Professional Documents

Culture Documents

Appendix-1 (HAZOPWorksheets)

Uploaded by

zohaib_farooqOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix-1 (HAZOPWorksheets)

Uploaded by

zohaib_farooqCopyright:

Available Formats

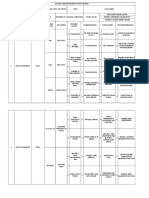

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-1 Ref. Drawings ID Guideword Karachi University Inlet of Compressor KU-0007PID-001 Deviation

Causes

Consequences

Safeguards

Recommendation

Action #

FCV not present Air inlet filter damage

A

flow

More

Possible liquid formation

1. High velocity may lead 1. Proper monitoring of to Erosion pressure diffrential across 2. Production loss filter

1. Install FCV 2. Install block and bleed arrangement

FCV not present AIR inlet filter block 1. Deferred Production

B

Install FCV

Flow

Low / No

1. SOP of pressure monitoring across air filter is present

Flow

Reverse

N/A

N/A

Compressor control malfunction Inadvertent closing of any inline isolation valve

D

Pressure

High

1. Deferred Production 2. High Pressure at upstream

1. Pressure Transmitter available 2. SOPs in place 3. Maintenance procedures incorporated

Pressure

Low

1.FCV partially closed or malfuntion 2. Inadvertent handling 3.Blockage of air filter Line rupture

1. Deferred Production

1. Pressure transsmitter available 2. Environmental Damage 2. SOPs in place

Level

High

N/A N/A

Level

Low

Temperature

High

N/A

Temperature

Low

n/a

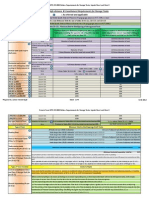

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-3 Ref. Drawings ID Guideword Karachi University Chiller upstream and downstream KU-0007-PID-001 Deviation Causes Consequences Safeguards Recommendation Action #

flow

More

1.Compressor control malfunction 2. 1.Compressor control malfunction 2.HEX choke

1. High velocity may lead 1. Proper monitoring to Erosion 2.high flow triping 2. Production loss available 3.comperssor tripping

Flow

Low / No

1. Production loss 2.plant shutdown

1.SOP developed

Pressure

High

1.Compressor control malfunction 2.antisurge valve malfunction 3.may leads to leakage

1. High Pressure at upstream 2. High velocity may lead to Erosion

1. Pressure Transmitter available 2. SOPs in place 3. Maintenance procedures incorporated

Pressure

Low

1.compressor triping 2.due to leakage

1. Deferred Production

1. Pressure transsmitter available 2. Environmental Damage 2. SOPs in place

Level

High

N/A N/A

Level

Low

Temperature

High

1. inefficient working of Chiller. 2.compersor malfunction

1.Compresor trip 2.plant shutdown 3.chiller work not proper

1.temparature transmitter available compressor internal available

Temperature

Low

1.TCV not working properly 1. Deferred Production 2.chiller not working 2. production off spec. properly

1.SOP in line 2.chiller schedule maintance in place.

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-2 Ref. Drawings ID Guideword Karachi University compressor Upstream KU-0007-PID-001 Deviation Causes Consequences Safeguards Recommendation Action #

inlet FCV not present

A

flow

More

1. High velocity may lead 1. Proper monitoring of to Erosion pressure diffrential across 2. Production loss filter

1. Install FCV

Filter choke

Flow

Low / No

1. Production loss 2.plant shutdown

1. Proper monitoring of pressure diffrential across filter 2.SOP developed

Compressor control malfunction Inadvertent closing of any inline isolation valve

D

Pressure

High

1. Deferred Production 2. High Pressure at upstream

1. Pressure Transmitter available 2. SOPs in place 3. Maintenance procedures incorporated

Pressure

Low

1.inlet FCV partially closed or malfuntion 2. Inadvertent handling 3.Blockage of air filter Line rupture

1. Deferred Production

1. Pressure transsmitter available 2. Environmental Damage 2. SOPs in place

Level

High

N/A N/A

Level

Low

Temperature

High

N/A

Temperature

Low

n/a

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-2 Ref. Drawings ID Guideword ENAR Head Office Downstream of Wellhead Latif-6 to the Suction of Wellhead Compressor A-470 & A-480 (FCV-671) 5007-11-16-10-PD-603-01, 5007-11-16-10-PD-604-01, 5010-11-16-10-PD-116-01 Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Choke valve FCV-612 fail open FIC-612 malfunction Compressor overspeed Compressor by-pass valve leakage or passes

A

Flow

More

FIC-671 malfunction leads to fully open (more than required) FCV-672 stuck close Inadvertent opening of isolation valve of vent/PSV617A/B passing Line rupture

1. High velocity may lead to Erosion 2. Production loss 3. Low pressure at compressor suction (A480)

1. Erosion Probe Installed 2. Adequate piping design 3. Compressor overspeed trip 4.

1. F&G Detection are in 1. Fire Hazard place 2. Production Loss 2. Pressure alarm low low 3. Environmental Damage & trip (16-PALL-615)

Choke valve FCV-612 fail close

Flow

Low / No

Inadvertent closing of any inline isolation valve

1. Deferred Production 2. High Pressure at upstream

1. Pressure alarm low low & trip (16-PALL-615) 2. Pressure alarm high high & trip (16-PAHH-615) 3. SOPs in place 4. Maintenance procedures incorporated 5. Pigging procedures in place

Choking of Cooler(E-1660) tubes

C

Flow

Reverse

1. Compressor by-pass valve leakage or passes 2. Choke valve FCV-612 fail close Inadvertent closing of any inline isolation valve

1. More flow at compressor suction 2. Deferred Production 1. High Pressure at upstream

NRV located at by-pass

Pressure

High

Choking of FE-612 Compressor control malfunction Water slugging FCV-671/672 stuck close Choking of Cooler tubes 2. Deferred Production

1. Pressure alarm low low & trip (16-PALL-615) 2. Pressure alarm high high & trip (16-PAHH-615) 3. SOPs in place 4. Maintenance procedures incorporated 5. Pigging procedures in place

Pressure

Low

1. Choke valve partially (less than required) closed/FIC-612 malfunction 2. Wellhead shutdown 1. Deferred Production 1. Pressure alarm low low 3. Inadvertent opening of 2. More flow towards FCV& trip (16-PALL-615) isolation valve of vent/PSV- 671 3. SOPs in place 617A/B passing 4. Choking of cooler tubes 5. FCV-672 stuck open

Line rupture

1. F&G Detection are in 1. Fire Hazard place 2. Production Loss 2. Pressure alarm low low 3. Environmental Damage & trip (16-PALL-615) 3. Adequate piping design

Level Level

High

N/A N/A

Low

AZOP WORKSHEET REPORT

01 Date: 1ST OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

16-01 Resp. Status Remarks

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-2 Ref. Drawings ID Guideword ENAR Head Office Downstream of Wellhead Latif-6 to the Suction of Wellhead Compressor A-470 & A-480 (FCV-672) 5007-11-16-10-PD-603-01, 5007-11-16-10-PD-604-01, 5010-11-16-10-PD-116-01 Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Choke valve FCV-612 fail open FIC-612 malfunction Compressor overspeed Compressor by-pass valve leakage or passes

A

Flow

More

FIC-672 malfunction leads to fully open (more than required) FCV-671 stuck close Inadvertent opening of isolation valve of vent/PSV617A/B passing Line rupture

1. High velocity may lead to Erosion 2. Production loss 3. Low pressure at compressor suction (A480)

1. Erosion Probe Installed 2. Adequate piping design 3. Compressor overspeed trip 4.

1. F&G Detection are in 1. Fire Hazard place 2. Production Loss 2. Pressure alarm low low 3. Environmental Damage & trip (16-PALL-615)

Choke valve FCV-612 fail close

Flow

Low / No

Inadvertent closing of any inline isolation valve

1. Deferred Production 2. High Pressure at upstream

1. Pressure alarm low low & trip (16-PALL-615) 2. Pressure alarm high high & trip (16-PAHH-615) 3. SOPs in place 4. Maintenance procedures incorporated 5. Pigging procedures in place

Choking of Cooler(E-1660) tubes

C

Flow

Reverse

1. Compressor by-pass valve leakage or passes 2.

1. More flow at compressor suction 2. Deferred Production

NRV located at by-pass

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-2 Ref. Drawings ID Guideword ENAR Head Office Downstream of Wellhead Latif-6 to the Suction of Wellhead Compressor A-470 & A-480 (FCV-672) 5007-11-16-10-PD-603-01, 5007-11-16-10-PD-604-01, 5010-11-16-10-PD-116-01 Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Choke valve FCV-612 fail close Inadvertent closing of any inline isolation valve

D

1. High Pressure at upstream 1. Pressure alarm low low & trip (16-PALL-615) 2. Pressure alarm high high & trip (16-PAHH-615) 3. SOPs in place 4. Maintenance procedures incorporated 5. Pigging procedures in place

Pressure

High

Choking of FE-612 Compressor control malfunction Water slugging FCV-671/672 stuck close Choking of Cooler tubes 2. Deferred Production

Pressure

Low

1. Choke valve partially (less than required) closed/FIC-612 malfunction 2. Wellhead shutdown 1. Deferred Production 1. Pressure alarm low low 3. Inadvertent opening of 2. More flow towards FCV& trip (16-PALL-615) isolation valve of vent/PSV- 671 3. SOPs in place 617A/B passing 4. Choking of cooler tubes 5. FCV-672 stuck open

Line rupture

1. F&G Detection are in 1. Fire Hazard place 2. Production Loss 2. Pressure alarm low low 3. Environmental Damage & trip (16-PALL-615) 3. Adequate piping design

Level Level

High

N/A N/A

Low

AZOP WORKSHEET REPORT

01 Date: 1ST OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

16-01 Resp. Status Remarks

AZOP WORKSHEET REPORT

01 Date: 1ST OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

16-01 Resp. Status Remarks

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-3 Ref. Drawings ID Guideword ENAR Head Office Discharge Flow Line of wellhead Compressor A-490 5010-11-16-10-PD-115-01, 5003-11-16-10-PD-102-00, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

1. Compressor overspeed

Flow

1. Deferred Production

1. Compressor Trip

More

2. Pipeline rupture 1. Compressor trip

2. Production Loss 3. Fire Hazard 4. Environmental Consequences 1. Deferred Production 2. High Pressure at upstream Possibility of high level at inlet separator (V-1,V-2) Deferred Production 1. Production Loss 2. Fire Hazard 3. Environmental Consequences

2. Adequate piping design

2. Water slugging

B

PAHH-3932 alarm & trip High level tripping

Flow

Low / No

3. Inadvertent closing of valve at manifold/tie-ins 4. Line rupture

Adequate piping design

Flow

Reverse

Refer reverse flow node-1 Refer to High pressure node-1

Pressure

High

Inadvertent closure of any manual valve upto tie-in

High pressure leads to line PAHH-3932 alarm & trip rupture

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-3 Ref. Drawings ID Guideword ENAR Head Office Discharge Flow Line of wellhead Compressor A-490 5010-11-16-10-PD-115-01, 5003-11-16-10-PD-102-00, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Compressor trip

Deferred Production

Low Compressor speed

E

Pressure

Low

Line rupture

1. Production Loss 2. Fire Hazard 3. Environmental Consequences

Adequate piping design

Level

High

N/A N/A

Level

Low

Temperature securities available in vendor package (Annex-01)

H

Consider installation of Temperature Transmitter at discharge of compressor

Temperature

High

Temperature

Low

AZOP WORKSHEET REPORT

02 Date: 2nd OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

AZOP WORKSHEET REPORT

02 Date: 2nd OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-4 Ref. Drawings ID Guideword ENAR Head Office Discharge Flow Line of wellhead Compressor A-470/A-480 5010-11-16-10-PD-116-01, 5007-11-16-10-PD-604-01 Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

1. Compressor overspeed

Flow

High velocity may lead to erosion in piping

More

1. Compressor Overspeed Tripping 2. Adequate piping design

2. Pipeline rupture

3. Inadvertent opening of any bleed valve 1. Compressor trip 2. Water slugging/High level at inlet separator (V1)

B

1. Production Loss 2. Fire Hazard/Asset loss 3. Environmental Consequences

1. F&G Detection system 2. Adequate piping design

1. SOPs in place 1. Deferred Production 2. High Pressure at upstream Possibility of high level at inlet separator (V-1,V-2) Deferred Production

PAHH-3932 alarm & trip High level tripping

3. Inadvertent closing of valve at manifold/tie-ins

Flow

Low / No

4. Line rupture (will cause no/low flow at downstream) 5. Inadvertent opening of any bleed valve 6. Malfunction of compressor recycle valve

1. Production Loss 2. Fire Hazard 3. Environmental Consequences

Adequate piping design

1. Deferred Production

1. Low pressure alarm at compressor discharge

To be checked with vendor for further safeguards

Flow

Reverse

No credible scenario

Pressure

High

1. Water slugging

1. High Pressure at upstream Possibility of high level at inlet separator (V-1,V-2)

PAHH-3932 alarm & trip High level tripping

2. Inadvertent closing of valve at manifold/tie-ins

Deferred Production

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-4 Ref. Drawings ID Guideword ENAR Head Office Discharge Flow Line of wellhead Compressor A-470/A-480 5010-11-16-10-PD-116-01, 5007-11-16-10-PD-604-01 Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

1. Compressor trip

1. Deferred Production

2. Inadvertent closing of valve at compressor discharge 3. Line rupture (will cause no/low flow at downstream)

Deferred Production

Pressure

Low

Adequate piping design 1. Production Loss 2. Fire Hazard 3. Environmental Consequences SOPs in place

4. Inadvertent opening of any bleed valve

5. Malfunction of compressor recycle valve

F

1. Deferred Production

1. Low pressure alarm at compressor discharge

To be checked with vendor for further safeguards

Level

High

N/A N/A

Level

Low

Temperature securities available in vendor package (Annex-01)

H

Consider installation of Temperature Transmitter at individual discharge of compressors

Temperature

High

Temperature

Low

ZOP WORKSHEET REPORT

01 Date: 1ST OCT - 2012

ON PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

ZOP WORKSHEET REPORT

01 Date: 1ST OCT - 2012

ON PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-5 Ref. Drawings ID Guideword ENAR Head Office Latif-North-1 Sour Gas Conditioning Skid 5003-11-16-10-PD-101-00, 5003-11-16-10-PD-105-00, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Flow

More

Flow

Low / No

C D E

Flow Pressure Pressure

Reverse High Low

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-5 Ref. Drawings ID Guideword ENAR Head Office Latif-North-1 Sour Gas Conditioning Skid 5003-11-16-10-PD-101-00, 5003-11-16-10-PD-105-00, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Level

High

Level

Low

Temperature

High

Temperature

Low

J K

Corrosion Fire / Explosion Pigging Operation Maintenance

SS tubing shall be used

Design Concern

The tie-in connection from sour gas skid to be taken of 1/2 inch for compressor package

AZOP WORKSHEET REPORT

01 Date: 1ST OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

AZOP WORKSHEET REPORT

01 Date: 1ST OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-6 Ref. Drawings ID Guideword ENAR Head Office Latif-North-1 Corrosion Inhibitor System 5003-11-16-10-PD-102-00, 5003-11-16-10-PD-104-00, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Flow

More

Instrument Gas Failure PSV Passing Inadvertent closure of isolation valves for pumps Choking of strainer CI layer shall not be formed leading to corrosion in line

Low flow alram (FSL302,303) SOPs incorporated Maintenance procedures incorporated/SOPs

Flow

Low / No

Flow Pressure

Reverse High

Tripping of low pressure pumps (P-1608 A/B) Inadvertent closure of isolation valves for pumps Choking of strainer Pump failure CI layer shall not be formed leading to corrosion in line

NRV installed at pumps discharge PSV available at discharge Preventive maintenance

Pressure

Low

Compressor trip Inadvertent opening of any bleed valve

SOPs incorporated

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-6 Ref. Drawings ID Guideword ENAR Head Office Latif-North-1 Corrosion Inhibitor System 5003-11-16-10-PD-102-00, 5003-11-16-10-PD-104-00, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Level

High

Level

Low

Temperature

High

Temperature

Low

AZOP WORKSHEET REPORT

01 Date: 1ST OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

AZOP WORKSHEET REPORT

01 Date: 1ST OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-7 Ref. Drawings ID Guideword ENAR Head Office Latif-06 Sour Gas Conditioning Skid 5007-11-16-10-PD-603-01, 5007-11-16-10-PD-605-01, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Flow

More

Flow

Low / No

C D E

Flow Pressure Pressure

Reverse High Low

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-7 Ref. Drawings ID Guideword ENAR Head Office Latif-06 Sour Gas Conditioning Skid 5007-11-16-10-PD-603-01, 5007-11-16-10-PD-605-01, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Level

High

Level

Low

Temperature

High

Temperature

Low

J K

Corrosion Fire / Explosion Pigging Operation Maintenance

SS tubing shall be used

Design Concern

The tie-in connection from sour gas skid to be taken of 1/2 inch for compressor package

AZOP WORKSHEET REPORT

02 Date: 2nd OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

AZOP WORKSHEET REPORT

02 Date: 2nd OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-8 Ref. Drawings ID Guideword ENAR Head Office Latif-06 Corrosion Inhibitor System 5007-11-16-10-PD-604-01, 5007-11-16-10-PD-606-01, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Flow

More

Instrument Gas Failure PSV Passing Inadvertent closure of isolation valves for pumps Choking of strainer CI layer shall not be formed leading to corrosion in line

Low flow alram (FSL639,640) SOPs incorporated Maintenance procedures incorporated/SOPs

Flow

Low / No

Flow Pressure

Reverse High

Tripping of low pressure pumps (P-1661 A/B) Inadvertent closure of isolation valves for pumps Choking of strainer Pump failure CI layer shall not be formed leading to corrosion in line

NRV installed at pumps discharge PSV available at discharge Preventive maintenance

Pressure

Low

Compressor trip Inadvertent opening of any bleed valve

SOPs incorporated

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-8 Ref. Drawings ID Guideword ENAR Head Office Latif-06 Corrosion Inhibitor System 5007-11-16-10-PD-604-01, 5007-11-16-10-PD-606-01, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Level

High

Level

Low

Temperature

High

Temperature

Low

J K

Corrosion Fire / Explosion Pigging Operation Maintenance Design Concern

AZOP WORKSHEET REPORT

02 Date: 2nd OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

AZOP WORKSHEET REPORT

02 Date: 2nd OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

Resp.

Status

Remarks

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-9 Ref. Drawings ID Guideword ENAR Head Office Latif North-01 & Latif-06 vent stack. (for Tie-ins) 5007-11-16-10-PD-603-01, 5010-11-16-10-PD-116-01,5003-11-16-10-PD-101-00,5010-11-16-10-PD-115-01, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Flow

More

Inadverdent opening of Isolation Valves on depressuring line N/A N/A N/A N/A

No credible sceniros

1. High Velocity

1.Globe valve at depressing line in locked closed. 2. SOPs are in place

Flow

Low / No

Flow

Reverse

D E

Pressure Pressure Level

High Low

High

Level

Low

HAZOP WORKSHEET REPORT

WELLHEAD COMPRESSION PROJECT AT LATIF-06 AND LATIF NORTH-01

Location Node-9 Ref. Drawings ID Guideword ENAR Head Office Latif North-01 & Latif-06 vent stack. (for Tie-ins) 5007-11-16-10-PD-603-01, 5010-11-16-10-PD-116-01,5003-11-16-10-PD-101-00,5010-11-16-10-PD-115-01, Deviation Causes Consequences Safeguards Recommendation Action # Action Session No. System

Temperature

High

Temperature

Low

Low temperature due to depressurization

1.Hydrate formation in vent & drain line.

1.SOP

Corrosion

Fire / Explosion

Lightening occurs at the time of venting.

1.Asset damage. 2. Loss of production.

1. SOP available. 2. Stack has been sized on API-521 considering radiation and dispersion.

Pigging Operation

Maintenance

SOP

Design Concern

1. Adequacy of existing vent stack of latif-North-1 and Latif 06 to be checked. 2. Back pressure as a result of Venting of Compressor at wellhead PSV shall also be checked.

AZOP WORKSHEET REPORT

02 Date: 2nd OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

1-00,5010-11-16-10-PD-115-01, Resp. Status Remarks

AZOP WORKSHEET REPORT

02 Date: 2nd OCT - 2012

ION PROJECT AT LATIF-06 AND LATIF NORTH-01

Wellhead compression for LATIF-06 AND LATIF NORTH-01 Target Dates

1-00,5010-11-16-10-PD-115-01, Resp. Status Remarks

You might also like

- Hazop Work SheetDocument15 pagesHazop Work SheetPablo Castro100% (1)

- Hazop Study-Etp - AcidDocument2 pagesHazop Study-Etp - Acidkirandevi1981100% (1)

- 01-HAZOP Worksheet Formaldehyde - (Corrosion)Document8 pages01-HAZOP Worksheet Formaldehyde - (Corrosion)Muhammad Zarif Amir100% (1)

- No-Flow Process Deviations GuideDocument5 pagesNo-Flow Process Deviations GuideAnonymous QqE5tcEa100% (5)

- Hazop Study TemplateDocument3 pagesHazop Study TemplateLunga Dan Patso100% (1)

- Introduction To HAZOPDocument39 pagesIntroduction To HAZOPapi-19846338100% (1)

- HazopDocument66 pagesHazopBlack WidowNo ratings yet

- Safety: Table 1: Safe Equipment. Authors: Cango. P, Espinoza. A, Lopez. C. (2019)Document4 pagesSafety: Table 1: Safe Equipment. Authors: Cango. P, Espinoza. A, Lopez. C. (2019)Alexander EspinozaNo ratings yet

- Hazard and Operability Study (Hazop) : Dr. M. Azam SaeedDocument39 pagesHazard and Operability Study (Hazop) : Dr. M. Azam SaeedMuhammad Bilal100% (1)

- HazopDocument8 pagesHazopferrari.indiaNo ratings yet

- HAZOP GuidelinesDocument43 pagesHAZOP GuidelinesKhan Lala100% (3)

- 03 Peter Ament Tata Steel Process Safety in IJmuidenDocument37 pages03 Peter Ament Tata Steel Process Safety in IJmuidenChaitanya VarmaNo ratings yet

- HAZOP Study (Part II)Document18 pagesHAZOP Study (Part II)Saad Ahmed100% (14)

- HAZOP STUDY Report (Kutch Chemical Industries Limited)Document82 pagesHAZOP STUDY Report (Kutch Chemical Industries Limited)kanakarao173% (11)

- HazopDocument75 pagesHazopSaima Saima89% (9)

- Safety HAZOP CourseworkDocument31 pagesSafety HAZOP CourseworkMaximiano Ferraz0% (1)

- HAZOPDocument18 pagesHAZOPMark GuevarraNo ratings yet

- 3.2 HazopDocument66 pages3.2 Hazops sanjai100% (1)

- HAZOP ExerciseDocument8 pagesHAZOP Exercisekefeinzel0% (1)

- Hazop ExampleDocument4 pagesHazop Exampledroffilcz27No ratings yet

- HazopDocument2 pagesHazopapi-292058494100% (1)

- Hazop.1092475 Appendix 30.hazopDocument67 pagesHazop.1092475 Appendix 30.hazopAudrey Patrick Kalla50% (2)

- Process Hazard Analysis DM Plant - 25.01.18Document51 pagesProcess Hazard Analysis DM Plant - 25.01.18Debabrata TantubaiNo ratings yet

- Sample HAZOP Study Worksheet (P&ID 100-002)Document5 pagesSample HAZOP Study Worksheet (P&ID 100-002)Mikee Felipe88% (8)

- Basics of HAZOPDocument26 pagesBasics of HAZOPNg JoshuaNo ratings yet

- HAZOP WORKSHEET FOR LIQUID NITROGEN AND OXYGEN SEPARATIONDocument9 pagesHAZOP WORKSHEET FOR LIQUID NITROGEN AND OXYGEN SEPARATIONzohaib_farooqNo ratings yet

- HAZOP WorksheetDocument5 pagesHAZOP WorksheetchristyleneNo ratings yet

- HAZOP ProcedureDocument10 pagesHAZOP Proceduresharjeel39100% (3)

- HAZOP ReportDocument27 pagesHAZOP ReportMuhammad.Saim100% (3)

- Design Project HAZOP Draft 6Document6 pagesDesign Project HAZOP Draft 6Aleksei SukhovNo ratings yet

- HAZOP Report PDFDocument5 pagesHAZOP Report PDFjacobpm2010No ratings yet

- Example: HAZOP Analysis of A Fueling Terminal For A BargeDocument4 pagesExample: HAZOP Analysis of A Fueling Terminal For A BargeBharat LalNo ratings yet

- HAZOPDocument35 pagesHAZOPRiyadh Saleh100% (1)

- Manage Chlorine Hazards SafelyDocument30 pagesManage Chlorine Hazards Safelypriyank gamiNo ratings yet

- PHA Training - Day 1Document50 pagesPHA Training - Day 1ahmad jamalNo ratings yet

- Chapter 7 HazopDocument11 pagesChapter 7 HazopMohd Azman Suwandi50% (2)

- Hazop StudyDocument7 pagesHazop StudyAnderson JoeNo ratings yet

- Safety LOPADocument28 pagesSafety LOPAnandorg1113100% (1)

- Menentukan Material Factor Berdasarkan IndexDocument18 pagesMenentukan Material Factor Berdasarkan IndexdevitajatiNo ratings yet

- Process Hazards Analysis MethodsDocument1 pageProcess Hazards Analysis MethodsRobert MontoyaNo ratings yet

- Process Hazard Analysis MethodsDocument61 pagesProcess Hazard Analysis Methodsjcv235100% (1)

- Atul LTD Risk AssessmentDocument108 pagesAtul LTD Risk AssessmentdevangNo ratings yet

- HAZOP Training290620Document93 pagesHAZOP Training290620NasrulNo ratings yet

- Process Safety Seminar SummaryDocument5 pagesProcess Safety Seminar SummaryBrijesh100% (1)

- Hazop Basic ConceptsDocument14 pagesHazop Basic ConceptsClaudio Sobarzo100% (1)

- Fertil Hazop StudyDocument9 pagesFertil Hazop Studypkannan0% (1)

- HAZOP FinalDocument2 pagesHAZOP Finalchiang95100% (3)

- HAZOP STUDY PLANNING AND LOGISTICSDocument21 pagesHAZOP STUDY PLANNING AND LOGISTICSMohd HisammudinNo ratings yet

- 8.2 HAZOP Study ProcedureDocument74 pages8.2 HAZOP Study ProcedureVijaya Seharan NairNo ratings yet

- HAZOP Study (Part I)Document4 pagesHAZOP Study (Part I)Saad Ahmed100% (1)

- HAZOP Implementation and Evaluation ProceduresDocument29 pagesHAZOP Implementation and Evaluation Proceduresamidi5555913No ratings yet

- Process Safety - Handbook - 2011 PDFDocument129 pagesProcess Safety - Handbook - 2011 PDFpnrao2p67% (3)

- Introduction to Hazardous Evaluation TechniquesDocument21 pagesIntroduction to Hazardous Evaluation TechniquesMalak HindiNo ratings yet

- Fire Load CalculationsDocument5 pagesFire Load Calculationskirandevi1981No ratings yet

- Hazop-Gas Processing ComplexDocument2 pagesHazop-Gas Processing ComplexjavadNo ratings yet

- Hazop Sheet - SSR-216Document10 pagesHazop Sheet - SSR-216dhanu_lagwankarNo ratings yet

- Findings and Actions from HAZOP StudyDocument4 pagesFindings and Actions from HAZOP Studydhanu_lagwankarNo ratings yet

- Start Up Slug Catcher and Train 1Document43 pagesStart Up Slug Catcher and Train 1Larbi HammounNo ratings yet

- Important (3.2) HazopDocument41 pagesImportant (3.2) Hazopmuhammad_asim_10No ratings yet

- N2 Chain Thawing - SOP U O 48 05Document6 pagesN2 Chain Thawing - SOP U O 48 05Harmohan KaulNo ratings yet

- NamazDocument55 pagesNamazzohaib_farooqNo ratings yet

- E GN 000Document90 pagesE GN 000أصلان أصلانNo ratings yet

- Sr. Risk Engineer Job DescriptionDocument3 pagesSr. Risk Engineer Job Descriptionzohaib_farooqNo ratings yet

- Pig Trap SizingDocument1 pagePig Trap Sizingzohaib_farooqNo ratings yet

- Mechanics of AirDocument4 pagesMechanics of Airzohaib_farooqNo ratings yet

- Intro To HAZID of PipelinesDocument30 pagesIntro To HAZID of Pipelineszohaib_farooq100% (3)

- The Galaxy Industries Production Problem - A Prototype ExampleDocument25 pagesThe Galaxy Industries Production Problem - A Prototype Examplezohaib_farooqNo ratings yet

- Fiance & Accounts - Session 1Document3 pagesFiance & Accounts - Session 1zohaib_farooqNo ratings yet

- Fiance & Accounts - Session 1Document3 pagesFiance & Accounts - Session 1zohaib_farooqNo ratings yet

- Sharjeel HassanDocument2 pagesSharjeel Hassanzohaib_farooqNo ratings yet

- Datasheet of Monitor (Sample)Document4 pagesDatasheet of Monitor (Sample)zohaib_farooqNo ratings yet

- CryogenicDocument19 pagesCryogeniczohaib_farooq100% (1)

- Solving Linear Programs: The Simplex MethodDocument10 pagesSolving Linear Programs: The Simplex MethodKhalid MalikNo ratings yet

- HSC Frame WorkDocument5 pagesHSC Frame Workzohaib_farooqNo ratings yet

- NFPA 30 2008 Edition, Requirements For Storage Tanks, Liquids Class I and Class IIDocument4 pagesNFPA 30 2008 Edition, Requirements For Storage Tanks, Liquids Class I and Class IIzohaib_farooqNo ratings yet

- Election MenifestoDocument1 pageElection Menifestozohaib_farooqNo ratings yet

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Ehsan Rashid InstrumentDocument1 pageEhsan Rashid Instrumentzohaib_farooqNo ratings yet

- Factor de UnidadesDocument81 pagesFactor de Unidadesyoly10No ratings yet

- ProfileDocument68 pagesProfilezohaib_farooqNo ratings yet

- HAZOP WORKSHEET FOR LIQUID NITROGEN AND OXYGEN SEPARATIONDocument9 pagesHAZOP WORKSHEET FOR LIQUID NITROGEN AND OXYGEN SEPARATIONzohaib_farooqNo ratings yet

- Pages From Selection and Sizing of Pressure Relief ValvesDocument1 pagePages From Selection and Sizing of Pressure Relief Valveszohaib_farooqNo ratings yet

- A Guide To Refinery ProcessDocument35 pagesA Guide To Refinery ProcessBalamurugan100% (3)

- Study Results For Process in Fig. 3-1: T-L Damage To Pump LIA-1, Can Reagent ReactDocument1 pageStudy Results For Process in Fig. 3-1: T-L Damage To Pump LIA-1, Can Reagent Reactzohaib_farooqNo ratings yet

- A Review of Air Separation Technologies and Their Integration With Energy Conversion Processes PDFDocument20 pagesA Review of Air Separation Technologies and Their Integration With Energy Conversion Processes PDFtiara arlettaNo ratings yet

- Umm Shaif - Ppef881cDocument26 pagesUmm Shaif - Ppef881czohaib_farooqNo ratings yet

- Packinox Catalytic ReformingDocument2 pagesPackinox Catalytic Reformingzohaib_farooqNo ratings yet

- Refinery Process Design Notes - For IITGDocument193 pagesRefinery Process Design Notes - For IITGLakshmi Devineni100% (3)

- Number Name Description Halal StatusDocument16 pagesNumber Name Description Halal Statuszohaib_farooqNo ratings yet

- A319 - A321 - LAA - and - LUS - A321NX - (Trouble Shooting Manual)Document23 pagesA319 - A321 - LAA - and - LUS - A321NX - (Trouble Shooting Manual)A WongNo ratings yet

- 3 - Simple Pneumatic Circuits Using Trainer KitDocument14 pages3 - Simple Pneumatic Circuits Using Trainer KitAbhay SinghNo ratings yet

- Invoice: Invoice No. 123 Dated Ref. No.: Pickup Near Janta Cold Storage Bhagwan Ganj Sagar, M.P. 9300298844, 7828823088Document1 pageInvoice: Invoice No. 123 Dated Ref. No.: Pickup Near Janta Cold Storage Bhagwan Ganj Sagar, M.P. 9300298844, 7828823088Best Auto TechNo ratings yet

- Gek 106840Document4 pagesGek 106840zakaria nouiNo ratings yet

- Plano Hidraulico M313CDocument2 pagesPlano Hidraulico M313CKrippy KushNo ratings yet

- ESD 144 230/1/50 Technical Data SheetDocument1 pageESD 144 230/1/50 Technical Data SheetMahmoud MagdyNo ratings yet

- How Is AC Gas Filling Done? The Complete Guide: Equipment RequiredDocument3 pagesHow Is AC Gas Filling Done? The Complete Guide: Equipment RequiredFaiyz SialaNo ratings yet

- Turbo Machine: Ioe, T CDocument35 pagesTurbo Machine: Ioe, T CCalcgen EngineeringNo ratings yet

- Spare Parts SAB193-233-283S-A-frame 2020.06Document52 pagesSpare Parts SAB193-233-283S-A-frame 2020.06Abdelkader AbdelkaderNo ratings yet

- Rencana Anggaran Biaya Pertashop Area JatimDocument4 pagesRencana Anggaran Biaya Pertashop Area JatimMust Harry100% (3)

- Pressure Relief Valve DrawingDocument1 pagePressure Relief Valve DrawingSRINIVAS KOMMINENINo ratings yet

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 pagesTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- Pump Impeller Trimming AspectsDocument17 pagesPump Impeller Trimming AspectsUdhayakumar VenkataramanNo ratings yet

- Esp Ash Hopper & Blow Tank SystemDocument13 pagesEsp Ash Hopper & Blow Tank SystemZaid ChelseaNo ratings yet

- Expansion valve malfunction diagnosisDocument1 pageExpansion valve malfunction diagnosisJulietina PerezNo ratings yet

- 924G WGXDocument2 pages924G WGXAndrei BleojuNo ratings yet

- IO&M - Jun Tai - Vane PumpDocument4 pagesIO&M - Jun Tai - Vane PumpGonzalo Matus de la Parra BNo ratings yet

- HKS SSQV4 Installation Manual ScanDocument10 pagesHKS SSQV4 Installation Manual ScanAnonymous ifef4nNo ratings yet

- Chinese Material To AstmDocument4 pagesChinese Material To Astmvalli rajuNo ratings yet

- Ref. IN For PROCUREMENTDocument68 pagesRef. IN For PROCUREMENThungleteNo ratings yet

- UL Listed Fire Protection System Control Valves and AccessoriesDocument1 pageUL Listed Fire Protection System Control Valves and Accessoriesanon_530257398No ratings yet

- Seal Gas SystemsDocument2 pagesSeal Gas Systemsdonald sinananNo ratings yet

- Boiler Mountings and Accessories PDFDocument4 pagesBoiler Mountings and Accessories PDFShankar JhaNo ratings yet

- Agricultural Bank Al Ehsaa Chilled Water Pumps Hydraulic CalculationDocument6 pagesAgricultural Bank Al Ehsaa Chilled Water Pumps Hydraulic CalculationMohammed TanveerNo ratings yet

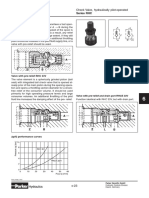

- Series RHC Characteristics: Check Valve, Hydraulically Pilot-OperatedDocument4 pagesSeries RHC Characteristics: Check Valve, Hydraulically Pilot-OperatedLLNo ratings yet

- Oil Injected Screw Compressors VMX - V1 020 10 - ENDocument4 pagesOil Injected Screw Compressors VMX - V1 020 10 - ENCaoDungNo ratings yet

- Imi Maxseal Ico3sDocument2 pagesImi Maxseal Ico3sAlessandro FontesNo ratings yet

- Fluid Mechanics and Hydraulics 4th EditionDocument285 pagesFluid Mechanics and Hydraulics 4th EditionSonic HedgehogNo ratings yet

- Spesifikasi Atlas Copco ZT 30Document5 pagesSpesifikasi Atlas Copco ZT 30Fithrul MubarokNo ratings yet

- Butterfly Torque Selection GuideDocument3 pagesButterfly Torque Selection Guidedragon2065No ratings yet