Professional Documents

Culture Documents

Concrete Model

Uploaded by

kbkshanakaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Model

Uploaded by

kbkshanakaCopyright:

Available Formats

Theory Reference Page: 1

4.10. Concrete

The concrete material model predicts the failure of brittle materials. Both cracking and crushing failure modes are accounted for. TB,CONCR accesses this material model, which is available with the reinforced concrete element SOLID65. The criterion for failure of concrete due to a multiaxial stress state can be expressed i the form (Willam and Warnke([37])): (432

where: F = a function (to be discussed) of the principal stress state ( xp, yp, zp) S = failure surface (to be discussed) expressed in terms of principal stresses and five input parameters ft, fc , fcb, f1 and f2 defined in Table 4.4: Concrete Material Table fc = uniaxial crushing strength xp , yp, zp = principal stresses in principal directions If Equation 4326 is satisfied, the material will crack or crush. A total of five input strength parameters (each of which can be temperature depende are needed to define the failure surface as well as an ambient hydrostatic stress state These are presented in Table 4.4: Concrete Material Table. Table 4.4: Concrete Material Table (Input on TBDATA Commands with TB,CONCR)

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 2

Label ft fc fcb

Description Ultimate uniaxial tensile strength Ultimate uniaxial compressive strength Ultimate biaxial compressive strength Ambient hydrostatic stress state

Constant 3 4 5 6 7

f1

Ultimate compressive strength for a state of biaxial compression superimposed on hydrostatic stress state Ultimate compressive strength for a state of uniaxial compression superimposed on hydrostatic stress state

f2

However, the failure surface can be specified with a minimum of two constants, f t and fc . The other three constants default to Willam and Warnke([37]): (432 (432 (432 However, these default values are valid only for stress states where the condition (433

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 3

(433

is satisfied. Thus condition Equation 4330 applies to stress situations with a low hydrostatic stress component. All five failure parameters should be specified when a large hydrostatic stress component is expected. If condition Equation 4330 is not satisfied and the default values shown in Equation 4327 thru Equation 4329 are assumed, the strength of the concrete material may be incorrectly evaluated. When the crushing capability is suppressed with fc = -1.0, the material cracks whenev a principal stress component exceeds f t. Both the function F and the failure surface S are expressed in terms of principal stress denoted as 1 , 2 , and 3 where: (433 (433 and 1 1. 0 2. 1 3. 1 4. 1 2 1 0 2 2 3. The failure of concrete is categorized into four domains: 2 2 0 3 3 (compression - compression - compression) 3 (tensile - compression - compression) 3 (tensile - tensile - compression) 0 (tensile - tensile - tensile)

In each domain, independent functions describe F and the failure surface S. The four functions describing the general function F are denoted as F 1 , F2 , F3, and F4 while th

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 4

functions describing S are denoted as S1, S2 , S3 , and S4 . The functions S i (i = 1,4) have the properties that the surface they describe is continuous while the surface gradients are not continuous when any one of the principal stresses changes sign. Th surface will be shown in Figure 4.30: 3-D Failure Surface in Principal Stress Space and Figure 4.32: Failure Surface in Principal Stress Space with Nearly Biaxial Stress. These functions are discussed in detail below for each domain.

4.10.1. The Domain (Compression Compression - Compression)

0 1 2 3

In the compression - compression - compression regime, the failure criterion of Willam and Warnke([37]) is implemented. In this case, F takes the form (433

and S is defined as

(433

Terms used to define S are:

(433

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 5

(433 (433

(433

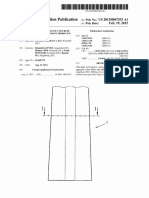

h is defined by Equation 4331 and the undetermined coefficients a0 , a1, a2 , b0 , b1, and b2 are discussed below. This failure surface is shown as Figure 4.30: 3-D Failure Surface in Principal Stress Space. The angle of similarity describes the relative magnitudes of the principal stresses. From Equation 4336, = 0 refers to any stress state such that 3 = 2 > 1 (e.g. uniaxial compression, biaxial tension) while = 60 for any stress state wher 3 >2 = 1 (e.g. uniaxial tension, biaxial compression). All other multiaxial stress sta have angles of similarity such that 0 60. When = 0, S 1 Equation 4335 equals r1 while if = 60, S1 equals r2 . Therefore, the function r1 represents the failu surface of all stress states with = 0. The functions r1 , r2 and the angle are depicted on Figure 4.30: 3-D Failure Surface in Principal Stress Space. Figure 4.30: 3-D Failure Surface in Principal Stress Space

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 6

It may be seen that the cross-section of the failure plane has cyclic symmetry about e 120 sector of the octahedral plane due to the range 0 < < 60 of the angle of similitude. The function r1 is determined by adjusting a0 , a1, and a2 such that ft, fcb, and f1 all lie on the failure surface. The proper values for these coefficients are determined through solution of the simultaneous equations:

(434

with (434

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 7

The function r2 is calculated by adjusting b0 , b1, and b 2 to satisfy the conditions:

(434

2 is defined by: (434

and 0 is the positive root of the equation (434 where a0 , a1, and a2 are evaluated by Equation 4340. Since the failure surface must remain convex, the ratio r1 / r2 is restricted to the rang (434 although the upper bound is not considered to be restrictive since r1 / r2 < 1 for mos

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 8

materials (Willam([36])). Also, the coefficients a 0 , a1 , a2, b0 , b1 , and b2 must satisfy the conditions (Willam and Warnke([37])): (434 (434 Therefore, the failure surface is closed and predicts failure under high hydrostatic pressure ( > 2). This closure of the failure surface has not been verified experiment and it has been suggested that a von Mises type cylinder is a more valid failure surfac for large compressive h values (Willam([36])). Consequently, it is recommended tha values of f1 and f2 are selected at a hydrostatic stress level in the vicinity of or above the expected maximum hydrostatic stress encountered in the structure.

Equation 4344 expresses the condition that the failure surface has an apex at = 0

A profile of r1 and r2 as a function of is shown in Figure 4.31: A Profile of the Failure Surface. Figure 4.31: A Profile of the Failure Surface

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 9

As a Function of

The lower curve represents all stress states such that = 0 while the upper curve represents stress states such that = 60. If the failure criterion is satisfied, the mate is assumed to crush.

4.10.2. The Domain (Tension - Compression Compression)

1 0 2 3

In the regime, F takes the form (434

and S is defined as (4 34

where cos is defined by Equation 4336 and (435

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 10

(435 The coefficients a 0, a1 , a2 , b0, b1 , b2 are defined by Equation 4340 and Equation 4 342 while (435

If the failure criterion is satisfied, cracking occurs in the plane perpendicular to princip stress 1 . This domain can also crush. See (Willam and Warnke([37])) for details.

4.10.3. The Domain (Tension - Tension Compression)

1 2 0 3

In the tension - tension - compression regime, F takes the form (435 and S is defined as (435

If the failure criterion for both i = 1, 2 is satisfied, cracking occurs in the planes

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 11

perpendicular to principal stresses 1 and 2 . If the failure criterion is satisfied only fo = 1, cracking occurs only in the plane perpendicular to principal stress 1 . This domain can also crush. See (Willam and Warnke([37])) for details.

4.10.4. The Domain (Tension - Tension Tension)

1 2 3 0

In the tension - tension - tension regimes, F takes the form (435 and S is defined as (435

If the failure criterion is satisfied in directions 1, 2, and 3, cracking occurs in the plane perpendicular to principal stresses 1, 2, and 3. If the failure criterion is satisfied in directions 1 and 2, cracking occurs in the plane perpendicular to principal stresses 1 and 2 . If the failure criterion is satisfied only in direction 1, cracking occurs in the plane perpendicular to principal stress 1 . Figure 4.32: Failure Surface in Principal Stress Space with Nearly Biaxial

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 12

Stress

Figure 4.32: Failure Surface in Principal Stress Space with Nearly Biaxial Stress

represents the 3-D failure surface for states of stress that are biaxial or nearly biaxial. the most significant nonzero principal stresses are in the xp and yp directions, the three surfaces presented are for zp slightly greater than zero, zp equal to zero, and zp slightly less than zero. Although the three surfaces, shown as projections on the xp - yp plane, are nearly equivalent and the 3-D failure surface is continuous, the mode of material failure is a function of the sign of zp. For example, if xp and yp a both negative and zp is slightly positive, cracking would be predicted in a direction

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

Theory Reference Page: 13

perpendicular to the zp direction. However, if zp is zero or slightly negative, the material is assumed to crush.

Release 14.5 - SAS IP, Inc. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Precast Balanced Cantilever BridgeDocument139 pagesPrecast Balanced Cantilever Bridgeوائل محمد محمودNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- City of Colombo Developmenty PlanDocument107 pagesCity of Colombo Developmenty PlanJeganath KabilNo ratings yet

- City of Colombo Developmenty PlanDocument107 pagesCity of Colombo Developmenty PlanJeganath KabilNo ratings yet

- IMO Regulatory Regime for Ship Safety and Pollution PreventionDocument32 pagesIMO Regulatory Regime for Ship Safety and Pollution PreventionThe Matrix100% (1)

- Axial Shortening of ColumnsDocument10 pagesAxial Shortening of Columnshaitham aliNo ratings yet

- MDSP Diag 1Document3 pagesMDSP Diag 1Tyron RebellonNo ratings yet

- Us 20150047533Document5 pagesUs 20150047533kbkshanakaNo ratings yet

- LabelDocument2 pagesLabelkbkshanakaNo ratings yet

- Test Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModulusDocument1 pageTest Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModuluskbkshanakaNo ratings yet

- Dangerous Goods: Property or The Environment"Document1 pageDangerous Goods: Property or The Environment"kbkshanakaNo ratings yet

- ICTAD-DEV-14 - Fire Regulations (Not Available) PDFDocument17 pagesICTAD-DEV-14 - Fire Regulations (Not Available) PDFAvk SanjeevanNo ratings yet

- Hemp in Construction - Shanaka2Document31 pagesHemp in Construction - Shanaka2kbkshanakaNo ratings yet

- Hemp concrete compression test resultsDocument1 pageHemp concrete compression test resultskbkshanakaNo ratings yet

- ICTAD-DEV-14 - Fire Regulations (Not Available) PDFDocument17 pagesICTAD-DEV-14 - Fire Regulations (Not Available) PDFAvk SanjeevanNo ratings yet

- Test Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModulusDocument1 pageTest Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModuluskbkshanakaNo ratings yet

- ICTAD-DEV-14 - Fire Regulations (Not Available) PDFDocument17 pagesICTAD-DEV-14 - Fire Regulations (Not Available) PDFAvk SanjeevanNo ratings yet

- Cembinder 8 TDSDocument1 pageCembinder 8 TDSkbkshanakaNo ratings yet

- Dangerous Goods: Property or The Environment"Document1 pageDangerous Goods: Property or The Environment"kbkshanakaNo ratings yet

- GFRP Predicted Results SummaryDocument1 pageGFRP Predicted Results SummarykbkshanakaNo ratings yet

- Silica Fume - High Strength ConcreteDocument2 pagesSilica Fume - High Strength ConcretekbkshanakaNo ratings yet

- Test Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModulusDocument1 pageTest Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModuluskbkshanakaNo ratings yet

- Times Me ReportDocument49 pagesTimes Me ReportHitesh BhatiaNo ratings yet

- Silica Fume - High Strength ConcreteDocument2 pagesSilica Fume - High Strength ConcretekbkshanakaNo ratings yet

- Test Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModulusDocument1 pageTest Standard Sample Size Length (MM) Width (MM) Thickness (MM) Tensile Stress ASTM D3039 203.2 12.7 3.2 Tensile ModuluskbkshanakaNo ratings yet

- Abaqus Analysis User's Manual (6Document3 pagesAbaqus Analysis User's Manual (6kbkshanakaNo ratings yet

- Silica Fume - High Strength ConcreteDocument2 pagesSilica Fume - High Strength ConcretekbkshanakaNo ratings yet

- Plasiticity Theory and Implementation in Exp and ImplirityDocument230 pagesPlasiticity Theory and Implementation in Exp and ImpliritykbkshanakaNo ratings yet

- Concrete EOS According To MAT 72 R3Document1 pageConcrete EOS According To MAT 72 R3kbkshanakaNo ratings yet

- Gies Barbecu E: August 8 at 2. 00pmDocument1 pageGies Barbecu E: August 8 at 2. 00pmkbkshanakaNo ratings yet

- Rate Dependent Plasticity Theory ManualDocument69 pagesRate Dependent Plasticity Theory ManualkbkshanakaNo ratings yet

- HPC Applications in France - ToutlemondeDocument18 pagesHPC Applications in France - ToutlemondekbkshanakaNo ratings yet

- Concrete ModelDocument13 pagesConcrete ModelkbkshanakaNo ratings yet

- Problem Set 3Document4 pagesProblem Set 3ReemALMousawiNo ratings yet

- Strength Properties of Plastic Bottle Bricks and Their Suitability As Construction Materials in Bangladesh PDFDocument7 pagesStrength Properties of Plastic Bottle Bricks and Their Suitability As Construction Materials in Bangladesh PDFAniel DiasNo ratings yet

- Thermal Stress Glass Cup ExampleDocument5 pagesThermal Stress Glass Cup ExampleTarek_ElmelegyNo ratings yet

- Buckling & Heat Transfer Analysis PDFDocument28 pagesBuckling & Heat Transfer Analysis PDFSwaraj Deep SharmaNo ratings yet

- Fatigue Behaviour of The Aeronautical Al-Li (2198) Aluminum AlloyDocument28 pagesFatigue Behaviour of The Aeronautical Al-Li (2198) Aluminum AlloyRichard HilsonNo ratings yet

- Code Based Fatigue Life Prediction and Validation of Pressure Vessel StressesDocument9 pagesCode Based Fatigue Life Prediction and Validation of Pressure Vessel StressesAdrian StoicescuNo ratings yet

- Finite Element Analysis Course ContentsDocument52 pagesFinite Element Analysis Course Contentsvivek panchalNo ratings yet

- KalaiyarasanDocument5 pagesKalaiyarasanBarath NMNo ratings yet

- Castinglianos Theorem ProofDocument5 pagesCastinglianos Theorem ProofkmssaileshNo ratings yet

- Analyse de La Déformation Et Évaluation de La Sécurité Des Tunnels de Métro ExistantsDocument11 pagesAnalyse de La Déformation Et Évaluation de La Sécurité Des Tunnels de Métro ExistantsMed El Hadi AbidiNo ratings yet

- Glass ConsultingDocument29 pagesGlass ConsultingJUAN DAVID AGUIRRE AVILANo ratings yet

- Vancouver Geotechnical Society: Critical State Soil Mechanics: NotesDocument57 pagesVancouver Geotechnical Society: Critical State Soil Mechanics: Notesa4abhirawatNo ratings yet

- 3D - On The Influence of Face Pressure, Grouting Pressure and TBM Design in Soft Ground TunnellingDocument12 pages3D - On The Influence of Face Pressure, Grouting Pressure and TBM Design in Soft Ground TunnellingTai TienNo ratings yet

- SOM ManualDocument43 pagesSOM ManualHuzaifa DarNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Dynamic Analysis of Tunnel in Weathered Rock Subjected To Internal Blast LoadingDocument18 pagesDynamic Analysis of Tunnel in Weathered Rock Subjected To Internal Blast LoadingSanjivani SharmaNo ratings yet

- 3959 1475Document130 pages3959 1475ElafanNo ratings yet

- RCC Shear Wall Analysis and DesignDocument31 pagesRCC Shear Wall Analysis and DesignSiddharthJoshiNo ratings yet

- Astm d1004Document4 pagesAstm d1004Ishtiaq HussainNo ratings yet

- Numerical Simulation of Cavitation Process in Diesel InjectorsDocument226 pagesNumerical Simulation of Cavitation Process in Diesel Injectorsfivos_rgNo ratings yet

- Load rating guidance for bolted and riveted gusset platesDocument48 pagesLoad rating guidance for bolted and riveted gusset platesSaeedNo ratings yet

- Chapter7 PDFDocument34 pagesChapter7 PDFWillian DiazNo ratings yet

- Chapter 7 - Structural AnalysisDocument34 pagesChapter 7 - Structural AnalysisDenice Castro100% (1)

- In Uence of Pre-Gelatinised Maize Starch On The Rheology, Microstructure and Processing of Imitation CheeseDocument8 pagesIn Uence of Pre-Gelatinised Maize Starch On The Rheology, Microstructure and Processing of Imitation CheeseLina1929No ratings yet

- Me414 Lecture 1 Analysis of Simple StressesDocument19 pagesMe414 Lecture 1 Analysis of Simple StressesILEENVIRUSNo ratings yet