Professional Documents

Culture Documents

Belt Filter

Uploaded by

EDUARDOCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Belt Filter

Uploaded by

EDUARDOCopyright:

Available Formats

Client: Project: Plant/Area: WO #: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 REV:

DATA SHEET

BELT FILTER

Equip. No: Equip. Name: ADL Doc. No:

ENG-DAT-000082

Rev: 0

DESIGN DATA - LOCATION, SITE AND OPERATING CONDITIONS Horizontal Other Type Max. Oper. Temperature (F) Elevation (ft) Continuous Batch Vacuum Operating schedule: ( hr/day ) Days/Year Indoor Outdoor Heated Unheated Ambient temperature Min Max (F) Electrical class.: CL Gr Div Relative humidity Min Max Toxic Corrosive Flammable Winterization Required Tropicalization Required Environment: CAPACITY Design Capacity (USgpm) Average Capacity (USgpm) Batch Size (USgal) Frequency Temperature (F) Normal Maximum Minimum S.G. Viscosity (cP) Active Area (ft2) Filtration Rate (USgpm) Belt Width (ft) Inlet Pres. (psig) Yes No Precoat Required Cycle Time Operating Vacuum (psig) Cake Thickness (in) Belt Speed (ft/s) Moisture in Discharge (%) MATERIAL - SOLIDS Description Concentration (%wt in feed) S.G. Screen Mesh Size Analysis % Granular Flaky Crystalline Friable Abrasive Corrosive Flammable Explosive Toxic Scales Clogging Sticky Other (See Notes) Description Toxic S.G. Corrosive MATERIAL - LIQUID Viscosity (cP) Volatile Fumes Other (See Notes) BELT FILTER PROFILE Vapour Pres (psia)

Flammable

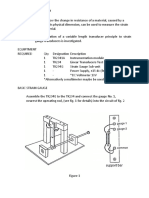

SKETCH ON HOLD

SKETCH IS AN EXAMPLE - ALTERNATE SKETCHES MAY BE SELECTED OR MODIFIED FROM ATTACHED PAGES REVISION LOG DESCRIPTION DATE BY CHK'D APP'D

Source Doc: DS.131.0027US.CAL.R00

Page 1 of 4

Client: Project: Plant/Area: WO #: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 FILTRATE Product Waste Recycled Filtrate Composition Max. Allowable Solids (%wt) Filtrate Rate (USgpm)

DATA SHEET

BELT FILTER

Equip. No: Equip. Name: ADL Doc. No:

ENG-DAT-000082

Rev: 0

Yes

S.G.

No

FIRST WASH Co Current Counter Current Type Washing Fluid Flow (USgpm) Temp. (F) ( Norm / Max / Min ) / Vap. Pres (psia) Inlet Pres.(psig) Viscosity (cP) S.G. Max. Allowable Liquid in Cake (%wt) Filtrate Composition Filtrate Flow (USgpm) Wash Ratio Batch Continuous Wash Cycle Time THIRD WASH Co Current Counter Current Type Washing Fluid Flow (USgpm) Temp. (F) ( Norm / Max / Min ) / Vap. Pres (psia) Inlet Pres.(psig) Viscosity (cP) S.G. Max. Allowable Liquid in Cake (%wt) Filtrate Composition Filtrate Flow (USgpm) Wash Ratio Batch Continuous Wash Cycle Time CLOUDY PORT Product Waste Recycled Filtrate Composition Max. Allowable Solids (%wt) Filtrate Rate (USgpm)

CAKE Product Waste Discharge Dry Cake Composition Max. Allowable Liquid (%wt) Density (lb/ft3) Rate (ton/hr) Sluicing Medium Rate (ton/hr) SECOND WASH Co Current Counter Current Type Washing Fluid Flow (USgpm) Temp. (F) ( Norm / Max / Min ) / Vap. Pres (psia) Inlet Pres.(psig) Viscosity (cP) S.G. Max. Allowable Liquid in Cake (%wt) Filtrate Composition Filtrate Flow (USgpm) Wash Ratio Batch Continuous Wash Cycle Time BELT & CLOTH WASH Spray Pipe Other Type Washing Fluid Flow (USgpm) Temp. (F) ( Norm / Max / Min ) / Vap. Pres (psia) Inlet Pres.(psig) Viscosity (cP) S.G. Max. Allowable Liquid in Cake (%wt) Filtrate Composition Filtrate Flow (USgpm) Wash Ratio Batch Continuous Wash Cycle Time /

Wet

Yes

S.G.

No

Size (mm) Lagged Size (mm) Lagged Quantity Shaft Diameter (in) Lagged

HEAD PULLEY Shaft Diameter (in) Crown Plain Straight Faced TAIL PULLEY Shaft Diameter (in) Crown Plain Straight Faced BELT RETURN IDLERS Size (in)

Plain

Crown

FILTER CLOTH

Straight Faced

Material Type of Yarn Quantity Shaft Diameter (in)

Type of Weave CLOTH ROLLERS Size

BELT CONSTRUCTION Manufacturer No. of Plies Weight of Fabric (lbs) Top/Bottom Cover Thickness (in) / RMA Grade Size of Grooves Spacing of Grooves(in) Describe Side Curbs HEAD PULLEY BEARINGS Type Size Type of Seal Method of Lubrication TAIL PULLEY BEARINGS Type Size Type of Seal Method of Lubrication BELT RETURN IDLER BEARINGS Type Size Type of Seal Method of Lubrication Belt Tensioning Device - describe Belt Alignment Assembly - describe CLOTH ROLLER BEARINGS Type Size Type of Seal Method of Lubrication Belt Tensioning Device - describe Belt Alignment Assembly - describe AIR BOX Construction Thickness (in)

VACUUM PAN Construction Seal Arrangement - describe

Source Doc: DS.131.0027US.CAL.R00

Page 2 of 4

Client: Project: Plant/Area: WO #: 1 Rev 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 HEAD PULLEY DRIVE ARRANGEMENT Manufacturer Gear Reduction Unit Type Gear Ratio Service Factor Method of Lubrication V-BELT DRIVE (if Applicable) Manufacturer Belt Section Type Belt Rating (hp/Belt) S.F. No. Belts Req'd Centre Distance (in) Belt Length (in) Belt Speed (ft/s) V-Belt Guard CHAIN DRIVE (If Applicable) Manufacturer Chain Type / ANSI No.: / Ultimate Strength ( lb ) No. of Strands Pitch (mm)

DATA SHEET

BELT FILTER

Equip. No: Equip. Name: ADL Doc. No:

ENG-DAT-000082 COUPLING (If Applicable)

Rev: 0

Manufacturer Speed Range

VARIABLE SPEED UNIT Type Service Factor

FEED DISTRIBUTOR Type Construction Thickness

VACUUM FILTRATE RECEIVER Manufacturer Overall Size (in) Thickness (in) Inlet Nozzle Size (in) Outlet Nozzle Size (in) Vacuum Relief Valve VACUUM REGULATING VALVE Manufacturer Size Requirements Volume (ft3) Pressure (psig) Vacuum Air

FAN Manufacturer Model No. Capacity (scfm) Manufacturer Type Frame Size FAN MOTOR Size ( hp ) Enclosure RPM S.F.

Manufacturer Type Size Basic Rating Service Factor Max / Min Bore Dia(in) Number Required SHEAVES (if Applicable) Manufacturer Speed Ratio No. of Grooves Outside Dia. Driver / Driven (in) / Bore Dia. Driver / Driven (in) / Hub Type: Driver / Driven / SPROCKETS (If Applicable) Manufacturer Outside Dia. Driver / Driven (in) / Bore Dia. Driver / Driven (in) / Hub Type: Driver / Driven / No. of Teeth: Driver / Driven / Speed Ratio MOTOR Manufacturer Type Size ( hp ) RPM Frame Enclosure S.F. Insulation Starter Type Rating Control WASH DISTRIBUTOR Type Construction Feed Dam - describe Wash Dam(s) - describe Scraper - describe ACID TRAP Manufacturer Overall Size (in) Thickness (in) Inlet Nozzle Size (in) Outlet Nozzle Size (in) Vacuum Relief Valve MATERIALS Material Weight (lb) Frame Belt Pulleys Filter Cloth Rollers Idlers Vacuum Pan Air Box Acid Trap Recievers Feed Distributor Wash Distributor

Source Doc: DS.131.0027US.CAL.R00

Page 3 of 4

Client: Project: Plant/Area: WO #: 1 Rev 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 Frame Visual Non-Destructive Radiography Ultrasonic - Before Stress Relieving - After Stress Relieving Magnetic Particle - Before Stress Relieving - After Stress Relieving Pulleys

DATA SHEET

BELT FILTER

Equip. No: Equip. Name: ADL Doc. No: TESTING Belt

ENG-DAT-000082

Rev: 0

Equipment Item Complete Unit Driver Driven Unit Other

Required

NOISE ( Maximum Sound Pressure Levels (dBA) @ 3 feet ) Manufacturer's Estimated Manufacturer's Guaranteed Maximum Maximum Normal Special Acoustical Normal Special Acoustical Design Design Treatment Design Design Treatment

Notes

Water Quantity ( ft3 /hr) Water Quality Steam Quantity ( lb/hr )

Pressure (psig) Electric (kW) Pressure (psig)

UTILITIES Plant Air Quantity ( ft3 /hr) Instrument Air ( ft3 /hr) Other NOTES

Pressure (psig) Pressure (psig)

Source Doc: DS.131.0027US.CAL.R00

Page 4 of 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Durban Classic Cover + Caposide in One Side (Shougang Project)Document4 pagesDurban Classic Cover + Caposide in One Side (Shougang Project)EDUARDONo ratings yet

- 820 CB 120G WM26 - Rev0Document1 page820 CB 120G WM26 - Rev0EDUARDONo ratings yet

- Dry CobbingDocument1 pageDry CobbingEDUARDONo ratings yet

- 820 CB 120G WM25 - Rev0Document1 page820 CB 120G WM25 - Rev0EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document12 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- 5921 D E DWG 0205 - RevADocument6 pages5921 D E DWG 0205 - RevAEDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- Steam BoilerDocument10 pagesSteam BoilerEDUARDONo ratings yet

- 5720 D E DWG 0201 - RevADocument4 pages5720 D E DWG 0201 - RevAEDUARDONo ratings yet

- 830 CB 120 M06 - Rev0Document1 page830 CB 120 M06 - Rev0EDUARDONo ratings yet

- 830 CB 120 M07 - Rev0Document1 page830 CB 120 M07 - Rev0EDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit PlantDocument10 pagesMine Operation Expansion Project and Benefit PlantEDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit PlantDocument10 pagesMine Operation Expansion Project and Benefit PlantEDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014Document14 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014EDUARDONo ratings yet

- 5921 D E DWG 0205 - RevADocument6 pages5921 D E DWG 0205 - RevAEDUARDONo ratings yet

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Document12 pagesMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONo ratings yet

- Data Sheet: DescriptionDocument6 pagesData Sheet: DescriptionEDUARDONo ratings yet

- 5921 D E DWG 0105 - RevADocument6 pages5921 D E DWG 0105 - RevAEDUARDONo ratings yet

- Sewagw Treatment FilterDocument1 pageSewagw Treatment FilterEDUARDONo ratings yet

- StrainerDocument3 pagesStrainerEDUARDONo ratings yet

- Schedule Levels - Major Projects: Core Scheduling Papers: #6Document5 pagesSchedule Levels - Major Projects: Core Scheduling Papers: #6EDUARDONo ratings yet

- Data Sheet: Description and Site ConditionsDocument2 pagesData Sheet: Description and Site ConditionsEDUARDONo ratings yet

- Sewage Treatment FloculantDocument1 pageSewage Treatment FloculantEDUARDONo ratings yet

- Sewage Treatment EfluentDocument5 pagesSewage Treatment EfluentEDUARDONo ratings yet

- Sewage Treatment Tank MixerDocument1 pageSewage Treatment Tank MixerEDUARDONo ratings yet

- Sewage Treatment Ultraviolet DeinfectionDocument1 pageSewage Treatment Ultraviolet DeinfectionEDUARDONo ratings yet

- Sewage Treatment PlantDocument2 pagesSewage Treatment PlantEDUARDONo ratings yet

- Sewage Treatment MenbraneDocument1 pageSewage Treatment MenbraneEDUARDONo ratings yet

- Separation CellDocument11 pagesSeparation CellEDUARDONo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Course Structure B.tech.2012-13Document4 pagesCourse Structure B.tech.2012-13fortunatesanjibNo ratings yet

- QEI - MCap II - UG1065 PDFDocument113 pagesQEI - MCap II - UG1065 PDFJohanes Nugroho Adhi PrakosaNo ratings yet

- NEXAFS Tutorial Review ArticleDocument12 pagesNEXAFS Tutorial Review ArticleAngelique LusuanNo ratings yet

- Conduction A Long Simple BarDocument5 pagesConduction A Long Simple Bardiaa ibrahimNo ratings yet

- Ebook Physics of Cryogenics An Ultralow Temperature Phenomenon PDF Full Chapter PDFDocument67 pagesEbook Physics of Cryogenics An Ultralow Temperature Phenomenon PDF Full Chapter PDFlouise.fleming716100% (25)

- Avogadro's NumberDocument5 pagesAvogadro's NumberM J RhoadesNo ratings yet

- Metric Measure For Wood ProductsDocument7 pagesMetric Measure For Wood ProductspopescucvNo ratings yet

- Strain GuageDocument6 pagesStrain GuageChristian EspanolNo ratings yet

- Elements of Feedback Control SystemsDocument53 pagesElements of Feedback Control SystemschanonNo ratings yet

- HTTPSWWW - Mathsgenie.co - Ukresources4 Plans and Elevations PDFDocument8 pagesHTTPSWWW - Mathsgenie.co - Ukresources4 Plans and Elevations PDFruth.ameyxxNo ratings yet

- Guide Du Soudage Des Aciers InoxydablesDocument92 pagesGuide Du Soudage Des Aciers InoxydablesFares Hayder100% (1)

- Tonnage CalculationDocument3 pagesTonnage CalculationEmba MadrasNo ratings yet

- Agarose Gel ElectrophoresisDocument4 pagesAgarose Gel ElectrophoresisTarequl Islam NishadNo ratings yet

- Radiology Physics Board Recalls 2005Document14 pagesRadiology Physics Board Recalls 2005Turki A. Saad100% (2)

- Task 3 Ronald GarzonDocument23 pagesTask 3 Ronald GarzonRonal Enrique Garzon SanchezNo ratings yet

- Moisture Content in PET PreformsDocument3 pagesMoisture Content in PET PreformsGeorge MarkasNo ratings yet

- Specifications: Comparison of Kajaria Tiles Parameters To International Standards Bib Iso-13006:2018-09Document1 pageSpecifications: Comparison of Kajaria Tiles Parameters To International Standards Bib Iso-13006:2018-09omerNo ratings yet

- Display Unit TechnologyDocument51 pagesDisplay Unit TechnologyNavin GillmanNo ratings yet

- WDM2 LOCO REPORT - Manoj Kr. KataraDocument23 pagesWDM2 LOCO REPORT - Manoj Kr. KataraAbhinav AgarwalNo ratings yet

- Micro-Urbanism: Chi Ti-Nan Develops A Project To Preserve Hong Kong Coastline Tai Long Sai WanDocument3 pagesMicro-Urbanism: Chi Ti-Nan Develops A Project To Preserve Hong Kong Coastline Tai Long Sai WanAr Nizya NoushadNo ratings yet

- Lecture 1 U & DDocument33 pagesLecture 1 U & DMr DrayNo ratings yet

- KVH TI Folder en Web3 02Document19 pagesKVH TI Folder en Web3 02mario_stefanecNo ratings yet

- Physics ProjectDocument16 pagesPhysics ProjectPriyanshuNo ratings yet

- Maxima and MinimaDocument4 pagesMaxima and MinimaAnudeex ShettyNo ratings yet

- Annual Plans 7th GradeDocument5 pagesAnnual Plans 7th GradeDiego Antonio RodriguezNo ratings yet

- Roof Beam Design CalculationDocument11 pagesRoof Beam Design CalculationArnold VercelesNo ratings yet

- MathsDocument2 pagesMathsAditya Singh PatelNo ratings yet

- Mathematics For Economics (ECON 104)Document46 pagesMathematics For Economics (ECON 104)Experimental BeXNo ratings yet

- A New Static Induction Thyristor (Sith) Analytical Model: Jue Wang and Barry W. WilliamsDocument11 pagesA New Static Induction Thyristor (Sith) Analytical Model: Jue Wang and Barry W. WilliamsAbdulAzizNo ratings yet