Professional Documents

Culture Documents

Technical Aspects of Desalination Plant

Uploaded by

Monica Urbieta0 ratings0% found this document useful (0 votes)

122 views12 pagesThe desalination plant will not be operated on a continuous basis because of its prohibitive operational cost. In the Reverse Osmosis process, water is made to pass from the more concentrated solution to a less concentrated one. The main attraction of the selected technology for this process is its low energy consumption.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe desalination plant will not be operated on a continuous basis because of its prohibitive operational cost. In the Reverse Osmosis process, water is made to pass from the more concentrated solution to a less concentrated one. The main attraction of the selected technology for this process is its low energy consumption.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

122 views12 pagesTechnical Aspects of Desalination Plant

Uploaded by

Monica UrbietaThe desalination plant will not be operated on a continuous basis because of its prohibitive operational cost. In the Reverse Osmosis process, water is made to pass from the more concentrated solution to a less concentrated one. The main attraction of the selected technology for this process is its low energy consumption.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

8.

TECHNICAL ASPECTS OF DESALINATION PLANT

8.1 DESALINATION PLANT

Considering the probable small water availability from the public utilities network, it is

proposed to supply and install a desalination plant of 4.15m

3

/hr, hence 100m

3

/day nominal

capacity, to supply water to the resort. The desalination plant will not be operated on a

continuous basis because of its prohibitive operational cost but rather on an as-required

basis, to supplement the normal mains supply, and therefore to make-up for any water

needs in excess of public utility water availability.

8.2 REVERSE OSMOSIS PROCESS

Within the scope of the project, the promoter intends to install a Reverse Osmosis process

desalinator.

In the reverse osmosis process, water is made to pass from the more concentrated solution

to a less concentrated one, which is the reverse of the principle of osmosis. The force

necessary to accomplish this is the application of pressure greater than the osmotic

pressure of the saline solution.

If a saline solution is in contact with a semi-permeable membrane which is placed under

pressure being in excess of its osmotic pressure, water from the solution will flow through

the membrane. Water flow will continue till the pressure created by the osmotic head

equals the osmotic pressure of the salt solution.

Polyamide membranes have proved most successful to be used for this purpose.

Membranes are not perfectly semi-permeable as they allow certain quantities of ions to

cross through the membranes. The salt content in the water produced is dependent upon the

feed-water temperature, salinity, membrane porosity and system pressure. This plan has

been designed with each of these factors in mind, to assure the best possible quality

permeate while keeping consumption of power and chemicals to a minimum.

8.2.1 Advantages of Reverse Osmosis Process

The main attraction of the selected technology for this process is its low energy

consumption. The energy required for operating the process is dependent on several factors

as described above, as well as appropriate selection of pumps, motors, piping etc. The

technical difficulties include fabrication, degree of semi-permeability, fouling, membrane

supports and the recovery of energy.

8.3 COMPONENTS OF DESALINATION PLANT

The proposed desalination plant will have a nominal capacity of 100m

3

/day to cater for the

resorts daily domestic requirements and will include:

1 set of fine filters to remove fine solid particles which would otherwise damage

the membranes.

1 No reverse osmosis desalination plant model PVSECO100

1No high pressure pump

1 No energy recovery unit with associated booster pump and accessories

1 No desalinated water neutralisation filter (outside of RO container)

2No pressure vessels

1 set of chemical dosing units

1 CIP system

1No beach intake well

1No dilution well

1 No seawater buffer tank

1 No dilution tank

The plant room will be located within the desalination plant room area as shown on the

Massing Plan enclosed at Annex 4B at the end of Section 4.

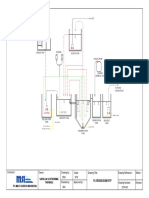

The basic simplified flowchart of the desalination plant is shown below in Figure 8-1.

Figure 8-1: Basic Process Flow Diagram

8.3.1 Production Capacity of Desalination Plant

The plant will be rated to produce a treated water volume of the order of 100m

3

/day. This

production is roughly equivalent to 1day demand of the hotel.

The water produced will feed the 250m

3

underground service reservoir which will be

located towards the south western tip, underneath the roundabout feature.

Disinfection of the stored water will be given consideration as part of the pipework exiting

the tank. UV disinfection is a clean and safe alternative to chlorine, and is being explored.

The RO plant will be demand-based. The service reservoir will be fitted with float

switches. When the level in the service reservoir drops to a pre-determined level, the RO

unit will start automatically and begin producing potable water. It will keep running until

the reservoir upper level switch is reached, when it will automatically switch off again. The

tank will be equipped with an outlet valve and associated piping for draining and cleaning

the reservoir, as required.

8.4 SEAWATER QUALITY

2No seawater samples have been taken to investigate the physico-chemical qualities of the

water and at the same time serve at baseline data. The location at which samples have been

taken is shown on the Massing Plan enclosed at Annex 8A at the end of Section 8.

Pre-Treatment

Post-Treatment

Stabilized Water

By-product Brine

Saline Feed Water

High Pressure

Pump

Membrane

Assembly

The laboratory results are enclosed at Annex 8B at the end of this section.

However for ease of reference, the results have been reproduced at Table 8-1 below.

Table 8-1: Physic-Chemical Quality Testing Results

Parameters Sample No 1 Sample No 2

pH 8.2 8.2

Salinity 34.5ppt 34.1ppt

Total Suspended Solids <2.0mg/L <2.0mg/L

Total Dissolved Solids 26, 300mg/L 26, 000mg/L

Biochemical Oxygen Demand <0.5mg/L <0.5mg/L

Chemical Oxygen Demand <5mg/L <5mg/L

8.5 FEATURES OF DESALINATION PLANT

As already mentioned, the desalination plant will be of the reverse osmosis type and will

make use of latest technology.

The desalination plant will be made-up of high quality materials (such as high quality

stainless steel and glass reinforced plastics (GRP) impervious to corrosion). The model to

be installed at Saint Francois will be PVSECO100 manufactured by Mllsystem PVS of

Vienna, Austria.

At this point in the projects procurement cycle, it is envisaged that the supplier will be

PVS of Austria, an Austrian-based company with over 35 years experience in the design,

manufacture, production, installation and commissioning in water management in

numerous countries including Maldives, Oman, Qatar, New Caledonia, Romania, Crotia

etc. The firm specializes in high-tech solutions for tourist industry applications, and

produces ready-to-use Reverse Osmosis desalination plants.

Note: This proposal is only a tentative one at this early stage of the project procurement

cycle.

A typical desalination kit is shown in the photographs below.

Photograph 8-1: Ready-To-Use R.O Plant

Photograph 8-2: Typical Indoor RO Plant

The desalination plant system will be equipped with all the appropriate sensors and

security devices to stop the production of desalinated water in case of any failure; hence,

discharge to the tank will automatically stop if salinity level of the outgoing water was

sensed to be above maximum acceptable level.

To ensure removal of brine solution from membranes and also avoid any standstill

corrosion of piping material, high pressure pump and other components, a cleaning-in-

place system is integrated in RO-container and it will permit flushing with fresh water at

any plant stop.

In case of necessity of cleaning the membranes with chemicals, the respective solution is

prepared in the tank and re-circulated through the membranes to restore their desalination

capacity.

8.6 DESCRIPTION OF PREFILTRATION FILTER UNITS

The proposed prefiltration units will consist of two components:

(i) Fine filters, followed by

(ii) Absolute Filters

8.7 HIGH PRESSURE PUMP UNIT

The plant will be fitted with a highest-efficiency high-pressure pump unit operating in

parallel with a small booster pump. The high-pressure pump will be a piston-type positive

displacement unit to increase the pressure from approx. 3 to approx. 60 bars. The pump

will be made of homogenous materials to avoid galvanic corrosion, which would have

otherwise rendered it unsuitable for working with seawater. The head, the internal parts,

the valve sealing rings, plugs etc. of the pump being in contact with seawater will be made

of stainless steel. All wear surfaces are lubricated/cooled by the pump medium (water) thus

oil and grease are not required.

All the materials will be fully compatible to avoid any possibility of electrolysis effect

between the different components.

The high-pressure pump unit will have a working capacity of:

High pressure pumping rate.... 84.15m

3

/hour

Motor power duty point power consumption . 13.7 kW

Pump efficiency ............. 90%

8.8 REVERSE OSMOSIS MEMBRANE ASSEMBLY

The membrane assembly will be composed of a range of 12 spiral wound polyamide

elements contained inside of 2 pressure vessels rated to operate at a pressure of approx 69

bars, depending on the feed water analysis results (assuming 27

0

C and 34, 000 TDS). The

membrane assembly will be efficiently designed to provide the required flow rate at

optimal flow velocity through the membrane units for long lasting life expectancy. At such

an operating pressure and flow conditions, the yield will be almost immediate and pure

drinking water will be available after a few seconds only.

During normal operation, the membrane units will be working simultaneously but in case

of damage or failure of one unit, this broken membrane unit will be by-passed with the

plant continuing to operate safely with the remaining ones.

8.9 HIGH PRESSURE INSTRUMENTS

The following minimum control and safety instruments will be provided in association

with the high pressure aspect of the plant:

1No electrical contact pressure gauge to monitor membrane inlet pressure

1No pressure gauge to monitor membrane discharge pressure

Emergency pressure switch for membrane inlet pressure

Flow meter for control of pressure exchanger flow

1 No Air relief valve

1 No security valve for excess pressure

8.10 LOW PRESSURE INSTRUMENTS

The following minimum instruments and control components will be provided for

monitoring and controlling the lower pressure sections of the plant:

1 No pressure control and gauge (manometer) to monitor inlet pressure

1 No pH indicator prior to feed filters

1 Redox prior to fine filters

1 No pressure control to monitor high-pressure pump inlet

Pressure gauges on all fine filter housing

Pressure gauges to monitor brine outlet pressure

Conductivity meter of permeate

1 No level control in CIP tank

3 No dry-run protection for CIP tank and dosing tanks

Re-hardening station including media

Flow meter for monitoring outgoing permeate

pH meter for drinking water, following the neutralisation media

Conductivity meter for drinking water, following the neutralisation media

2 No pressure gauge to monitor feed into and out of neutralisation filter

SDI meter on inlet piping

8.11 ELECTRICAL PANEL

A control panel will be delivered with the plant so as to control and monitor all the

operating and security functions of the plant. The central switchboard is designed

according to IEC/VDE/OVE-standards and it includes:

PLC-system (programmable logic controller) for data processing

Process control system

Main interruptor

Central visual alarm

All necessary contactors, fuses, status lights/displays

A busbar for power cable connection

The alarm panel will be designed to indicate the following important parameters:

(i) Overload relay of pump motors

(ii) Mini/maxi abnormal pressure conditions

(iii) High salinity pre-alarm/pH/Redox

(iv) Operating hour recording

8.12 CLEANING IN PLACE UNIT

The CIP-system (cleaning-in-place) is integrated in the RO-container and permits

flushing with fresh water at any plant stop. This ensures removal of brine solution from the

membranes and also avoids any standstill corrosion of piping material, high pressure pump

and other components. In case of necessity of cleaning the membranes with chemicals, the

respective solution is prepared in this tank and re-circulated through the membranes to

restore their desalination capacity.

The cleaning in place unit will comprise of:

1No pump with 14m

3

/hr capacity, working at 5 bar pressure

1No 2,000 Litre plastic holding tank to contain water and chemical products for

membrane cleaning. A mixer is installed in the tank to optimally dilute and prepare

the solution prior to beginning the cleaning process.

8.13 SKID FRAME AND ASSEMBLY MATERIALS

The skid frame will be entirely made-up in high quality ST37 alloy, sand-blasted and

coated, suitable for working in saline environment.

Manifolds and clamps will all be in ST37 sand-blasted and coated for extended life span.

Screws, nuts, bolts and high pressure piping will be 1.4571 staninless steel. Connections

between stainless steel pipes and ST37 steel will feature galvanic insulated separators.

8.14 BEACH INTAKE BOREHOLE

The feeding seawater will be pumped from a beach intake borehole situated within the

hotel premises, at 36metres from the High Water Mark as shown on the Massing Plan

enclosed at Annex 8A at the end of Section 8. It should be highlighted that this is tentative

positioning of the desalination components which will have to be validated by the M&E

Engineer at design stage.

The borehole will be drilled to a depth of 20 metres and in 250 mm diameter. The borehole

will be lined with a PVC lining of diameter 200mm, which is wrapped with geotextile

membrane with an end cap at the bottom. The PVC lining will be plain from ground level

i.e. 0.0 8.0 metres and slotted from 8.0 20.0 metres.

After drilling, an air lift will be carried out during 1 hour in order to clean and develop the

borehole, following which a pumping test will be carried out for 6-8 hours, to determine

the maximum aquifer recharge rate and associated draw down. Finally, a physical and

chemical test of the seawater will be undertaken to determine the water quality during

pumping rate.

The borehole will be equipped with a submersible pump placed at a depth of

approximately 19.2 metres within the 20m deep borehole. The submersible pump will feed

the seawater storage tank via a 150mm HDPE pipeline connected to it.

Seawater will be pumped directly from the beach intake borehole at a rate of 10.4m

3

/hour

(i.e. 250m

3

/day) at 3 bar for the desalination process. A storage tank is not recommended,

in order to inhibit possible biological activity and water contamination.

The plan view and section of the proposed beach intake borehole is enclosed at Annex 8C

at the end of Section 8.

8.15 BRINE PRODUCTION

The output of the desalinator which can also referred to as the by-product or permeate of

the desalination plant process will be a concentrated salt solution having a salinity level of

67,000ppm. This concentrated brine solution which will be discharged from the

desalination plant at a rate of 4.15m

3

/hour (1.15litres/second) during the operation of the

plant will be pumped at the required pressure and flow rate to the dilution tank prior to

discharge back to the sea.

8.15.1 Brine Dilution Tank

Dilution and disposal through percolation occur in the dilution tank.

Prior to disposal of brine into the dilution tank, the brine of salinity level 67000ppm

coming from the desalination plant at a rate of 6.25m

3

/hour will be diluted in the same

dilution tank with seawater of nominal salinity level 34,000ppm being pumped from

dilution well at a rate of 33m

3

/hour.

Within the dilution tank, receiving 33m

3

/hour of seawater 34,000ppm from dilution tank,

the brine will be pre-diluted with the seawater to reach a plus 10% salinity level of

37,400ppm before percolating the sand matrix.

The brine returning to a final salinity of about 10% higher to the ambient salinity will no

longer be a threat to flora, fauna and human beings.

The typical features of the dilution tank are enclosed at Annex 8D at the end of this

section.

8.15.2 Brine Dilution Calculation

Prior to percolation of diluted brine into the dilution tank, the brine of salinity of level

67000ppm coming as effluent from the desalination plant at a rate of 4.15m

3

/hour will be

diluted in the dilution tank with seawater of salinity level 34,000ppm being pumped from

the dilution well or borehole at a rate of 33m

3

/hour.

The dilution tank has 2 entry points:

(i) Seawater at a flow rate of 33m

3

/hr, concentration 34,000ppm from dilution well

(ii) Brine at flow rate of 4.15m

3

/hr, concentration 67,000ppm from desalination plant

If the brine at a concentration of 67000ppm is discharged into the lagoon without any

induced dilution treatment, it will adversely affect the marine ecosystem i.e. the marine

flora and fauna. It is therefore imperative that the salinity of the brine should be reduced to

an acceptable level (not exceeding 37, 400ppm) i.e. 10% higher than ambient salinity prior

to discharge into the lagoon. This will be carried out by incorporating a dilution tank into

the design of the desalination plant system.

To ensure a half hour retention time, the dilution tank will have a volume of 20m

3

with the

following dimensions:

Length = 4 metres

Width = 3 metres

Depth = 2 metres

8.15.2.1 Computation of Required Flow Rate from Existing Dilution Well for Brine Dilution

Pumping rate of seawater for desalination 10.4m

3

/hr

Rate of production of desalinated water 4.15m

3

/hr

Hence rate of production of brine 6.25m

3

/hr

Salinity of feed seawater 34,000ppm

Salinity of outflow from dilution tank 37, 400

Salinity of brine from desalinator 67,000

Assume pumping rate from Dilution Well (DW) for dilution to be Vm

3

/hr

Salinity Mass Balance

(Vm

3

/hr x 34ppt) + (6.25m

3

/hr x 67ppt) = (V + 6.25)m

3

/hr x 37.4ppt

34V + 418.75 = 37.4V + 233.75

185 = 3.4V

54.4m

3

/hr = V

Inflow Rate of Seawater from Dilution well = 54.4m

3

/hr SAY 54m

3

/hr

8.15.3 Brine Disposal Site

After dilution and return of salinity to a 10% higher salinity level of 37, 400ppm, the brine

will be discharged/injected into the dilution well situated tentatively at 32metres from the

High Water Mark as shown on the Massing Plan enclosed at Annex 8A at the end of

Section 8.

The diluted brine will percolate the sandy matrix within the dilution tank.

The proposed method of disposal of the brine by-product of the desalination plant process

will ensure a controlled and/or constant release of the brine effluent to the sandy soil

through which it will percolate before reaching the lagoon. The depth of the well will be

fixed at about 2.0 metres below the existing ground level.

8.16 SUMMARY OF TECHNICAL FEATURES

The technical features of the desalination plant are summarized as below:

Feeding seawater temperature.............. 27

0

C

Feeding silt density index. Max. 3

Feeding seawater pH Approx.8.3

(V + 6.25) m

3

/hr

Diluted Brine

Required Salinity:

37.4ppt = 37400ppm

Brine 6.25m

3

/hr at 67ppt

Dilution Tank

34ppt Seawater

Dilution Well = Vm

3

/hr

Feeding seawater Total Dissolved Solids (TDS) 26,000 TDS

Percentage of permeate recovery 40%

Pumping rate seawater from beach intake borehole 1.04m

3

/hr, 2.5 5 bar

Hourly production of desalinated water.. 4.15m

3

/hr

Daily production of desalinated water. 100m

3

/hr

Expected salinity of desalinated water.. <500ppm (150-250ppm)

Rate of brine effluent discharge........ 6.25m

3

/hr

Expected brine salinity. 67,000ppm

Expected brine temperature.. Slightly higher than inlet

Expected brine pH 7

Power required 2.0-2.4kWh/m

3

Supply voltage. 400V/ 50Hz

Overall dimensions (metres) 9.0 x 1.2 x 2.2

Total Weight. 3,000kg

Expected salinity of final effluent

< 500ppm after post

treatment

8.17 DESALINATION PLANTROOM

The plant room will house the desalination plant components and the inter-connecting

pipeworks.

It will be provided with a sump from which any collected water on the floor will be

pumped out.

The various piping arrangements for the connection of the beach borehole to the

desalination unit will be designed by the project M&E Engineer during the Detailed

Design Stage, namely:

the seawater supply pipelines from the beach borehole

the pure water pipeline from the desalinator to the existing potable water tank

the CIP system pipework

support plinths (concrete) for RO container.

The plant room will house and enclose the desalination equipment, the sand filters and the

chlorine tank and dosing pump. It will be 18 metres long and 5 metres wide (area 90m

2

),

and will be constructed out of block work and concrete roof slab. The neutralisation filter

will be outside of the main RO skid.

8.18 CLEANING PROCESSES

Flushing will take place using clean water at each stop of the RO, using the permeate

collected in the CIP tank. The RO membranes will periodically be cleaned with an acidic

and an alkaline cleaning solution to prevent salt accumulation and fouling. The duration

and frequency of such process will be determined through the monitoring of the pressure

drop above the membrane.

Furthermore, in order to prevent bacterial growth on the membrane surface, the membranes

will periodically be regenerated via a diluted acid solution, as described above, using the

CIP system. Organic acids have proven to be attacked by microbes and can contribute to

degradation of the membranes; for that reason this process has been selected.

Manual cleaning of some tanks are required in order to mix the required chemical solution

the CIP. From the tank, the solution will be pumped through the entire membrane system.

Circulation takes place for a few minutes, then the CIP tank and RO system will be flushed

and the water drained out of the system (not into the drinking water reservoir).

If the plant has to stop for a prolonged period of more that 1 month, prior to stoppage of

operation, a regeneration process will be carried out after which the membranes will be

soaked and preserved in a more concentrated solution of acid in a proportion of 1.5kg in 50

litres of water which will be drained in the same way as described above when the plant

will be put back in operation.

8.19 LIFESPAN AND COMPONENTS OF DESALINATION PLANT

The desalination plant will consist of components which will be made-up of non-corrosive

materials having a minimum estimated life span of 10 years.

The different components comprising the desalination network system are as follows:

1No. intake borehole equipped with an adequate pump of 10.4m

3

/hour, i.e.

250m

3

/day

1No. set of fine cartridge filters immediately upstream of the R.O apparatus

1No desalinator model PVSECO100

1No desalinated water filter

8.20 SOLID WASTES

Seawater pumped from the beach intake borehole will be pre-filtered through the geo-

textile cloth provided around the 200mm PVC lining in the intake borehole. Consequently

the majority of solid particles will be stopped at the well level while only fine silt or sludge

particles are expected to reach the RO.

Backwashing to clean the sand filters will then be done for not more that 5 to 10 minutes.

The backwash water will afterwards be discharged into sewage treatment plant.

8.21 DOCUMENTATION, TESTING AND COMMISSIONING

All the technical documentation including erection drawings and wiring diagrams will be

provided by the plant supplier.

The desalination equipment basement will be delivered entirely assembled, ready to

operate. The supplier will be responsible for the final testing and commissioning of the

entire desalination plant, under the supervision of the Projects M&E Engineer.

8.22 ENERGY CONSERVATION

8.22.1 The Philosophy

Due to the recent dramatic increase in energy prices, commercial aspects for technical

equipment have become more and more important than ever before. From the

environmental point of view, energy conservation is more and more becoming the

leitmotiv of all development projects.

Combining these two critical criteria therefore, energy consumption and efficiency

(including energy conservation measures) have become the more important factors when

making a decision concerning the investment in a desalination plant as a long-term

investment.

In this respect a high-tech desalination equipment is proposed to be installed at Anse

Femie.

8.22.2 The RO Plant

The PVS-ECO system is a high-tech product with high efficiency and low specific power

consumption for each litre of drinking water produced. As an example, a PVS-ECO RO

plant produces drinking water from seawater at an electricity consumption rate of 2.0 to

2.4kWh/m

3

compared to 6.5kWh/m

3

for a low-tech conventional plant.

The low energy consumption and the resulting low-operating costs guarantee the shortest

possible amortization for the return on investment and achieve energy-savings which is

conducive to the protection of the environment.

You might also like

- Reverse Osmosis R24-SERIES Installation InstructionsDocument44 pagesReverse Osmosis R24-SERIES Installation InstructionsWattsNo ratings yet

- Closed SystemsDocument3 pagesClosed SystemsMohamed IrfanNo ratings yet

- Ultrapure Water ReprintDocument2 pagesUltrapure Water Reprintluispereira89No ratings yet

- Ecolutia - Proteus Fact Sheet PDFDocument2 pagesEcolutia - Proteus Fact Sheet PDFJoselito CortesNo ratings yet

- MBBR Technical BreifDocument12 pagesMBBR Technical Breifraghu kiran100% (1)

- Product Catalog: Compact Screen, Single Screen & Multi Screen FiltersDocument26 pagesProduct Catalog: Compact Screen, Single Screen & Multi Screen FiltersLuan NguyenNo ratings yet

- MBR-Tertiary UF ComparisonDocument9 pagesMBR-Tertiary UF ComparisonAkhmad RidhaniNo ratings yet

- 1000 LPH Ro Plant PDFDocument4 pages1000 LPH Ro Plant PDFrajeevNo ratings yet

- Syngineering Water MBR Vs SBR PDFDocument5 pagesSyngineering Water MBR Vs SBR PDFjaianit89No ratings yet

- 1.0-Introduction: Technical Proposal R.O. SystemDocument13 pages1.0-Introduction: Technical Proposal R.O. SystemZarkKhanNo ratings yet

- Travelling Band ScreensDocument2 pagesTravelling Band ScreensIngénérie traitement des eauxNo ratings yet

- MBR Technologies: East Valley Water DistrictDocument17 pagesMBR Technologies: East Valley Water Districtkaran198524No ratings yet

- AKSA EGYPT 150CMD Well SourceDocument9 pagesAKSA EGYPT 150CMD Well SourceAquasoul CoNo ratings yet

- MBCR FlyerDocument4 pagesMBCR FlyerunconformistNo ratings yet

- Daf English 2009 PDFDocument2 pagesDaf English 2009 PDFAquasoul CoNo ratings yet

- Industrial RO Plant in AhmedabadDocument5 pagesIndustrial RO Plant in AhmedabadShubham India - Sewage Treatment PlantNo ratings yet

- Series 900 BrochureDocument40 pagesSeries 900 BrochureLungisaniNo ratings yet

- What Is ?: Combined Technology of Activated Sludge Process and Membrane Separation ProcessDocument15 pagesWhat Is ?: Combined Technology of Activated Sludge Process and Membrane Separation Processyo5208No ratings yet

- Micro and Ultra FiltrationDocument16 pagesMicro and Ultra FiltrationGregor Grbec100% (1)

- 1000LPH RO System HinadaDocument5 pages1000LPH RO System HinadaBrenda HaroNo ratings yet

- Techno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteDocument9 pagesTechno-Commercial Offer 100 KLD TM Shiv Shakti Developers, Betul SiteTech MongerNo ratings yet

- STP Drawing PDFDocument7 pagesSTP Drawing PDFRudi suhendroNo ratings yet

- Automatic Water Softener 3mDocument26 pagesAutomatic Water Softener 3mxhaneriNo ratings yet

- Static MixerDocument8 pagesStatic MixerEric ToroNo ratings yet

- SEKO Solenoid Dosing Pumps Kompact SeriesDocument3 pagesSEKO Solenoid Dosing Pumps Kompact SeriesmauiraNo ratings yet

- Basic Ion Exchange ProcessesDocument9 pagesBasic Ion Exchange ProcessesSAYEDNo ratings yet

- Water TreatmentDocument19 pagesWater TreatmentRujem CuliNo ratings yet

- HeadworksBio (2) - Latest - Eg - Ro - 047543 PDFDocument40 pagesHeadworksBio (2) - Latest - Eg - Ro - 047543 PDFrjohnson277100% (1)

- 250-Lph-Ro SpecificationDocument7 pages250-Lph-Ro Specificationsubhananda routNo ratings yet

- Membrane TechnologyDocument47 pagesMembrane TechnologyDwiMariaUlfahNo ratings yet

- Brushbond TGPDocument2 pagesBrushbond TGPBalasubramanian AnanthNo ratings yet

- Industrial Ro Plant Manufacturer and SupplierDocument11 pagesIndustrial Ro Plant Manufacturer and SupplierindustrialroplantNo ratings yet

- Static Mixers Waste & WaterDocument3 pagesStatic Mixers Waste & WaterIsmael KhalilNo ratings yet

- Primary ClarificationDocument1 pagePrimary ClarificationDerek ColandunoNo ratings yet

- Pipe Freezing ProblemDocument3 pagesPipe Freezing Problembrock100% (1)

- External MBR Vs Internal MBRDocument8 pagesExternal MBR Vs Internal MBRwacsii ccasullaNo ratings yet

- Marks Ion Exchange - RO Plant - 1Document7 pagesMarks Ion Exchange - RO Plant - 1Rabindra SinghNo ratings yet

- 46 07 13 - Packaged Water Treatment Equipment PDFDocument9 pages46 07 13 - Packaged Water Treatment Equipment PDFmasoodaeNo ratings yet

- Technical Specification SWRO 4x2500cmdDocument23 pagesTechnical Specification SWRO 4x2500cmdJeyakumar Arumugam100% (2)

- 16-103 RO-EDI ManualDocument64 pages16-103 RO-EDI Manual860707No ratings yet

- TS 112 Process and Instrument DiagramsDocument27 pagesTS 112 Process and Instrument DiagramsGeetha_jagadish30100% (1)

- Lab DI Water SystemsDocument6 pagesLab DI Water SystemsHaidee Che RizminNo ratings yet

- SBR DesignDocument10 pagesSBR DesignQuốc TuyênNo ratings yet

- O&M Offer For STP - 75KLD & WTP - 100 KLDDocument11 pagesO&M Offer For STP - 75KLD & WTP - 100 KLDbioengsolutionschnNo ratings yet

- Volume IV Filter Plant DTPDocument182 pagesVolume IV Filter Plant DTPNihar SagarNo ratings yet

- MBRDocument9 pagesMBRAuspicious MuthuNo ratings yet

- Bill of Quantities Sewage Treatment PlanDocument11 pagesBill of Quantities Sewage Treatment PlanMiguel ChanNo ratings yet

- Veolia Containerised WTP BrochureDocument8 pagesVeolia Containerised WTP BrochureJim TsikasNo ratings yet

- 50T/D Ro Seawater Desalination Equipment: Technical ProposalDocument11 pages50T/D Ro Seawater Desalination Equipment: Technical ProposalMicah Ironfalcon ArceñoNo ratings yet

- Main CatalogueDocument10 pagesMain CatalogueMohamed SalahNo ratings yet

- Design An Extended Aeration Package PlantDocument5 pagesDesign An Extended Aeration Package PlantFortaengineering FortaenviroNo ratings yet

- Reed Bed System FINALDocument12 pagesReed Bed System FINALHardik Kashyap VepariNo ratings yet

- Data Sheet Filter MediaDocument1 pageData Sheet Filter MediaNeelkantNo ratings yet

- HydroClear BrochureDocument12 pagesHydroClear BrochuremutazsalihNo ratings yet

- Technical Aspects of Desalination PlantDocument0 pagesTechnical Aspects of Desalination PlantSIVANo ratings yet

- 4 Technical Aspects of Desalination PlantDocument11 pages4 Technical Aspects of Desalination PlantadelNo ratings yet

- Reverse Osmosis Model #R44 Installation InstructionsDocument40 pagesReverse Osmosis Model #R44 Installation InstructionsWatts100% (1)

- Reverse Osmosis R12-Wall Mount Installation InstructionsDocument15 pagesReverse Osmosis R12-Wall Mount Installation InstructionsWattsNo ratings yet

- Reverse Osmosis R14-SERIES Installation InstructionsDocument44 pagesReverse Osmosis R14-SERIES Installation InstructionsWattsNo ratings yet

- Norma Part 146 - 40 CFR CH PDFDocument31 pagesNorma Part 146 - 40 CFR CH PDFmurbietaNo ratings yet

- Oxigeno Disuelto - USGSDocument48 pagesOxigeno Disuelto - USGSMonica UrbietaNo ratings yet

- Concentrations of Dissolved Oxygen in The Lower Puyallup and White Revers, WashingtonDocument40 pagesConcentrations of Dissolved Oxygen in The Lower Puyallup and White Revers, WashingtonMonica UrbietaNo ratings yet

- Class I Underground Injection Control ProgramDocument113 pagesClass I Underground Injection Control ProgramMonica UrbietaNo ratings yet

- Class V - EPADocument2 pagesClass V - EPAMonica UrbietaNo ratings yet

- Injection Wells - An Introduction To Their Use Operation and RegulationDocument16 pagesInjection Wells - An Introduction To Their Use Operation and RegulationMonica UrbietaNo ratings yet

- Florida Environmental Protection - Memorandum Effluent Disposal Via Injection WellDocument7 pagesFlorida Environmental Protection - Memorandum Effluent Disposal Via Injection WellMonica UrbietaNo ratings yet

- A Comparative Study of Specific Yield Determinations For A Shallow Sand AquiferDocument9 pagesA Comparative Study of Specific Yield Determinations For A Shallow Sand AquiferMonica UrbietaNo ratings yet

- Eutrophication of Lake Tahoe Emphasizing Water QualityDocument428 pagesEutrophication of Lake Tahoe Emphasizing Water QualityMonica UrbietaNo ratings yet

- Anisotropic Dispersive Henry ProblemDocument14 pagesAnisotropic Dispersive Henry ProblemMonica UrbietaNo ratings yet

- Modelling Transport of Salts Through CeramicDocument18 pagesModelling Transport of Salts Through CeramicMonica UrbietaNo ratings yet

- Studies of Injection Into Naturally Fractured ReservoirsDocument6 pagesStudies of Injection Into Naturally Fractured ReservoirsMonica UrbietaNo ratings yet

- Deep Well Injection For Concentrate Disposal PDFDocument15 pagesDeep Well Injection For Concentrate Disposal PDFmurbietaNo ratings yet

- Disposal-Recovery Options For Brine WatersDocument161 pagesDisposal-Recovery Options For Brine WatersMonica UrbietaNo ratings yet

- Design Principles For AquiferDocument5 pagesDesign Principles For AquifermurbietaNo ratings yet

- Estado Tro Co y Variacion Estacional de Nutrientes en Los Rıos y Canales Del Humedal Mixo-Halino de Bahia Somborombon - ArgentinaDocument8 pagesEstado Tro Co y Variacion Estacional de Nutrientes en Los Rıos y Canales Del Humedal Mixo-Halino de Bahia Somborombon - ArgentinaMonica UrbietaNo ratings yet

- Well Test Results and Reservoir Performance For A Carbon Dioxide Injection Test Michigan BasinDocument10 pagesWell Test Results and Reservoir Performance For A Carbon Dioxide Injection Test Michigan BasinMonica UrbietaNo ratings yet

- Injection Well Design and Protective MechanismsDocument1 pageInjection Well Design and Protective MechanismsMonica UrbietaNo ratings yet

- Artificial Mixing To Reduce Growth of The Blue-Green Alga Microcystis in Lake Nieuwe Meer, Amsterdam Am Evaluation of 7 Years of ExperienceDocument7 pagesArtificial Mixing To Reduce Growth of The Blue-Green Alga Microcystis in Lake Nieuwe Meer, Amsterdam Am Evaluation of 7 Years of ExperienceMonica UrbietaNo ratings yet

- Evolution Earth AtmosphereDocument8 pagesEvolution Earth AtmosphereMonica UrbietaNo ratings yet

- Brine Injection StudiesDocument6 pagesBrine Injection StudiesMonica UrbietaNo ratings yet

- Sea Water Intake and Discharge OptionsDocument7 pagesSea Water Intake and Discharge OptionsMonica UrbietaNo ratings yet

- A Numerical Investigation of Turbulence-Driven and Forced Generation of Internal Gravity Waves in Stratified Mid-WaterDocument198 pagesA Numerical Investigation of Turbulence-Driven and Forced Generation of Internal Gravity Waves in Stratified Mid-WaterMonica UrbietaNo ratings yet

- Corrupcion en IndonesiaDocument24 pagesCorrupcion en IndonesiaMonica UrbietaNo ratings yet

- GWM Briefing 11 Utilization of Non-Renewable GroundwaterDocument6 pagesGWM Briefing 11 Utilization of Non-Renewable GroundwaterMonica UrbietaNo ratings yet

- Class I Underground Injection Control ProgramDocument113 pagesClass I Underground Injection Control ProgramMonica UrbietaNo ratings yet

- Brine DisposalDocument16 pagesBrine DisposalPENYU_1855100% (1)

- GWM - Briefing - 6 - Mobilizing and Sustaining Aquifer Management OrganizationsDocument6 pagesGWM - Briefing - 6 - Mobilizing and Sustaining Aquifer Management OrganizationsMonica UrbietaNo ratings yet

- GWM Briefing 11 Utilization of Non-Renewable GroundwaterDocument6 pagesGWM Briefing 11 Utilization of Non-Renewable GroundwaterMonica UrbietaNo ratings yet

- Property Case DENR Sec V YapDocument27 pagesProperty Case DENR Sec V YapPRECIOUS GRACE DAROYNo ratings yet

- Developmental Lesson Plan 2Document7 pagesDevelopmental Lesson Plan 2api-545431181No ratings yet

- AP Layout Rules-2017 (G.O.ms - No.275, Dt18!07!2017 With Amendments of GO.178)Document62 pagesAP Layout Rules-2017 (G.O.ms - No.275, Dt18!07!2017 With Amendments of GO.178)Raghu RamNo ratings yet

- Poucna Staza BaskaDocument2 pagesPoucna Staza Baskastormich656No ratings yet

- 03-Plumbing Code ListDocument4 pages03-Plumbing Code Listsam karimNo ratings yet

- B.M.Chatwani B.E. (Mech) - M.I.E. FIWWA Chartered Engineer M - 0087313 Govt. Regd. Valuer (P & M)Document1 pageB.M.Chatwani B.E. (Mech) - M.I.E. FIWWA Chartered Engineer M - 0087313 Govt. Regd. Valuer (P & M)bsanidhya10No ratings yet

- Supersand: Continuous Backwash FiltersDocument4 pagesSupersand: Continuous Backwash FiltersCornel NasturasNo ratings yet

- BÀI THUYẾT TRÌNH NÓI CHỦ ĐỀ MUSIC - MY FAVORITE SONGDocument2 pagesBÀI THUYẾT TRÌNH NÓI CHỦ ĐỀ MUSIC - MY FAVORITE SONGThanh xuân TrầnNo ratings yet

- Adirondack Explorer - May-June 2020Document66 pagesAdirondack Explorer - May-June 2020fath ceNo ratings yet

- On Seamus Heaney PDFDocument7 pagesOn Seamus Heaney PDFSham ShamkarNo ratings yet

- Ground Improvement TechniquesDocument5 pagesGround Improvement TechniquesebinVettuchirayil100% (1)

- Chemical InjectionDocument7 pagesChemical InjectionAga Sanity SainsNo ratings yet

- VULNERABILITYDocument1 pageVULNERABILITYIcee AlejandrinoNo ratings yet

- Konso, Construction AheadDocument11 pagesKonso, Construction AheadLorenzo FontanaNo ratings yet

- General Ielts Practice Test 1 Reading Writing SpeakingDocument17 pagesGeneral Ielts Practice Test 1 Reading Writing SpeakingAbbakeer Mina88% (8)

- Ebook dd103 Book2 E1i1 n9781780079561 l3Document376 pagesEbook dd103 Book2 E1i1 n9781780079561 l3Tre Walbrooke-RossNo ratings yet

- Soak-Away Pit DesignDocument1 pageSoak-Away Pit DesignAbdul Hayyi bin AwangNo ratings yet

- Alubijid ReportDocument3 pagesAlubijid ReportRoberto Galano Jr.No ratings yet

- Darley WaterPurificationSystems LRDocument4 pagesDarley WaterPurificationSystems LRvaglohrdNo ratings yet

- Barron Essential Words For IELTSDocument371 pagesBarron Essential Words For IELTSThanh Thúy Phạm67% (3)

- 763 NB Triple Bottom Line ReportDocument34 pages763 NB Triple Bottom Line ReportsharjeelNo ratings yet

- Stabilization-Reinforced Soil WallDocument4 pagesStabilization-Reinforced Soil WallNamal ChathurangaNo ratings yet

- Desalination: Mohammed Shadi S. Abujazar, S. Fatihah, A.R. Rakmi, M.Z. ShahromDocument16 pagesDesalination: Mohammed Shadi S. Abujazar, S. Fatihah, A.R. Rakmi, M.Z. ShahromSurendra LuckyNo ratings yet

- 8 - Phil - Fishery LawsDocument47 pages8 - Phil - Fishery LawsJonas CabacunganNo ratings yet

- Unit 5 Lab Questions ForestryDocument2 pagesUnit 5 Lab Questions ForestryClara GreenNo ratings yet

- Connect (5 Plus) Final Revision Final 25-12-2023Document38 pagesConnect (5 Plus) Final Revision Final 25-12-2023montaser ibrahimNo ratings yet

- Furrow Irrigation System Design PDFDocument27 pagesFurrow Irrigation System Design PDFamir_mNo ratings yet

- Pump Station StandardsDocument97 pagesPump Station StandardsHRK65100% (2)

- 15 Laguna de Bay 27february2006Document34 pages15 Laguna de Bay 27february2006Dex CabalzaNo ratings yet

- Division 200 EarthworkDocument50 pagesDivision 200 EarthworkSooraj RajendranNo ratings yet

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Guide to the Practical Use of Chemicals in Refineries and PipelinesFrom EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesRating: 5 out of 5 stars5/5 (1)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- The Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsFrom EverandThe Petroleum Engineering Handbook: Sustainable Operations: Sustainable OperationsRating: 3.5 out of 5 stars3.5/5 (5)

- Acquisition and Processing of Marine Seismic DataFrom EverandAcquisition and Processing of Marine Seismic DataRating: 4 out of 5 stars4/5 (4)