Professional Documents

Culture Documents

Yeastautolysis 1

Uploaded by

Margo SmithOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yeastautolysis 1

Uploaded by

Margo SmithCopyright:

Available Formats

Yeast Autolysis

By Murli Dharmadhikari

The term autolysis literally means 'self-destruction'. It represents self-degradation of the cellular constituents of a cell by its own enzymes following the death of the cell. In the process of autolysis, the medium (wine) is enriched by the compounds released as a result of the degradation of intracellular constituents. These yeast constituents have an important influence on the sensory properties and biological stability of wine. Yeast autolysis is very important to the food industry. Yeast extract is used as an additive in the production of meat paste, meat pie filling, soups, sauces, and snacks. Yeast autolysate is a good source of nutrients such as proteins, vitamins, fiber, and micronutrients. It is also used to enhance the color and flavor of food products. The process (autolysis) is of great value to biochemical researchers, since it is used in the extraction and purification of enzymes and coenzymes. In the wine industry, yeast autolysis is important in the production of sparkling wines, sherry, and white wines produced with prolonged yeast contact, such as the "sur lie" method. The process of autolysis The process of autolysis begins with the death of the cell. At first, disorganization of membranous systems (cytoplasmic membrane and other organelles) of the cell occurs. This permits the enzymes to come in contact with cellular constituents which are degraded and rendered soluble. The proteolytic enzyme, protease, attacks proteins and breaks them down into smaller constituent units, such as peptides and amino acids. Likewise, enzyme nuclease degrades RNA and DNA yielding compounds such as nucleosides, mononucleotides, and polynucleotides. The enzymes glucanase and proteinase degrade the cell wall constituents such as glucans and mannoproteins, which causes the cell wall to become porous. The autolysate (the mixture of degraded cellular components) leaks through the cell wall into the surrounding medium. The process of degradation of the cellular components continues to occur in the surrounding medium. Yeast autolysis is strongly influenced by temperature and pH. In wine, the process occurs at low pHs (3 to 4), and at relatively low temperatures, e.g., 15 to 18C, and also in the presence of ethanol. These conditions are less than ideal for autolysis, and the autolytic process is likely to occur at a much slower rate. By permitting the wine to be in contact with the yeast for a longer period, a wine maker can secure the beneficial effects of autolysis.

The two important aspects of yeast autolysis are (i) degradation and solubilization of cellular components, and (ii) degradation of the cell wall. The concentrated form of solubilized cell constituents resulting from autolysis is referred to as yeast extract. The breakdown product of the whole cell, i.e., the cell wall and the cytoplasm, are referred to as yeast autolysate. The process of yeast autolysis can be divided into two parts: 1. Degradation of cellular constituents which is predominantly the breakdown of proteinaceous substances also known as proteolysis. 2. Degradation of the cell wall, which is a rigid structure that is responsible for the shape of the yeast cell. Proteolysis The yeast cell contains a wide array of protein degrading enzymes. These enzymes are mostly located in a vacuole. Upon cell death, the cellular matrix becomes disorganized and the enzymes come in contact with their substrate. The proteolytic enzymes hydrolyze peptide bonds and yield protein breakdown products such as peptides and amino acids. It should be noted that an increase in amino acid content in the medium (wine) does not necessarily mean the beginning of the autolytic processes. It has been observed that at the end of alcoholic fermentation, when the sugars are used up, amino acids located within the cells are passively released into the wine. This leads to an increase in amino acid content, but does not involve enzymatic action. With the beginning of the autolytic process, there is a significant increase in amino acids and other nitrogenous compounds. The concentration of various nitrogenous compounds released during autolysis was studied by Freyssinet (1988). In the experiment, the autolysis was conducted at pH 3.0 and 40C to expedite the process. The results showed that about 42% of the total nitrogen was released within the first 24 hours of the experiment; the remaining 58% was released during the following 14 days. The nitrogenous compounds released at the beginning consisted mostly of large protein fractions. At a later state, the protein fragments were further degraded, and an increase in amino acid concentration was noted. Degradation of cell The cell wall is a rigid outer layer of the cell. It envelops the protoplast and confers specific shape to the cell. Many enzymatic activities are associated with the cell wall. These enzymes participate in the degradation of extracellular constituents, and also in the breakdown of cell wall components. On a dry weight basis, the cell wall constitutes 15 to 20% of the cell's weight. It (the cell wall) consists of 80 to 90% polysaccharides and a small amount of proteins and lipids. The main polysaccharides include glucans and mannans, and a small amount of

chitin. The glucan polymer exists in both alkali insoluble, acid insoluble, and alkali soluble forms. The insoluble glucan fraction helps the cell to retain its shape. In the cell wall, the mannans are linked to protein. They are commonly described as mannoproteins and are important structural components of the cell wall. The enzymes glucanase and protease play a significant role in the degradation of cell wall constituents. As a result of their action, the cell wall becomes porous and a mixture of glucan, mannan, protein, and 6-(1-3) linked oligosaccharides is released into the surrounding medium. Importance of yeast autolysis The phenomenon of autolysis is of great importance to the producers of sparkling wine (methode champenoise) and white wine by "sur lie" method. Sparkling wine - In the case of sparkling wine produced by methode champenoise, the wine in the bottle (cuvee) is kept in contact with the yeast lees for a long period (1 to 3 years). following secondary fermentation in the bottle. During this prolonged yeast contact, the yeast undergoes autolysis and consequently, the sparkling wine is enriched by the components of the autolysate. It should be noted that many factors influence the quality and quantity of yeast autolysate (released in the wine during the course of autolysis). The important factors include the yeast strain, its conditions of growth and population, storage temperature, ethanol content, wine pH, and the duration of yeast contact. The major constituents formed during autolysis include: nitrogenous compounds, polysaccharides, nucleic acid components, fatty acids, various vitamins, and aroma compounds. These and other components of autolysate play an important role in the aroma and quality of sparkling wine. Nitrogenous compounds An increase in the concentration of protein degradation products such as amino acids has usually been considered characteristic of yeast autolysis. It has been mentioned earlier that an increase in amino acid content in wine can occur in the absence of the autolytic process. During the course of secondary fermentation in the bottle, the yeasts utilize the amino acids present in the wine. Following the end of the secondary fermentation, when all the sugar is used up, the yeasts release amino acids back into the wine. This movement of amino acid from the intracellular pool to the surrounding medium occurs passively and results in higher amino acid levels in the wine. This new amino acid level in the wine stays relatively stable, usually for a 3 to 4 month period. Following this phase, the amino acid concentration in the wine begins to increase. This increase is attributed to the autolytic process, where cell proteins are degraded, solubilized, and released into the wine. With the continuation of the autolytic process, the wine becomes richer in amino

acid content. Some of these amino acids undergo a transformation due to decarboxylation and deamination reactions. The net amount of amino acid present at a given point represents the difference between the amino acids formed during autolysis (plus passive release) and the amount utilized in other reactions. In addition to amino acids, other nitrogenous compounds obtained during autolysis include polypeptides, peptides, and nucleic acid components. Polysaccharides The polysaccharides found in yeast autolysate originate from the breakdown of cell wall components. It has been mentioned earlier that the main polysaccharides in the cell wall are B1->3-glucans and mannoproteins, with some chitin. The degradation products of these polysaccharides are glucose and man nose. Several studies have reported an increase in these sugars and other polysaccharide fragments in sparkling wine following secondary fermentation and subsequent aging of wine on lees in the bottle. Following autolysis, changes in the concentrations of these constituents may occur due to other chemical reactions such as hydrolysis by B-(1->3)-glucanase. It is important to note that mannoproteins formed during autolysis contribute significantly to the quality of sparkling wine, such as fineness and persistence of bubbles. One reason for methode champenoise wine to be considered superior to the bulk process sparkling wine is the fact that the former is enriched by yeast autolysate. Fatty acids In yeast cells, the lipids are mostly associated with plasma membrane and cell wall. A small amount is also found in cytoplasm. During autolysis the lipids are degraded to fatty acids. These fatty acids are saturated and consist of 8 to 16 carbon atoms. Once released, these fatty acids can be involved in the formation of esters, aldehydes, and other volatile compounds. Fatty acids and other fatty acid-derived volatile compounds can have a significant impact on the flavor of sparkling wine. Volatile compounds Many aromatic compounds released during yeast autolysis have been reported to influence the aroma profile of sparkling wines. These substances include heavy esters, terpenes, higher alcohols, and other volatile substances. A list of some of the important aroma contributing compounds is given in Table 1.

________________________________________________________________________ Table 1. Compounds contributing to the aroma of sparkling wine. ________________________________________________________________________ 1. Heavy esters isoamylcaproate octylacetate phenylethylacetate phenylethylcaproate ethyllinoleate diethylsuccinate 2. Terpene compounds linalool a-terpenol nerolidol farnesol 3. Higher alcohols isoamyl alcohol phenylethyl alcohol 4. Other volatile compounds methyl- 2-ethoxy-2-furane dimethyl-4,5-tetrahydrofu rane-2-3-dione vitispirane ________________________________________________________________________ Maturing white wine on lees or sur lie. In the "sur lie" wine production technique, the wine is matured in contact with yeast lees following the alcoholic fermentation. This method has traditionally been used in Burgundy for Chardonnay production. However, the method is now used by many winemakers for white wine production in many parts of the world. In the traditional approach, the must is fermented in the barrel. Following alcoholic fermentation, malolactic fermentation is encouraged and the wine is kept on lees, usually for a period of 6 to 12 months. In some cases, the wine is matured on lees for an even longer duration. While on lees, the wine is stirred periodically to resuspend the sediment. Wine kept on lees for a long period shows an increased concentration of nitrogenous compounds (such as amino acids and peptides) as well as polysaccharide breakdown products, such as mannoproteins. The enrichment of wine by these compounds is considered to be due to yeast autolysis. There are several reasons as to why a winemaker may choose the "sur lie" method of wine production. The most important reason being the influence of yeast lees on the organoleptic properties of wine. The wine is often described to have enhanced body,

creamier, richer, mouth feel, greater complexity and depth of flavor, and a better integration of fruit-and-wood-derived components. The other reasons for choosing prolonged yeast contact are: 1. To encourage malolactic fermentation. As mentioned earlier, during lees contact, the wine becomes richer with yeast autolysate which serves as a source of nutrients for bacterial growth. 2. Use of S02 can be minimized. Sulfur dioxide is often added to a wine to protect it from oxidation. Yeasts are good scavengers of oxygen and yeast lees contribute to the reductive atmosphere (when it is retained during maturation.) Because of this, the need to add S02 is minimized. 3. To soften the effect of aggressive oak tannins. This point is discussed later. There are two ways in which lees contact affects the quality of wines matured in oak barrels: 1. During extended lees contact, yeast autolysis occurs and many constituents are released into the wine. These substances affect the body (mouthfeel) and the aroma of wine. 2. Yeast as well as products of autolysis interacts with oak-derived components and this interaction leads to the changes in wine composition and its organoleptic character. The effect of lees contact (yeast autolysate) on wine has been mentioned earlier. The influence of lees on oak extractives warrants some discussion. Influence of yeast lees on the composition and quality of wine matured in oak barrels. Yeast lees ("sur lie" aging) exerts a great influence on the composition of wine. During barrel fermentation and aging, many components are extracted from the oak. The important constituents include: furan derivatives, oak lactones, volatile phenols, and phenolic aldehydes (see Table 2). The yeast lees affects the concentration of many oak constituents and thus influences the organoleptic character of the wine. ________________________________________________________________________ Table 2. Important oak-derived compounds. __________________________________________________________________ Furans furfural 5-methylfurfural furfural alcohol Methyloctalactones cis methyloctalactone trans methyloctalactone

Volatile phenols guaiacol 4-methylguaiacol 4-ethylguaiacol 4-vi nylguaiacol eugenol phenol + o-cresol 4-vi nylphenol Phenolic aldehydes vanillin syringaldehyde __________________________________________________________________ Influence of lees contact on oak-derived aromatic compounds. When the wine is stored in wooden barrels, the components of the wood are extracted into the wine. The concentration of some of the compounds is altered when a wine is matured in contact with lees for a long period. Observations indicate that contact with yeast lees results in the reduction of the woody aroma in wine. Such a reduction in the intensity of woody aroma can be explained on the basis of two possible reasons. First is the fixation of certain volatile compounds, such as volatile phenols and lactones, by the yeast cell wall. Another is the conversion of aroma compounds to less aromatic forms by the yeast enzyme. For example, vanillin could be converted to vanillyl alcohol. Effect of lees contact on phenolic compounds Prolonged maturation on lees with periodic stirring causes a reduction in the concentration of polyphenols in wine. The wood tannins (polyphenols) are adsorbed onto yeast cell walls and mannoproteins released during autolysis, and are removed with the lees. In this manner yeast lees acts as a fining agent that lowers the tannin content of the wine. Effect of lees contact on varietal aroma Many reports indicate that varietal or fruity aroma is enhanced when a wine is matured on the lees. The reason for such an effect is not clear. However, the role of yeast enzymes in the development of fruity compounds is suspected. In this context, the results of an Australian study are worth considering. In an experiment, Chardonnay wine was matured on the lees for five months, with and without periodic stirring. The judges were asked to evaluate wine aroma using aroma descriptors such as fruity, woody, and yeasty. The results of the sensory analysis showed that in the control treatment (no lees contact),

fruit and wood aromas were dominant. In wine with lees contact, but no stirring, the fruit aroma was enhanced, the wood component was subdued, and the yeasty character was a little more noticeable as compared to the control. In samples where the lees was stirred, the yeast component increased and both fruit and wood aromas were reduced. It seems that lees contact, in general, causes a reduction in the aggressive wood characters. However, its effect on fruity aroma is less clear. In certain cases it may enhance, while in others it may not. The important influence of lees contact should be viewed in terms of flavor complexity and how well the various flavors (fruit, wood, and yeast) are balanced and integrated. The "sur lie" method can sometimes have a negative effect on wine quality. Higher amounts of acetic acid and acetaldehyde can result. But more importantly, reduced sulfur compounds, such as hydrogen sulfide and mercaptans with unpleasant odors can be formed. It is important to exercise great care when wine is sitting on lees, and appropriate action should be quickly taken if off odors from reduced sulfur compounds are noticed. Stirring the lees can be helpful in removing the odors, but sometimes that is not enough. In this regard, it should be mentioned that certain phenolic compounds from the barrel can help in minimizing the problem of off sulfide odors. Gallic acid can be formed in the wine from the hydrolysis of wood ellagitannins. Oxidation of gallic acid yields hydrogen peroxide (a highly reactive oxydizing agent) which can oxidize the sulfide compounds, and thus prevent or reduce the occurrence of off sulfide odors. It should be noted that the new barrels would have greater amounts of hydrolyzable tannins than the old barrels; consequently, the chance of these unpleasant sulfide odors would be greater in old barrels.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- FiAsia2014 Postcard Eng NonPostal LowresDocument2 pagesFiAsia2014 Postcard Eng NonPostal LowresMargo SmithNo ratings yet

- General Principles of HPLC Method Development PDFDocument53 pagesGeneral Principles of HPLC Method Development PDFJoshua Castillo100% (1)

- Bao Bi Thuc PhamDocument115 pagesBao Bi Thuc PhamMargo SmithNo ratings yet

- Barley Malt BeerDocument67 pagesBarley Malt BeerJaideep Banerjee100% (2)

- Schaum S French Vocabulary PDFDocument412 pagesSchaum S French Vocabulary PDFArjun ArjunNo ratings yet

- Engineering Statistics Handbook 2003Document1,522 pagesEngineering Statistics Handbook 2003d-fbuser-67904250No ratings yet

- Beehive DrinksDocument2 pagesBeehive DrinksMargo SmithNo ratings yet

- ZL Modrybar Koktejl WebDocument2 pagesZL Modrybar Koktejl WebMargo SmithNo ratings yet

- 1001 Vocabulary and Spelling QuestionsDocument160 pages1001 Vocabulary and Spelling Questionssashi01092% (12)

- TIS-113-Prime Surface Heat ExchangerDocument0 pagesTIS-113-Prime Surface Heat Exchangerhappale2002No ratings yet

- Winedev GuideDocument133 pagesWinedev GuideMargo SmithNo ratings yet

- Zinc Beverage ListDocument20 pagesZinc Beverage ListMargo SmithNo ratings yet

- Wedding KitDocument13 pagesWedding KitMargo SmithNo ratings yet

- WSWA SPIRITS Final ListingsDocument9 pagesWSWA SPIRITS Final ListingsMargo SmithNo ratings yet

- YxA Bar MenuDocument8 pagesYxA Bar MenuMargo SmithNo ratings yet

- EER Alk: Cheers WithDocument4 pagesEER Alk: Cheers WithMargo SmithNo ratings yet

- Chateau Haut-Bailly Press KitDocument24 pagesChateau Haut-Bailly Press KitMargo SmithNo ratings yet

- CockDocument6 pagesCockMargo SmithNo ratings yet

- Versie01 004Document4 pagesVersie01 004Margo SmithNo ratings yet

- Wine Is Medicine: Georges M. Halpern, MD, PHDDocument49 pagesWine Is Medicine: Georges M. Halpern, MD, PHDMargo SmithNo ratings yet

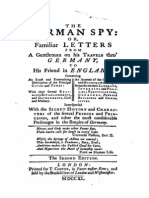

- The German SpyDocument38 pagesThe German SpyMargo SmithNo ratings yet

- 2010 Section 3 by ArtistDocument164 pages2010 Section 3 by ArtistMargo SmithNo ratings yet

- BBC TechnologyDocument4 pagesBBC TechnologyMargo SmithNo ratings yet

- WV Cal Trinity RedDocument2 pagesWV Cal Trinity RedMargo SmithNo ratings yet

- WV Brochure HotelsDocument2 pagesWV Brochure HotelsMargo SmithNo ratings yet

- Zinc Beverage ListDocument20 pagesZinc Beverage ListMargo SmithNo ratings yet

- Zen Liquor Menu 2 2010Document1 pageZen Liquor Menu 2 2010Margo SmithNo ratings yet

- Cashew Value ChainDocument9 pagesCashew Value ChainMargo SmithNo ratings yet

- ZL Modrybar Koktejl WebDocument2 pagesZL Modrybar Koktejl WebMargo SmithNo ratings yet

- Asselin Payette Ecoscience 06Document8 pagesAsselin Payette Ecoscience 06Margo SmithNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bacterial Cell AnatomyDocument3 pagesBacterial Cell AnatomyTreshia SusonNo ratings yet

- Chapter 2 Prokaryotic and EukaryoticDocument13 pagesChapter 2 Prokaryotic and EukaryoticMark Francis S. RajasNo ratings yet

- Chapter 19 PDFDocument30 pagesChapter 19 PDFJeanPaule JoumaaNo ratings yet

- Biology (Ethiopian Students' Textbook)Document280 pagesBiology (Ethiopian Students' Textbook)Gadisa100% (1)

- Chapter 1 Introduction and OverviewDocument11 pagesChapter 1 Introduction and OverviewAsmamaw TesfawNo ratings yet

- Section: Cell BiologyDocument12 pagesSection: Cell BiologyHanzala ShahidNo ratings yet

- Clinical BacteriologyDocument123 pagesClinical Bacteriologykurotsukki todoroki100% (1)

- Assignment of Class VIIIDocument4 pagesAssignment of Class VIIIMd A RAZZAKNo ratings yet

- Raven Biology of Plants 8th Edition Evert Test BankDocument35 pagesRaven Biology of Plants 8th Edition Evert Test Banklumen.megasse.sez3100% (24)

- MaceralsDocument40 pagesMaceralsPurushottam Gupta100% (7)

- Microbiology NotesDocument83 pagesMicrobiology NotesPauline Añes100% (1)

- Antibiotics ActivitiesDocument8 pagesAntibiotics ActivitiesdrgunNo ratings yet

- CHM4125 Antibiotics FINAL 2023 UnannotatedDocument106 pagesCHM4125 Antibiotics FINAL 2023 Unannotatedalec.lafrance88No ratings yet

- Test Bank For Microbiology An Introduction 10th Edition TortoraDocument16 pagesTest Bank For Microbiology An Introduction 10th Edition Tortorahieugiaoau0mNo ratings yet

- ClassXI XenglishBiology 9 10Document358 pagesClassXI XenglishBiology 9 10Anusha Sathi100% (2)

- Lower Secondary Science Learner 7-AnswersDocument4 pagesLower Secondary Science Learner 7-Answershiori San83% (12)

- General Biology 1Document153 pagesGeneral Biology 1Alvin PaboresNo ratings yet

- AS Biology Unit 2 Topic 4 Notes Study Revision Guide Summary Edexcel Practice Biodiversity Plant Cell OrganellesDocument50 pagesAS Biology Unit 2 Topic 4 Notes Study Revision Guide Summary Edexcel Practice Biodiversity Plant Cell Organellesshamxrock90% (59)

- Pharmacognosy BookDocument100 pagesPharmacognosy BookYoussef ElhamamyNo ratings yet

- 100 Objective Question and Answer of Plant PathologyDocument23 pages100 Objective Question and Answer of Plant PathologyAnitharaj Alaguvel100% (2)

- Quitina PDFDocument8 pagesQuitina PDFEDWIN VELOZNo ratings yet

- Domains Kingdoms and Hierarchy PDFDocument5 pagesDomains Kingdoms and Hierarchy PDFEj FerrerNo ratings yet

- MCQs About Cell OrganellesDocument4 pagesMCQs About Cell OrganellesHeba M.abueyadaNo ratings yet

- Structure of BacteriaDocument95 pagesStructure of BacteriaMaulyda Awwaliyah PawallungiNo ratings yet

- Biotechnological Admixtures For Cement and Mortars: 3.1 The Types of BiopolymersDocument10 pagesBiotechnological Admixtures For Cement and Mortars: 3.1 The Types of Biopolymersvidal3213No ratings yet

- Chemistry in Our Life - Chemicals in MedicinesDocument9 pagesChemistry in Our Life - Chemicals in MedicinesNafis AhmadNo ratings yet

- The Three Domains of LifeDocument1 pageThe Three Domains of Lifeella retizaNo ratings yet

- ANDRITZ StockPrep - RefiningDocument47 pagesANDRITZ StockPrep - RefiningPhu, Le HuuNo ratings yet

- BCH 4107 - Plant BiochemistryDocument13 pagesBCH 4107 - Plant BiochemistryOLUWASEGUN K AfolabiNo ratings yet

- Microbiology Unit 1: Mansi Damani BNCPDocument73 pagesMicrobiology Unit 1: Mansi Damani BNCPSiddhant BanwatNo ratings yet