Professional Documents

Culture Documents

Flash Vessel Spirax Sarco FV-FINAL

Uploaded by

kawkatrCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flash Vessel Spirax Sarco FV-FINAL

Uploaded by

kawkatrCopyright:

Available Formats

Page 1 of 3

TI-P404-03

AB Issue 8

Cert. No. LRQ 0963008 ISO 9001

FV Flash Vessel

lifiting lugs FV6 No lifting lugs FV8 and FV12 1 lifting lug FV15 and FV18 2 lifting lugs

Description

The Spirax Sarco FV flash vessel is designed and constructed to ASME VIII DIV 1 2004 + ADD06. The design is free-draining which is essential in boiler blowdown applications. Applications These vessels are particularly suited to boiler blowdown heat recovery systems where efficient separation of the flash steam from the blowdown is essential to prevent contamination of the boiler feedtank and / or heat transfer surfaces. Spirax Sarco flash vessels are equally suited to condensate flash steam applications. Principal features: - Designed and constructed in compliance with the European Pressure Equipment Regulations 97 / 23 / EC. - Low separation velocity to produce drier steam. - Free-draining.

Flash steam outlet

10 2

Sizes and pipe connections

3 3 7 6 5 1

Connections available as standard: Screwed connections to BS 21 taper. Flanged connections to EN 1092 PN16. Note: Vessels are available flanged to BS 1560 Class 150 or 300, or screwed NPT.

Limiting conditions

Maximum design conditions are 14 bar g @ 198C (saturation temperature of steam). Minimum design (operating) temperature -10C Cold hydraulic test pressure in accordance with European Pressure Equipment Directive 97 / 23 / EC. Note: These vessels will withstand full vacuum conditions. Inlet

8 11

7 2

Model FV15 and FV18 shown

Condensate /residual blowdown outlet

Materials

No. 1 2 3 4 5 6 7 8 9 10 11 Part Shell cylinder End cap Nozzle - Half coupling Nozzle - Full coupling Nozzle - Flange Nozzle - Pipe Blanking plug Wrapper plate Name-plate bracket Lifting lugs Support foot /gusset Material ASTM A106B ASTM A234 WPB ASTM A105N ASTM A105N ASTM A516-70 ASTM A106B ASTM A105N ASTM A516-60 BS EN 10028-2 P265GH ASTM A516-60 BS EN 10025 S275 C. Max. 0.25% C. Max. 0.25% C. Max. 0.25% C. Max. 0.25% C. Max. 0.25% C. Max. 0.25% C. Max. 0.25% C. Max. 0.25% C. Max. 0.25% C. Max. 0.21%

Local regulations may restrict the use of this product to below the conditions quoted. In the interests of development and improvement of the product, we reserve the right to change the specification without notice.

Copyright 2008

Page 2 of 3

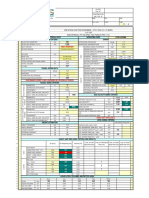

How to size

Use the chart below to select the appropriate flash vessel. It is necessary to know the pressure on the steam traps or boiler pressure in the case of blowdown heat recovery, the flash steam pressure (desired or existing), and the condensate or blowdown flowrate. Example 1: (solid lines) A boiler plant operating at 12 bar g has a TDS control blowdown flowrate of 2 500 kg /h (3 boilers at 833 kg / h each). The flash steam from the blowdown is to be added to the low pressure steam system operating at 1 bar g. 1. 2. 3. 4. From boiler pressure move horizontally to flash steam pressure - A Drop vertically to blowdown flowrate in kg / h - B Follow curve to right-hand scale and across to same flash pressure - C Move upwards to flash vessel size. Select flash vessel - in this case an FV8 is required.

Example 2: (dotted lines) A plant operating on steam at 11 bar g condenses 4 000 kg / h of steam. Flash is to be recovered at 0.5 bar g. 1. 2. 3. 4. From pressure on steam traps move horizontally to flash steam pressure - A1 Drop vertically to condensate flowrate in kg / h - B1 Follow curve to right hand scale and across to same flash pressure - C1 Move upwards to flash vessel size. Select flash vessel - in this case an FV12 is required.

Pressure on steam traps or boiler pressure for blowdown applications bar g

Flash steam pressure bar g

Example 1 Example 2

Flash vessel size

FV 15

FV

FV

FV

FV

18

12

Flash steam pressure bar g

Condensate or blowdown flowrate kg / h

FV Flash Vessel

TI-P404-03 AB Issue 8

Page 3 of 3

B J B L

J K

B L K J

L M G E M G E G M

D D C C

D C

H A F

H A F

H A F

FV6 Dimensions / weights

A B C D E F G H J K L M Weight FV6 168 104 370 620 1 225 230 2" 2" 2" " " 2" 45 FV8 219 210 413 663 1 391 281 DN80 2" DN80 " 1" 2" 76

FV8 and FV12

(approximate) in ins, mm and kg FV12 FV15 FV18 324 406 457 262 303 329 418 390 514 668 640 764 1 400 1 275 1 521 411 492 544 DN100 DN150 DN150 2" DN80 DN80 DN100 DN150 DN150 " " " 1" 1" 2" 2" 2" 2" 130 150 193 Safety valve connection

FV15 and FV18

Installation

The vessel should be mounted with the flash steam outlet at the top, and connected as indicated below. Each vessel incorporates a " screwed boss for a pressure gauge. For drainage, it is recommended that a float trap is fitted. A safety valve connection is provided on the vessel. It should not be assumed that the safety valve will be the same size as the connection. Safety valve sizing and selection should be in accordance with National and Local Regulations. Flash steam outlet

Lifting lugs

Pressure gauge connection Inspection cover

Inlet

Installation supports Inspection cover

How to order

Example: 1 off Spirax Sarco FV6 flash vessel having screwed BSP connections. The unit is to be constructed to ASME VIII DIV 1 2004 + ADD06.

Model FV15 and FV18 shown

Condensate / residual blowdown outlet

FV Flash Vessel

TI-P404-03 AB Issue 8

You might also like

- Guide Line To Vendor Regarding Tube Layout PreparationDocument4 pagesGuide Line To Vendor Regarding Tube Layout PreparationSalman AkramNo ratings yet

- Instructions: Landing Loss EmissionsDocument15 pagesInstructions: Landing Loss Emissionssunildubey02No ratings yet

- 007-Stand Post Type Fire HydrantDocument6 pages007-Stand Post Type Fire HydrantshabahatNo ratings yet

- Section 23 - Physical PropertiesDocument14 pagesSection 23 - Physical PropertiesCHANADASNo ratings yet

- MyChemE Calculating Pressure Drops in Straight PipeDocument8 pagesMyChemE Calculating Pressure Drops in Straight PipeShantanuNo ratings yet

- 100-T-1100 Methanol Tank SampleDocument3 pages100-T-1100 Methanol Tank SampleSachinl PatelNo ratings yet

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodNo ratings yet

- LPG Blending Facilities Tender Documents ListDocument235 pagesLPG Blending Facilities Tender Documents ListManish MehtaNo ratings yet

- StrainerDocument2 pagesStrainerRanjithNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedDocument28 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Datasheet For Vent ScrubberDocument5 pagesDatasheet For Vent ScrubbercliffrajjoelNo ratings yet

- Condensate Stabilization Design BasisDocument22 pagesCondensate Stabilization Design BasisMuhammad.SaimNo ratings yet

- Brochure - Loading Spout - Pubc-0499-AulDocument2 pagesBrochure - Loading Spout - Pubc-0499-Aulm_verma21No ratings yet

- Data Sheet For Flare Package (PK-720)Document3 pagesData Sheet For Flare Package (PK-720)samynatha PrasathNo ratings yet

- Tank BlankettingDocument6 pagesTank BlankettingBaskar KannaiahNo ratings yet

- Control Valve Sizing Based on Masonelian MethodDocument10 pagesControl Valve Sizing Based on Masonelian Methodmanoj_amritkarNo ratings yet

- Pc12002-368-03-Sp-002, Rev 1 Specification For Scada SystemDocument21 pagesPc12002-368-03-Sp-002, Rev 1 Specification For Scada SystemHamza ShujaNo ratings yet

- 7-Ideal and Real GasDocument12 pages7-Ideal and Real GasLeoThomasNo ratings yet

- Flush Bottom ValvesDocument3 pagesFlush Bottom ValvesErkan TakNo ratings yet

- WRC 107 WRC 297 Co MP PDFDocument11 pagesWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

- Ione VP 14 P 102ab 001 - 1Document8 pagesIone VP 14 P 102ab 001 - 1ضياء محمدNo ratings yet

- IPS-MBD21907-In-511A-Data Sheet of Level Gauge (Side Mounted) - ADocument3 pagesIPS-MBD21907-In-511A-Data Sheet of Level Gauge (Side Mounted) - ANikhil KarkeraNo ratings yet

- KPD-TAY Integrated Development Project Phase-II DatasheetDocument2 pagesKPD-TAY Integrated Development Project Phase-II Datasheetm.shehreyar.khanNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: Pramod KhotDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: Pramod Khotsumit kumarNo ratings yet

- Guide For Loading and Unloading of Cryogenic Liquid TankersDocument14 pagesGuide For Loading and Unloading of Cryogenic Liquid Tankersmohsin husen BargirNo ratings yet

- Psych Process 09Document9 pagesPsych Process 09mauricio duran albertosNo ratings yet

- 05 FS GduDocument18 pages05 FS GduAnonymous O0lyGOShYGNo ratings yet

- Section 7Document64 pagesSection 7WlopezaNo ratings yet

- 24338-8.0100.00.0 - SPR Ngplade IntroduktionDocument4 pages24338-8.0100.00.0 - SPR Ngplade IntroduktionDinesh KumarNo ratings yet

- To-HQ-02-037 Rev 00 Philosophy For Piping Design - OnshoreDocument41 pagesTo-HQ-02-037 Rev 00 Philosophy For Piping Design - OnshoreBassem BalghouthiNo ratings yet

- Clampco CatalogueDocument39 pagesClampco CatalogueMisaghNo ratings yet

- VCTDS-01061 Sizing of Tank Blanketing System-EnDocument3 pagesVCTDS-01061 Sizing of Tank Blanketing System-EnvipinNo ratings yet

- Limpet With Jacket Nozzle OrientationDocument1 pageLimpet With Jacket Nozzle OrientationArunkumar MyakalaNo ratings yet

- ME ProductCatalogDocument20 pagesME ProductCatalogLim Chee SiangNo ratings yet

- WPRK Pack Preparation PDFDocument42 pagesWPRK Pack Preparation PDFYusufNo ratings yet

- Flaretip Design Condition, Technical Specification and Spare Parts List PDFDocument15 pagesFlaretip Design Condition, Technical Specification and Spare Parts List PDFJabel Oil Services Technical DPTNo ratings yet

- API 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Document7 pagesAPI 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Ricardo NapitupuluNo ratings yet

- Screw Conveyor and Feeder Calculation FiDocument90 pagesScrew Conveyor and Feeder Calculation FiTheodoros AtheridisNo ratings yet

- Input From Simulation Result From Table or Chart AssumptionDocument31 pagesInput From Simulation Result From Table or Chart AssumptionMohamed Mamdouh AbdelHameed100% (1)

- DR - Reciprocating Compressor Table of Contents (Process)Document5 pagesDR - Reciprocating Compressor Table of Contents (Process)rutujaNo ratings yet

- E07 QDocument20 pagesE07 QSoledad Fernández SantosNo ratings yet

- 411 E10AB AdequacyDocument7 pages411 E10AB AdequacyMuhammadUsmanSaeed100% (1)

- The New Fifth Edition of Api 618 For Reciprocating Compressors - Which Pulsation and Vibration Control Philosophy Should You Use?Document14 pagesThe New Fifth Edition of Api 618 For Reciprocating Compressors - Which Pulsation and Vibration Control Philosophy Should You Use?rajurajangam100% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedDocument21 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- C35 Positive Displacement FlowMeterDocument4 pagesC35 Positive Displacement FlowMetersanjay6969No ratings yet

- Upgrading Iraq's Sarqala CPF Piping MaterialsDocument62 pagesUpgrading Iraq's Sarqala CPF Piping MaterialsSubash ChandraboseNo ratings yet

- Blower's pulsation dampener using reactive silencers: 30 dB reductionDocument7 pagesBlower's pulsation dampener using reactive silencers: 30 dB reductionShubham patilNo ratings yet

- Air Separation Plants History and Technological Progress 2019 Tcm19 457349Document28 pagesAir Separation Plants History and Technological Progress 2019 Tcm19 457349Jambanlaya JasdNo ratings yet

- DcrerweDocument1 pageDcrerwesri9987No ratings yet

- Chemical Injection System (Construct)Document2 pagesChemical Injection System (Construct)Raj Mohan100% (1)

- P&ID Cooling System (PHE 1 Set)Document1 pageP&ID Cooling System (PHE 1 Set)Moon JaehyunNo ratings yet

- FV Flash Vessel-Technical Information-1Document3 pagesFV Flash Vessel-Technical Information-1Vanessa Elizabeth BeshaiesNo ratings yet

- Condensate Flash Vessel HandbookDocument3 pagesCondensate Flash Vessel HandbookHari Gunawan NugrahaNo ratings yet

- p405 01Document8 pagesp405 01Utku KepcenNo ratings yet

- High pressure bladder accumulators conform to EC regulationsDocument9 pagesHigh pressure bladder accumulators conform to EC regulationsMetin GüvenNo ratings yet

- 23.bladder AccumlatorDocument12 pages23.bladder AccumlatorM S GokulNo ratings yet

- Vertical Steam Distribution Manifold - FabricatedDocument2 pagesVertical Steam Distribution Manifold - Fabricatedkresimir.mikoc9765No ratings yet

- Olaer EhvDocument12 pagesOlaer EhvandinoNo ratings yet

- Manual Spirax SarcoDocument2 pagesManual Spirax SarcoAlex CarreraNo ratings yet

- Autopipe SampleDocument1 pageAutopipe SamplekawkatrNo ratings yet

- Ga SSVSL022 03 en 11 13Document6 pagesGa SSVSL022 03 en 11 13kawkatrNo ratings yet

- Delta Delta Meter InfoDocument8 pagesDelta Delta Meter InfokawkatrNo ratings yet

- Condenser Technical DataDocument3 pagesCondenser Technical DatakawkatrNo ratings yet

- VF006-IN-ILD-0002 - Instrument Loop Drawing - Rev.0Document197 pagesVF006-IN-ILD-0002 - Instrument Loop Drawing - Rev.0Phạm Tấn PhướcNo ratings yet

- Valve Sizing W IEC Noise - Gas VolumetricDocument64 pagesValve Sizing W IEC Noise - Gas VolumetricskalanidhiNo ratings yet

- An Ideal Dual Cycle Using Cold Air Compresses 145 Kpa 81Document3 pagesAn Ideal Dual Cycle Using Cold Air Compresses 145 Kpa 81Jehana NaolNo ratings yet

- Practice 14Document9 pagesPractice 14ALEJA MNo ratings yet

- PK 50002 (Hydraulic Diagram)Document90 pagesPK 50002 (Hydraulic Diagram)Alejandro Torrealba100% (8)

- Hydroprocessing Catalyst EvaluationDocument15 pagesHydroprocessing Catalyst EvaluationKashifNo ratings yet

- Introducción A Los Bioreactores - Reactor BatchDocument14 pagesIntroducción A Los Bioreactores - Reactor BatchMilton SteevenNo ratings yet

- Fire Fighting System Part 02 by Er. Ezazul HaqueDocument293 pagesFire Fighting System Part 02 by Er. Ezazul HaqueEZAZNo ratings yet

- Well Intervention Course: OrganizationsDocument31 pagesWell Intervention Course: OrganizationsAkol Majook100% (1)

- 1 4 Calculation of Acoustic BHP 2014Document60 pages1 4 Calculation of Acoustic BHP 2014Luis Enrique Muñoz SeguraNo ratings yet

- Automatic Control ValvesDocument36 pagesAutomatic Control Valveshoxoxi1234No ratings yet

- Shailesh Final ThesisDocument70 pagesShailesh Final Thesisabdulazeez88No ratings yet

- R134a VwebDocument1,014 pagesR134a VwebAlexandre GelsiNo ratings yet

- Quantity of Material (LPBS)Document8 pagesQuantity of Material (LPBS)Billy DNo ratings yet

- Published by Technical Services / PSSR For Internal CirculationDocument33 pagesPublished by Technical Services / PSSR For Internal CirculationVed PrakashNo ratings yet

- Fire Pump Pressure SettingsDocument2 pagesFire Pump Pressure SettingsJhe Inibam100% (1)

- Ball Valves Seat Variations: Standard SeatsDocument2 pagesBall Valves Seat Variations: Standard SeatsSantiago GarciaNo ratings yet

- Siphon in Piping SystemsDocument6 pagesSiphon in Piping SystemsAli Naveed FarookiNo ratings yet

- Aerodynamic DevicesDocument10 pagesAerodynamic DevicesCollege BoysNo ratings yet

- Microstructure - Key Factors That Influence Material PropertiesDocument6 pagesMicrostructure - Key Factors That Influence Material PropertiesAriyan AriyanNo ratings yet

- PETRO Filtration Donaldson Fuel and OilDocument32 pagesPETRO Filtration Donaldson Fuel and OilGustavoNo ratings yet

- Field Devices - Flow: Product SpecificationsDocument32 pagesField Devices - Flow: Product SpecificationsMohd JannahNo ratings yet

- Calculation OfCumulative Water Influx Using Van-Everdingen Model With Superposition Concept by MATLAB ProgramDocument48 pagesCalculation OfCumulative Water Influx Using Van-Everdingen Model With Superposition Concept by MATLAB ProgramAlberto MoroNo ratings yet

- Rapid Transverse and Feed Control Hydraulic CircuitDocument10 pagesRapid Transverse and Feed Control Hydraulic CircuitAditya GosiNo ratings yet

- Calculate total pipe lengthDocument6 pagesCalculate total pipe lengthImtinan MohsinNo ratings yet

- Pressure Switch Assembly For Portable Air Compressors: DescriptionDocument8 pagesPressure Switch Assembly For Portable Air Compressors: DescriptionA delca-No ratings yet

- KINETICDocument9 pagesKINETICGabriel BonciuNo ratings yet

- A/SA 333 Spec Sheet A333 Pipe Specifications: ScopeDocument8 pagesA/SA 333 Spec Sheet A333 Pipe Specifications: ScopeAdrian EspinosaNo ratings yet

- Basic Theory of PumpDocument19 pagesBasic Theory of PumpJoon Eeo100% (4)

- Fluid Level Shots To Optimize Chemical Treatment ProgramsDocument15 pagesFluid Level Shots To Optimize Chemical Treatment ProgramsWilliam100% (1)