi) = Subject to:

aiPgi2 + biPgi + ci)

1. gi = PD + PL 2. Pgimin Pgi Pgimax

Where

(i=1,2,3,.......NG)

ai, bi and ci are cost coefficients PD = Load demand Pgi = Real power generation of ith generator NG = number of generator buses PL = Transmission power loss and PL = B00 +

giBi0

giBijPgj

where B00, Bio and Bij are loss coefficients

The above constrained optimization problem is converted into an unconstrained optimization problem. Lagrange multiplier is used in which a function is minimized with side condition in the form of equality constraints. Using Lagrange multiplier, an augmented function is defined as L(Pgi, ) = F(Pgi) + (PD + PL -

gi)

Necessary conditions for the optimization problem are = =( +( ) )=0 (1)

Bi0 +

gjBij gi)

= (PD + PL -

=0

(2)

= incremental operating cost of the ith generator

= incremental transmission losses

Taylor series expansion to second order of equation (1) and (2) are

The above equations can be written in the matrix form as

][

The derivatives can be obtained as follows = +

( ) = (2aiPgi + bi) + (Bi0 +

gjBij

1)

{i = 1,2,.......NG ; j = 1,2,.......NG ; j i}

And can be calculated as,

Problem: To determine economic load schedule to meet the demand of 150MW. Given- PD = 150MW Fuel inputs of two plants are given as F1 = 0.00889 F2 = 0.00741 + 10.333P1 + 200 + 10.833P2 + 240

The transmission losses are given by PL = 0.001 + 0.002 2*0.0002P1P2

Since for 2 units, PL = B11 Therefore, B11 = 0.001 B22 = 0.002 B12 = B21 = 0.0002 + B22 + 2B12P1P2

Also initial value of is =

= 11.81812 /MWh

Since, therefore, P1 = and P2 =

][

By Gauss elimination

[ ][ ] [ ]

Using back substitution

;

You might also like

- Economic Operation of Power SystemsDocument21 pagesEconomic Operation of Power Systemsvidya_sagar826No ratings yet

- PS2 - Unit 4Document27 pagesPS2 - Unit 4PETER PARKERNo ratings yet

- FFDocument22 pagesFFDeepak DasNo ratings yet

- Economic Operation of Power SystemsDocument21 pagesEconomic Operation of Power SystemsHarish Kumar GNo ratings yet

- Lecture 2 & 3 Unit Commitment and ELDDocument42 pagesLecture 2 & 3 Unit Commitment and ELDSantosh ThapaNo ratings yet

- Economic Dispatch Power SystemDocument36 pagesEconomic Dispatch Power SystemBanan Al BarghouthiNo ratings yet

- Lecture 7 PDFDocument24 pagesLecture 7 PDFSubrat BarsainyaNo ratings yet

- 34343Document5 pages34343Anand KalNo ratings yet

- Unit - IvDocument40 pagesUnit - IvChockalingamNo ratings yet

- Economic Operation of Power System - Economic Dispatch: Decisions, Called Unit CommitmentDocument14 pagesEconomic Operation of Power System - Economic Dispatch: Decisions, Called Unit CommitmentVishvas Singhal 18BEE0232No ratings yet

- Economic Load Dispatch Using PSO MethodeDocument53 pagesEconomic Load Dispatch Using PSO MethodeBhavya AlapatiNo ratings yet

- Economic Dispatch and Unit CommitmentDocument36 pagesEconomic Dispatch and Unit CommitmentRahul rajNo ratings yet

- Optimum Power Dispatch Problems: An Overview: F. R. Pazheri, N. H. Malik, M. F. Othman and M. BabarDocument6 pagesOptimum Power Dispatch Problems: An Overview: F. R. Pazheri, N. H. Malik, M. F. Othman and M. BabarInternational Journal of Engineering Inventions (IJEI)No ratings yet

- Placement of DG in Distribution System For Loss ReductionDocument6 pagesPlacement of DG in Distribution System For Loss ReductionBibhudatta PatnaikNo ratings yet

- Application of Fuzzy Logic To Priced-Based Unit Commitment Under Price UncertaintyDocument5 pagesApplication of Fuzzy Logic To Priced-Based Unit Commitment Under Price UncertaintyHafeez AnsariNo ratings yet

- Economic DispatchDocument37 pagesEconomic DispatchHasan KurniawanNo ratings yet

- Economic Operation of Power SystemDocument6 pagesEconomic Operation of Power SystemAshok SainiNo ratings yet

- EE4031 2 Economic OperationDocument31 pagesEE4031 2 Economic OperationjaysonlkhNo ratings yet

- Power System Planning and Operational ProblemsDocument39 pagesPower System Planning and Operational ProblemsAddisu MengeshaNo ratings yet

- Sigma Institute of EngineeringDocument56 pagesSigma Institute of EngineeringbhavikNo ratings yet

- Modified Particle Swarm Optimization For Economic-Emission Load Dispatch of Power System OperationDocument15 pagesModified Particle Swarm Optimization For Economic-Emission Load Dispatch of Power System OperationArifAmzarNo ratings yet

- Least Cost System Operation: Economic Dispatch 2: Smith College, EGR 325 March 10, 2006Document37 pagesLeast Cost System Operation: Economic Dispatch 2: Smith College, EGR 325 March 10, 2006DalessandroNo ratings yet

- Iare - Psoc - Lecture NotesDocument67 pagesIare - Psoc - Lecture NotesKURAKULA VIMAL KUMARNo ratings yet

- Chapter 4 Economic DispatchDocument77 pagesChapter 4 Economic DispatchAnubhav Shakya100% (1)

- Unit 5.1-Economic Load DispatchDocument5 pagesUnit 5.1-Economic Load Dispatchmarathi sidNo ratings yet

- Chapter4 Power System Operation-2-26Document25 pagesChapter4 Power System Operation-2-26Rishabh JaiswalNo ratings yet

- Power System Engineering MaterialDocument6 pagesPower System Engineering MaterialAshok SainiNo ratings yet

- Genetic Algorithm For Solving The Economic Load DispatchDocument6 pagesGenetic Algorithm For Solving The Economic Load DispatchSatyendra Pratap SinghNo ratings yet

- Economic Dispatch by Tom Overbye and Ross BaldickDocument39 pagesEconomic Dispatch by Tom Overbye and Ross Baldickfwlwllw100% (1)

- Multi Objective Economic Load Dispatch Using Hybrid Fuzzy, BacterialDocument10 pagesMulti Objective Economic Load Dispatch Using Hybrid Fuzzy, BacterialIAEME PublicationNo ratings yet

- Economic Dispatch 1Document76 pagesEconomic Dispatch 1RathinaKumar100% (1)

- Numericals Unit Commitment Economic DispatchDocument76 pagesNumericals Unit Commitment Economic DispatchyeshhudNo ratings yet

- Power System Analysis: Economic DispatchDocument39 pagesPower System Analysis: Economic DispatchJhon Harold Mercado JuanNo ratings yet

- Psoc Unit 4 NotesDocument16 pagesPsoc Unit 4 NotesAnbalagan GuruNo ratings yet

- P + P P P: Gi I Gi 2 I Gi IDocument5 pagesP + P P P: Gi I Gi 2 I Gi IRajveer FandanNo ratings yet

- 6unit - Optimization Algorithm For Combined Economic and Emission Dispatch With Security ConstraintsDocument4 pages6unit - Optimization Algorithm For Combined Economic and Emission Dispatch With Security ConstraintsDr. B. Srinivasa Rao Professor, EEE DepartmentNo ratings yet

- 34AGDocument5 pages34AGgaribello.davidNo ratings yet

- Hooke Jeeves Method - 15Document11 pagesHooke Jeeves Method - 15Kelly SantosNo ratings yet

- PSOC Unit#4Document10 pagesPSOC Unit#4api-3741873No ratings yet

- Solution of Non-Convex Economic Load Dispatch Problem With Valve Point Loading Effects Using PSODocument9 pagesSolution of Non-Convex Economic Load Dispatch Problem With Valve Point Loading Effects Using PSOTaimur KhanNo ratings yet

- Optimal Economic Dispatch of Power Generation Solution Using Lightning Search AlgorithmDocument8 pagesOptimal Economic Dispatch of Power Generation Solution Using Lightning Search AlgorithmIAES IJAINo ratings yet

- Lec 3-Economic Dispatch of A Power SystemDocument16 pagesLec 3-Economic Dispatch of A Power Systemجلال محسنNo ratings yet

- EE4031 2 Economic Operation PDFDocument31 pagesEE4031 2 Economic Operation PDFRavishankar KankaleNo ratings yet

- Electrical Engineering Engineering Computer Techniques in Power System Analysis Economic Operation of Power System NotesDocument26 pagesElectrical Engineering Engineering Computer Techniques in Power System Analysis Economic Operation of Power System NotesSIDDHANT SAHUNo ratings yet

- Syllabus Unit Iv Unit Commitment and Economic DispatchDocument23 pagesSyllabus Unit Iv Unit Commitment and Economic DispatchBALAKRISHNANNo ratings yet

- Economic Load Dispatch Using A Chemotactic Differential Evolution AlgorithmDocument8 pagesEconomic Load Dispatch Using A Chemotactic Differential Evolution AlgorithmSandeep SahuNo ratings yet

- Power System Control and OperationDocument3 pagesPower System Control and OperationSantosh ThapaNo ratings yet

- Distributed GenerationDocument6 pagesDistributed GenerationBibhudatta PatnaikNo ratings yet

- Approximation of Variable Cost For The Voltage SupportDocument6 pagesApproximation of Variable Cost For The Voltage SupportInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Psoc 0Document60 pagesPsoc 0Santosh ThapaNo ratings yet

- Economic Dispatch ControlDocument31 pagesEconomic Dispatch ControlTirumalesh ReddyNo ratings yet

- Optimal Power System Analysis Using Matlab Saket Saurabh, MD Irfan Ahmed & Pallavi SoniDocument5 pagesOptimal Power System Analysis Using Matlab Saket Saurabh, MD Irfan Ahmed & Pallavi SoniRai Nazer Hussain KharlNo ratings yet

- Energy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyFrom EverandEnergy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyChristine JuniorNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- EU China Energy Magazine 2023 Summer Double Issue: 2023, #7From EverandEU China Energy Magazine 2023 Summer Double Issue: 2023, #7No ratings yet

- Production and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesFrom EverandProduction and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesNo ratings yet

- Renewable Energy Tariffs and Incentives in Indonesia: Review and RecommendationsFrom EverandRenewable Energy Tariffs and Incentives in Indonesia: Review and RecommendationsNo ratings yet

- Module 4Document67 pagesModule 4Rajveer FandanNo ratings yet

- Quiz1 98Document2 pagesQuiz1 98Rajveer FandanNo ratings yet

- Octave Linux InstructionsDocument1 pageOctave Linux InstructionsRajveer FandanNo ratings yet

- Thermodynamics ProblemDocument2 pagesThermodynamics ProblemRajveer Fandan100% (1)

- Schrodinger: A Wave Equation For Electrons: WavefunctionDocument6 pagesSchrodinger: A Wave Equation For Electrons: WavefunctionRajveer FandanNo ratings yet

- BisectorDocument3 pagesBisectorRajveer FandanNo ratings yet

- P + P P P: Gi I Gi 2 I Gi IDocument5 pagesP + P P P: Gi I Gi 2 I Gi IRajveer FandanNo ratings yet

- Thomson Invented The World's First Pneumatic Tyres in 1845. They Consisted of Rubber Tubes FilledDocument2 pagesThomson Invented The World's First Pneumatic Tyres in 1845. They Consisted of Rubber Tubes FilledRajveer Fandan100% (1)

- Rubber TireDocument5 pagesRubber TireRajveer FandanNo ratings yet

- 88.automatic Power Failure Indication System For Domestic and Commercial UseDocument5 pages88.automatic Power Failure Indication System For Domestic and Commercial UseRajveer Fandan100% (1)

- Makeup Test: All Independence Day HMCTDocument7 pagesMakeup Test: All Independence Day HMCTRajveer FandanNo ratings yet

- Air-Bag: (1) Connector InformationDocument34 pagesAir-Bag: (1) Connector InformationbakriramziNo ratings yet

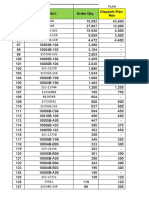

- Order Qty Vs Dispatch Plan - 04 11 20Document13 pagesOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNo ratings yet

- WDU 2.5 enDocument14 pagesWDU 2.5 enAhmadBintangNegoroNo ratings yet

- Sewerage & Sewage Treatment PlantDocument26 pagesSewerage & Sewage Treatment PlantSyed ZamanNo ratings yet

- PT14 Engine Monitor 1Document2 pagesPT14 Engine Monitor 1BJ DixNo ratings yet

- Comparative Tracking Index of Electrical Insulating MaterialsDocument6 pagesComparative Tracking Index of Electrical Insulating MaterialsAbu Anas M.SalaheldinNo ratings yet

- Production of Isopropyl Palmitate-Experimental StudiesDocument12 pagesProduction of Isopropyl Palmitate-Experimental Studiesikaw_3No ratings yet

- Genius Publication CatalogueDocument16 pagesGenius Publication CatalogueRaheel KhanNo ratings yet

- Asgmnt HECRASDocument7 pagesAsgmnt HECRASShahruzi MahadzirNo ratings yet

- Comfort and Performance Your Customers DemandDocument18 pagesComfort and Performance Your Customers Demandgizex2013No ratings yet

- GM Passlock II SystemDocument14 pagesGM Passlock II Systemalmia tronicsNo ratings yet

- SemDocument31 pagesSemkaushik4208No ratings yet

- Differences Between VSI and CSI Converter Operation Modes.Document1 pageDifferences Between VSI and CSI Converter Operation Modes.Sushil NamoijamNo ratings yet

- AB-522 Standard Pneumatic Test Procedure RequirementsDocument16 pagesAB-522 Standard Pneumatic Test Procedure RequirementsShank HackerNo ratings yet

- Elevator Traffic Analysis - Passanger Elevators Option-1Document5 pagesElevator Traffic Analysis - Passanger Elevators Option-1Amit GuptaNo ratings yet

- High Integrity Aluminum (GENERAL)Document140 pagesHigh Integrity Aluminum (GENERAL)Kmilo Giraldo100% (3)

- Prospects For Alkaline Zero Gap Water Electrolysers For Hydrogen ProductionDocument16 pagesProspects For Alkaline Zero Gap Water Electrolysers For Hydrogen Productionkhan47pkNo ratings yet

- BD+ CD+ XD+ - tcm833-3534072Document20 pagesBD+ CD+ XD+ - tcm833-3534072MisterMMNo ratings yet

- Bazele Matematice Ale Calculatoarelor - Florian Mircea BoianDocument132 pagesBazele Matematice Ale Calculatoarelor - Florian Mircea BoiannimsocNo ratings yet

- EMOC 208 Installation of VITT For N2 Cylinder FillingDocument12 pagesEMOC 208 Installation of VITT For N2 Cylinder Fillingtejcd1234No ratings yet

- Quantity Surveying Division Assessment of Professional Competence Final Assessment 2014 Practice Problems / Part Ii Written TestDocument31 pagesQuantity Surveying Division Assessment of Professional Competence Final Assessment 2014 Practice Problems / Part Ii Written TestjackyNo ratings yet

- 03-1 Synchronous Machines 1 DNDocument25 pages03-1 Synchronous Machines 1 DNsaif thuraonNo ratings yet

- Folder Fiamm Neptune 2010 EngDocument4 pagesFolder Fiamm Neptune 2010 EngchokribNo ratings yet

- Justine J. Beroy: Career ObjectivesDocument5 pagesJustine J. Beroy: Career ObjectivesJustine BeroyNo ratings yet

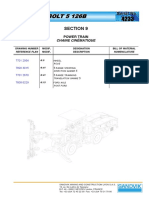

- S09 Power TrainDocument90 pagesS09 Power TrainPLANEAMIENTO MDRILLNo ratings yet

- Apqp - DR SHFTDocument60 pagesApqp - DR SHFTrajesh5000100% (2)

- Whirlpool Duet HTDocument96 pagesWhirlpool Duet HTdanny85901100% (2)

- Lecure Two. ReactorsDocument56 pagesLecure Two. ReactorsSophia WambuiNo ratings yet

- Stair Cases DesignDocument19 pagesStair Cases DesignWrishad Zia93% (14)

- Internship Report May 2016Document11 pagesInternship Report May 2016Rupini RagaviahNo ratings yet