Professional Documents

Culture Documents

Miggy 170 MC6918900020 32

Uploaded by

Patricio HerreraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Miggy 170 MC6918900020 32

Uploaded by

Patricio HerreraCopyright:

Available Formats

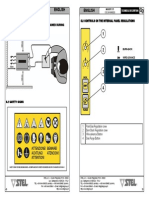

TECHNICAL DESCRIPTION

MIGGY 171

COD. 6918900020

ENGLISH

ENGLISH

MIGGY 171

COD. 6918900020

TRUOBLESHOOTING

sources, or any abnormal situations. MAINS VOLTAGE The generator works at mains voltages differing by 20% from the rated mains value (rated voltage 230V, minimum voltage 185V, maximum voltage 275V). SUPPLY BY MOTOR GENERATOR The generator is designed to work supplied by generating sets. 1) - The 230V a.c. auxiliary socket must be able to supply suitable power as indicated in the section (electrical characteristics listed in paragraph 2.2). 2) - The auxiliary socket of the generating set must satisfy the following conditions: - peak voltage of the a.c. wave lower than 423V a.c. - frequency of the a.c. wave between 50 and 60Hz. - RMS voltage of the a.c. wave higher than 180V c.a. It is important for the generating set to satisfy the conditions listed in points1 and 2. It is recommended not to use this machine with generating sets that do not respect these conditions because it could be damaged. Warning: Turn on the machine only after the motogenerator state initiated CONNECTION - Before making the electrical connections between the current generator and the line switch, ensure that the switch is turned off. - The distribution panel must comply with the regulations in force in the country of use . - The mains system must be of the industrial type. - The multipolar cable is provided with a type G32 plug (Schuko) complying with standard UNI 47 166/68. Provide a special socket, model SCHUKO 16A , which can receive leads with a section of 2.5mm. - For longer connecting cables, increase the lead section as required. - Upstream, the mains socket must have a suitable switch provided with delayed fuses.

7.0 WELDING DEFECTS AND MALFUNCTIONS 7.1 POSSIBLE WELDING DEFECTS

DEFECT

CRACKS

CAUSES

ADVICE

Acid electrode on steel with a high sulphur Use a basic electrode. content. Excessive swinging of the electrode. Move the edges to be welded closer together. Distance between the parts to be welded is Advance slowly at the start. too great. Part being welded is cold. Decrease the welding current. Material to be welded is dirty (e.g. oil, paint, Cleaning the parts before welding is a rust, oxides). fundamental principle for obtaining good Insufficient current. welding seams. Low current. High welding speed. Inverted polarity . Electrode tilted in position opposite its movement. Regulate the operative parameters and improve preparation of the parts to be welded.

POROSITY POOR PENETRATION

HIGH SPLASHING PROFILE DEFECTS

Excessive electrode inclination . Incorrect welding parameters. Passing speed not linked with the needs of the operative parameters. Electrode inclination not constant during welding.

Make the necessary corrections. Respect the basic and general welding principles.

ARC INSTABILITY THE ELECTRODE MELTS OBLIQUELY

Insufficient current. Electrode with core not centred. Magnetic blowing phenomenon.

Check the state of the electrode and the connection of the earth cable. Change the electrode. Connect two earth cables to the opposite sides of the part to be welded.

7.2 POSSIBLE MALFUNCTIONS MALFUNCTIONS

PROBLEM

DOES NOT SWITCH ON

CAUSES

-Incorrect primary connection. -Faulty inverter card.

REMEDY

-Check the primary connection. -Apply to the nearest service centre. -Wait for thermal reset. -Apply to the nearest service centre.

NO VOLTAGE AT OUTPUT

MODEL

MIGGY 171

VOLTAGE/PHASES

DELAYED FUSE

16 A

INCORRECT OUTPUT CURRENT

-Machine overheated (yellow led lit). -Faulty inverter card. -Low primary supply voltage.

1 phase 230V

-Faulty regulating potentiometer. -Low primary supply voltage.

-Apply to the nearest service centre. -Check the distribution mains.

30

STEL s.r.l. Via del Progresso n 59 36020 Loc. Castegnero (VICENZA) - ITALY TEL. +39 0444 639525 (central.) +39 0444 639682 (comm.) FAX +39 0444 639641 E-mail: info@stelgroup.it http: www.stelgroup.it

STEL s.r.l. Via del Progresso n 59 36020 Loc. Castegnero (VICENZA) - ITALY TEL. +39 0444 639525 (central.) +39 0444 639682 (comm.) FAX +39 0444 639641 E-mail: info@stelgroup.it http: www.stelgroup.it

43

You might also like

- Effect of Active and Modified Atmosphere Packaging On Quality Retention of DarkDocument10 pagesEffect of Active and Modified Atmosphere Packaging On Quality Retention of DarkPatricio HerreraNo ratings yet

- Miggy 170 MC6918900020 35Document1 pageMiggy 170 MC6918900020 35Patricio HerreraNo ratings yet

- Active Packaging in Food Industry - A Review PDFDocument7 pagesActive Packaging in Food Industry - A Review PDFPatricio HerreraNo ratings yet

- Miggy 170 MC6918900020 38Document1 pageMiggy 170 MC6918900020 38Patricio HerreraNo ratings yet

- Miggy 170 MC6918900020 34Document1 pageMiggy 170 MC6918900020 34Patricio HerreraNo ratings yet

- Miggy 170 MC6918900020 36Document1 pageMiggy 170 MC6918900020 36Patricio HerreraNo ratings yet

- Miggy 170 MC6918900020 37Document1 pageMiggy 170 MC6918900020 37Patricio HerreraNo ratings yet

- Miggy 170 MC6918900020 33Document1 pageMiggy 170 MC6918900020 33Patricio HerreraNo ratings yet

- English: 1°) Composition GEN MIGGY 171 SALE CODE 601075000LDocument1 pageEnglish: 1°) Composition GEN MIGGY 171 SALE CODE 601075000LPatricio HerreraNo ratings yet

- Miggy 170 MC6918900020 28Document1 pageMiggy 170 MC6918900020 28Patricio HerreraNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Natural Gas Dryers: Pipeline SeriesDocument2 pagesNatural Gas Dryers: Pipeline SeriesAnonymous 70lCzDJvNo ratings yet

- Need For Earthing and Double Insulation PDFDocument2 pagesNeed For Earthing and Double Insulation PDFMeNo ratings yet

- Air Compressor Presentation 1.1Document20 pagesAir Compressor Presentation 1.1ROBERTO FELIX RUEDASNo ratings yet

- Removable Francis Turbine SealsDocument4 pagesRemovable Francis Turbine SealsmachevelNo ratings yet

- DigitalDocument4 pagesDigitalideal assignment helper 2629No ratings yet

- Gates em Ingles 2010Document76 pagesGates em Ingles 2010felipeintegraNo ratings yet

- Photoassociation Spectroscopy of A Spin-1 Bose-Einstein CondensateDocument5 pagesPhotoassociation Spectroscopy of A Spin-1 Bose-Einstein Condensatee99930No ratings yet

- Electrical Machines EE-260 Lecture-04: Instructor: DR Mehmood AlamDocument12 pagesElectrical Machines EE-260 Lecture-04: Instructor: DR Mehmood AlamSaif Ur RehmanNo ratings yet

- Eastern Visayas State University-Ormoc City CampusDocument3 pagesEastern Visayas State University-Ormoc City Campuskhellian villameroNo ratings yet

- Electric Vehicle ChargingDocument60 pagesElectric Vehicle Chargingvinod 7100% (1)

- Accuspin 1 120V 230VDocument60 pagesAccuspin 1 120V 230VAndrew HolmesNo ratings yet

- Type FL Low Profile NTC Temperature Sensor: AmphenolDocument3 pagesType FL Low Profile NTC Temperature Sensor: Amphenolmauricio alfonsoNo ratings yet

- PIPENET VISION SPRAY MODULE TRAINING MANUALDocument48 pagesPIPENET VISION SPRAY MODULE TRAINING MANUALElton Situmeang50% (2)

- Pressue CompensatorDocument2 pagesPressue CompensatorMahmud MaherNo ratings yet

- Macroeconomic Modeling for SDGs in Least Developing EconomiesDocument25 pagesMacroeconomic Modeling for SDGs in Least Developing EconomiesAM operationNo ratings yet

- Pompe Perkins 3340f261t PDFDocument2 pagesPompe Perkins 3340f261t PDFKamel BelhibaNo ratings yet

- Lecture-3,4, 5-Weirs and BarragesDocument41 pagesLecture-3,4, 5-Weirs and BarragesMuhammad Sakib0% (1)

- MATE 280 Characterization of Powders and Porous MaterialsDocument65 pagesMATE 280 Characterization of Powders and Porous MaterialsAnissa Adiwena100% (1)

- ms300 SeriesqDocument516 pagesms300 SeriesqHerbert Quispe RjsNo ratings yet

- FertiOne Manual (30.11.15)Document36 pagesFertiOne Manual (30.11.15)YacineNo ratings yet

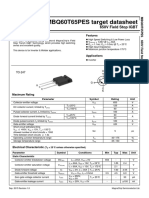

- MBQ60T65PES Target Datasheet: 650V Field Stop IGBTDocument1 pageMBQ60T65PES Target Datasheet: 650V Field Stop IGBTamrNo ratings yet

- A4 G970 - G990 Product Brochure enDocument17 pagesA4 G970 - G990 Product Brochure endalibor_bogdan100% (3)

- Switch and Types of Switch: What Is A Switch?Document5 pagesSwitch and Types of Switch: What Is A Switch?Swagat PradhanNo ratings yet

- Pneumatic Maneuvering SystemDocument65 pagesPneumatic Maneuvering Systemminhankyaw100% (3)

- Chemical ThermodynamicsDocument46 pagesChemical ThermodynamicsHardik0% (1)

- Anomaly Events GuideDocument33 pagesAnomaly Events GuideRichard LittlesNo ratings yet

- Cole Tarango - Research Paper 2018-2019Document5 pagesCole Tarango - Research Paper 2018-2019api-447838694No ratings yet

- OMS 605 User Manual ENUDocument86 pagesOMS 605 User Manual ENUlatifNo ratings yet

- Menard vertical drains consolidate soilsDocument3 pagesMenard vertical drains consolidate soilsSyed Shariq HassanNo ratings yet

- OCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Document12 pagesOCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Soham PatwardhanNo ratings yet