Professional Documents

Culture Documents

ASDIP Steel - Composite Beam Verification Example

Uploaded by

edwinvizueteOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASDIP Steel - Composite Beam Verification Example

Uploaded by

edwinvizueteCopyright:

Available Formats

I-6

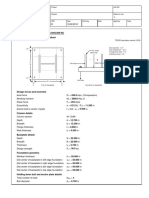

Example I-1

Given:

Composite Beam Design

A series of 45-ft. span composite beams at 10 ft. o/c are carrying the loads shown below. The beams are ASTM A992 and are unshored. The concrete has fc = 4 ksi. Design a typical floor beam with 3 in. 18 gage composite deck, and 4 in. normal weight concrete above the deck, for fire protection and mass. Select an appropriate beam and determine the required number of shear studs.

Solution: Material Properties: Concrete fc = 4 ksi Beam Fy = 50 ksi Fu = 65 ksi Manual Table 2-3

Loads: Dead load: Slab = 0.075 kip/ft2 Beam weight = 0.008 kip/ft2 (assumed) Miscellaneous = 0.010 kip/ft2 (ceiling etc.) Live load: Non-reduced = 0.10 kips/ft2 Since each beam is spaced at 10 ft. o.c. Total dead load Total live load = 0.093 kip/ft2(10 ft.) = 0.93 kips/ft. = 0.10 kip/ft2(10ft.) = 1.00 kips/ft.

Construction dead load (unshored) = 0.083 kip/ft2(10 ft) = 0.83 kips/ft Construction live load (unshored) = 0.020 kip/ft2(10 ft) = 0.20 kips/ft

ASDIP Steel is available for purchase online at www.asdipsoft.com

I-7

Determine the required flexural strength

LRFD ASD

wu = 1.2(0.93 kip/ft) + 1.6(1.0 kip/ft) = 2.72 kip/ft 2.72 kip/ft(45 ft)2 = 687 kip-ft. Mu = 8

wa = 0.93 kip/ft + 1.0 kip/ft = 1.93 kip/ft 1.93 kip/ft(45 ft)2 = 489 kip-ft. Ma = 8

Use Tables 3-19, 3-20 and 3-21 from the Manual to select an appropriate member

Determine beff The effective width of the concrete slab is the sum of the effective widths for each side of the beam centerline, which shall not exceed: (1) one-eighth of the beam span, center to center of supports 45 ft. ( 2 ) = 11.3 ft. 8 (2) one-half the distance to center-line of the adjacent beam 10 ft. ( 2 ) = 10.0 ft. Controls 2 (3) the distance to the edge of the slab Not applicable Calculate the moment arm for the concrete force measured from the top of the steel shape, Y2. Assume a = 1.0 in. (Some assumption must be made to start the design process. An assumption of 1.0 in. has proven to be a reasonable starting point in many design problems.) Y2 = tslab a/2 = 7.5 = 7.0 in. Enter Manual Table 3-19 with the required strength and Y2=7.0 in. Select a beam and neutral axis location that indicates sufficient available strength. Select a W2150 as a trial beam. When PNA location 5 (BFL), this composite shape has an available strength of:

LRFD ASD

Section I.3.1.1a

Manual Table 3-19

bMn= 770 kip-ft > 687 kip-ft

o.k.

Mn/b = 512 kip-ft > 489 kip-ft

o.k.

Manual Table 3-19

Note that the required PNA location for ASD and LRFD differ. This is because the live to dead load ratio in this example is not equal to 3. Thus, the PNA location requiring the most shear transfer is selected to be acceptable for ASD. It will be conservative for LRFD.

ASDIP Steel is available for purchase online at www.asdipsoft.com

I-8

Check the beam deflections and available strength Check the deflection of the beam under construction, considering only the weight of concrete as contributing to the construction dead load. Limit deflection to a maximum of 2.5 in. to facilitate concrete placement.

I req =

3 3 5 wDLl 4 5 ( 0.83 kip/ft )( 45 ft ) (1728 in. /ft ) = = 1, 060 in.4 384 E 384 ( 29,000 ksi )( 2.5 in.) 4

From Manual Table 3-20, a W2150 has Ix = 984 in.4, therefore this member does not satisfy the deflection criteria under construction. Using Manual Table 3-20, revise the trial member selection to a W2155, which has Ix = 1140 in.4, as noted in parenthesis below the shape designation. Check selected member strength as an un-shored beam under construction loads assuming adequate lateral bracing through the deck attachment to the beam flange.

LRFD ASD

Calculate the required strength 1.4 DL = 1.4 (0.83 kips/ft) = 1.16 kips/ft 1.2DL+1.6LL = 1.2 (0.83) + 1.6(0.20) = 1.32 klf Mu (unshored) =

1.31 kip/ft(45 ft) 2 8 =331 kip-ft

Calculate the required strength DL+LL = 0.83 + 0.20 = 1.03 kips.ft

Ma (unshored) =

1.03 kips/ft(45 ft) 2 8 = 260 kip-ft

The design strength for a W2155 is 473 kip-ft > 331 kip-ft o.k.

The allowable strength for a W21 55 is 314 kip-ft > 260 kip-ft o.k. Manual Table 3-19

For a W2155 with Y2=7.0 in, the member has sufficient available strength when the PNA is at location 6 and Qn = 292 kips.

LRFD ASD

bMn=767 kip-ft > 687 kip-ft

o.k.

Mn/b = 510 kip-ft > 489 kip-ft

o.k.

Manual Table 3-19

Check a Qn 292 kips = = 0.716 in. a= ' 0.85(4 ksi)(10 ft.)(12 in./ft.) 0.85 f c b 0.716 in. < 1.0 in. assumed o.k.

Check live load deflection LL < l/360 = ((45 ft.)(12 in./ft))/360 = 1.5 in. A lower bound moment of inertia for composite beams is tabulated in Manual Table 3-20.

ASDIP Steel is available for purchase online at www.asdipsoft.com

I-9

For a W2155 with Y2=7.0 and the PNA at location 6, ILB = 2440 in.4

LL =

3 3 5 wLL l 4 5 (1.0 kip/ft )( 45 ft ) (1728 in. /ft ) = = 1.30 in. 384 EI LB 384 ( 29,000 ksi ) ( 2440 in.4 ) 4

Manual Table 3-20

1.30 in. < 1.5 in. o.k. Determine if the beam has sufficient available shear strength

LRFD ASD

Vu=

45ft ( 2.72kip/ft ) = 61.2 kips 2 Vn= 234 kips > 61.2 kips

o.k.

45ft (1.93kip/ft ) = 43.4 kips 2 Vn/ = 156 kips > 43.4 kips

Va =

Manual Table 3-3

o.k.

Determine the required number of shear stud connectors Using perpendicular deck with one -in. diameter weak stud per rib in normal weight 4 ksi concrete. Qn = 17.2 kips/stud

Qn 292 kips = = 17, on each side of the beam. 17.2 kips Qn

Manual Table 3-21

Section 3.2d(5)

Total number of shear connectors; use 2(17) = 34 shear connectors. Check the spacing of shear connectors Since each flute is 12 in., use one stud every flute, starting at each support, and proceed for 17 studs on each end of the span. 6dstud < 12 in. < 8tslab , therefore, the shear stud spacing requirements are met. The studs are to be 5 in. long, so that they will extend a minimum of 12 in. into slab.

Section 3.2d(6)

Section I3.2c (b)

ASDIP Steel is available for purchase online at www.asdipsoft.com

ASDIP Steel is available for purchase online at www.asdipsoft.com

ASDIP Steel is available for purchase online at www.asdipsoft.com

You might also like

- Design CaculationsDocument29 pagesDesign Caculationsg4goharNo ratings yet

- Documento 5 - RR01c - Narrative With Appendices Revised 05.16.12Document113 pagesDocumento 5 - RR01c - Narrative With Appendices Revised 05.16.12Galo SerranoNo ratings yet

- Comparison For 1200mm Dia & 600 MM Dia and DismantlingDocument5 pagesComparison For 1200mm Dia & 600 MM Dia and DismantlingUmamaheshwarrao VarmaNo ratings yet

- CCT CT ConcreteDocument2 pagesCCT CT Concreteepe civil1No ratings yet

- Bangladesh National Building CodeDocument1,870 pagesBangladesh National Building CodeTaz UddinNo ratings yet

- KamranDocument7 pagesKamranHunterNo ratings yet

- Control Room Building EstimatingDocument11 pagesControl Room Building EstimatingVikas NagalNo ratings yet

- Sectional Propert Chart-NewDocument3 pagesSectional Propert Chart-Newrajeshmk2002No ratings yet

- 37 PDFDocument14 pages37 PDFID SkechtNo ratings yet

- RCDC V6 Release NotesDocument13 pagesRCDC V6 Release NotesManju BirjeNo ratings yet

- Trus-Joist Specifier's GuideDocument24 pagesTrus-Joist Specifier's Guiderhunter2010No ratings yet

- Steel Structures 2 Project AnalysisDocument36 pagesSteel Structures 2 Project AnalysisAnamaria-Ileana LăzăroiuNo ratings yet

- Spreadsheets To Ec2Document25 pagesSpreadsheets To Ec2mustafurade1No ratings yet

- Rapid Dry Envelope Construction Using Ayrshire Steel FramingDocument34 pagesRapid Dry Envelope Construction Using Ayrshire Steel FramingjohnautodidacteNo ratings yet

- Bom - HeadraceDocument14 pagesBom - HeadraceBethoven KhoNo ratings yet

- Metal Pro Info GuideDocument17 pagesMetal Pro Info GuideSanjay EgnotoNo ratings yet

- Industrial ConstDocument34 pagesIndustrial Constkirti0% (1)

- Admore Gas (PVT) LTD: Bulk Oil Installation Depot at DaulatpurDocument12 pagesAdmore Gas (PVT) LTD: Bulk Oil Installation Depot at DaulatpurBilal Mustafa SiddiquiNo ratings yet

- Itemwise Detailed Technical SpecificationDocument3 pagesItemwise Detailed Technical Specificationanku4frenzNo ratings yet

- Composite Deck Design GuideDocument16 pagesComposite Deck Design GuideLatha MaNo ratings yet

- Concrete Frame Design Manual: Hong Kong Code of Practice 2013Document57 pagesConcrete Frame Design Manual: Hong Kong Code of Practice 2013huyxpkissNo ratings yet

- SBS Design GuideDocument28 pagesSBS Design GuideKristjan IgastaNo ratings yet

- FootingDocument84 pagesFootingUma MaheshNo ratings yet

- A XX Is Builder BrochureDocument20 pagesA XX Is Builder BrochureLollipopsuckerNo ratings yet

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliNo ratings yet

- Pressure Plate PDFDocument1 pagePressure Plate PDFparag narkhedeNo ratings yet

- Pre-Engineered Building - Wikipedia PDFDocument13 pagesPre-Engineered Building - Wikipedia PDFshubham kothawadeNo ratings yet

- Sign Board Frame Design For Offshore AreDocument14 pagesSign Board Frame Design For Offshore AreOmer HayatNo ratings yet

- Comtech Metals Pvt Ltd Manufacturing Facility ProfileDocument17 pagesComtech Metals Pvt Ltd Manufacturing Facility ProfilepalsNo ratings yet

- Sectional Properties of Standard Steel Beams and ColumnsDocument4 pagesSectional Properties of Standard Steel Beams and Columnsinsane88No ratings yet

- DE010 of-053123-1.0-P-Vulcraft Joist and Deck Plans - Datum ReviewedDocument9 pagesDE010 of-053123-1.0-P-Vulcraft Joist and Deck Plans - Datum ReviewedAzeemuddin Gulam MohammedNo ratings yet

- Joist Design GuideDocument1 pageJoist Design Guidealexkirokos0% (1)

- Daily Site Book My HouseDocument11 pagesDaily Site Book My Housemustafurade1No ratings yet

- Beam1 Working StressDocument36 pagesBeam1 Working Stresssoumi bhattacharyaNo ratings yet

- 003.beam Design DocumentDocument59 pages003.beam Design Documentmathu100% (1)

- Description Layers Dia Length Spacing GF PT SLAB 280 MM Thick Sl. NoDocument103 pagesDescription Layers Dia Length Spacing GF PT SLAB 280 MM Thick Sl. Noepe civil1No ratings yet

- M.Sc. Steel - 4 Composite Steel-Concrete DesignDocument56 pagesM.Sc. Steel - 4 Composite Steel-Concrete DesignAbdullahNo ratings yet

- (James M. Ramirez JR.) : FeaturesDocument7 pages(James M. Ramirez JR.) : FeaturesJames Ramirez Jr.No ratings yet

- Tubes and PipesDocument1 pageTubes and PipesLLNo ratings yet

- Civil & Structures: Scope SummaryDocument4 pagesCivil & Structures: Scope Summaryriaz16shaikNo ratings yet

- Report Final1 PDFDocument49 pagesReport Final1 PDFyogenNo ratings yet

- Spreadsheets To BS 8110Document11 pagesSpreadsheets To BS 8110NitinShepurNo ratings yet

- Builder's Mart Access Road Construction Cost EstimateDocument3 pagesBuilder's Mart Access Road Construction Cost EstimateDamola PopoolaNo ratings yet

- British Verification Problem 2Document7 pagesBritish Verification Problem 2elixnzNo ratings yet

- Hollow Block and Tile EstimatorDocument65 pagesHollow Block and Tile EstimatorNiño MejiasNo ratings yet

- Shear Wall Design Manual: IS 456:2000 and IS 13920:1993Document98 pagesShear Wall Design Manual: IS 456:2000 and IS 13920:1993soumyadeep19478425No ratings yet

- 08MCL002Document137 pages08MCL002Rahil QureshiNo ratings yet

- AISC ExamI1&2&3Document11 pagesAISC ExamI1&2&3Dhurai KesavanNo ratings yet

- Composite Beam ExampleDocument4 pagesComposite Beam Examplexxazninvasionxx2697100% (1)

- Example I-1 PDFDocument6 pagesExample I-1 PDFboone37No ratings yet

- LRFD-Composite Beam Desing With MetaldeckDocument12 pagesLRFD-Composite Beam Desing With MetaldeckMaria FabianaNo ratings yet

- Discussion - Strengthening of Existing Composite Beams Using LRFD ProceduresDocument2 pagesDiscussion - Strengthening of Existing Composite Beams Using LRFD ProceduresCaesar JJNo ratings yet

- Example Calculations: Example Problems For Concentrated LoadsDocument4 pagesExample Calculations: Example Problems For Concentrated LoadsKho C AhlNo ratings yet

- Chapter J Design of ConnectionsDocument16 pagesChapter J Design of Connectionsghosh73No ratings yet

- Beam Bearing PlatesDocument23 pagesBeam Bearing PlatesShah Jehan HanifNo ratings yet

- 425 Footing Design ExamplesDocument60 pages425 Footing Design ExamplesKakaNo ratings yet

- CVEN 444 - Homework 5 - Concrete beam and slab design problemsDocument9 pagesCVEN 444 - Homework 5 - Concrete beam and slab design problemsOmar Calisaya RamosNo ratings yet

- Ce 03024Document211 pagesCe 03024kimchhoungNo ratings yet

- Example II.A-12 All-Bolted Unstiffened Seated Connection (Beam-To-Column Web)Document12 pagesExample II.A-12 All-Bolted Unstiffened Seated Connection (Beam-To-Column Web)mohdnazirNo ratings yet

- Design of Welded StructuresDocument842 pagesDesign of Welded StructuresRancor8297% (39)

- Seismic Analysis of Cantilever Retaining Walls, Phase I Erdcitl Tr-02-3Document104 pagesSeismic Analysis of Cantilever Retaining Walls, Phase I Erdcitl Tr-02-3ctrle100% (1)

- Using Python for Civil and Mechanical Engineering ProblemsDocument194 pagesUsing Python for Civil and Mechanical Engineering ProblemsAbhijit Kulkarni100% (11)

- Using Python for Civil and Mechanical Engineering ProblemsDocument194 pagesUsing Python for Civil and Mechanical Engineering ProblemsAbhijit Kulkarni100% (11)

- BASE PLATE AND ANCHOR ROD DESIGN GUIDEDocument4 pagesBASE PLATE AND ANCHOR ROD DESIGN GUIDEEdwin VizueteNo ratings yet

- Design Shear WallDocument26 pagesDesign Shear WallCaoTrungThành100% (2)

- Tesis Loor D. - Mosquera H.Document101 pagesTesis Loor D. - Mosquera H.Edwin VizueteNo ratings yet

- Prestressed Concrete Bridges - C. Menn PDFDocument549 pagesPrestressed Concrete Bridges - C. Menn PDFEdwin Vizuete50% (2)

- Aci 355.2-2007 PDFDocument39 pagesAci 355.2-2007 PDFMichael BesaNo ratings yet

- Albañileria - Diseño de Escalera PDFDocument13 pagesAlbañileria - Diseño de Escalera PDFEdwin VizueteNo ratings yet

- SAFE Users GuideDocument62 pagesSAFE Users GuideMonica Maria OquendoNo ratings yet

- CBD Csa S16 09Document195 pagesCBD Csa S16 09Edwin VizueteNo ratings yet

- CH 2 - Part I-Structural Steel BuildingsDocument46 pagesCH 2 - Part I-Structural Steel Buildingsnazgul85No ratings yet

- Datos PunzonamientoDocument1 pageDatos PunzonamientoEmerson Osorio HilarioNo ratings yet

- Albañileria - Diseño de Escalera PDFDocument13 pagesAlbañileria - Diseño de Escalera PDFEdwin VizueteNo ratings yet

- Plastic Desing of Frames 1971 - Jaques Heyman PDFDocument300 pagesPlastic Desing of Frames 1971 - Jaques Heyman PDFEdwin VizueteNo ratings yet

- The Mohr Circle PDFDocument14 pagesThe Mohr Circle PDFryan rakhmat setiadiNo ratings yet

- ETABS Composite BSDocument190 pagesETABS Composite BSMongkol JirawacharadetNo ratings yet

- CBD Aisc 360 05Document211 pagesCBD Aisc 360 05Edwin VizueteNo ratings yet

- P C Varghese-Advanced Reinforced Concrete Design, 2nd Edition-PHI Learning Pvt. LTD (2009)Document282 pagesP C Varghese-Advanced Reinforced Concrete Design, 2nd Edition-PHI Learning Pvt. LTD (2009)Anban Guna100% (1)

- Bridge Design Manual (LRFD) : M 23-50.12 August 2012Document1,332 pagesBridge Design Manual (LRFD) : M 23-50.12 August 2012Hector GuillenNo ratings yet

- CBD Aisc 360 10Document211 pagesCBD Aisc 360 10Edwin Vizuete100% (1)

- FootingsDocument14 pagesFootingsEdwin VizueteNo ratings yet

- Risa FoundationDocument274 pagesRisa FoundationEdwin Vizuete100% (1)

- Seismic and Wind Design of Concrete BuildingsDocument542 pagesSeismic and Wind Design of Concrete BuildingsMonde Nuylan100% (12)

- Spread Footing Analysis and DesignDocument21 pagesSpread Footing Analysis and DesignEdwin VizueteNo ratings yet

- Spread Footing Analysis and DesignDocument21 pagesSpread Footing Analysis and DesignEdwin VizueteNo ratings yet

- 02 WallsDocument32 pages02 WallsAmmar AbusalehNo ratings yet

- Seismic Behaviour of Micropiles-Thesis - Joo Chai WongDocument156 pagesSeismic Behaviour of Micropiles-Thesis - Joo Chai WongmigueldiNo ratings yet

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- Create Profitable Side Hustles with Artificial IntelligenceFrom EverandCreate Profitable Side Hustles with Artificial IntelligenceNo ratings yet

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityFrom EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (115)

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- Modeling, Dynamics, and Control of Electrified VehiclesFrom EverandModeling, Dynamics, and Control of Electrified VehiclesRating: 5 out of 5 stars5/5 (1)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Design and Operation of Human Locomotion SystemsFrom EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNo ratings yet

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Visions Of Technology: A Century Of Vital Debate About Machines Systems AFrom EverandVisions Of Technology: A Century Of Vital Debate About Machines Systems ARating: 4 out of 5 stars4/5 (9)

- Building Server-side and Microservices with Go: Building Modern Backends and Microservices Using Go, Docker and KubernetesFrom EverandBuilding Server-side and Microservices with Go: Building Modern Backends and Microservices Using Go, Docker and KubernetesNo ratings yet

- RoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingFrom EverandRoboNexus: Bridging Realms: The Confluence of Mechanics, Electronics, and ProgrammingNo ratings yet

- Learning Robotics, with Robotics, by Robotics: Educational RoboticsFrom EverandLearning Robotics, with Robotics, by Robotics: Educational RoboticsNo ratings yet