Professional Documents

Culture Documents

Model of Risk Assessment

Uploaded by

Tony GallacherOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model of Risk Assessment

Uploaded by

Tony GallacherCopyright:

Available Formats

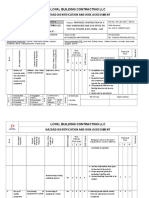

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

Company Name: . Work Description: ..

Risk

S/N

Permit Type: ............. Date: ...

Activity

Hazard

Probability (P)

Severity (S)

Risk Rating (PXS)

Control Measures Toolbox talk prior to start work. Cotton gloves, goggles, safety shoes, long-sleeve coverall & helmet are provided as Personal Protective Equipment (PPE). Use approved tools only. No home-made or damage tools allowed. Only trained personnel to operate. All moving parts to be guarded. Switched off machines when not in use. PPE (gloves, safety glasses, helmet, safety shoes, & coverall) are provided. Good ventilation & lighting. Use dust mask & work at ventilated area. Use rubber gloves while applying wood glue & follow the instruction from Material Safety Data Sheet (MSDS). Machinery to be maintained properly. Inspections to be carried out. Use of earplugs.

Injury from tools, flying nails or wooden pieces

Carpentry works (include fixing of internal/external wooden elements, doors, wall panel & gypsum boards)

Injury from wood working machines.

16

Exposure to wood dust and wood glue/adhesive.

Release of noise.

12

Document No: ADM HSEI GL 02

Issue no: 01

Issue Date: 11.01.2011

Page: 1 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

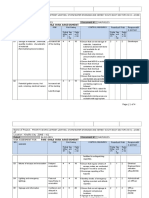

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

Risk

S/N

Activity

Hazard

Probability (P)

Severity (S)

Risk Rating (PXS)

Control Measures Skips/bins for collection & sorting wood waste from other wastes to be provided in the area. Waste to be removed from the area to designated area before it overflows. Toolbox talk before work stars to be conducted. Training & toolbox talk to be provided. Proper PPE for hand, foot, body & respiratory protection are provided. Chemical containers must be covered if not in use & stored in suitable chemical store. Cleaning of any excess or spilled paints/chemicals immediately. Spill kits to be provided. Paints/chemicals should be kept to minimum quantity at site, & must be stored in tight & proper containers or drums. Provision of dripping trays where applicable. Carry out periodical inspection for machine, disc, extension cables & connections. Wear face shield & safety glass,

Carpentry works (include fixing of internal/external wooden elements, doors, wall panel & gypsum boards)

Waste generation may lead to pollution & contamination.

Chemical hazards such as inhalation & exposure to paints & chemicals vapors & mists, which may cause health implications (respiratory system & eyes related).

2

Painting & polishing Paints /chemicals spillage, which may leads to soil pollution & contamination.

Grinding/cutting

Disc breaking / flying fragments caught in eye or cause injury or wounds. Flying- off sparks may cause injury or fire.

Issue no: 01

Document No: ADM HSEI GL 02

Issue Date: 11.01.2011

Page: 2 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

Risk

S/N

Activity

Hazard

Probability (P)

Severity (S)

Risk Rating (PXS)

Control Measures leather gloves, safety shoes, fire retardant clothing & safety helmet. Grinding wheels stored on hangers. Do not place machine down. Provision of fire extinguisher. Cable protectors to be used while crossing pathway (if no other route can not be found). Earth Leakage Circuit Breaker (ELCB) to be provided & ensure proper earthing. Operator to use gloves. Maintain follow-up & checks. Toolbox talks to be conducted before work starts. Full personal protective equipment to be used at all times (i.e. gloves), breaks to be taken as & when required. Toolbox talks should be convened before work starts. Provision of suitable respiratory protective equipment, i.e. air fed face shield or mask (with cartridge). Where necessary, work area shall be enclosed to protect other workers/vicinity or

Electric shock or burns.

15

Grinding/cutting

Vibration which may lead to white finger (Hand Arm Vibration Syndrome, HAVS)

12

Exposure to fumes and dust in case of paint removal which may lead to health hazards.

Document No: ADM HSEI GL 02

Issue no: 01

Issue Date: 11.01.2011

Page: 3 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

Risk

S/N

Activity

Hazard

Probability (P)

Severity (S)

Risk Rating (PXS)

Control Measures barriers shall be erected around the work area to prevent access.

Grinding/cutting

Slip, trip & fall due to improper arrangement of electrical cables/leads. Flying particles & slags may cause eyes or skin injuries. Emitted ultra-violet ray and arc will lead to eyes irritation.

Cables/leads shall be tied , secured & fixed properly. Welders to wear full face welding mask (welding hood) with dark eye protection. Dark safety glasses for helpers. Toolbox talks should be conducted before job starts. Extractors shall be used at all times for any welding and cutting activities. Welding hood & cartridge mask should be used. Periodical inspection for electrical welding equipment. ELCB to be provided and ensure proper earthing & testing to be conducted. Electrode holders are to be properly insulated & have no bare parts except electrode itself. Welding cables are to be connected properly.

12

Inhalation of toxic fumes & gases may lead to health implications.

4

12

Welding and flame cutting

Electric shock, or electrocution.

15

Document No: ADM HSEI GL 02

Issue no: 01

Issue Date: 11.01.2011

Page: 4 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

Risk

S/N

Activity

Hazard

Probability (P)

Severity (S)

Risk Rating (PXS)

Control Measures leather gloves & safety boot. Only trained & authorized personnel to use welding machine. Enclose welding area as possible & use fire blanket/fire extinguisher as required. Use of hot work permit. Toolbox talks should be conducted before job starts. Oxygen, acetylene and/or propane cylinders shall be secured & provided with regulator & flash back arrestor. Allocation of suitable fire extinguisher. All scaffolding/platforms material to be of sound materials. Provision of edges protection & life- line. Training & toolbox talk to be conducted. Only trained scaffolders/specialists to be used on the job. Use appropriate PPE. Only certified body harnesses to be used. Use of appropriate tools.

Skin burns and fire

Welding and flame cutting

Gas leakage, fire or explosion (from acetylene /propane cylinders when using flame cutting).

15

Use of scaffolding and platforms (cradles)

Fall from height may lead to injury or fractures.

Document No: ADM HSEI GL 02

Issue no: 01

Issue Date: 11.01.2011

Page: 5 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

Risk

S/N

Activity

Hazard

Probability (P)

Severity (S)

Risk Rating (PXS)

Control Measures Scaffolding/platforms to be erected as per applicable standards. Manual handling as per procedure. Continuous supervision on the job. Scaff tag system to be adopted. Provide adequate warning signs. Scaffolding/platforms to be inspected by certified inspectors prior of usage. Toolbox talks before job starts. Equipped with fully boarded platforms that are wide enough for the work and access. Equipped with appropriate protective measures to prevent people or objects falling from height. Guardrails and toe boards. Provided with a safe means of access. Ladders to be tied on top & bottom. Home-made ladders are not allowed. Safe landing distance (1 meter) on the top of the ladder should be maintained. Toolbox talk about proper use of suitable ladders to be provided.

Scaffolds/platform s collapsing can cause injury, fatality or damage.

Use of scaffolding and platforms (cradles)

Falling of materials may lead to injury or fractures.

12

Use of ladders

Fall from height may lead to injury or fractures.

12

Document No: ADM HSEI GL 02

Issue no: 01

Issue Date: 11.01.2011

Page: 6 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

Risk

S/N

Activity

Hazard

Probability (P)

Severity (S)

Risk Rating (PXS)

Control Measures Only fiber glass-made ladder or inspected wooden manufactured ladder to be used. Proper isolation of the electrical source. Toolbox talks before job commences. Required safety equipments to be used in DBs (e.g. Breakers, ELCB). Applying work permit, lockout/tagout procedure & isolation. Provision of suitable PPE. Allocation of suitable fire extinguisher. Training and toolbox talk to be provided. Provision of suitable PPE (gloves, long-sleeve coverall. Appropriate tools should be used. Toolbox talks should be provided. Suitable Personal Protective Equipment (PPE) must be worn, e.g. mask, goggle, gloves, long sleeve coverall, safety shoes. MSDS (Material Safety Data Sheet) should be obtained and read carefully. Arranging of tool box talk before work begins.

Electrocution when unsuitable ladder (metallic) used on electrical work.

15

Electrical shocks, burns or electrocution and fire. Electrical works (installation, & maintenance). Cuts, laceration & bruises in case of termination cables and wires. Inhalation of vapors and fumes may lead to health effects (upper & lower respirator y system. Splash into eyes may lead to irritation and harm. Suffocation in case of poor ventilation Exposure, contact & absorption through skin may cause burns and dermatitis

Issue no: 01

15

12

Working with chemicals and solvents.

Document No: ADM HSEI GL 02

Issue Date: 11.01.2011

Page: 7 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

Risk

S/N

Activity

Hazard

Probability (P)

Severity (S)

Risk Rating (PXS)

Control Measures Provision of suitable fire extinguisher close-by. Smoking in not allowed in working area. Cleaning of any excess or spilled chemicals immediately. Spill kits to be provided. Chemicals should be kept to minimum quantity at site, & must be stored in tight & proper containers or drums. Provision of dripping trays where applicable. Proper tools should be used. Suitable PPE to be provided. Toolbox talk to be conducted regularly. Proper ventilation & provision of suitable PPE (mask, of face shield) Good sorting & storing of materials. Appropriate housekeeping. Suitable Personal Protective Equipment (PPE) must be worn, e.g. mask, goggle, gloves, safety shoes/boot, and long-sleeve coverall.

Fire

10

Working with chemicals and solvents. Leakage and spillage may lead to soil pollution 2 2 4

Cuts and laceration caused by using hand tools.

8

Plumbing, fixing toilets set and sanitary wares, ceramics and tiles.

Suffocation caused by using glues, silicon and solvents. Trips and falls which may lead to injury. Inhalation of odors, vapors & fumes may lead to health effects (respirator y system). Splash into eyes may lead to irritation.

Issue no: 01

Plastering

12

Document No: ADM HSEI GL 02

Issue Date: 11.01.2011

Page: 8 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

Risk

S/N

Activity

Hazard Exposure & contact into skin may cause inflammation & dermatitis. Inhalation & contact with cement & powder may cause skin dermatitis, eyes and respiratory system inflammation. Health hazard related to the skin contact with concrete may cause skin inflammation. Health hazards such as muscles Strains/sprains and back pain. Slips, trips & falls which may lead to injury or harm.

Probability (P)

Severity (S)

Risk Rating (PXS)

Control Measures Good ventilation must be maintained. MSDS (Material Safety Data Sheet) should be obtained and read carefully. Arranging of tool box talk before work begins.

Plastering

12

10

Using concrete and cement mortar.

12

11

Manual handling

Fall of load which may lead to body injury or fracture.

12

Any high risk task should be identified and mechanized. Package size must be reduced, lifting aid is used, and load is secured. Access routes shall be kept clear at all times. Suitable PPE shall be worn to protect feet, legs and hands. Toolbox talk should be conducted before work starts.

Document No: ADM HSEI GL 02

Issue no: 01

Issue Date: 11.01.2011

Page: 9 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

Risk

S/N

Activity

Hazard

Probability (P)

Severity (S)

Risk Rating (PXS)

Control Measures

12

All activities

Generation of wastes and debris which may lead to contamination and pollution.

Skips/bins for collection and segregation of waste and debris must be provided in the site. Waste & debris to be removed from the site to designated approved disposal area. Toolbox talk about proper collection and segregation of waste should be conducted.

Document No: ADM HSEI GL 02

Issue no: 01

Issue Date: 11.01.2011

Page: 10 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

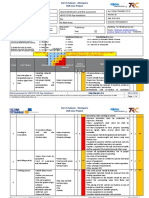

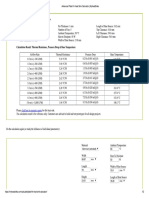

Risk Grading Matrix Risk Grading Matrix

SEVERITY PROBABILITY Rare (1) Possible (2) Likely (3) Often (4) Frequent/Almost Certain (5) 15 - 25 8 - 12 46 1 -3 Extreme Risk High Risk Moderate Risk Low Risk Insignificant (1) 1 2 3 4 5 Minor (2) 2 4 6 8 10 Moderate (3) 3 6 9 12 15 Major (4) 4 8 12 16 20 Catastrophic (5) 5 10 15 20 25

Absolutely Unacceptably High Activity or industry should not proceed in current form Unacceptably High Activity or industry should be modified to include remedial planning and action and be subject to detailed HSE assessment Acceptable but must be managed at As Low As Reasonably Practicable (ALARP) Activity or industry can operate subject to management and / or modification Acceptable without required further action No action required unless escalation of risk is possible

Hierarchy of Control (Controls identified may be a mixture of the hierarchy in order to provide minimum operator exposure) Risk Grading Matrix

Elimination Substitution Engineering Controls Administrative Controls Personal Protective Equipment Eliminate the hazard. Provide an alternative that is capable of performing the same task and is safer to use. Provide or construct a physical barrier or guard or technical measures Develop policies, procedures practices and guidelines, in consultation with employees, to mitigate the risk. Provide training, instruction and supervision about the hazard. Personal equipment designed to protect the individual from the hazard.

Document No: ADM HSEI GL 02

Issue no: 01

Issue Date: 11.01.2011

Page: 11 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

MANAGEMENT PROCEDURES MANUAL Model of Risk Assessment

Prepared By: ....

Approved By: ...

Designation: .

Designation: ..

Signature: .....

Signature: ..

Companys Stamp:

Document No: ADM HSEI GL 02

Issue no: 01

Issue Date: 11.01.2011

Page: 12 of 12

Copies of this document available in ADM HSE Intranet are only the latest, valid and controlled documents. All other copies are uncontrolled and valid only on the date printed. Last printed: 1/12/2011 9:53:00 AM

You might also like

- Risk AssessmentDocument6 pagesRisk Assessmentkaruppusamymari100% (1)

- 125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتDocument3 pages125 MVA 400 KV Transformer Overhauling at site.: Risk Assessment And Analysis رطاـــــخملا مــــــييقتeng_hma75% (4)

- 6-Steel Work Risk Assessment ReportDocument7 pages6-Steel Work Risk Assessment ReportSyed Ali Hassan67% (3)

- Risk AssessmentDocument10 pagesRisk AssessmentKyaw Kyaw Aung89% (9)

- Safety Risk AssessmentDocument52 pagesSafety Risk Assessmentmujahid113794% (36)

- Hazard Identification Risk Assessment and Risk ControlDocument7 pagesHazard Identification Risk Assessment and Risk ControlChowKC03100% (17)

- Supervisor's Investigative Report Form and InsructionsDocument2 pagesSupervisor's Investigative Report Form and InsructionsRyan FlemingNo ratings yet

- Contractor Risk Assessment FormDocument5 pagesContractor Risk Assessment FormRoger Simbhoo100% (1)

- Risk AssessmentDocument10 pagesRisk Assessmentalamdar321100% (2)

- Risk Assessment of Scaffolding Works - Rev. 1Document20 pagesRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- Risk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONDocument6 pagesRisk Ass - TK-4742-WELDING ACTVITIES FOR REST AREA PREPARATIONnsadnanNo ratings yet

- Forklift Risk AssessmentDocument6 pagesForklift Risk AssessmentMoayed Altaweel76% (29)

- Task Specific Risk AssessmentDocument22 pagesTask Specific Risk Assessmentsimone92% (12)

- Sample Risk AssessmentDocument12 pagesSample Risk Assessmentpaansaeng82% (17)

- Full Risk Assessment Package PDFDocument75 pagesFull Risk Assessment Package PDFDaDemon100% (1)

- 4.2 - Risk Assessment Project - SAMPLEDocument3 pages4.2 - Risk Assessment Project - SAMPLEDhana Sekar71% (21)

- Project Risk Assessment For Design and ConstructionDocument32 pagesProject Risk Assessment For Design and ConstructionAjas Aju100% (31)

- 002 Working at Height Risk AssessmentDocument4 pages002 Working at Height Risk Assessmentgangadharan000100% (14)

- Project:: Fujairah F3 Independent Power Project (IPP) Electrical Special Facility (ESF) - 400KV SWITCHING STATIONDocument20 pagesProject:: Fujairah F3 Independent Power Project (IPP) Electrical Special Facility (ESF) - 400KV SWITCHING STATIONghaleb alhourani100% (1)

- Office Risk Assessment SampleDocument3 pagesOffice Risk Assessment SampleGanchocute80% (5)

- SWP 002 - Risk AssessmentDocument23 pagesSWP 002 - Risk AssessmentAbhinavBanerjee100% (2)

- Risk Assessment ConstructionDocument70 pagesRisk Assessment ConstructionArun Celestin93% (42)

- Risk Assessment Template For Fit-OutDocument5 pagesRisk Assessment Template For Fit-OutJedz Gumapas79% (14)

- All Tyeps Risk Assessment in Construction PDFDocument112 pagesAll Tyeps Risk Assessment in Construction PDFSorin Tec100% (1)

- Risk Assessment of Construction ProjectsDocument15 pagesRisk Assessment of Construction ProjectsShashi RanjanNo ratings yet

- Example Risk Assessment For ExcavationsDocument3 pagesExample Risk Assessment For ExcavationsYaser A. Al-Bustanji72% (18)

- Site Activities Risk AssessmentDocument50 pagesSite Activities Risk Assessmentjamie542393% (41)

- Working at Height Risk AssessmentDocument7 pagesWorking at Height Risk AssessmentAshish100% (3)

- RA-LBC-007 Risk Assessment Concrete WorksDocument8 pagesRA-LBC-007 Risk Assessment Concrete Worksjones100% (1)

- 3-REV.1 - Hot Work - Risk Assessment JHADocument16 pages3-REV.1 - Hot Work - Risk Assessment JHAnaiyar100% (1)

- Baseline Risk Assessment & Hazard Identification With Ohs SpecificationDocument21 pagesBaseline Risk Assessment & Hazard Identification With Ohs SpecificationschoemanNo ratings yet

- Risk Assessment For Cable InstallationDocument15 pagesRisk Assessment For Cable InstallationKaruppu Samy86% (7)

- Office Risk AssessmentDocument4 pagesOffice Risk AssessmentRameeSahiba100% (1)

- Fire Risk Assessment TemplateDocument39 pagesFire Risk Assessment TemplateDhira 'Princess Kalonk' Anindita67% (3)

- 13.2.4 RA SWP For Cable Installation Glanding Terminating Testing To Site Cabins at DCLDocument13 pages13.2.4 RA SWP For Cable Installation Glanding Terminating Testing To Site Cabins at DCLMARIAN100% (1)

- Fire Risk Assessment-Rev 001Document5 pagesFire Risk Assessment-Rev 001ramodNo ratings yet

- Safety Management MidtermDocument23 pagesSafety Management MidtermKent Edve Neil Rabe100% (1)

- 2 Risk Assessment Rev 00 EHS FormatDocument45 pages2 Risk Assessment Rev 00 EHS Formatkumar100% (1)

- RA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & TrenchesDocument11 pagesRA 020 Risk Assessment - Risk Assessment - Installation of Cables in Ducts & Trenchesthomson100% (1)

- Construction Risk Assessment PackDocument41 pagesConstruction Risk Assessment Packmasoodae100% (4)

- Risk AssessmentDocument9 pagesRisk AssessmentSAYED100% (4)

- Risk Assessment Construction SiteDocument9 pagesRisk Assessment Construction SiteJuned Hamid Khan100% (2)

- Risk AssessmentDocument4 pagesRisk AssessmentSyedQamarIqbal50% (2)

- DSM-FRM-0001-27-0, HDPE PE-100 Pipe InstallationDocument4 pagesDSM-FRM-0001-27-0, HDPE PE-100 Pipe Installationkadir tanzaniaNo ratings yet

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- 28 Job Safety AnalysisDocument7 pages28 Job Safety Analysisashish_kamat100% (3)

- Excavation Risk Assessment SheetDocument3 pagesExcavation Risk Assessment SheetMuhammad Ibrahim93% (46)

- Electrical Installation Risk AssesmentDocument6 pagesElectrical Installation Risk AssesmentSumit KumarNo ratings yet

- Iosh Risk AssessmentDocument3 pagesIosh Risk Assessmentmilan shrestha80% (25)

- Example Risk Assessment For Contract Bricklayers: How Was The Site-Specific Risk Assessment Done? Setting The SceneDocument16 pagesExample Risk Assessment For Contract Bricklayers: How Was The Site-Specific Risk Assessment Done? Setting The SceneWeei Zhee70No ratings yet

- Risk Assessment For Tank BaseDocument5 pagesRisk Assessment For Tank Baseramod100% (2)

- Risk Assessment - GeneralDocument10 pagesRisk Assessment - Generallasenggo100% (2)

- Driver Risk-Assessment-And-Policy-Template 5Document3 pagesDriver Risk-Assessment-And-Policy-Template 5api-309414767100% (1)

- RA.013 - Green Field Risk Assessment (Demolision Works For HMR & SR Ext of PL1&2) .Rev.02Document41 pagesRA.013 - Green Field Risk Assessment (Demolision Works For HMR & SR Ext of PL1&2) .Rev.02Venkadesh Periathambi100% (3)

- GL 28 Material Loading PlatformDocument1 pageGL 28 Material Loading Platformtp101267No ratings yet

- Scaffolding Risk AssessmentDocument3 pagesScaffolding Risk AssessmentAlexandru Ghigea100% (1)

- JSA FormDocument6 pagesJSA FormAjeesh CochinNo ratings yet

- Risk Assessment No. 41 WORKING IN MACHINERY SPACE Rev. 02 20Document3 pagesRisk Assessment No. 41 WORKING IN MACHINERY SPACE Rev. 02 20Devi Ratna Pratiwi100% (3)

- How Chin Engineering: Job Safety AnalysisDocument6 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Belt & Orbital Sander PDFDocument2 pagesBelt & Orbital Sander PDFcityofdarwingisNo ratings yet

- DIAC DIFC ComparisonDocument4 pagesDIAC DIFC ComparisonTony GallacherNo ratings yet

- Technical Guidance Document For Construction Environmental Management Plan (CEMP)Document31 pagesTechnical Guidance Document For Construction Environmental Management Plan (CEMP)Tony GallacherNo ratings yet

- Forestry Note, How To Install A Forest Road CulvertDocument4 pagesForestry Note, How To Install A Forest Road CulvertTony GallacherNo ratings yet

- Viking Johnson Maxi FitDocument12 pagesViking Johnson Maxi FitTony GallacherNo ratings yet

- 2013-2014 Worldwide Personal Tax GuideDocument1,399 pages2013-2014 Worldwide Personal Tax GuideTony GallacherNo ratings yet

- Kentanks BrochureDocument2 pagesKentanks BrochureJoel Ochieng50% (2)

- Mss AudidriverDocument3 pagesMss AudidriverTony GallacherNo ratings yet

- The Sand Book PDFDocument126 pagesThe Sand Book PDFTony GallacherNo ratings yet

- QS Manual (QS) - ReferenceDocument44 pagesQS Manual (QS) - ReferenceGani Osal TyNo ratings yet

- Boiler Book 2010Document1,419 pagesBoiler Book 2010Izali NizarNo ratings yet

- The Theory of ImprevisionDocument12 pagesThe Theory of ImprevisionTony GallacherNo ratings yet

- A&D Bedrooms V Michael PDFDocument5 pagesA&D Bedrooms V Michael PDFTony GallacherNo ratings yet

- Epa Water Treatment Manual PreliminaryDocument111 pagesEpa Water Treatment Manual PreliminaryTony GallacherNo ratings yet

- Delay and Disruption ClaimsDocument13 pagesDelay and Disruption ClaimsTony GallacherNo ratings yet

- Overview of Smoke Control System DesignDocument7 pagesOverview of Smoke Control System DesignTony GallacherNo ratings yet

- The IBA Conflict Guidelines - Who Is Using Them and How PDFDocument15 pagesThe IBA Conflict Guidelines - Who Is Using Them and How PDFTony GallacherNo ratings yet

- 157 E.R. 709Document5 pages157 E.R. 709Tony GallacherNo ratings yet

- Y62 Patrol Full EditionDocument163 pagesY62 Patrol Full EditionEric Golden100% (8)

- 2SK2188Document2 pages2SK2188Abigail HoobsNo ratings yet

- On Aircraft ComDocument24 pagesOn Aircraft ComAakriti GuptaNo ratings yet

- Pioneer PDP-501MX Plasma DisplayDocument96 pagesPioneer PDP-501MX Plasma DisplayJavier RodriguezNo ratings yet

- CATALO VetivDocument240 pagesCATALO VetivHữu CôngNo ratings yet

- I.Objectives: Grades 1 To 12 Daily Lesson Log School Grade Level Teacher Learning Area Teaching Dates and Time QuarterDocument4 pagesI.Objectives: Grades 1 To 12 Daily Lesson Log School Grade Level Teacher Learning Area Teaching Dates and Time QuarterMarryShailaine CletNo ratings yet

- TractionBatteries Technical WebDocument20 pagesTractionBatteries Technical WebnarakribNo ratings yet

- BEAFAd 01Document124 pagesBEAFAd 01Vina Zavira NizarNo ratings yet

- Operations Management: William J. StevensonDocument36 pagesOperations Management: William J. StevensonRubel Barua100% (4)

- DatasheetDocument4 pagesDatasheetJs CameloNo ratings yet

- Mohiuddin Ahmad and Rafiqul Tarefder Department of Civil Engineering, University of New MexicoDocument1 pageMohiuddin Ahmad and Rafiqul Tarefder Department of Civil Engineering, University of New MexicoMohiuddin AhmadNo ratings yet

- Rotork: Product TrainingDocument4 pagesRotork: Product TraininghieuNo ratings yet

- XII Bahasa Inggris No. 16-18Document3 pagesXII Bahasa Inggris No. 16-18Auryn AnastashaNo ratings yet

- DCTN Lsqmdocu63774Document21 pagesDCTN Lsqmdocu63774Bharani KumarNo ratings yet

- The Butt Joint Tool: Product InformationDocument8 pagesThe Butt Joint Tool: Product InformationElias de Souza RezendeNo ratings yet

- Manual Redutores SEWDocument154 pagesManual Redutores SEWLucas Issamu Nakasone PauloNo ratings yet

- Methodology: Procedure For Checking of VerticalityDocument6 pagesMethodology: Procedure For Checking of VerticalityDinesh Kumar PatelNo ratings yet

- CV - Shakir Alhitari - HR ManagerDocument3 pagesCV - Shakir Alhitari - HR ManagerAnonymous WU31onNo ratings yet

- Mode ReversionsDocument15 pagesMode ReversionsISHAANNo ratings yet

- Design Checklist-9 USACE AngineeringDocument15 pagesDesign Checklist-9 USACE AngineeringSankar CdmNo ratings yet

- BSNL CRM FTTH User Manual - Release1.0 - ShiftDocument25 pagesBSNL CRM FTTH User Manual - Release1.0 - ShiftJTONIB AIZAWLNo ratings yet

- All C PG and CPP Service ManualDocument60 pagesAll C PG and CPP Service Manualhurantia100% (1)

- Advanced Plate Fin Heat Sink Calculator - MyHeatSinksDocument2 pagesAdvanced Plate Fin Heat Sink Calculator - MyHeatSinksHarsh BhardwajNo ratings yet

- Cyber Bully ArticleDocument2 pagesCyber Bully ArticleCharline A. Radislao100% (1)

- R Values For Z PurlinsDocument71 pagesR Values For Z PurlinsJohn TreffNo ratings yet

- Classroom PoliciesDocument4 pagesClassroom PoliciesadrianrivalNo ratings yet

- Data0305 KX18DCDocument3 pagesData0305 KX18DCAbdelhamid SammoudiNo ratings yet

- Real Time Blood Type Determination by Gel Test Method On An Embedded SystemDocument4 pagesReal Time Blood Type Determination by Gel Test Method On An Embedded Systemngocbienk56No ratings yet

- Sony Video Camera Manual PDFDocument118 pagesSony Video Camera Manual PDFGary Hoehler100% (1)

- Electrical Machines (K-18EL101) (Mid-Term Presentation)Document11 pagesElectrical Machines (K-18EL101) (Mid-Term Presentation)Noor SabaNo ratings yet