Professional Documents

Culture Documents

7710 Tech Report SterilAmp 5230 Rev.5 26SEP11

Uploaded by

Donig FermanianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7710 Tech Report SterilAmp 5230 Rev.5 26SEP11

Uploaded by

Donig FermanianCopyright:

Available Formats

Bozeman Manufacturing Facility

SterilAmp II

Bacillus subtilis 5230

TECHNICAL REPORT

Complies with: USP ISO 11138 and all appropriate subsections.

Technical Data and Use of SterilAmp II

Rev. 5 26SEP11 Part No.7710

10 Evergreen Drive Bozeman, MT 59715 Phone: 406-585-9535 FAX: 406-585-9219 www.sgmbiotech.com e-mail: info@sgmbiotech.com Page 1 of 5

Bozeman Manufacturing Facility

INTRODUCTION SterilAmp II is a biological indicator produced for the manufacturers of sterile solutions. The product is manufactured for low temperature steam sterilization of solutions. Spores in this unit respond predictably to specific F 0 exposures measured inside the product container by certified thermocouples. It is a totally self-contained unit. SterilAmp II is easy to use, no sophisticated laboratory testing or analysis is required. These specially engineered ampoules contain spores of Bacillus subtilis 5230 35021 , suspended in a specially formulated culture medium. The 0.3 mL of the spore/medium suspension is sealed inside a small thin walled pharmaceutical grade glass ampoule. These ampoules are approximately 1/4" in diameter and 1" long. This size allows them to be placed inside even the smallest product vials or ampoules. It also allows them to be packaged inside the small medical device plastic trays containing liquid such as those used for packaging contact lenses. These units can also be placed inside thermowells to effectively monitor Sterilization-in-Place (SIP) of product transport lines and filling machines. STORAGE SterilAmp II should be refrigerated upon receipt. Bacillus subtilis 5230 spores contained in the SterilAmp II has a recommended growth temperature of 35 to 39 C. Refrigeration is necessary to assure stable indicators. In our laboratory, we have determined refrigerated stability for at least 15 months. MEDIUM The culture medium has phenol red, a pH indicator to aid in the early detection of growth. If the spores grow, the medium changes to yellow indicating viable spores were present and acid is being produced. If the medium remains red/orange, the spores did not grow, indicating they were killed in the sterilization process. Therefore, if the sterilization process was not effective, the spores will grow and turn the medium cloudy and yellow. If any ampoules show signs of a visual color change or turbidity prior to use, they should be autoclaved and discarded. USE The SterilAmp II biological indicators should be removed from the refrigerator and allowed to warm to room temperature. NOTE: Once the ampoules have reached room temperature, they must be used or refrigerated within a half-hour. The spores will germinate at room temperature. The ampoules should then be placed inside identical product containers as the product being sterilized. If more than one size container is used, then each different size should be monitored. The product containers should be filled to the same level or fill volume used for the product. If extremely small volumes are used, 1 to 2 mL, the volume displacement and mass of the SterilAmp II must be considered. Each SterilAmp II displaces approximately 0.8 mL of liquid and weighs approximately 0.7 grams. The liquid may be the product or simulated product. If a simulated product is used, it should have similar heat transfer characteristics. This most often varies with viscosity. The "product packages" should be closed in a similar manner as the actual product being sterilized. It is recommended that a minimum of 10 BIs be distributed throughout each load. The positions in the

Culture is traceable to a recognized culture collection identified in USP and ISO 11138.

10 Evergreen Drive Bozeman, MT 59715 Phone: 406-585-9535 FAX: 406-585-9219 www.sgmbiotech.com e-mail: info@sgmbiotech.com Page 2 of 5

Bozeman Manufacturing Facility

load should be based on thermocouple profiling of the loaded chamber to assure that the "most difficult to sterilize" locations are being monitored. Generally, locations consist of placing BIs top to bottom, front to back, and in the geometric center of the load. Following sterilization, the BIs should be removed from the load, cooled at least to incubation temperature (35 to 39 C) and then placed into the incubator. The SterilAmp II may remain inside the product container if the color change can be easily observed. Growth inside the SterilAmp II will turn the red/orange growth medium yellow. This indicates a positive test (non-sterile). A positive control should be run for each cycle tested or at least once per week. The positive control typically turns yellow within 24 hours of incubation. As soon as a control turns yellow, it should be appropriately recorded and then autoclaved and discarded. It should not be held any longer than necessary because of the possibility of contaminating your work area with organisms resistant to sterilization. The positive control is intended to confirm that viable spores are present in the biological indicators. Positive controls are not intended to be a "color standard" for comparing test results. It is not recommended to incubate these positive controls more than 72 hours. A true negative or no growth in a positive control is a serious problem. Fortunately the causes are few: a grossly malfunctioning incubator; inadvertent sterilization of the control vial; or inadvertent sterilization of the bag of indicators - due to improper storage. If the control is negative because of one of the latter two causes, do not use any of the biological indicators from the same bag. Discard the entire bag of units after confirmation of test results. INCUBATION CONDITIONS The recommended incubation temperature is 35 to 39 C. Since SterilAmp II is a totally self-contained system, it can be incubated in either a water bath or standard bacteriological incubator. If the SterilAmp II is incubated inside the product container, the time to reach incubation temperature will vary based on the mass of the product container and solution, as well as the start temperature of the container and contents. SterilAmp II ampoules can be placed in zip lock bags for convenience during incubation. The recommended incubation time for SterilAmp II is 72 hours. RESISTANCE PERFORMANCE TESTING D-value determination was performed by fraction negative analysis and a population assay was performed on the biological indicators. SterilAmp II biological indicators were exposed in a steam BIER vessel that meets the AAMI BIER standard. Exposure conditions were at 115 0.5 C and 121C 0.5C in saturated steam using a pre-vacuum cycle. Twenty units per exposure were used. Following exposure, samples were incubated at 35 to 39 C for 72 hours. Performance data is presented in Tables 1 and 2.

Table 1: Resistance Performance Data at 115 Number Positive Out of 20 Exposure Times Population/Unit (in minutes) 8 10 12 14 20 2 0 0 2.1 x 106 13 4 0 0 3.8 x 106 19 4 0 0 1.3 x 106

BI Lot Number

SASU-223 SASU-224 SASU-225

(1)

D-value(1)

(Minutes)

6 20 20 20

1.4 1.3 1.5

Calculated according to USP methods.

10 Evergreen Drive Bozeman, MT 59715 Phone: 406-585-9535 FAX: 406-585-9219 www.sgmbiotech.com e-mail: info@sgmbiotech.com Page 3 of 5

Bozeman Manufacturing Facility

Table 2: Resistance Performance Data at 121C BI Lot Number SASU-223 SASU-224 SASU-225

(1)

20 20 20

Number Positive Out of 20 Exposure Times (in minutes)

1.5

Population/Unit

2.5

D-value(1) (Minutes) 0.2 0.2 0.2

2 1 7

0 0 1

0 0 0

2.1 x 106 3.8 x 106 1.3 x 106

Calculated according to USP methods.

POPULATION DETERMINATION Detailed population assay instructions are available in PDF format on the SGM Biotech website. Log onto the www.sgmbiotech.com home page, and select Accessories Population Assay Kit Product Manuals (on the right-hand side).

10 Evergreen Drive Bozeman, MT 59715 Phone: 406-585-9535 FAX: 406-585-9219 www.sgmbiotech.com e-mail: info@sgmbiotech.com Page 4 of 5

Bozeman Manufacturing Facility

CERTIFICATE Units are manufactured in compliance with Mesa Laboratories, Bozeman Manufacturing Facilitys, quality standards, USP, and ISO 11138 guidelines and all appropriate subsections.

BIOLOGICAL INDICATOR FOR INDUSTRIAL USE ONLY

CERTIFICATE OF ANALYSIS

Reorder No: SASU/6 35021 Bacillus subtilis 5230 Biological Indicator for: Culture: Purity:

Low Temperature Steam Sterilization of Solutions.

35-39C. The supplied bacteriological medium will meet requirements for growth promoting ability. No evidence of contaminants using standard plate count techniques.

Lot No: SASU-000 Manufacture Date: YEAR MONTH DAY Expiration: 15 months from Manufacture Date. Spores / Unit Heat Shocked Population: 0.0 x 106 Assayed Resistance: Steam (110C) Steam (115C) Steam (121C) Z-value: 0.0C D-Value(2) 0.0 0.0 0.0 Survival 00.00(3) 0.0

(4) (4)

S A M P L E

Kill 00.00(3) 0.0

(4) (4)

0.0

0.0

D-value reproducible only when exposed in an AAMI BIER vessel and cultured under the exact conditions used to obtain results reported here. MPN method used. Units are manufactured in compliance with SGM Biotech's quality standards.

Culture is traceable to a recognized culture collection identified in USP and ISO 11138. D-value calculated using the Limited-Holcomb-Spearman-Karber method. Survival/Kill values are calculated according to a formula in USP and ISO 11138. SGM uses a D-value rounded to four decimal places in this calculation. (4) Empirically derived data/F 0 data.

(2) (3)

Certified By: _____________________________________________

10 Evergreen Drive Bozeman, MT 59715 Phone: 406-585-9535 FAX: 406-585-9219 www.sgmbiotech.com e-mail: info@sgmbiotech.com Page 5 of 5

10 Evergreen Drive Bozeman, MT 59715 406/585-9535 www.sgmbiotech.com

min min min

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- This Publ Icati On Is Avai Labl e Free of Cha Rge Fro M: S://D Oi.o rg/1 0.6 028 /NI St.I R.6 969 - 201 9Document11 pagesThis Publ Icati On Is Avai Labl e Free of Cha Rge Fro M: S://D Oi.o rg/1 0.6 028 /NI St.I R.6 969 - 201 9Donig FermanianNo ratings yet

- Process Monitoring Systems PDFDocument4 pagesProcess Monitoring Systems PDFDonig FermanianNo ratings yet

- ImpartialityDocument2 pagesImpartialitysujud100% (2)

- NISTIR 6969 20140926 20160121rev PDFDocument210 pagesNISTIR 6969 20140926 20160121rev PDFDonig FermanianNo ratings yet

- Impartiality PDFDocument2 pagesImpartiality PDFDonig FermanianNo ratings yet

- BS en Iso 00787-5-1995 (2000)Document10 pagesBS en Iso 00787-5-1995 (2000)Donig FermanianNo ratings yet

- TG14 Version 3 July 2019Document7 pagesTG14 Version 3 July 2019Donig FermanianNo ratings yet

- Rotronic HL 1D TL 1D ManualDocument4 pagesRotronic HL 1D TL 1D ManualDonig FermanianNo ratings yet

- SF500 InstructionDocument142 pagesSF500 InstructionDonig FermanianNo ratings yet

- ISO 14644 - Revised Cleanroom Standard: February 2016Document36 pagesISO 14644 - Revised Cleanroom Standard: February 2016Donig FermanianNo ratings yet

- Temperature Mapping Study Protocol Procedure PDFDocument15 pagesTemperature Mapping Study Protocol Procedure PDFJhonnnnnnNo ratings yet

- TGGuideline 114 Viscosity of LiquidsDocument7 pagesTGGuideline 114 Viscosity of LiquidsDonig FermanianNo ratings yet

- Fuel Handling Jet Fuel Quality and Test Procedure Manual Petrovalue Aviation 2008.2 0-1 PDFDocument45 pagesFuel Handling Jet Fuel Quality and Test Procedure Manual Petrovalue Aviation 2008.2 0-1 PDFDonig FermanianNo ratings yet

- I-CAL-GUI-013 Calibration Guide No. 13 WebDocument13 pagesI-CAL-GUI-013 Calibration Guide No. 13 WebDonig FermanianNo ratings yet

- BLP 530 Gas Porosimeter127 20 - InstructionsDocument11 pagesBLP 530 Gas Porosimeter127 20 - InstructionsDonig FermanianNo ratings yet

- Calibration Kit Dw-3 F-Mod 35 ViscometerDocument1 pageCalibration Kit Dw-3 F-Mod 35 ViscometerDonig FermanianNo ratings yet

- D2493Document5 pagesD2493Donig FermanianNo ratings yet

- Types of Pressure:: When and Why Are They Used?Document4 pagesTypes of Pressure:: When and Why Are They Used?Donig FermanianNo ratings yet

- Adm 870 PDFDocument54 pagesAdm 870 PDFDonig FermanianNo ratings yet

- Density of Water (G/ML) vs. Temperature (°C) : (From Handbook of Chemistry and Physics, 53rd Edition, P. F4)Document1 pageDensity of Water (G/ML) vs. Temperature (°C) : (From Handbook of Chemistry and Physics, 53rd Edition, P. F4)Donig FermanianNo ratings yet

- 3 Theory Calibration JKBHJGHJGHHFGHFGDocument88 pages3 Theory Calibration JKBHJGHJGHHFGHFGDonig FermanianNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Gmail - RedBus Ticket - TN7R20093672Document2 pagesGmail - RedBus Ticket - TN7R20093672Bappa RoyNo ratings yet

- SUPERHERO Suspension Training ManualDocument11 pagesSUPERHERO Suspension Training ManualCaleb Leadingham100% (5)

- EngineCleaningAndVolcanicAsh InternDocument69 pagesEngineCleaningAndVolcanicAsh InternLucio Portuguez AlmanzaNo ratings yet

- Astm A712 PDFDocument3 pagesAstm A712 PDFCristian OtivoNo ratings yet

- Senographe Crystal: The Choice Is Crystal ClearDocument7 pagesSenographe Crystal: The Choice Is Crystal ClearmuhammadyassirNo ratings yet

- Capacitor BanksDocument49 pagesCapacitor BanksAmal P RaviNo ratings yet

- Guidelines For Forensic Report Writing: Helping Trainees Understand Common PitfallsDocument54 pagesGuidelines For Forensic Report Writing: Helping Trainees Understand Common PitfallsNorfolk Journal100% (1)

- Extraordinary GazetteDocument10 pagesExtraordinary GazetteAdaderana OnlineNo ratings yet

- Installation Manual (DH84309201) - 07Document24 pagesInstallation Manual (DH84309201) - 07mquaiottiNo ratings yet

- Generic 5S ChecklistDocument2 pagesGeneric 5S Checklistswamireddy100% (1)

- Sports MedicineDocument2 pagesSports MedicineShelby HooklynNo ratings yet

- MSU-Iligan Institute of TechnologyDocument5 pagesMSU-Iligan Institute of TechnologyYuvi Rociandel LUARDONo ratings yet

- Artesunat Injection 2009Document4 pagesArtesunat Injection 2009Franca ImadiyiNo ratings yet

- Erich FrommDocument2 pagesErich FrommTina NavarroNo ratings yet

- People vs. MediosDocument10 pagesPeople vs. MediostheresagriggsNo ratings yet

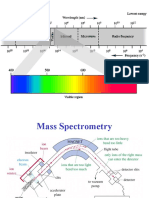

- Mass SpectrometryDocument49 pagesMass SpectrometryUbaid ShabirNo ratings yet

- 感應馬達安裝、保養使用說明書31057H402E (英)Document17 pages感應馬達安裝、保養使用說明書31057H402E (英)Rosyad Broe CaporegimeNo ratings yet

- BlackCat ManualDocument14 pagesBlackCat ManualNestor Marquez-DiazNo ratings yet

- Just Another RantDocument6 pagesJust Another RantJuan Manuel VargasNo ratings yet

- February 2019Document4 pagesFebruary 2019sagar manghwaniNo ratings yet

- Private Standard: Shahram GhanbarichelaresiDocument2 pagesPrivate Standard: Shahram Ghanbarichelaresiarian tejaratNo ratings yet

- Technical Publication: Direction 2296441-100 Revision 06 Ge Medical Systems Lightspeed 3.X - Schematics and BoardsDocument380 pagesTechnical Publication: Direction 2296441-100 Revision 06 Ge Medical Systems Lightspeed 3.X - Schematics and BoardsJairo Manzaneda100% (2)

- Rotary Screw Gas: CompressorsDocument2 pagesRotary Screw Gas: CompressorsLucas SilvestreNo ratings yet

- Citizen's 8651 Manual PDFDocument16 pagesCitizen's 8651 Manual PDFtfriebusNo ratings yet

- Toaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRDocument17 pagesToaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRBhumika SahuNo ratings yet

- How To Create Your Cosmetic Product Information FileDocument12 pagesHow To Create Your Cosmetic Product Information Filewill100% (3)

- TS802 - Support StandardDocument68 pagesTS802 - Support StandardCassy AbulenciaNo ratings yet

- Bulk-Fill Composite RestorationsDocument9 pagesBulk-Fill Composite RestorationssusethNo ratings yet

- Ifm Product Innovations PDFDocument109 pagesIfm Product Innovations PDFJC InquillayNo ratings yet

- Ineffective Breastfeeding - NCPDocument10 pagesIneffective Breastfeeding - NCPJullian PloyaNo ratings yet