Professional Documents

Culture Documents

6 Drive Mechs

Uploaded by

Hafiz AsyrafCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 Drive Mechs

Uploaded by

Hafiz AsyrafCopyright:

Available Formats

Schlumberger

Basic Petroleum Engineering

FTC

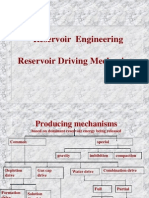

Drive Mechanisms

Drive Mechanisms Water Drive Gas Cap drive Solution Gas Drive Drive problems Secondary Recovery

Notes

JJ Consulting 1997

1 1 1

Schlumberger

Basic Petroleum Engineering

FTC

There is also the gravity drive.

Drive Mechanisms

A virgin reservoir has a pressure controlled by the local gradient. Hydrocarbons will flow if the reservoir pressure is sufficient to drive the fluids to the surface (otherwise they have to be pumped). As the fluid is produced reservoir pressure drops. The rate of pressure drop is controlled by the Reservoir Drive Mechanism. Drive Mechanism depends on the rate at which fluid expands to fill the space vacated by the produced fluid. Main Reservoir Drive Mechanism types are: Water drive. Gas cap drive. Gas solution drive

2 2 2

Notes

Schlumberger

Basic Petroleum Engineering

FTC

Water Invasion 1

Water invading an oil zone, moves close to the grain surface, pushing the oil out of its way in a piston-like fashion.

Water has two advantages , firstly there is water in the hydrocarbon zone in the form of irreducible water with which it can join and hence clean around the grains. Secondly capillary pressure helps the water up the small pore channels.

Notes

The capillary pressure gradient forces water to move ahead faster in the smaller pore channels.

3 3 3

Schlumberger

Basic Petroleum Engineering

FTC

There will always be some oil left in the rock, 100% recovery is impossible.

Water Invasion 2

The remaining thread of oil becomes smaller.

It finally breaks into smaller pieces.

Notes

As a result, some drops of oil are left behind in the channel.

4 4 4

Schlumberger

Basic Petroleum Engineering

FTC

Water Drive

The (normally) large volume of the water system gives additional assistance to this type of drive. The hydrocarbon is pushed out as its pressure drops, while the pressure in the water remains higher hence the water will move to force the oil out.

Notes

Water moves up to fill the "space" vacated by the oil as it is produced.

5 5 5

Schlumberger

Basic Petroleum Engineering

FTC

The production of water will invariably increase. The amount of water finally produced depends on capabilities of the surface production facilities and the economics of the process. It can be as much as 98%. Gas production is simply that associated with the oil and depends on the gas-oil ratio.

Water Drive 2

Water Production

Notes

This type of drive usually keeps the reservoir pressure fairly constant. After the initial dry oil production, water may be produced. The amount of produced water increases as the volume of oil in the reservoir decreases. Dissolved gas in the oil is released to form produced gas.

6 6 6

Schlumberger

Basic Petroleum Engineering

FTC

The very high mobility of gas (low viscosity) means that it goes down the large pore channels bypassing the smaller ones. Once past a zone the gas will continue leaving the oil trapped; it will not be produced.

Gas Invasion

Gas is more mobile than oil and takes the path of least resistance along the centre of the larger channels. As a result, oil is left behind in the smaller, less permeable, channels.

Notes

7 7 7

Schlumberger

Basic Petroleum Engineering

FTC

The main type of gas drive is the gas cap drive. The gas cap expansion forces the oil out. The gas cap needs to be large for this type of drive to succeed.

Gas Cap Drive

Notes

Gas from the gas cap expands to fill the space vacated by the produced oil.

8 8 8

Schlumberger

Basic Petroleum Engineering

FTC

As the gas cap expands the pressure drops hence the drive efficiency goes down. In addition there is always breakthrough of the free gas and production at an apparent high GOR. The reservoir pressure will go down quickly.

Gas Cap Drive 2

As oil production declines, gas production increases. Rapid pressure drop at the start of production.

Notes

9 9 9

Schlumberger

Basic Petroleum Engineering

FTC

Solution Gas Drive

This type of drive uses the energy of expansion of the gas dissolved in the oil as there is no appreciable water or gas cap drive. This is very inefficient as there on a little possible expansion. In addition the reservoir rapidly drops below bubble point in the reservoir itself. This means that gas comes out of solution in the reservoir. This will create problems for production and eventually the reservoir will die.

Notes

After some time the oil in the reservoir is below the bubble point.

10 10 10

Schlumberger

Basic Petroleum Engineering

FTC

The slide shows the rapid decline in all the parameters in the reservoir, pressure, production. The GOR also declines as the gas is produced.

Solution Gas Drive 2

An initial high oil production is followed by a rapid decline. The Gas/Oil ratio has a peak corresponding to the higher permeability to gas. The reservoir pressure exhibits a fast decline.

Notes

11 11 11

Schlumberger

Basic Petroleum Engineering

FTC

Drives General

A water drive can recover up to 60% of the oil in place. A gas cap drive can recover only 40% with a greater reduction in pressure. A solution gas drive has a low recovery.

The slide compares the total cumulative production of the various drive mechanisms against the reservoir pressure. The water drive keeps the pressure high and hence is the most efficient at production the reservoir fluids.

Notes

12 12 12

Schlumberger

Basic Petroleum Engineering

FTC

Drive Problems

Water Drive: Water can cone upwards and be produced through the lower perforations. Gas Cap Drive: Gas can cone downwards and be produced through the upper perforations. Pressure is rapidly lost as the gas expands. Gas Solution Drive: Gas production can occur in the reservoir, skin damage. Very short-lived.

13 13 13

Coning is caused by producing the reservoir at a drawdown that is too high and also having perforations that are too long. The water (or gas) is drawn to the perforated interval and produced. This problem can usually be fixed.

cones upwards

Notes

Schlumberger

Basic Petroleum Engineering

FTC

Secondary Recovery 1

Secondary recovery covers a range of techniques used to augment the natural drive of a reservoir or boost production at a later stage in the life of a reservoir. A field often needs enhanced oil recovery (EOR) techniques to maximise its production. Common recovery methods are: Water injection. Gas injection. In difficult reservoirs, such as those containing heavy oil, more advanced recovery methods are used: Steam flood. Polymer injection. . CO2 injection. In-situ combustion.

14 14 14

Most modern reservoirs have some sort of secondary recovery built into their management from their initial production. The aim of all these schemes is to maintain the pressure in the reservoir as high as possible for as long as possible. The main problem with heavy oil is its high viscosity. Reduction of the viscosity is achieved by heating the fluid, hence the steam injection and the in-situ combustion or by adding CO2 . This substance reduces the viscosity of the oil by two orders of magnitude, for example from 500 centipoise to 5. Polymer injection adds polymers to the injection water to increase the viscosity of this fluid. Ordinary water has a much lower viscosity and hence does not sweep the heavy oil efficiently.

Notes

Schlumberger

Basic Petroleum Engineering

FTC

Water can come from the sea water, or a nearby and different aquifer. The injectors are set in patterns depending on the permeability of the reservoir. Gas often comes from produced can which can be compressed and reinjected into the gas cap. Both types of injection can operate at the same time.

Secondary Recovery 2

water injection

gas injection

Notes

15 15 15

Schlumberger

Basic Petroleum Engineering

FTC

Water Injection

The simplest ( and cheapest) of the techniques Water is injected into a nearby well forcing the oil out The water can either be: sea water Recycled produced water From an aquifer different to that of the reservoir The pattern of injectors depends on the permeability of the reservoir rock and the possibility of problems Five and nine spot are common

Notes

16 16 16

Schlumberger

Basic Petroleum Engineering

FTC

Material Balance

Material Balance Oil Volumes General Equation Simplified Equation Reservoir Simulation

Notes

17 17 17

Schlumberger

Basic Petroleum Engineering

FTC

A reservoir contains an original volume of oil, as this oil is removed the other components of the system move/expand to fill the space vacated. This is described by the drawing. It is not to scale as the gas will expand much more than the rock and water.

Oil volume

gas cap expansion released gas volume Oil Volume oil volume rock/water expansion net water influx

Notes

The original oil volume is replaced by the expansion of the other system components - gas - water - rock

18 18 18

Schlumberger

Basic Petroleum Engineering

FTC

G - original gas cap in place - cumulative gas produced from the gas cap, scf - gas formation volume factor at current pressure RB/scf - gas formation volume factor at the original pressure

Gas Cap Expansion

When oil is produced the gas gap expands to replace part of the oil.

Gpc Bgc Bgci

(G G ) B

pc

gc

GBgci

Notes

The gas cap may shrink if the gas produced is a significant fraction of the initial amount.

19 19 19

Schlumberger

Basic Petroleum Engineering

FTC

N Np Rsi Rs Gps Bgs - original oil in place - cumulative oil produced - initial solution gas oil retio - solution gas-oil ratio at current pressure - cumulative gas produced - current solution gas formation volume factor

Released Gas Volume

Gas cap expansion is always accompanied by the release of gas from the reservoir oil The gas originally in solution can be placed in three categories still in solution produced from the reservoir released from solution but still in the reservoir The equation for the reservoir volume of released gas is:

Notes

[ NR ( N N ) R G ] B

si p s ps

gs

This is the difference between the original gas in solution and the current gas in solution. Subtracting the gas produced gives the released gas still in the reservoir.

20 20 20

Schlumberger

Basic Petroleum Engineering

FTC

N - original oil in place - oil produced - oil formation volume factor

Oil Volume

Np Bo

The reservoir volume of oil remaining at reservoir conditions is:

( N N )B

p

o

Notes

21 21 21

Schlumberger

Basic Petroleum Engineering

FTC

cf pi p cw - formation compressibility (1/psi) - initial formation pressure - current reservoir pressure - water compressibility - initial water saturation

Rock and Connate Water Expansion

Rock and connate (original formation water) expansion are combined in one term for convenience rock expansion =

Swi

NBoi cf ( p p) (1 S ) i wi

Notes

connate water expansion =

NBoi cw Swi ( p p) ( 1 S ) i wi

combining both expressions gives Rock and water expansion =

NBoi (c f + cw Swi ) (1 S )( pi p)) wi

22 22 22

Schlumberger

Basic Petroleum Engineering

FTC

We - cumulative water influx - cumulative produced water - water formation volume factor

Water Influx

The volume of water influx cannot be computed from pressure and fluid properties as has been done for the other fluids. The influx can be inferred from a knowledge of the other terms in the general material balance equation

Wp Bw

Net water influx =

We Wp Bw

Notes

23 23 23

Schlumberger

Basic Petroleum Engineering

FTC

This is the complete equation made up of the terms from the previous pages. Most of the items in the equation are measured, Bo, Rs etc. This general equation assumes everything that could happen does. In practice there are always simplifications, for example there may be no gas cap.

General Material Balance Equation

Original Oil Volume = Gas cap Expansion + Released Gas volume + Oil volume + Rock and Water Expansion + Net Water Influx

Notes

[ NR ( N N ) R G ] B

si p s ps

NBoi = ( G G pc ) B gc GB gci +

gs

( N N ) B + (c

p o

+ cw Swi )

NBoi ( p p) + 1 Swi i

24 24 24

We Wp Bw

Schlumberger

Basic Petroleum Engineering

FTC

N m Np Rp Rsi Rs Boi Bo Bgi Bg Sw cw cf

initial oil in place (initial gas cap volume)/(initial oil volume) cumulative oil production on surface cumulative gas oil ratio initial gas oil ratio gas oil ratio after pressure drop (ie production) initial oil FVF oil FVF after production initial FVF gas gas FVF after production original connate water saturation water compressibility total pore space compressibility

Simplified Material balance

Underground withdrawal

F = N p Bo + ( Rp Rs )Bg + W p Bw

Original oil and dissolved gas expansion

E0 = ( B0 B0 i ) + ( Rsi Rs ) Bg

Gas cap expansion

Eg = B0 i ( Bg Bgi 1)

The objective here is to make a simple term for each specific item. Notes

Expansion of connate water

E f , w = (1 m ) B0 i ( cw Sw + c f 1 Sw )p

Material balance equation

F = N( Eo + m Eg + E f ,w ) + We Bw

25 25 25

Schlumberger

Basic Petroleum Engineering

FTC

Taking the final equation of the previous page and assuming no gas cap and no water movement results in a very simple linear equation. A plot of the observed production, F, against the oil factor, Eo should give a straight line whose slope is the original oil in place.

Simplified Equation

Assuming no initial gas cap and negligible water influx

If the slope if not straight the assumptions of no other fluid interaction are wrong. One possibility is water influx leading to the equation at the bottom, where another linear equation is created, and both N and We are found.

F = NEo

The observed production is a linear function of the the expansion of the oil plus the dissolved gas

If the plot is non linear it could mean water influx

F We = N+ Eo Eo

Notes

This linear equation will take this into account

26 26 26

Schlumberger

Basic Petroleum Engineering

FTC

This form of the equation assumes a gas cap drive mechanism with no water. A plot of F against (Eo +mEg) will give the value for m, the size of the gas cap.

Gas cap drive

In a gas cap drive the equation reduces to

The equation can also be used to solve for both N and m if they are unknown. This type of approach is a good way of obtaining the reserves figures.

F = N( Eo + mEg )

this can be solved for m if the initial oil in place N in known. If both N and m are unknown the equation is rewritten as

Notes

Eg F = N + mN Eo Eo

a best fit solution for both N and m is then found on a linear plot

27 27 27

Schlumberger

Basic Petroleum Engineering

FTC

A reservoir simulation is a modern way of using material balance together with a description of the reservoir to properly manage the resources. It requires a large amount of data and the work of a number of disciplines to get the best possible answer.

Objective of Reservoir Simulation

The objective is to create a live description of the reservoir

The inputs are geology - lithology, units, core data, maps reservoir engineering - flow systems, fluid behaviour, and PVT analysis petrophysics - log interpretation, reservoir parameters, zoning geophysics - areal extent, large scale features

Notes

28 28 28

Schlumberger

Basic Petroleum Engineering

FTC

Model Building

A model of the formation is created using all the available information. This model is divided into blocks. Each block is described by its properties, porosity, permeability, saturations, fluid properties, pressures and so on. The objective is to create a complete description of the reservoir.

One of the major steps in the simulation is the creation of the reservoir model. The process uses data from well logs and tests and seismic surveys to paint a picture of the part of the system under study. This can vary from a small part of the reservoir to an entire field. The more complex the model the more information that is required.

Notes

29 29 29

Schlumberger

Basic Petroleum Engineering

FTC

The procedure outlined is a crude approximation of the work involved. Before even this flow chart there is the vital stage of data collection. Reservoir characterisation is the process of making a detailed analysis of the log and core data. The model is then constructed from this and test data. The history match checks the models validity by comparing the predicted past with the actual past in terms of pressures and production. The reservoir management plan can only be made if the history match has worked.

Reservoir Simulation Procedure

Reservoir Characterisation

Model Construction

Model Validation History Match

Notes

Prediction of Future Performance

Prepare Reservoir Management Plan

30 30 30

Schlumberger

Basic Petroleum Engineering

FTC

History Match

A match is made of the rates and pressures measured over time with those predicted by the computer model. If the match is good reservoir management plans can be made. If the match is poor the model has to be reviewed.

The example shows the match of water and gas rates over a period of a few years. In general the match is good. If there were large deviations the model has to be reviewed and the process rerun. A single pass of a history match can take over a day to run.

Notes

31 31 31

You might also like

- Petroleum Production Engineering Boyun GuoDocument15 pagesPetroleum Production Engineering Boyun GuoDiandra Aullia100% (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Carrier Refrigerant Piping SystemsDocument57 pagesCarrier Refrigerant Piping Systemsrpiland2100% (5)

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Reservoir Material BalanceDocument37 pagesReservoir Material BalancejacobNo ratings yet

- Tutorial On Cryogenic Turboexpanders: by Jigger JumonvilleDocument8 pagesTutorial On Cryogenic Turboexpanders: by Jigger JumonvilleabuahnfNo ratings yet

- 2 Phase Seperator PDFDocument66 pages2 Phase Seperator PDFKanthan DevanNo ratings yet

- Oil Facility: Main ProcessDocument1 pageOil Facility: Main ProcessRaghavan VenkatramanNo ratings yet

- Otc 15179 MSDocument10 pagesOtc 15179 MSHafiz AsyrafNo ratings yet

- C 5 Vacuum DistillationDocument20 pagesC 5 Vacuum DistillationAhmed Mohamed KhalilNo ratings yet

- Basic Tank Battery DesignDocument14 pagesBasic Tank Battery Designgermangsilva100% (2)

- Aapg Memoir Drive System MechanicalDocument11 pagesAapg Memoir Drive System MechanicalMuhammad Ihsan AljabbarNo ratings yet

- Reservoir Engineering-: Primary Recovery MechanismsDocument16 pagesReservoir Engineering-: Primary Recovery Mechanismsعلي حسين جميل100% (1)

- Petroleum Refinery EngineeringDocument9 pagesPetroleum Refinery EngineeringMahtab SajnaniNo ratings yet

- Crude Oil Processing On Offshore Facilities PDFDocument14 pagesCrude Oil Processing On Offshore Facilities PDFmohit4821No ratings yet

- Introduction To Plunger LiftDocument6 pagesIntroduction To Plunger LiftMiguel Urzagaste CruzNo ratings yet

- Gas LiftDocument17 pagesGas LiftSaurabhNo ratings yet

- h2 Dew PointDocument4 pagesh2 Dew Pointgeddam0610882592% (12)

- Drive MechanismsDocument12 pagesDrive Mechanismsl3gsdNo ratings yet

- PerforationDocument20 pagesPerforationHafiz AsyrafNo ratings yet

- 6 - Miscible FloodingDocument53 pages6 - Miscible FloodingAndi Susetio100% (1)

- Introductión The Plunger LiftDocument10 pagesIntroductión The Plunger LiftLuis Enrrique ArellanoNo ratings yet

- 8a. Reservoir Drive Mechanics and Recovery Factors PDFDocument16 pages8a. Reservoir Drive Mechanics and Recovery Factors PDFShadan JavedNo ratings yet

- Primary RecoveryDocument20 pagesPrimary RecoveryMohammed OmranNo ratings yet

- Chap 3 - Drive Mechanism & MBEDocument29 pagesChap 3 - Drive Mechanism & MBEMohammed BahramNo ratings yet

- Drive Mechanisms: FTC Basic Petroleum EngineeringDocument31 pagesDrive Mechanisms: FTC Basic Petroleum EngineeringAnwer MohammedNo ratings yet

- SC RE Chap11-Drive MechanismsDocument45 pagesSC RE Chap11-Drive Mechanismsweldsv100% (1)

- Pro Tech 1 CH 2Document29 pagesPro Tech 1 CH 2weldsvNo ratings yet

- Gemsa Company Exam From AONG WebsiteDocument12 pagesGemsa Company Exam From AONG WebsiteezioNo ratings yet

- Reservoir Drive MechanismsDocument28 pagesReservoir Drive Mechanismsnovia100% (1)

- .The Term Refers To The Production of Hydrocarbons From A Reservoir Without The Use of Any Process (Such As Fluid Injection) To Supplement The Natural Energy of The ReservoirDocument32 pages.The Term Refers To The Production of Hydrocarbons From A Reservoir Without The Use of Any Process (Such As Fluid Injection) To Supplement The Natural Energy of The ReservoirHomam MohammadNo ratings yet

- PTRT 1301 CH7 Managing Oil and Gas ProductionDocument24 pagesPTRT 1301 CH7 Managing Oil and Gas ProductionMohammed adelNo ratings yet

- Chapter 3: Reservoir DrivesDocument14 pagesChapter 3: Reservoir Drivesardie rayNo ratings yet

- Drive MechanismsDocument36 pagesDrive MechanismsLemony SnickitNo ratings yet

- Mekanisme Aliran FluidaDocument24 pagesMekanisme Aliran FluidaFaisal FadilahNo ratings yet

- Gas Lift in Heavy Oil ManuscriptDocument9 pagesGas Lift in Heavy Oil Manuscriptmahmoud korieshNo ratings yet

- Reservoir Engineering Reservoir Driving MechanismsDocument23 pagesReservoir Engineering Reservoir Driving MechanismsAnoo SebastianNo ratings yet

- SPE 141026 Development and Application of Foamers To Enhance Crude Oil ProductionDocument8 pagesSPE 141026 Development and Application of Foamers To Enhance Crude Oil ProductionRégis OngolloNo ratings yet

- Reservoir Drive MechanismsDocument7 pagesReservoir Drive MechanismsgorkemerkanliNo ratings yet

- Chapter 3Document28 pagesChapter 3peter.pucciNo ratings yet

- Drive MechanismsDocument5 pagesDrive MechanismsVGNo ratings yet

- Various Methods of Oil Recovery: By:-Geikaran Patel ROLL NO:-U10CH025Document26 pagesVarious Methods of Oil Recovery: By:-Geikaran Patel ROLL NO:-U10CH025duyvkNo ratings yet

- Natural Gas Production: FormationDocument11 pagesNatural Gas Production: FormationmohamedNo ratings yet

- A. Water DriveDocument4 pagesA. Water DriveRazzelNo ratings yet

- Reservoir Drive Mechanism-FinalDocument52 pagesReservoir Drive Mechanism-Finalasdfghj100% (1)

- Enhanced Oil Recovery Techniques: Jntu Iv Year B.Tech Petroleum EngineeringDocument54 pagesEnhanced Oil Recovery Techniques: Jntu Iv Year B.Tech Petroleum EngineeringNadeemSKNo ratings yet

- 1.3 NotedDocument2 pages1.3 NotedAlbus SeverusNo ratings yet

- ESP Component and Design ItDocument76 pagesESP Component and Design ItomerkhalidhameedNo ratings yet

- Drive Mechanisms For Reservoir EngineeringDocument9 pagesDrive Mechanisms For Reservoir Engineeringrichardkasana54No ratings yet

- Chapter 5: Exploration and General Methods For Oil Recovery NotesDocument18 pagesChapter 5: Exploration and General Methods For Oil Recovery NotesAnonymous rKosw5xbJtNo ratings yet

- Production OptimizationDocument7 pagesProduction OptimizationYudi Setiawan100% (1)

- Secondary Recorvery in Dulang FieldDocument10 pagesSecondary Recorvery in Dulang FieldEga Puspita LerianaNo ratings yet

- Ikwumonu 2011Document11 pagesIkwumonu 2011Google mailNo ratings yet

- C-18.a-Intro To Natural Gas WellsDocument6 pagesC-18.a-Intro To Natural Gas Wellsteddy132No ratings yet

- Natural Drive MechanismsDocument4 pagesNatural Drive MechanismsWaleed Ejaz0% (1)

- Chapter 3 ProductionDocument10 pagesChapter 3 ProductionMuhamed BadawiNo ratings yet

- Ref Three EditionDocument9 pagesRef Three EditionDragon DangerNo ratings yet

- Reservoir Drive MechanismsDocument36 pagesReservoir Drive MechanismsVGNo ratings yet

- Session VI - Petrochemical Processing: A. PropyleneDocument5 pagesSession VI - Petrochemical Processing: A. PropyleneMallela Sampath KumarNo ratings yet

- 03-Petroleum Recovery ProcessesDocument20 pages03-Petroleum Recovery Processesmagdy1991No ratings yet

- Enhanced Oil Recovery TechnologyDocument4 pagesEnhanced Oil Recovery Technologykhalifa abdulsalamNo ratings yet

- 3 Quarterly Presentation: Presented by MentorDocument33 pages3 Quarterly Presentation: Presented by MentorRishiNo ratings yet

- Institute For Research and Urban Planning of CuritibaDocument42 pagesInstitute For Research and Urban Planning of CuritibaHafiz AsyrafNo ratings yet

- Word 2010 For DissertationDocument18 pagesWord 2010 For DissertationAnuj BishtNo ratings yet

- Lecture 2.0 PolymerisationDocument24 pagesLecture 2.0 PolymerisationkechikkrunchNo ratings yet

- Lecture 2.0 PolymerisationDocument24 pagesLecture 2.0 PolymerisationkechikkrunchNo ratings yet

- MeshingDocument35 pagesMeshingNilambar BarihaNo ratings yet

- 2-Urban Rail Development Plan Urdp June2013Document71 pages2-Urban Rail Development Plan Urdp June2013Hafiz AsyrafNo ratings yet

- Faretable Cash Rapidkl 2015Document1 pageFaretable Cash Rapidkl 2015Safar BrolyNo ratings yet

- Otc 5402 MSDocument10 pagesOtc 5402 MSHafiz AsyrafNo ratings yet

- WP2000 13Document32 pagesWP2000 13Hafiz AsyrafNo ratings yet

- ChangLiu General CFDDocument2 pagesChangLiu General CFDprakash_vinayak4946No ratings yet

- 7-Interchange Integration Plan Iip June2013Document47 pages7-Interchange Integration Plan Iip June2013Hafiz AsyrafNo ratings yet

- IntelligentDocument0 pagesIntelligentCarlos MagnoNo ratings yet

- Otc 5402 MSDocument10 pagesOtc 5402 MSHafiz AsyrafNo ratings yet

- Evaluation of Fishing Gear Induced Pipeline Damage: B. King R. DaviesDocument8 pagesEvaluation of Fishing Gear Induced Pipeline Damage: B. King R. DaviesHafiz AsyrafNo ratings yet

- Of Failure, Weak Formations Can Be Strengthened By: Oil, J 0Document9 pagesOf Failure, Weak Formations Can Be Strengthened By: Oil, J 0Hafiz AsyrafNo ratings yet

- OTC 15177 Well Intervention Using Rigless TechniquesDocument13 pagesOTC 15177 Well Intervention Using Rigless TechniquesHafiz Asyraf100% (1)

- Otc 23916 MSDocument7 pagesOtc 23916 MSHafiz AsyrafNo ratings yet

- OTC 5808 Deepwater Drilling: References and Illustrations at End of Paper in A Second Stage Initiated WithDocument10 pagesOTC 5808 Deepwater Drilling: References and Illustrations at End of Paper in A Second Stage Initiated WithHafiz AsyrafNo ratings yet

- SPE 10035 MS Production LoggingDocument32 pagesSPE 10035 MS Production LoggingHafiz Asyraf100% (2)

- Drilling Speeds: Size of HoleDocument6 pagesDrilling Speeds: Size of Holeshaumeng9292No ratings yet

- Api 55 103Document8 pagesApi 55 103shaumeng9292No ratings yet

- SPE-64425-MS-Considering The Reservoir in Determining A Perforation StrategyDocument8 pagesSPE-64425-MS-Considering The Reservoir in Determining A Perforation StrategyHafiz AsyrafNo ratings yet

- Water - Chemical Treatment and ManagementDocument8 pagesWater - Chemical Treatment and ManagementHafiz AsyrafNo ratings yet

- SPE-58985-MS-Production Analysis of Commingled Gas Reservoirs - Case HistoriesDocument10 pagesSPE-58985-MS-Production Analysis of Commingled Gas Reservoirs - Case HistoriesHafiz AsyrafNo ratings yet

- Heavy Duty Wireline Fishing in HPHT Sour WellDocument11 pagesHeavy Duty Wireline Fishing in HPHT Sour WellHafiz AsyrafNo ratings yet

- SPE-160924-MS - To Develop The Optimum Field Development Plan For Condensate Well Using IPMDocument12 pagesSPE-160924-MS - To Develop The Optimum Field Development Plan For Condensate Well Using IPMHafiz AsyrafNo ratings yet

- Drilling & Completion of Horizontal WellsDocument59 pagesDrilling & Completion of Horizontal WellsHafiz AsyrafNo ratings yet