Professional Documents

Culture Documents

NSK CAT E1102k A20-23

Uploaded by

nvkjayanth0 ratings0% found this document useful (0 votes)

29 views2 pagesCatalog

Original Title

NSK_CAT_E1102k_A20-23

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCatalog

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views2 pagesNSK CAT E1102k A20-23

Uploaded by

nvkjayanthCatalog

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

A 20 A 21

In general, shafts are supported by only two bearings.

When considering the bearing mounting arrangement,

the following items must be investigated:

(1) Expansion and contraction of the shaft caused by

temperature variations.

(2) Ease of bearing mounting and dismounting.

(3) Misalignment of the inner and outer rings caused

by deflection of the shaft or mounting error.

(4) Rigidity of the entire system including bearings and

preloading method.

(5) Capability to sustain the loads at their proper

positions and to transmit them.

4.1 Fixed-End and Free-End Bearings

Among the bearings on a shaft, only one can be a

"fixed-end" bearing that is used to fix the shaft axially.

For this fixed-end bearing, a type which can carry both

radial and axial loads must be selected.

Bearings other than the fixed-end one must be "free-

end" bearings that carry only radial loads to relieve the

shaft's thermal elongation and contraction.

If measures to relieve a shafts thermal elongation and

contraction are insufficient, abnormal axial loads are

applied to the bearings, which can cause premature

failure.

For free-end bearings, cylindrical roller bearings

or needle roller bearings with separable inner and

outer rings that are free to move axially (NU, N types,

etc.) are recommended. When these types are used,

mounting and dismounting are also easier.

When non-separable types are used as free-end

bearings, usually the fit between the outer ring and

housing is loose to allow axial movement of the

running shaft together with the bearing. Sometimes,

such elongation is relieved by a loose fitting between

the inner ring and shaft.

When the distance between the bearings is short and

the influence of the shaft elongation and contraction is

negligible, two opposed angular contact ball bearings

or tapered roller bearings are used. The axial clearance

(possible axial movement) after the mounting is

adjusted using nuts or shims.

4. SELECTION OF BEARING ARRANGEMENT

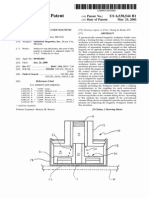

The distinction between free-end and fixed-end

bearings and some possible bearing mounting

arrangements for various bearing types are shown in

Fig. 4.1.

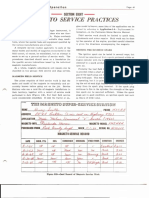

4.2 Example of Bearing Arrangements

Some representative bearing mounting arrangements

considering preload and rigidity of the entire assembly,

shaft elongation and contraction, mounting error, etc.

are shown in Table 4.1.

A B

A

D

C

D

F F

E E

Fixed-end Free-end (separable bearing)

Fixed-end Free-end (non-separable bearing)

No distinction between fixed-end and free-end

No distinction between fixed-end and free-end

No distinction between fixed-end and free-end

Bearing Arrangements

Remarks

fThis is a common arrangement in which

abnormal loads are not applied to bearings

even if the shaft expands or contracts.

fIf the mounting error is small, this is suitable

for high speeds.

Medium size electric motors,

blowers

fThis can withstand heavy loads and shock loads

and can take some axial load.

fEvery type of cylindrical roller bearing is

separable. This is helpful when interference is

necessary for both the inner and outer rings.

Traction motors for rolling

stock

fThis is used when loads are relatively heavy.

fFor maximum rigidity of the fixed-end bearing,

it is a back-to-back type.

fBoth the shaft and housing must have high

accuracy and the mounting error must be small.

Table rollers for steel mills,

main spindles of lathes

fThis is also suitable when interference is

necessary for both the inner and outer rings.

Heavy axial loads cannot be applied.

Calender rolls of paper making

machi nes, axl es of di esel

locomotives

fThis is suitable for high speeds and heavy radial

loads. Moderate axial loads can also be applied.

fIt is necessary to provide some clearance

between the outer ring of the deep groove ball

bearing and the housing bore in order to avoid

subjecting it to radial loads.

Reducti on gears i n di esel

locomotives

Application Examples

Fixed-end Free-end

Table 4. 1 Representative Bearing Mounting Arrangements

and Application Examples

Continued on next page

BEARING A

Deep Groove Ball Bearing

Matched Angular Contact

Ball Bearing

Double-Row Angular

Contact Ball Bearing

Self-Aligning Ball Bearing

Cylindrical Roller Bearing

with Ribs (NH, NUP

types)

Double-Row Tapered

Roller Bearing

Spherical Roller Bearing

BEARING B

Cylindrical Roller Bearing

(NU, N types)

Needle Roller Bearing (NA

type, etc.)

BEARING C(

1

)

Deep Groove Ball Bearing

Matched Angular Contact

Ball Bearing (back-to-

back)

Double-Row Angular

Contact Ball Bearing

Self-Aligning Ball Bearing

Double-Row Tapered

Roller Bearing (KBE type)

Spherical Roller Bearing

BEARING F

Deep Groove Ball Bearing

Self-Aligning Ball Bearing

Spherical Roller Bearing

BEARING D,E(

2

)

Angular Contact Ball

Bearing

Tapered Roller Bearing

Magneto Bearing

Cylindrical Roller Bearing

(NJ, NF types)

Notes: (

1

) In the figure, shaft elongation and contraction are

relieved at the outside surface of the outer ring, but

sometimes it is done at the bore.

(

2

) For each type, two bearings are used in opposition.

Fig. 4.1 Bearing Mounting Arrangements and Bearing Types

A007-023E.indd 20-21 11/5/12 5:22:05 PM

A 22 A 23

Bearing Arrangements

When there is no distinction between

fixed-end and free-end

Remarks Application Examples

fThis arrangement is widely used since it can

withstand heavy loads and shock loads.

fThe back-to-back arrangement is especially

good when the distance between bearings is

short and moment loads are applied.

fFace-to-face mounting makes mounting easier

when interference is necessary for the inner

ring. In general, this arrangement is good when

there is mounting error.

fTo use this arrangement with a preload,

affection must be paid to the amount of preload

and clearance adjustment.

Pinion shafts of automotive

differential gears, automotive

front and rear axles, worm gear

reducers

Remarks

fThis is the most common arrangement.

fIt can sustain not only radial loads, but

moderate axial loads also.

Double suction volute pumps,

automotive transmissions

fThis is the most suitable arrangement when

there is mounting error or shaft deflection.

fIt is often used for general and industrial

applications in which heavy loads are applied.

Speed reducers, table rollers of

steel mills, wheels for overhead

travelling cranes

fThis is suitable when there are rather heavy

axial loads in both directions.

fDouble row angular contact bearings may be

used instead of a arrangement of two angular

contact ball bearings.

Worm gear reducers

fThis is used at high speeds when radial loads

are not so heavy and axial loads are relatively

heavy.

fIt provides good rigidity of the shaft by

preloading.

fFor moment loads, back-to-back mounting is

better than face-to-face mounting.

Grinding wheel shafts

Application Examples

Fixed-end Free-end

Back-to-back mounting

Back-to-back mounting

Face-to-face mounting

Table 4. 1 Representative Bearing Mounting Arrangements

and Application Examples (cont'd)

Continued on next page

SELECTION OF BEARING ARRANGEMENT

When there is no distinction between

fixed-end and free-end

Vertical arrangements Remarks Application Examples

fMatched angular contact ball bearings are on

the fixed end.

fCylindrical roller bearing is on the free end.

Vertical electric motors

Remarks

fThis can withstand heavy loads and shock

loads.

fIt can be used if interference is necessary for

both the inner and outer rings.

fCare must be taken so the axial clearance

doesn't become too small during running.

fNF type + NF type mounting is also possible.

Fi nal reduct i on gears of

construction machines

fSometimes a spring is used at the side of the

outer ring of one bearing.

Small electric motors, small

speed reducers, small pumps

fThe spherical center of the self-aligning seat

must coincide with that of the self-aligning ball

bearing.

fThe upper bearing is on the free end.

Vertical openers (spinning and

weaving machines)

Application Examples

NJ + NJ mounting

A007-023E.indd 22-23 11/5/12 5:22:06 PM

You might also like

- Nnospace Rofile: 2.0 Company HistoryDocument11 pagesNnospace Rofile: 2.0 Company HistorynvkjayanthNo ratings yet

- Filter - Inline - HFR: (Threads To Depth 20mm)Document2 pagesFilter - Inline - HFR: (Threads To Depth 20mm)nvkjayanthNo ratings yet

- DVP201/202/211LC-SL Load Cell Module Operation Manual: Industrial Automation HeadquartersDocument41 pagesDVP201/202/211LC-SL Load Cell Module Operation Manual: Industrial Automation HeadquartersnvkjayanthNo ratings yet

- Power Entry ComponentsDocument40 pagesPower Entry ComponentsnvkjayanthNo ratings yet

- Digix-2Document2 pagesDigix-2nvkjayanthNo ratings yet

- Dec Eb BillDocument1 pageDec Eb BillnvkjayanthNo ratings yet

- Simple / Special Order Sheet: Assembly Break-Up and Price CalculationDocument1 pageSimple / Special Order Sheet: Assembly Break-Up and Price CalculationnvkjayanthNo ratings yet

- 9964 MFHB07343 MFHD02744 EngbDocument2 pages9964 MFHB07343 MFHD02744 Engbnvkjayanth0% (1)

- Large Spring - Sheet1Document1 pageLarge Spring - Sheet1nvkjayanthNo ratings yet

- Spring Push LVDT HB LVDT HB LVDT HB LVDT HB: Measurement PerformanceDocument2 pagesSpring Push LVDT HB LVDT HB LVDT HB LVDT HB: Measurement PerformancenvkjayanthNo ratings yet

- Challenger Computer: Boards For Extreme Edition (LGA2011 v3) Intel Sixth Gen Processor SkylakeDocument9 pagesChallenger Computer: Boards For Extreme Edition (LGA2011 v3) Intel Sixth Gen Processor SkylakenvkjayanthNo ratings yet

- Gravity Plate - Sheet1Document1 pageGravity Plate - Sheet1nvkjayanthNo ratings yet

- United States Patent (10) Patent N0.: US 6,538,544 B1Document7 pagesUnited States Patent (10) Patent N0.: US 6,538,544 B1nvkjayanthNo ratings yet

- Single-Direction Thrust Ball BearingsDocument14 pagesSingle-Direction Thrust Ball BearingsnvkjayanthNo ratings yet

- DesktopDocument12 pagesDesktopnvkjayanthNo ratings yet

- To Calculate:: To Calculate, Enter Your Figures Into The Grey AreasDocument4 pagesTo Calculate:: To Calculate, Enter Your Figures Into The Grey AreasnvkjayanthNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hafele Furniture Hinge PDFDocument16 pagesHafele Furniture Hinge PDFRehan100% (1)

- Bearing Data GeneralDocument17 pagesBearing Data GeneralpdmserviceNo ratings yet

- Torque Overload Release CouplingDocument12 pagesTorque Overload Release CouplingAldi YansahNo ratings yet

- NSK & RHP Designation SystemsDocument64 pagesNSK & RHP Designation SystemsmanapanhomNo ratings yet

- BearingDocument24 pagesBearingniteen_mulmule485No ratings yet

- Proiect Om2Document20 pagesProiect Om2Gabriel CimpeanNo ratings yet

- Stihl TS 510 Cut-Off Saw Service Repair ManualDocument18 pagesStihl TS 510 Cut-Off Saw Service Repair Manualshishankaogou4No ratings yet

- Bearing Fit ChartDocument6 pagesBearing Fit ChartAvinash MamillapalliNo ratings yet

- Stern TubeDocument3 pagesStern TubeJohn Rey TumalaNo ratings yet

- Hyundai HD78 Propeller Shaft and Axle (Мост и Редуктор)Document94 pagesHyundai HD78 Propeller Shaft and Axle (Мост и Редуктор)Bigfair HD78100% (1)

- Magneto Service Practices (49-64)Document16 pagesMagneto Service Practices (49-64)TIMNo ratings yet

- Catalogo Chumaceras Sonl PDFDocument48 pagesCatalogo Chumaceras Sonl PDFLuis DíazNo ratings yet

- BA Pump BrochurDocument8 pagesBA Pump Brochurelmer sanchezNo ratings yet

- Build Your Own 3d Printing Filament Factory FilameDocument26 pagesBuild Your Own 3d Printing Filament Factory Filamemarius_danila8736No ratings yet

- Centrifugal Pump Set Failure ModesDocument59 pagesCentrifugal Pump Set Failure Modesyozetb80% (5)

- Підшипники SPZ - catalog - 06-07Document154 pagesПідшипники SPZ - catalog - 06-07YDECH_82No ratings yet

- M190-730 MRC Engineering Handbook 2015Document396 pagesM190-730 MRC Engineering Handbook 2015Far Han100% (1)

- DTE Comprehensive TestDocument66 pagesDTE Comprehensive TestMannam Sarath SarathNo ratings yet

- Turb AireCentrifugal PDFDocument2 pagesTurb AireCentrifugal PDFBoBo KyawNo ratings yet

- Testing Machines To Study Fretting WearDocument13 pagesTesting Machines To Study Fretting WearJesus ZilchNo ratings yet

- Videira - DESIGN, ASSEMBLY AND PRELOADING OF BALL BEARINGSDocument9 pagesVideira - DESIGN, ASSEMBLY AND PRELOADING OF BALL BEARINGSAnonymous lEX5U51wOANo ratings yet

- NewwDocument7 pagesNewwIrfanmaulana ardiansyahNo ratings yet

- Bearings For KomatsuDocument2 pagesBearings For KomatsuCadeco ZamoraNo ratings yet

- Design Project 11Document38 pagesDesign Project 11Hemanth VeeraNo ratings yet

- FAN Technical Data Brief Description: - Square Inline Fan, Belt DrivenDocument8 pagesFAN Technical Data Brief Description: - Square Inline Fan, Belt DrivenMohamad MhannaNo ratings yet

- TT Products eDocument163 pagesTT Products eOana CimpulungeanuNo ratings yet

- Bearing FitsDocument7 pagesBearing FitsBurak KoyuncuogluNo ratings yet

- NTN Bearing en AllDocument411 pagesNTN Bearing en Allbhupinder85No ratings yet

- Multi Nut Project ReportDocument45 pagesMulti Nut Project ReportPravin Kangne77% (13)

- Deepwell Submersible MotorDocument31 pagesDeepwell Submersible Motorsales sinar waluya abadiNo ratings yet