Professional Documents

Culture Documents

SWMSElevated Work Platforms

Uploaded by

Ray LeeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SWMSElevated Work Platforms

Uploaded by

Ray LeeCopyright:

Available Formats

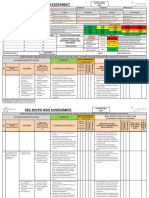

Safe Work Method Statement

ABN: 86 058 929 428 Postal address: PO Box 21 Cleveland Qld 4163 SWMS number: Risk Register reference: Date: Location: Generic

IMPORTANT NOTE: This SWMS is a site-specic statement that must be prepared before any extreme risk or high risk work is commenced. Person responsible for ensuring compliance with this SWMS: Person in control of the place of work Desciption of high-risk job: Working at heights from elevating work platforms (EWP) Generic Steps for lling out this form 1. Discuss with relevant employees, contractors and HSRs what work will be high-risk, the tasks and associated hazards, risks and controls. 2. In the What are the task involved? column, list the work tasks in sequence (the order they will be carried out in. 3. In the What are the hazards and risks? column, list the hazards and risks for each work task 4. In the How will the hards and risks be controlled? column, select the hazard or risk and then work through the control levels 1-4 from top to bottom. Choose a control measure (and how it is to be used) that is as close to level 1 as is reasonable practicable. Control levels 1. Eliminate any risk to health or safety associated with work. 2. Reduce the risk to health or safety by any one or any combination of the following: Substituting a new activity, procedure, plant, process or substance Isolating persons from the hazard, such as barricading, fencing or guardrailing Using engineering controls such as mechanical or electrical devices. 3. Use administrative controls, such as changing the way the work is done. 4. Provide appropriate personal protective equipment. 5. Brief each team member on this SWMS before commencing work. Ensure team knows that work is to immediately stop if the SWMS is not being followed. 6. Observe work being carried out. If controls are not adequete, stop the work, review the SWMS, adjust as required and re-brief the team. 7. Retain this SWMS for the duration of the high-risk work.

Safe Work Method Statement (Continued)

What are the tasks involved? What are the hazards and risks? How will hazards & risks be controlled? (Describe the control measures and how they will be used) Responsibility for monitoring

REMEMBER: Think about the worksite and each stage of the project including preparation and cleanup.

Mobile elevating platforms are only to be operated by a competent person. For platforms over 11 meters a license is required. Prior to work commencing WH&S Regs. (2008) Part 20 Has a risk assessment been completed for the task? AS 2550 Has a management plan been established? Have the control measures been implemented? Has the daily pre-operational checklist been completed for all mobile plant? WH&S Regs Part 20. All site personnel are to have completed the General Safety induction course (Construction Industry) 30215 Qld as well as a site specific Workplace Health and Safety induction. All EWP used are to comply with:- AS 1418.10 and to be used in accordance with AS 2550 Before selecting a EWP for a particular application, all relevant information shall be obtained and all relevant operational criteria shall be determined, including rated capacity of the EWP. Classification of the EWP taking into account the application, including: (i) type of loads to be lifted (ii) mass of loads to be lifted (iii) speed of lifts (iv) frequency of lifts. Placement of elevating work platform Injury from EWP collapse AS 2550. A competent person shall ensure that the loads imposed by the EWP can be sustained by the ground or any other means of support. All aspects of wind loading, both in and out of service, on the EWP standing due to location, shall be taken into account, including the increased wind loads caused by funneling effects between adjacent buildings or structures. The site shall be checked for the presence of underground services, ducts and the like. Where the check reveals the existence of underground services, precautions shall be taken to ensure the stability of the EWP. Where an EWP is required to work in the vicinity of an excavation or an embankment, the possibility of slip or collapse of the supporting surface shall be evaluated by a competent person. Where necessary, the excavation or embankment shall be reinforced. AS 2550. Principal contractor, site supervisor and EWP operator Principal contractor and site supervisor Principal contractor and site supervisor

Selection of elevating work platforms

Death or serious injury if falling from height

What are the tasks involved?

Placement of elevating work platform (continued)

What are the hazards and risks?

Electrocution

How will hazards & risks be controlled? (Describe the control measures and how they will be used)

Before setting the EWP into operational configuration, a check for the presence of overhead conductors and power lines is to be undertaken. Contact the electrical entity responsible for the lines to confirm voltage insulation and appropriate systems of work.

Responsibility for monitoring

Injury from mobile plant and vehicular traffic impact

Determine the exclusion zone as required by Electrical Safety Regs 2002. Re-route vehicles away from the location. Use barricades, signs and buffer rails to prevent vehicles coming into contact with the work platform.

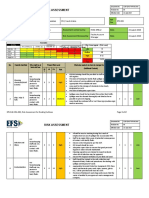

Safe use of elevating work platforms

Serious injury from equipment malfunction

To be used in accordance with AS 2550, Plant Code of Practice and Queensland transport guidelines. Only a competent person is permitted to operate a mechanical elevating work platform. Pre-operational inspections are to be carried out by the designated person at the beginning of each working shift in accordance with the pre-operational check list. Where pre-operational inspections reveal a safety malfunction or potential risk, the EWP shall not be put into service. All malfunctions and hazards shall be reported and properly recorded for assessment by a competent person and acted upon as appropriate. AS 1418.10 Boom-type elevating work platforms shall have suitable anchorages for the attachment of safety harnesses for each occupant. Each anchorage shall be designed to withstand the forces specified in AS/NZS 1891. EWPs with boom lengths exceeding 11 meters are to be operated by suitably qualified personnel. NCOP for prevention of falls. Where there is a risk of falling more than 2 meters, fall arrest equipment compliant with AS/NZS 1891 is to be used. The inclination of the surface will not exceed the manufacturers recommendations. Platforms are not to be extended past their limits.

Principal contractor, site supervisor and EWP operator

What are the tasks involved?

Safe use of elevating work platforms (continued)

What are the hazards and risks?

Electrocution

How will hazards & risks be controlled? (Describe the control measures and how they will be used)

Protection of operators The following requirements apply. EWPs rated for low-voltage work shall have cover insulation that complies with the requirements of AS 1418. They shall be fitted with an insulated basket or an insulated platform thatcomplies with AS 1418 EWPs rated for high-voltage work shall have a boom-insulating insert located between the basket and ground level in accordance with AS 1418. The insulating insert shall be located as close as practicable to the basket. All exposed metal fittings above the insulating insert shall be protected from direct contact with live conductors or equipment in accordance AS 1418.

Responsibility for monitoring

Injury from falling objects Environmental loads

Use perimeter containment screening to avoid objects being dropped from the platform. Consider the effects that environmental loads can have on the work platform. Do not work in unsafe conditions.

You might also like

- SWMS 67 - Safe Use of Nail GunsDocument4 pagesSWMS 67 - Safe Use of Nail GunsJonasNo ratings yet

- UG RA 009 - Light Materials and Equipment Loading and UnloadingDocument6 pagesUG RA 009 - Light Materials and Equipment Loading and Unloadingshamshuddin100% (1)

- SFPSG-Rescue Persons From MEWPsDocument10 pagesSFPSG-Rescue Persons From MEWPsLyle KorytarNo ratings yet

- SOP For Working at HeightDocument19 pagesSOP For Working at HeightShreedhar94% (18)

- Flagman/ Banksman TrainingDocument25 pagesFlagman/ Banksman TrainingAatif Patil100% (1)

- Safe Work Procedure, Gem MaintenanceDocument46 pagesSafe Work Procedure, Gem MaintenanceAsif Khanzada100% (1)

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- PPE Written ReportsdsdadDocument10 pagesPPE Written ReportsdsdadAdvincula JericsonNo ratings yet

- Role of Safety Professional in Construction IndustryDocument30 pagesRole of Safety Professional in Construction IndustryKiranSivakumarNo ratings yet

- Fall ProtectionDocument24 pagesFall Protectionmdfahad0047No ratings yet

- Design Capacity Tables For Structural Steel Hollow SectionsDocument180 pagesDesign Capacity Tables For Structural Steel Hollow Sectionsdoshi7850% (2)

- Confined Spaces PDFDocument2 pagesConfined Spaces PDFcityofdarwingisNo ratings yet

- Appendix-B - Construction Safey Manual at ProjectsDocument112 pagesAppendix-B - Construction Safey Manual at ProjectsvinodNo ratings yet

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationMohammed Ali QaziNo ratings yet

- Permit To Work - Mobile CraneDocument2 pagesPermit To Work - Mobile CraneMIDWEST BUILDING DEMOLITIONS100% (1)

- TOOLBOX TALKS FOR CONSTRUCTION SUPERVISORSDocument52 pagesTOOLBOX TALKS FOR CONSTRUCTION SUPERVISORSAji WidyartaNo ratings yet

- Safe Work Method StatementDocument7 pagesSafe Work Method StatementianllagasNo ratings yet

- Crane Tower SmsDocument16 pagesCrane Tower Smspeter morganNo ratings yet

- Work Height ProcedureDocument7 pagesWork Height ProcedureardodotNo ratings yet

- Safety Arabtec FormsDocument49 pagesSafety Arabtec FormsEtibar AliyevNo ratings yet

- IndiGo Airlines International Business Strategy Case StudyDocument59 pagesIndiGo Airlines International Business Strategy Case StudyPRACHI DAS100% (1)

- Hse Hanbook Final 2010Document38 pagesHse Hanbook Final 2010wferry27100% (2)

- 94 Supra Wiring DiagramsDocument59 pages94 Supra Wiring DiagramsGaston MerinoNo ratings yet

- Removal of Debris-Filling - Levelling & CompactingDocument8 pagesRemoval of Debris-Filling - Levelling & CompactingAl Mughsar CompanyNo ratings yet

- Risk Assessment for Bodily Fluid Spillage CleaningDocument2 pagesRisk Assessment for Bodily Fluid Spillage Cleaningmohammed ayazNo ratings yet

- JSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationDocument10 pagesJSA Formwork (Shuttering), Concrete Pouring, Curing, Surface PreparationMohammad Al Masa'dehNo ratings yet

- Drivers Handbook On Cargo SecurementDocument141 pagesDrivers Handbook On Cargo SecurementPatrick Duff100% (1)

- B737 800 Checklist PDFDocument4 pagesB737 800 Checklist PDFRichard Lund60% (5)

- IPCC Near Miss Form ReviewDocument2 pagesIPCC Near Miss Form Reviewkirandevi1981No ratings yet

- Ironbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy FlooringDocument12 pagesIronbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy Flooringklp_kedarpNo ratings yet

- Sample Calculatio For Design of Structures and Foundations For Vibrating MachinesDocument6 pagesSample Calculatio For Design of Structures and Foundations For Vibrating MachinesRay LeeNo ratings yet

- Diesel Filling JSADocument6 pagesDiesel Filling JSAMohammed Ali QaziNo ratings yet

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- Risk Assessment 5 Use of Mob Elevating Working Platform (MewDocument1 pageRisk Assessment 5 Use of Mob Elevating Working Platform (Mewjamilhse7759No ratings yet

- Rogue Trader RPG Action Cards v1.05Document20 pagesRogue Trader RPG Action Cards v1.05CloudStormer100% (3)

- As 2172-2010Document41 pagesAs 2172-2010Ray LeeNo ratings yet

- SWMS Scaffold FixedDocument11 pagesSWMS Scaffold FixedEdha AliNo ratings yet

- HSE guidance on safety devices for rapid roller doorsDocument11 pagesHSE guidance on safety devices for rapid roller doorsmsc920138No ratings yet

- Hydrodynamic Coefficients For Calculation ofDocument14 pagesHydrodynamic Coefficients For Calculation ofAnoop GeorgeNo ratings yet

- TBT-Driving in FogDocument2 pagesTBT-Driving in FogImran KhanNo ratings yet

- Piling Safety PlanDocument8 pagesPiling Safety PlanBalogun Isaac100% (1)

- Construction Safety: Page 1 of 4Document4 pagesConstruction Safety: Page 1 of 4ryan.aniceteNo ratings yet

- Litz Safe Work Procedures 2011Document195 pagesLitz Safe Work Procedures 2011Naz ッ WanyNo ratings yet

- RA For Nitoflor FC150Document4 pagesRA For Nitoflor FC150kkhafajiNo ratings yet

- Play It SAFE: Working AT HeightDocument20 pagesPlay It SAFE: Working AT Heightandi permanaNo ratings yet

- Jsa Civil Work (00000002)Document6 pagesJsa Civil Work (00000002)Ali AlahmaNo ratings yet

- Safe Use of MEWP 241008Document3 pagesSafe Use of MEWP 241008Ojo OgboadayegbeNo ratings yet

- Advanced MathematicsDocument185 pagesAdvanced MathematicsRay LeeNo ratings yet

- Safe Use of Work PlatformsDocument5 pagesSafe Use of Work PlatformsFrancis Enriquez TanNo ratings yet

- Plumber - Drainer SWMSDocument12 pagesPlumber - Drainer SWMSallen2912100% (1)

- Construction Site Safety ChecklistDocument3 pagesConstruction Site Safety ChecklistHtoo Htoo Kyaw100% (1)

- EHSWP004 - Hot Work Permit PDFDocument2 pagesEHSWP004 - Hot Work Permit PDFRand raiNo ratings yet

- 5490060A01 VDR F1 S-VDR S1 User Guide PDFDocument74 pages5490060A01 VDR F1 S-VDR S1 User Guide PDFAjay Singh67% (3)

- Completion ChecklistDocument2 pagesCompletion ChecklistDenise2512No ratings yet

- Pirates A Dungeon World SourcebookDocument14 pagesPirates A Dungeon World SourcebookLloyd Collins100% (1)

- Construction Equipment GuideDocument88 pagesConstruction Equipment GuideKasim MalekNo ratings yet

- Safety Rules of ContractDocument7 pagesSafety Rules of ContractArup ChatterjeeNo ratings yet

- Electrical Hazards ConstructionDocument77 pagesElectrical Hazards Constructiondh25881No ratings yet

- Emergency Plan For Rescue From HeightsDocument9 pagesEmergency Plan For Rescue From Heightsochieng denisNo ratings yet

- Loading & Lifting ProcedureDocument5 pagesLoading & Lifting Procedurekhurram shahzadNo ratings yet

- CV - 11 10 2021Document4 pagesCV - 11 10 2021Fuzail AyazNo ratings yet

- SWP Excavation Near Overhead Electrical Live LinesDocument2 pagesSWP Excavation Near Overhead Electrical Live LinesSn AhsanNo ratings yet

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- Safe Unloading of Cut and BentDocument16 pagesSafe Unloading of Cut and BentAbhinav SinhaNo ratings yet

- Simulation and Structural Analysis of Modules During Land TransportationDocument6 pagesSimulation and Structural Analysis of Modules During Land TransportationRay Lee100% (1)

- Crude Oil Loading ProcedureDocument6 pagesCrude Oil Loading ProcedureMardanusNo ratings yet

- Job Safety Analysis: S.No Activities Hazard Risk Control MeasuresDocument2 pagesJob Safety Analysis: S.No Activities Hazard Risk Control Measureskhaja asifuddinNo ratings yet

- Part I, Sea Going Ship, Vol I Rules For Classification and Survey.Document148 pagesPart I, Sea Going Ship, Vol I Rules For Classification and Survey.Angjuang Adi Panji PratamaNo ratings yet

- RA Tower 0004 Dec 2011Document8 pagesRA Tower 0004 Dec 2011grandeNo ratings yet

- Shotcrete For Tunnel Final Linings Design and Construction ConsiderationsDocument8 pagesShotcrete For Tunnel Final Linings Design and Construction ConsiderationsDaniel ZabalaNo ratings yet

- 01 WI HSE 001 - Risk Assessment GroutingDocument4 pages01 WI HSE 001 - Risk Assessment GroutingMisbah Ul Haq Labeed100% (1)

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocument4 pagesJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradNo ratings yet

- Emergency Drill ReportDocument10 pagesEmergency Drill ReportSheri DiĺlNo ratings yet

- Crane Safety Tool Box TalkDocument2 pagesCrane Safety Tool Box Talksathees4329No ratings yet

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- Working at Height Training ModuleDocument41 pagesWorking at Height Training ModuleYudha kurniawanNo ratings yet

- Heavy Duty Industrial Slabs and Pavements FRANK FILIPPONEDocument23 pagesHeavy Duty Industrial Slabs and Pavements FRANK FILIPPONERay LeeNo ratings yet

- FILEIONODocument7 pagesFILEIONOJoseph GonzalezNo ratings yet

- MRWA Backfill SpecificationsDocument3 pagesMRWA Backfill SpecificationsRay LeeNo ratings yet

- Process Water Tanks - Design PhotlosDocument4 pagesProcess Water Tanks - Design PhotlosRay LeeNo ratings yet

- Steel Beam Loading Types GuideDocument1 pageSteel Beam Loading Types GuideRay LeeNo ratings yet

- 2 ExampleDocument39 pages2 ExampleRay LeeNo ratings yet

- Freestanding WallsDocument26 pagesFreestanding Wallschaeld2010No ratings yet

- NCC2015 Performance RequirementsDocument69 pagesNCC2015 Performance RequirementsJay Ryan SantosNo ratings yet

- Structure Pipe FEMDocument57 pagesStructure Pipe FEMFemi Richard FakoyaNo ratings yet

- Floor Plan House Frame-18022015183106Document1 pageFloor Plan House Frame-18022015183106Ray LeeNo ratings yet

- The Parents Guide To Caring For A Child in A Pavlik HarnessDocument6 pagesThe Parents Guide To Caring For A Child in A Pavlik HarnessRayGaintNo ratings yet

- Structural Evaluation of FSO Ground Build Load-OutDocument8 pagesStructural Evaluation of FSO Ground Build Load-OutRay LeeNo ratings yet

- Cranes Hoists Winches Guide 4422 PDFDocument7 pagesCranes Hoists Winches Guide 4422 PDFToni RenedoNo ratings yet

- CPH1 4Document16 pagesCPH1 4Ray LeeNo ratings yet

- CIDocument0 pagesCIRay LeeNo ratings yet

- The Wave Equation: 2: Solution Using The Finite Difference MethodDocument20 pagesThe Wave Equation: 2: Solution Using The Finite Difference MethodRay LeeNo ratings yet

- FatjackDocument160 pagesFatjackRay LeeNo ratings yet

- STAAD Plane Portal Frame on Footing FoundationDocument5 pagesSTAAD Plane Portal Frame on Footing FoundationRay LeeNo ratings yet

- Structure Pipe FEMDocument57 pagesStructure Pipe FEMFemi Richard FakoyaNo ratings yet

- Structural Evaluation of FSO Ground Build Load-OutDocument8 pagesStructural Evaluation of FSO Ground Build Load-OutRay LeeNo ratings yet

- Eucaro OffshoreDocument34 pagesEucaro OffshoreRay LeeNo ratings yet

- 04-The Wave EquationDocument41 pages04-The Wave EquationRay LeeNo ratings yet

- DGCA HAZARD LOG EXEMPTIONSDocument1 pageDGCA HAZARD LOG EXEMPTIONScarltonfenandesNo ratings yet

- KTM LC4 400 - LsemilDocument50 pagesKTM LC4 400 - LsemilAngel VázquezNo ratings yet

- General Declaration (Outward/Inward) Agriculture, Customs, Immigration, and Public HealthDocument2 pagesGeneral Declaration (Outward/Inward) Agriculture, Customs, Immigration, and Public HealthJessicca YevaraNo ratings yet

- Deerfoot Trail Study: December 2020Document52 pagesDeerfoot Trail Study: December 2020Darren KrauseNo ratings yet

- Wiring Diagram Anti-Lock Brake System (ABS) - Acceleration Slip Regulation (ASR)Document3 pagesWiring Diagram Anti-Lock Brake System (ABS) - Acceleration Slip Regulation (ASR)MVPNo ratings yet

- Good, Bad, The PicknellsDocument107 pagesGood, Bad, The PicknellsJasmine BlueNo ratings yet

- Diary of Sailor On Battleship U.S.S. NEW MEXICO in Pacific During World War II ELPALACIO MAGAZINE Vol. 107, No. 2 May 2002Document6 pagesDiary of Sailor On Battleship U.S.S. NEW MEXICO in Pacific During World War II ELPALACIO MAGAZINE Vol. 107, No. 2 May 2002wcharbenNo ratings yet

- FGSL/SSG Malabo, Equatorial Guinea: Dla 1A, Gebro 1A Bimod 2A Nly 1A, Visco 2ADocument2 pagesFGSL/SSG Malabo, Equatorial Guinea: Dla 1A, Gebro 1A Bimod 2A Nly 1A, Visco 2Achochoman1234No ratings yet

- LDT SyllabusDocument107 pagesLDT SyllabusKim2x TamparongNo ratings yet

- BRUSH Switchgear Product Brochure 10 20Document16 pagesBRUSH Switchgear Product Brochure 10 20clauNo ratings yet

- Measurement Sheet For Ag Piping FabricationDocument30 pagesMeasurement Sheet For Ag Piping FabricationDebashish ChatterjeeNo ratings yet

- Sands Models Full List09-09Document20 pagesSands Models Full List09-09bnice2sarah4031No ratings yet

- c32 Gear Group PDFDocument3 pagesc32 Gear Group PDFHaidar SareeniNo ratings yet

- Transportation and Traffic TheoryDocument21 pagesTransportation and Traffic TheorysaobracajniNo ratings yet

- Express Lifts Planning GuideDocument24 pagesExpress Lifts Planning GuideFERNSNo ratings yet

- Site Analysis: Samskruthi ArchitectsDocument12 pagesSite Analysis: Samskruthi ArchitectsAr. MidhilaNo ratings yet