Professional Documents

Culture Documents

Transient Stability Analysis of An Industrial Cogeneration System

Uploaded by

vetsasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Transient Stability Analysis of An Industrial Cogeneration System

Uploaded by

vetsasCopyright:

Available Formats

Transient Stability Analysis of an Industrial Cogeneration System

Hung-Cheng Chen Shang-Yi Chen Shun-Chung Shih Department of Electrical Engineering, National Chin-Yi University of Technology hcchen@ncut.edu.tw chenshangyi@xuite.net scsu@ncut.edu.tw Abstract

The purpose of the paper is to analyze the transient stability of an industrial cogeneration system in Hsin-Chu Science-Based Industrial Park using ETAP software. The cogeneration system is installed two 161kV/161kV high-impendence transformers with tap-changer to connect with TPC for decreasing the short-circuit fault current and increasing the fault critical clearing time. The transient stability of three types of operation modes in cogeneration units, 3G1S, 2G1S, and 1G1S, is analyzed. Under the 3G1S operation mode, the system frequency immediately restores to 60Hz after tie line tripping with the TPC. Under the 1G1S and 2G1S operation modes, the system frequency will continuously decrease after tie line tripping with the TPC. The system frequency must perform the load shedding to put back to 60Hz. Keywords: cogeneration, protection transient stability relays, power supply for Power Company, but solving the problems of unstable power quality in power system. The results of this study can make a reference to the cogeneration facility constructed by high-tech factory and help the high-tech manufacturers to face the dilemma of the current electricity problems. Finally, the TPC and manufacturers in the Science Park can create the aspect of twin win.

2. System Structure

The cogeneration system for this study is built in Hsin-Chu ScienceBased Industrial Park. Hsin-Yu cogeneration factory has built three 45 MW gas turbine generators and one 36.6 MW steam turbine unit. Single line diagram of the system is shown in figure 1 [1], [2]. The cogeneration units are parallel connected with TPC mainly by two three-winding isolation transformers: TRAA and TRBB. The primary and secondary windings of the transformers all adopt 161 kV with Y-connection, their capacities are 90MVA and 60MVA, respectively. The third winding adopts 11kV with -connection, its capacity is 30MVA. There is a parallel connection between transformers and TPC. In addition to improving the power supply reliability, it also achieves the goal of the fault current restriction.

1. Introduction

The cogeneration system in Hsin-Chu Science-Based Industrial Park is selected for case study in this paper. Because the Science Park is one of the most important high-tech semiconductor industries in Taiwan, the needs of power service quality and reliability are much higher than those of general customers. When suffering from the abnormal power failure and voltage dips, the high-tech manufacturers not only cause a loss, but even the high-precision processing equipments lead to the serious damages. Therefore, keeping the reliability and stability of power service quality for the Science Park become a quite important issue. To solve the power quality problems for the Science Park, Taiwan Power Company (TPC) has additional set the power substation to the Science Park and changed the catenarys power wire into underground distribution system with loop scheme. Power system in the Science Park keeping a duty of high power quality is the joint duty for the TPC and Science Park customers. Especially, many manufacturers in Science Park installing the cogeneration equipments will lead to one of the important factors about the effects of power service quality. Therefore, if we can properly plan cogeneration units in high-tech Science Park, it not only effectively copes with insufficient

Figure 1. One-Line Diagram of the cogeneration System

2.1 Short-Circuit Fault Analysis

The breaker capacity is 40kA usually used at 161kV power supply loop. The TPC limits the maximum short-circuit current not exceeding 2kA for the cogeneration units because the TPC provides a maximum fault current 38.06kA. To deal with this problem, the cogeneration system has set two 161kV/161kV high-impendence transformers with tap-changer, which restricts the breaking fault current provided by the cogeneration units. According to ANSI standard, the breaking speed of the breaker and the parting time of the contact are set as 3 and 2 cycles, respectively. Having been installed the 161kV/161kV transformers, the instantaneous fault current provided by the cogeneration units is 1.54kA, which will satisfy the demands of TPC. The originally total instantaneous symmetric short-circuit current is 38.06kA at the TPC Long-Song substation. If the 161kV/161kV transformers are not installed, then the instantaneous fault current increases 2.64kA provide by the cogeneration units. Unfortunately, the total instantaneous symmetric short-circuit current is increased to 40.7kA at the Long-Song substation. From the short-circuit fault analysis, if the industrial cogeneration system is directly connected to the TPC system, the short-circuit capacity of the Long-Song substation will be greater than 40kA when a fault occurs. Therefore, we should adopt the 161kV/161kV transformers to connect with TPC system and then the short-circuit capacity is less than 40kA to meet the requirement of the TPC.

respectively.

2.2.3 Governor Model

The rotor speed of the generator in the governor control system serves as a main feedback signal. The comparison between the signal and reference speed gets the speed error, again by the error, it will serve as the change in the position of the steam valve to regulate the amount of steam entering the turbine. At last, the change in the output of mechanical power for turbine is performed so that the generators after the system disturbance occurred can restore to synchronous operation. The governors of gas turbine from GTG1 to GTG3 in the industrial cogeneration system are all GAST TYPE, but the governor of steam turbine STG is IEEE TYPE1. Their control block diagrams are shown in Figures 4 and Figures 5, respectively.

Figure 2. Block Diagram of Exciter Control System for the Gas Turbines

2.2 System Modeling

The cogeneration system consists of generators, exciters, governors, load and other equipments. In this study we would like to establish the mathematical models of these components first. We will now illustrate the equivalent models of the important components for this system below.

2.2.1 Generator Model

In this paper, the generator sets of the industrial cogeneration system will take into account the detailed effects of transient and sub-transient on the generator. It is assumed that the d-axis and q-axis all have damping coils. We will perform the simulation of the operation of generator under the saturation and un-saturation to obtain the more precise transient stability [3]. Figure 3. Block Diagram of Exciter Control System for the Steam Turbine

2.2.2 Exciter Model

The excitation systems of gas turbine units from GTG1 to GTG3 in the cogeneration system are all IEEE TYPE3, but the excitation system of steam turbine unit STG is IEEE TYPE2 [4]. Their control block diagrams are shown in Figures 2 and Figures 3,

Figure 4. Block Diagram of Governor Control System for the Gas Turbines

Figure 5. Block Diagram of Governor Control System for the Steam Turbine

Figure 6. Voltage variations at Bus 903, 931, and 932 with 161kV/161kV Transformers

3. Relay Setting for Tie Line Tripping

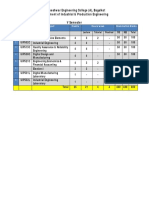

To make sure the power quality, power supply reliability, and utility safety operation of cogeneration plant after connecting to the TPC system, the cogeneration plant must install some different types of protection relays at TPC duty point. When the TPC system occurs fault disturbance resulting in cogeneration generator units or significant loads tripping inside the plant, it is necessary to trigger the protection relays action to trip the main breaker in TPC system tie line. The cogeneration plant can then be kept at an independent stable operation [5], [6]. The severest fault in power system is the ground faults. The customers equipments should ensure keeping continuously stable operation when a ground fault occurred. Therefore, the relay for tie line tripping connected to the TPC system must trip within 0.1 sec. Because bus 903 is more close to the fault point than bus 931 and 932, the voltage drop at bus 903 is deeper than others. The voltage drops to 0.2456pu during the fault period with 161kV/161kV transformers and 0.0037pu without 161kV/161kV transformers, respectively. The bus 931 voltage drops to 0.4543pu and 0.3029pu, and the bus 932 voltage drops to 0.4223pu and 0.251pu. From these results, we observe that the voltage drop at bus 903 is greater than those at bus 931 and 932, as shown in Figures 6 and 7 [7]. In this paper, we will analyze the following three different types of operation modes for the industrial cogeneration system. The power generation for each gas turbine is 56.25MW with a power factor of 0.8 and for steam turbine is 36.6MW with a power factor of 0.8. The total load of the customers in cogeneration system is 153.97MW. Table 1 shows all the output power of each cogeneration unit and total load for three different types of operation modes.

Figure 7. Voltage variations at Bus 903, 931, and 932 without 161kV/161kV Transformers Table 1. Operation Modes of Cogeneration Units

Operation Modes 3G1S 2G1S 1G1S GTG1 (MW) 45 45 45 GTG2 (MW) 45 45 OFF GTG3 (MW) 45 OFF OFF STG (MW) 36.6 36.6 36.6 Total Gen(MW) 171.6 126.6 81.6 Total Load(MW) 153.97 153.97 153.97

3.1

3G1S Operation Mode

Under the 3G1S operation mode, we suppose that a fault is occurred at bus 901 in TPC system at 0.2 sec. The tie line between the cogeneration plant and the TPC system must be tripped after fault occurrence. At the moment, the power generation capacity is greater than the load demand, which the electrical powers of the gas and steam turbines are at their maximum ratings of 45MW and 36.6MW, respectively. After the tie line tripping, all the cogeneration units will settle to a new stable operation point at which the electrical power outputs will achieve to the 42.114MW, 35.839MW, 39.018MW, and 39.103MW, respectively. The cogeneration system frequency can fast restore to 60Hz. Figures 8 and 9 show the curves of the electrical power outputs and speeds.

Figure 11. Generator Speeds for 2G1S Operation Mode Figure 8. Electrical Power Outputs for 3G1S Operation Mode

3.3

1G1S Operation Mode

Under the 1G1S operation mode, after the cogeneration plant has been isolated from the TPC system, the frequency will continuously drop and eventually collapse, as shown in Figures 12 and 13. From the preceding results, if the system frequency wants to restore to the 60Hz and keep stable operation for both 1G1S and 2G2S operation modes, then it must perform the load shedding. The foregoing cases can be simulated using electrical transient analysis program (ETAP) software [8].

Figure 9. Generator Speeds for 3G1S Operation Mode

3.2

2G1S Operation Mode

Under the 2G1S operation mode, the cogeneration plant has been isolated from the TPC system after the tie line tripping at 23th cycles (0.384 sec.). The electrical power outputs of the generators have reached their maximum values of 56.25MW, 39.914 MW, and 56.25MW. At the moment, the total power generation capacity is less than the load demands. Hence, the generator frequencies will drop slowly so that these generator units can not keep operating for a long time, as shown in Figures 10 and 11.

Figure 12. Electrical Power Outputs for 1G1S Operation Mode

Figure 10. Electrical Power Outputs for 2G1S Operation Mode

Figure 13. Generator Speeds for 1G1S Mode Operation Mode

4. Study on Load Shedding

The cogeneration plant performs the parallel operation with the TPC in order to supply power with reliability and safety. When the system operates at a stable equilibrium status, the cogeneration plant is not necessary to carry out any load shedding. However, when the fault is occurred and the tie line is tripped to isolate from the TPC system, the electric power generation may be insufficient to supply to the demand inside the cogeneration system. The system frequency will continuously drop. Consequently, it causes the industrial cogeneration units to trip and factory to power off. Therefore, after the cogeneration system has isolated from the TPC system, performing the load shedding based on the change in frequency becomes an extremely important thing. Through shedding some unimportant load, generator units can maintain and restore the stable operation. After performing the tie line tripping, we can compute the initial frequency decay rate of the industrial cogeneration system. From equation (1), the amount of load to be unloaded can be determined [9] to avoid the occurrence of a misjudged thing due to the rapid load changes. The incorrect unloading in the cogeneration units results in the collapse of the power system. From equation (1), the initial frequency decay rate can be solved to determine the amount of unloading which can reduce the drawbacks of both excess in unloading and insufficient unloading. Moreover, the computation of equation (1) spends less time.

Pstep = 2 H sys d w 2 H sys = m0 w0 dt 60

27.8 MW, respectively. Under the 2G1S operation mode, the electrical power outputs after the tie line tripping from the TPC system and load shedding are shown in Figure 14. At this moment, the amount of power generation and the amount of load demand inside the cogeneration plant has reached the balanced condition. Namely, the output power of the gas and steam turbines are 48.004MW, 36.578MW and 44.988MW, respectively. Figure 15 shows the frequency curve after the tie line tripping from the TPC system for the 2G1S operation mode. This figure shows that the system performs the load shedding after 3.86sec., the frequency of the cogeneration plant has restored to the stable state of 60 Hz. Under the 1G1S operation mode and after the tie line tripping from the TPC system, the amount of power generation and the amount of load demand inside the cogeneration plant have reached the balanced condition. The power outputs of the gas and steam turbines are 48.247MW and 36.62MW, as shown in Figure 16. The frequency curve before and after load shedding is given in Figure 17. This figure shows that the frequency of the cogeneration system has restored to the stable state of 60Hz after performing the load shedding and through 6.645 sec.

(1)

where Pstep is the total amount of load to be shed. mo is the initial frequency decay rate at the moment of tie line tripping.

H sys H MVA1 + H 2 MVA2 + ...... + H n MVAn = 1 MVAsys

(2)

Figure 14. Electrical Power Outputs for 2G1S Operation Mode with Load Shedding

where Hsys is the equivalent system inertia constant of the cogeneration system and n is the number of the cogeneration units. This study finds that the cogeneration system encountered the short-circuit fault in the 1G1S and 2G2S operation modes and performed the tie line tripping from the TPC system, it was necessary to execute load shedding to prevent frequency continuously drop and had an opportunity of recovering to 60Hz. We adopted the load shedding of a detective frequency drop manner to perform the unloading. For 1G1S operation mode, we obtained the inertia constant H and mo as 2.065 and 11.84 based on equations (1) and (2). For 2G1S operation mode, the H and mo can be computed as 3.101 and 2.69. Again, substituting the foregoing values into equation (1), we can obtain the Pstep as 81.5MW and

Figure 15. Generator Speeds for 2G1S Operation Mode with Load shedding

power systems of the TPC and cogeneration plant can keep a normal independent operation after the tie line tripping.

Acknowledgements

The research was supported in part by the National Science Council of the Republic of China, under Grant No. NSC96-2221-E-167-029-MY3.

References

Figure 16. Electrical Power Outputs for 1G1S Operation Mode with Load Shedding [1] H.C. Yu, Fault Calculation and Stability Analysis for a Cogeneration System in Science Park, Master Thesis, Department of Electrical Engineering, National Sun Yat-Sen University, Kaohsiung, Taiwan, Dec. 2000. [2] C.T. Hsu, Cogeneration System Design for a High-Tech Science-Based Industrial Park, IEEE Trans. On Industrial Applications, Vol. 39, No. 5, pp.1486-1492, Sep/Oct 2003. [3] IEEE Working Group, Hydraulic Turbine and Turbine Control Modes for System Dynamic Studies, Technical Report, IEEE Trans. on Power Systems, Vol. 7, No. 1, pp. 167-179, Feb. 1992. [4] IEEE Standards Board eds., IEEE Recommended Practice for Excitation System Models for Power System Stability Studies, Technical Report, Institute of Electrical and Electronics Engineers, Inc. Press, New York, March 1992. [5] Y.D. Lee, The Settings of Tie Line Tripping and Load Shedding for Cogeneration Systems, Master Thesis, National Taiwan University of Science and Technology, Taipei, June 1999. [6] P. M. Anderson and M. Mirheydar, An Adaptive Method for Setting Under frequency Load Shedding Relays, IEEE Trans. on Power System, Vol. 7, No. 2, pp. 647-655, May 1992. [7] C.T. Hsu, Voltage Sags Improvement for the High-Tech Industrial Customers by Using Cogeneration System, IEEE Region 10 Conference, Taipei, Taiwan, pp. 1-4, Oct/Nov 2007. [8] ETAP 2010 Operations Technology, Inc., Available: http://www.etap.com [9] C.L. Chang et al., Practical Measurement and Improvement for Low Frequency Oscillation Phenomenon of Taipower System, Research Report, Ministry of Economic Affairs, R.O.C., June 1994. [10] P. Kundur, Power System Stability and Control, McGraw-Hill Press, New York, 1994.

Figure 17. Generator Speeds for 1G1S Operation Mode with Load Shedding

6. Conclusions

This paper mainly investigates the power system transient stability for the high-tech Science Park with cogeneration facility. The load shedding has been applied to the industrial cogeneration system under the different tie line tripping opportunities and operation modes. If the system adopts 161kV/161kV transformers to connect to the TPC system in parallel, this study finds that the industrial customers system voltage sags can be improved during fault contingency. The manufacturers can avoid a serious loss caused by the power failure, which contributes the coordination between the protective relays [10]. In addition, the mechanism of tie line tripping is very important between cogeneration plant and the TPC system. Except that we can select the frequency relays to activity we can also utilize the under voltage relays to perform a proper load shedding. In this way, the improper tie line tripping can be avoided due to the internal fault of cogeneration system, and the both

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Modeling and Control For Large Capacity PDFDocument8 pagesModeling and Control For Large Capacity PDFvetsasNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Technical Implementation of Cross Bonding On Underground High Voltage Lines Projects (Sobral2011) PDFDocument4 pagesTechnical Implementation of Cross Bonding On Underground High Voltage Lines Projects (Sobral2011) PDFdaegerteNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Meeting NEC For Selective Coordination - Long R2Document213 pagesMeeting NEC For Selective Coordination - Long R2Gilberto Mejia100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Basler Edm 2000 AvrDocument23 pagesBasler Edm 2000 AvrvetsasNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 87t CharacteristicsDocument1 page87t CharacteristicsvetsasNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Required Data - Ground Grid SystemsDocument3 pagesRequired Data - Ground Grid SystemsvetsasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- AUPEC 2013 conference features grid-scale Li-ion batteryDocument6 pagesAUPEC 2013 conference features grid-scale Li-ion batteryvetsasNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- BESS ApplicationExample PDFDocument29 pagesBESS ApplicationExample PDFJeff JabeNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Digsilent Powerfactory: Application GuideDocument12 pagesDigsilent Powerfactory: Application GuideAlexNo ratings yet

- 0900766b814b54d2 PDFDocument42 pages0900766b814b54d2 PDFvetsasNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Required Data - Ground Grid SystemsDocument3 pagesRequired Data - Ground Grid SystemsvetsasNo ratings yet

- At ExDocument2 pagesAt ExMoustafa Ibrahim YehyaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- General Executive Screening BasicDocument2 pagesGeneral Executive Screening BasicvetsasNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Cable AmpacityDocument81 pagesCable Ampacitysamsunglover50% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- PSRC D3 Considerations in Choosing Directional Polarizing Methods For Ground Overcurrent Elements in Line Protection ApplicationsDocument67 pagesPSRC D3 Considerations in Choosing Directional Polarizing Methods For Ground Overcurrent Elements in Line Protection ApplicationsRolando Henry Flores CamavilcaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- PSCAD Main component simulationDocument4 pagesPSCAD Main component simulationvetsasNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Chennai To Rjy Train TicketDocument1 pageChennai To Rjy Train TicketvetsasNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Grados de Proteccion Nema-IecDocument4 pagesGrados de Proteccion Nema-IecsignaltracerNo ratings yet

- 01 1 Catalogos500 s800Document184 pages01 1 Catalogos500 s800amjcarvalhoNo ratings yet

- ETAP IEC Short Circuit Calculation MethodsDocument7 pagesETAP IEC Short Circuit Calculation MethodsvetsasNo ratings yet

- Switch Board Wise-Unit ProtectionDocument2 pagesSwitch Board Wise-Unit ProtectionvetsasNo ratings yet

- GV2 & GV3Document82 pagesGV2 & GV3thongtn2007No ratings yet

- Surge Diverters Type VSD: Response TimeDocument2 pagesSurge Diverters Type VSD: Response TimevetsasNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ups BatteriesDocument8 pagesUps Batteriesegal1100% (1)

- ClearenceDocument4 pagesClearenceajith143420100% (1)

- Steam TurbinesDocument6 pagesSteam TurbinesmuksinNo ratings yet

- Trans Calc HelpDocument13 pagesTrans Calc HelpSajeeth AliNo ratings yet

- Smart Grids and The New Age of Energy - EEPDocument11 pagesSmart Grids and The New Age of Energy - EEPvetsasNo ratings yet

- Technical Report - Internal Arc - OrmazabalDocument10 pagesTechnical Report - Internal Arc - OrmazabalAshish RanjanNo ratings yet

- A Comparison of Finite ElementDocument4 pagesA Comparison of Finite Elementjuan floresNo ratings yet

- Product Lifecycle - WikipediaDocument10 pagesProduct Lifecycle - WikipediaMahmoudMaherNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Indian Electricity RulesDocument5 pagesIndian Electricity RulesP Venu Gopala RaoNo ratings yet

- BS en 00040-1-1992 (2006) PDFDocument14 pagesBS en 00040-1-1992 (2006) PDFShan Sandaruwan AbeywardeneNo ratings yet

- Cost estimate for construction of RCC footing and wall shutteringDocument2 pagesCost estimate for construction of RCC footing and wall shutteringAtulJainNo ratings yet

- Wire Reinforcement InstituteDocument6 pagesWire Reinforcement InstituteVu NguyenNo ratings yet

- ELECTRICAL DRAWINGS AND SCHEMATICS WORKSHOPDocument2 pagesELECTRICAL DRAWINGS AND SCHEMATICS WORKSHOPhmatora72_905124701No ratings yet

- MPRDocument12 pagesMPRDeepak yadavNo ratings yet

- AP EAMCET Results 2019 - EAMCET 2019 - AP EAMCET 2019 Marks - 2019 AP EAMCET RanksDocument3 pagesAP EAMCET Results 2019 - EAMCET 2019 - AP EAMCET 2019 Marks - 2019 AP EAMCET RanksSai BabaNo ratings yet

- BBDM2153 Operations Management 1Document27 pagesBBDM2153 Operations Management 1Keith GabrielNo ratings yet

- Lebeitsuk Mattias EplanDocument63 pagesLebeitsuk Mattias EplanAdnan KhanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NDT Report PDFDocument5 pagesNDT Report PDFUmesh Mishra100% (1)

- Electrical Design Tall BuildingsDocument3 pagesElectrical Design Tall Buildingsmaster9137100% (1)

- Low Cost Housing PDFDocument4 pagesLow Cost Housing PDFkalimNo ratings yet

- 165 Gmaw Zug Asme (Imam Mustofa 3g) WPQDocument4 pages165 Gmaw Zug Asme (Imam Mustofa 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- INCOSE IS2016 RDS - A Common Naming Convention For Systems and ElementsDocument18 pagesINCOSE IS2016 RDS - A Common Naming Convention For Systems and ElementsbobblejotNo ratings yet

- Biju Patnaik University of Technology Odisha Grade SheetDocument1 pageBiju Patnaik University of Technology Odisha Grade SheetSangram keshari jenaNo ratings yet

- B.Tech Power System Operation and Control Exam QuestionsDocument8 pagesB.Tech Power System Operation and Control Exam QuestionsMedha AravindNo ratings yet

- 02 Lean ManufacturingDocument32 pages02 Lean ManufacturingKristine Mae CabreraNo ratings yet

- UIP501C: Design of Machine Elements 04 Credits L-T-P:3-2-0Document16 pagesUIP501C: Design of Machine Elements 04 Credits L-T-P:3-2-0satishNo ratings yet

- Lec1 PDFDocument4 pagesLec1 PDFBaskaran MNo ratings yet

- Henry Berger ResumeDocument1 pageHenry Berger Resumeapi-581806915No ratings yet

- General Notes: VC 9003 IN COMPLIANCE WITH SANS 1263-1:2013Document10 pagesGeneral Notes: VC 9003 IN COMPLIANCE WITH SANS 1263-1:2013Ryan SutherlandNo ratings yet

- CISC GUIDE FOR ARCHITECTURAL EXPOSED STEEL AESSGuide2EDocument52 pagesCISC GUIDE FOR ARCHITECTURAL EXPOSED STEEL AESSGuide2EmindwriterNo ratings yet

- Final Penn Work 08 091webDocument75 pagesFinal Penn Work 08 091webJames LowderNo ratings yet

- Chemical Engineering Course OutlineDocument4 pagesChemical Engineering Course OutlinePSIBSNo ratings yet

- Design of Welded Tubular ConnectionsDocument415 pagesDesign of Welded Tubular ConnectionsAli Khodsiani100% (1)

- BASKARAN and MORLEY - Strength Assessment of Flat Slabs On Nonrectangular Column GridDocument14 pagesBASKARAN and MORLEY - Strength Assessment of Flat Slabs On Nonrectangular Column GridMaurício FerreiraNo ratings yet

- Software Engineering Question BankDocument6 pagesSoftware Engineering Question BankDr. A. Pathanjali Sastri100% (1)

- Technical Data Sheet MAS Element Z-BlockDocument3 pagesTechnical Data Sheet MAS Element Z-BlockArnold TunduliNo ratings yet

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet