Professional Documents

Culture Documents

GS106 4

Uploaded by

dediekosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GS106 4

Uploaded by

dediekosCopyright:

Available Formats

GS 106-4 Guidance for Specification 106-4 POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

March 1995

Copyright The British Petroleum Company p.l.c.

Copyright The British Petroleum Company p.l.c.

All rights reserved. The information contained in this document is subject to the terms and conditions of the agreement or contract under which the document was supplied to the recipient's organisation. None of the information contained in this document shall be disclosed outside the recipient's own organisation without the prior written permission of Manager, Standards, BP International Limited, unless the terms of such agreement or contract expressly allow.

BP GROUP RECOMMENDED PRACTICES AND SPECIFICATIONS FOR ENGINEERING Issue Date Doc. No.

March 1995

GS 106-4

Latest Amendment Date

Document Title

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

(Replaces BP Engineering Standard 171)

APPLICABILITY Regional Applicability: SCOPE AND PURPOSE

International

This Specification covers the requirements for the polychloroprene coating of offshore risers and their guides and supports. Polychloroprene is the preferred coating to protect offshore risers against external corrosion in the splash zone. It is intended for use by BP or its Contractor as a document for all contracts involving the external application of polychloroprene to offshore risers

AMENDMENTS Amd Date

Page(s)

Description

CUSTODIAN (See Quarterly Status List for Contact)

Materials Engineering

Issued by:-

Engineering Practices Group, BP International Limited, Research & Engineering Centre Chertsey Road, Sunbury-on-Thames, Middlesex, TW16 7LN, UNITED KINGDOM Tel: +44 1932 76 4067 Fax: +44 1932 76 4077 Telex: 296041

CONTENTS Section Page

FOREWORD .................................................................................................................. iii 1. INTRODUCTION..................................................................................................... 1 1.1 Scope .............................................................................................................. 1 2. SAFETY (At Jacket Fabrication Site)...................................................................... 1 2.1 Regulations...................................................................................................... 1 2.2 Safety Precautions for Pressurised Hoses ......................................................... 2 2.3 General Hazards .............................................................................................. 2 2.4 Primer and Bonding Agent Manufacturer's Information .................................... 2 3. CONTRACTOR'S RESPONSIBILITY ................................................................... 3 3.1 Approval of Proposals...................................................................................... 3 3.2 Manufacturing Procedure................................................................................. 3 3.3 Work Plan........................................................................................................ 3 3.4 Material Specifications..................................................................................... 4 3.5 Prequalification Tests....................................................................................... 4 3.6 Inspection Requirements .................................................................................. 4 3.7 Personnel/Facilities .......................................................................................... 4 3.8 Integrity of Elastomer Coating ......................................................................... 4 3.9 Quality Assurance ............................................................................................ 5 4. MATERIALS ............................................................................................................ 5 4.1 Elastomer Type................................................................................................ 5 4.2 Environmental Resistance ................................................................................ 5 4.3 Material Storage and Usage ............................................................................. 6 4.4 Anti-Fouling Treatments .................................................................................. 6 4.5 Copper-Nickel Sleeves..................................................................................... 6 5. PRODUCTION COATING PROCESS ................................................................... 6 5.1 General ............................................................................................................ 6 5.2 Preliminary Inspection...................................................................................... 7 5.3 Surface Preparation.......................................................................................... 7 5.4 Preparation of Rubber Compound.................................................................... 9 5.5 Coating Thickness and Layering....................................................................... 9 5.6 Primer and Bonding Agent............................................................................... 10 5.7 Application by Machine Winding (Riser Pipes)................................................. 10 5.8 Application of Sheet in Workshop (Riser Pipes) ............................................... 11 5.9 Application of Field Joints (Riser Pipes) ........................................................... 12 5.10 Application of Sheet to Clamps and Guides................................................... 12 5.11 Application of Copper-Nickel Sleeves ........................................................... 13 6. TESTING OF ELASTOMER PROPERTIES ......................................................... 14 6.1 Compound Material Control ............................................................................ 14 6.2 Testing of Vulcanised Rubber Coating ............................................................. 15 7. COATING REPAIRS ............................................................................................... 17

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE i

7.1 Allowable Defects............................................................................................ 17 7.2 Repairs ............................................................................................................ 18 8. HANDLING AND STORAGE ................................................................................. 19 9. DOCUMENTATION ................................................................................................ 19 TABLE 1 ......................................................................................................................... 20 PHYSICAL PROPERTIES OF ELASTOMER COATING MATERIAL .............. 20 FIGURE 1 (PAGE 1 OF 2) ............................................................................................. 21 POLYCHLOROPRENE (NEOPRENE) COATING OF RISERS, GUIDES AND SUPPORTS ................................................................................................. 21 APPENDIX A.................................................................................................................. 23 DEFINITIONS AND ABBREVIATIONS............................................................. 23 APPENDIX B.................................................................................................................. 24 LIST OF REFERENCED DOCUMENTS ............................................................. 24 APPENDIX C.................................................................................................................. 26 CATHODIC DISBONDMENT TEST................................................................... 26

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE ii

FOREWORD Introduction to BP Group Recommended Practices and Specifications for Engineering The Introductory Volume contains a series of documents that provide an introduction to the BP Group Recommended Practices and Specifications for Engineering (RPSEs). In particular, the 'General Foreword' sets out the philosophy of the RPSEs. Other documents in the Introductory Volume provide general guidance on using the RPSEs and background information to Engineering Standards in BP. There are also recommendations for specific definitions and requirements. Value of this Guidance for Specification There is no internationally recognised standard covering the polychloroprene coating of offshore risers, guides and supports, and therefore this document is written as a stand-alone document. This document provides guidance on the engineering requirements for polychloroprene coating and defines the maximum requirements for the application of the polychloroprene coating. Application This Guidance for Specification is intended to guide the purchaser in the use or creation of a fit-for-purpose specification for enquiry or purchasing activity. Text in italics is Commentary. Commentary provides background information which supports the requirements of the Specification, and may discuss alternative options. It also gives guidance on the implementation of any 'Specification' or 'Approval' actions; specific actions are indicated by an asterisk (*) preceding a paragraph number. This document may refer to certain local, national or international regulations but the responsibility to ensure compliance with legislation and any other statutory requirements lies with the user. The user should adapt or supplement this document to ensure compliance for the specific application. Specification Ready for Application A Specification (BP Spec 106-4) is available which may be suitable for enquiry or purchasing without modification. It is derived from this BP Group Guidance for Specification by retaining the technical body unaltered but omitting all commentary, omitting the data page and inserting a modified Foreword. Principal Changes from Previous Edition This document is a complete revision of BP Std 171. It has been carried out in order that it can be issued for enquiry or purchasing without modification. In this first revision there have been extensive changes and the user is therefore advised to regard this Guidance for Specification as a new document.

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE iii

The revised specification now incorporates the complete requirements for the polychloroprene coating of risers in the splash zone and at the riser guide and anchor flange locations. An anti-fouling treatment which utilises cupro-nickel sleeves to prevent marine fouling on the polychloroprene coating is specified in the document. The ribbed polychloroprene coating requirements for clamps and guides are included for the first time. Feedback and Further Information Users are invited to feed back any comments and to detail experiences in the application of BP RPSE's, to assist in the process of their continuous improvement. For feedback and further information, please contact Standards Group, BP International or the Custodian. See Quarterly Status List for contracts

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE iv

1.

INTRODUCTION 1.1 1.1.1 Scope This Specification defines the minimum requirements for the selection of materials, pre-qualification tests, surface preparation, coating application, curing, inspection, repairs and handling of elastomer (polychloroprene) coating of risers, guides and supports to be installed in offshore applications. It also includes the application of field joint coating at fabrication sites. This Specification gives some details of preferred production techniques. However, the contractors and manufacturers are required to meet performance specifications. Where the contractor's or manufacturer's own production techniques differ from the preferred methods, these differences shall be discussed and agreed with BP. 1.1.2 Plain or ribbed elastomer coatings shall be applied to the inner bore of guides (lining), dead weight supports, and surfaces of anchor flanges on risers. Shaped profiles are required for some coatings and will be shown on the relevant contract drawings. Copper-nickel sleeves shall be used on the elastomer coating at riser guide locations to avoid marine fouling, to provide a low friction surface and to protect the elastomer coating against penetration from sharp objects that may become trapped between riser and guide. This Specification defines the requirements for the shop application of the copper-nickel sleeves to the elastomer coating at riser guide locations. This Specification is applicable for the polychloroprene coating of risers transporting hydrocarbons with a maximum process temperature of 110 C. Codes and standards of the country where the equipment is manufactured and/or operated should be considered and may be accepted by BP where they can be used to achieve an equivalent technical result. In any case applicable statutory and local regulations must be complied with. The polychloroprene coating requirements for offshore risers, guides and supports are shown in Figure 1.

1.1.3

1.1.4

1.1.5

1.1.6

2.

SAFETY (AT Jacket Fabrication Site) 2.1 Regulations Account shall be taken of all relevant technical, health, safety and environmental legislation.

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 1

Plant and equipment shall be maintained in good condition and shall comply with applicable health, safety and environmental (HSE) requirements:(a) (b) National or local law requirements. Statutory requirements. Compressors and any associated pressure vessels shall be protected against overpressure. Current test certificates shall be held on site for inspection. (c) (d) Site regulations. Explosive atmosphere special regulations. Blast cleaning and spray painting equipment shall be continuously bonded from the nozzle to the surface being painted and backwards from the nozzle to the compressors, which shall be earthed. 2.2 Safety Precautions for Pressurised Hoses Pressurised hoses used for blast cleaning shall be marked, tested and results logged to ensure safe operation. Test certificates shall be provided giving the maximum safe working pressure. 2.3 General Hazards All hazards shall be identified and all necessary safety items shall be provided to ensure personnel protection. Work areas shall be cordoned off with appropriate warning signs. The Contractor shall provide all the necessary items to ensure protection of his personnel whilst carrying out their duties. Appropriate protective clothing shall be worn at all times. Whilst grit blasting, independent air-fed masks shall be worn such that the operator is unaffected by the environment. The operator's hood should be cleaned and disinfected at least weekly. 2.4 Primer and Bonding Agent Manufacturer's Information Manufacturer's data sheets and safety sheets shall be provided by the Contractor to BP, prior to the start of the work, and shall be available on site at the job location.

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 2

These sheets should contain the information contained on internationally recognised formats such as OSHAs Material Safety Data Sheets, or their nationally recognised equivalent, as a minimum.

3.

CONTRACTOR'S RESPONSIBILITY 3.1 Approval of Proposals All production coating work shall be carried out strictly in accordance with procedures approved by BP. Coating work shall not commence until all relevant documents and the Quality/Inspection Plan have been approved by BP. The Quality/Inspection Plan shall list the activities defined in the procedure along with the relevant acceptance criteria, and inspection hold points to ensure full compliance with the procedure. 3.2 Manufacturing Procedure The Contractor shall submit for BP approval a comprehensive manufacturing procedure covering all aspects of the work, including the following:(a) (b) (c) (d) (e) (f) (g) (h) material receipt, inspection and storage; formulation, manufacture and testing of coating materials, including physical, chemical and performance characteristics; surface preparation methods, steel defect removal, blast cleaning equipment and consumables; material application and curing; copper-nickel/polychloroprene bonding procedure; field joint application procedure; inspection, testing and repair of coatings; instructions for storage and handling of the coated items.

The Contractor shall indicate differences between application processes for plain and ribbed coatings, and between external coatings and linings. The method of applying compression onto coatings during the curing operation to ensure full bonding shall be clearly defined. Applied elastomer coatings shall be protected during surface preparation and painting operations when paint coatings are applied to adjacent steel surfaces (except for allowed overlap). No welding, grinding or heat treatment shall be carried out on, or adjacent to, coated surfaces since this may damage the coating. 3.3 Work Plan The Contractor shall prepare a work plan, with drawings, showing the sub-fabrication sizes and locations of subsequent welds. Due regard shall be taken of the maximum size of sub-fabrication that can be handled and coated satisfactorily, including autoclave size for curing of the applied materials, to avoid subsequent welding damage and handling problems.

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 3

3.4

Material Specifications The Contractor shall provide full material specifications and shall include historical data and test reports showing evidence of material suitability. Cathodic disbondment test results shall also be included. If alternative materials are proposed, he shall provide full information on previous service history, mechanical properties and application procedures. He shall also provide manufacturer's data sheets for all materials and may be required to provide material samples, and/or test panels, of the coatings to BP.

3.5 *

Prequalification Tests Prequalification tests may be specified by BP for the shop applied elastomer coating. A prequalification trial for field joint application may be requested by BP before the commencement of field joint coating. For prequalification testing, the Contractor shall coat two 3 metre lengths of 100 mm diameter pipe (coated in the centre 2.8 m of their length) with a coating of thickness 6 mm. One pipe shall have a copper-nickel sleeve; the other shall incorporate two field joints. These coated pipes shall be subject to testing of their properties by the Contractor. The tests shall be witnessed by BP.

3.6 *

Inspection Requirements Inspection and test methods shall be demonstrated by the Contractor on coated panels or samples to BP satisfaction prior to use on production components. Should the Contractor wish to use an ultrasonic test (to supplement the sounding test), details, including a copy of the ultrasonic trace, shall be provided to BP for approval, demonstrating that porosity, disbondment, air pockets and similar defects can be reliably detected.

3.7

Personnel/Facilities All coating work and inspection work shall be performed by competent personnel experienced in the materials and processes involved. Adequate lighting and inspection facilities shall be provided for all stages of the work.

3.8

Integrity of Elastomer Coating Final acceptance of the coating shall be the responsibility of BP. Any addition testing, and the costs incurred, as requested by BP shall be the responsibility of the Contractor. Failure to satisfy BP as to the bond between the coating and the steel pipe, and the copper-nickel sleeve and the coating, shall be grounds for rejection.

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 4

3.9

Quality Assurance Verification of the vendor's quality system is normally part of the pre-qualification procedure, and is therefore not specified in the core text of this specification. If this is not the case, clauses should be inserted to require the vendor to operate and be prepared to demonstrate the quality system to the purchaser. The quality system should ensure that the technical and QA requirements specified in the enquiry and purchase documents are applied to all materials, equipment and services provided by sub-contractors and to any free issue materials. Further suggestions may be found in the BP Group RPSEs Introductory Volume

4.

MATERIALS 4.1 4.1.1 Elastomer Type The materials to be used for the elastomer coating shall be formulated using polychloroprene rubber. The elastomer shall be applied to the pipework by a hot vulcanising process. The Contractor shall purchase material from an approved manufacturer. Primer, bonding agents and the elastomer curing agents used shall be those recommended by the polychloroprene rubber manufacturer as selected or developed for the environments and application processes considered in this Specification. Only carbon black shall be used as a filler. The cured elastomer coating and lining material shall have properties in accordance with those listed in Table 1. Environmental Resistance The elastomer shall be suitable for long term use in offshore environments when immersed continuously in seawater (under the influence of cathodic protection); in the splash zone; or in the atmospheric zone with moist, salt laden air. The design life of the elastomer shall be 25 years.

Note that BP may specify a different design life in particular circumstances.

4.1.2

4.1.3 4.1.4

4.2 4.2.1

4.2.2

The elastomer shall be stable and suitable for service at operational temperatures in the range -10C to 90C. It shall be resistant to solar radiation, ozone, oil contamination, and marine organisms, and be capable of preventing corrosion of the steel substrate under the specified conditions.

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 5

4.2.3

The elastomer shall have proven resistance to cathodic disbondment at -1.05 V, versus a Ag/AgC1/seawater reference electrode, at pipe metal temperatures up to 90C. Material Storage and Usage The coating material manufacturer's instructions on storage shall be followed at all times. Coating materials shall be used within their shelf life limits and before any signs of degradation occur. Materials shall be stored in the manufacturer's sealed containers until use. All containers shall be identified with the manufacturer's name, product designation, batch number, QC pass sheet, manufacturing date and shelf life, and shall be protected against damage and contamination. No material from containers which are damaged or showing signs of contamination shall be used. Anti-Fouling Treatments Anti-fouling treatments to the surface of the coated pipework may be specified. In most cases the thickness of any treatment will be in addition to the minimum thickness specified for the elastomer coating. The preferred anti-fouling treatment requires the bonding of a 1.0 mm thick copper-nickel sleeve to the outside of the elastomer coating. There shall be a 2-5 mm gap between the longitudinal edges and a maximum gap of 10 mm between the circumferential edges. The Contractor shall provide full details of the application procedure for this anti-fouling treatment. Copper-Nickel Sleeves The copper-nickel alloy for the sleeves shall conform to BS 2870, Grade CN 102.

4.3 4.3.1

4.3.2

4.3.3

4.4 4.4.1

4.5 4.5.1

5.

PRODUCTION COATING PROCESS 5.1 5.1.1 General All coating work shall be performed in an indoor, controlled environment. The steel surface to be coated shall be completely dry during the coating process. Components to be coated shall be kept in an environment which is above 10C, at a minimum of 4C above the dewpoint and where relative humidity is below 85% during the entire process from surface preparation to coating acceptance.

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 6

5.1.2

The Contractor shall maintain the identity of every component throughout the surface preparation and coating process by use of recorded weatherproof marks. The following information shall be recorded for each component, at each stage of the work:identification number and size temperature of steel and air relative humidity coating material batch numbers date progress non-conformances

5.1.3

5.1.4

The application process shall be designed to achieve a coating which is free from inhomogeneities, porosity, inclusions, laminations or poor bond. Cured properties shall be consistent throughout the thickness. Preliminary Inspection Components received for coating shall be checked for damage and out of roundness. Remedial actions shall not be carried out by the Contractor without BP approval. All surfaces to be coated shall be visually inspected for weld spatter, slivers, laps and other defects which would impair the application or performance of the finished coating. Such defects shall be brought to the attention of BP and suitable remedial action shall be taken by the Contractor. All welds in the areas to be coated shall be flush with the pipe surface, smooth, free of porosity, undercuts, cracks and cavities. If grinding is necessary, it shall be subject to BP approval and checking of the remaining wall thickness. Surface Preparation Prior to blast cleaning, all surfaces to be coated shall be cleaned with solvent to remove all traces of oil and grease. Immediately prior to blast cleaning, all surfaces shall be steam cleaned to remove salts. After cleaning the components shall be handled and moved in such a manner as to ensure that no contamination occurs. Clean, lint free gloves shall be worn by all personnel contacting or handling surfaces to be coated.

5.2 5.2.1

5.2.2

5.2.3

5.2.4

5.3 5.3.1

5.3.2

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 7

5.3.3

Should the surface become contaminated with oil, grease or other medium injurious to the coating, then the entire preparation sequence shall be repeated. All surfaces to be coated shall be dry blast cleaned to BS 7079 Sa 2 1/2. Reference shall be made to BS 7079 Part AI for a photograph of this quality. Blasting chambers and automatic blasting units shall have suitable flooring, lighting, abrasive and dust removal equipment and shall be well maintained and kept clean. All compressed air used shall be free from oil, grease and moisture contamination. Compressors shall be fitted with effective oil and water filters/traps. These shall be regularly purged. Abrasive for carbon steel components shall be steel grit or steel shot. Abrasive for stainless steel components shall be stainless steel shot or iron-free aluminium oxide. The abrasive shall be kept dry, clean and free from contaminants. It shall be selected in accordance with BS 2451 to give a surface profile in the range 50 to 100 microns on carbon steel components. The surface profile on stainless steel components shall be in the range 25 to 50 microns. Blast cleaned stainless steel surfaces prior to priming shall not come into contact with carbon steel. Examination and sieve analysis of blasting abrasive shall be performed at least two times per shift to ensure that only uncontaminated abrasive of approved size grading is used. Any defects exposed during blast cleaning, such as slivers, burrs, gouges, and surface laminations, shall be removed by the Contractor. If extensive grinding is necessary, it shall be subject to BP approval and checking of the remaining wall thickness. Ground areas shall be solvent cleaned and blast cleaned again. Following blast cleaning, the total surface to be coated shall be examined, by reference to standard panels, for standard of cleanliness and surface profile. In addition, surface profile measurements shall be made using tape replicas in accordance with NACE RP-02-87 at a frequency of at least three times per shift.

5.3.4

5.3.5

5.3.6

5.3.7

5.3.8

5.3.9

5.3.10

5.3.11

5.3.12

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 8

5.3.13

Immediately after blast cleaning, all dust or abrasive residues shall be removed from the component surface by brushing using uncontaminated foam pads and vacuum cleaning. Freedom from blast residues shall be checked using clear adhesive tape on at least four points on any surface to be coated. The tape shall be pressed onto the surface, then lifted off and placed on a clean white surface for inspection under a microscope at X5 magnification. If only a portion of the pipe is being coated then the blast cleaning shall extend at least 200 mm beyond the area where coating is to be applied. Preparation of Rubber Compound The formulation ingredients shall be mixed to achieve the optimum and even dispersion in an internal mixer. Mixing shall be followed by 2-roll milling and stripping and the strips allowed to cool. The application of talc, or other powder, to the strips to avoid sticking may be allowed but such an application shall not adversely affect the subsequent bonding characteristics of the polychloroprene coating. The strips shall be covered to prevent contamination. Where uncured compounds are being stored for more than 7 days, storage temperatures shall be less than 15C. Rubber compound shall be vulcanised into sample sheets and tested to ensure conformity with the requirements of 6.1. Coating Thickness and Layering The thickness of the coatings after vulcanisation are given on the contract drawings. Tolerances are given in 6.2.1. The minimum coating thickness in any case shall be 4 mm. The thickness for machine-applied coated pipework shall be achieved preferably in one layer (maximum two layers). Where hand-applied circumferential joints are necessary and thicknesses greater than 6 mm are specified, a minimum of two layers of uncured material shall be applied. Circumferential and longitudinal joints shall be staggered such that no single circumferential or longitudinal joint extends through the total thickness of the coating. All terminations shall be chamfered to 30 degrees, 5 degrees, to the pipe axis with 200 mm, 25 mm, of uncoated pipe left at the pipe ends to permit welding. (The cut-back area may be increased where thickwall pipe is to be coated, subject to BP approval). Care shall be

5.3.14

5.3.15

5.4 5.4.1

5.4.2

5.4.3

5.4.4

5.5 5.5.1

5.5.2

5.5.3

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 9

taken during the formation of chamfered terminations to ensure that the pipe wall thickness is not ground below its minimum permitted value. 5.6 5.6.1 Primer and Bonding Agent Equipment and methods used for primer and bonding agent application shall be in accordance with the material manufacturer's recommendations. Surfaces shall be primed within 4 hours of blast cleaning and before any contamination of the surface or visible rusting occurs. Affected surfaces shall be cleaned, or re-prepared as necessary. The primer shall be allowed to dry fully. The primer and bonding agent shall be stirred thoroughly to form a homogeneous mix before use to ensure that solids are fully in suspension. Materials that have become contaminated during use, or thickened through evaporation of solvent, shall not be used. The bonding agent shall be applied over the primer within the time period recommended by the material manufacturer, which shall not exceed 72 hours. The primer surface shall be uncontaminated at time of bonding agent application. Contaminated surfaces, including primed pipe which has been left for more than 72 hours, shall be re-blast cleaned and re-primed. The bonding agent shall be allowed to dry fully. Primer and bonding agent materials shall be applied to the thicknesses recommended by the coating manufacturer and be uniform and free from floods, drips, runs, sags and holidays. Such defects shall be removed by approved methods or, at BP option, the surface shall be reblast cleaned and re-primed. Application of the rubber coating shall proceed within 24 hours after all solvents contained in the bonding agents have evaporated. Any prepared surface left for more than 24 hours shall be rejected and shall be fully cleaned and prepared again. Application by Machine Winding (Riser Pipes) The prepared pipe section (or other suitable component) shall be placed in a lathe permitting rotation and complete access to the area to be coated. Strips of uncured rubber material shall be fed into an extruder. The hot extrudate shall be wound, in a helical manner, over the pipe surface using a profiled roller and applied pressure. The overlap of each helix

5.6.2

5.6.3

5.6.4

5.6.5

5.6.6

5.6.7

5.7 5.7.1

5.7.2

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 10

shall be a minimum of 50%. The pipe surface shall be completely covered. There shall be no air entrapment. 5.7.3 A nylon wrapping tape, of width 50 to 100 mm, shall be wound under tension (preferably simultaneously with the extrusion process) over the length of the coated pipe. A minimum of four full rotations (square to the pipe axis) shall be made at the start of the winding operation. Thereafter, wrapping shall proceed progressively along the length of the pipe: the travel speed of the winding head being controlled such that at least a 50% tape overlap is achieved. When a second, or subsequent, tape is needed during the wrapping process it shall be started at least 300 mm back from the end of the previously completed tape-wrapped section. Again, a minimum of four full rotations (square to the pipe axis) shall be made before proceeding along the pipe. At the end of the length of rubber coating four full rotations shall be made before tying-off the tape. When the wrapping tape is not applied simultaneously with the extruded rubber, and the pipe stands in excess of 4 hours, a second wrapping tape shall be applied. The coated pipes shall be placed in a steam pressure autoclave, with curing time, temperature and pressure controlled and recorded to achieve the required bonding and material properties. Three hours after removal from the autoclave, the nylon tape shall be removed completely. Application of Sheet in Workshop (Riser Pipes) Elastomer sheet shall only be used when approved by BP and where it is not possible to machine apply using the extrusion method, for example where the piping is not straight and for fittings. The application of sheet shall be followed by wet tape wrapping using two layers of tape. Field joints shall be treated as specified in 5.9. The sheet shall be produced by calendering, or roller die, to the correct thickness to allow for any shrinkage in the vulcanisation process. The preparation of the substrate, raw material requirements, application of the primer and bonding agents shall be in accordance with the relevant requirements for machine applied rubber strip. An additional bonding layer of building cement (solution of polychloroprene) shall be applied to the bonding agent and chamfered edges of the sheet.

5.7.4

5.7.5

5.7.6

5.7.7

5.8

5.8.1

5.8.2

5.8.3

5.8.4

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 11

5.8.5

Where only one layer of rubber is applied an uncured rubber strip approximately 1 mm thick and 50 mm wide, shall be applied over both the longitudinal and circumferential seams. Vulcanisation shall be as specified in 5.7.7. After curing, three hours shall elapse before the tape wrapping is removed. Application of Field Joints (Riser Pipes) As the availability of pressure and temperature treatment facilities are limited on site, a polychloroprene compound of a different formulation is normally used for the field joint material. The properties of this compound shall also meet the requirements of Table 1. Suitable protection against the weather shall be provided for all stages of the coating work. The edges of the existing coating shall be cut to a 30 degree angle to allow overlap of the field joint coating. The preparation of steel, the application of primer and bonding agents and sheet material, and tape wrapping shall proceed as detailed in 5.2 to 5.6 inclusive and 5.8. Vulcanisation shall be effected by covering the field joint area with a suitable temperature-controlled electric heating tape or blanket. All field joints made on site shall be carried out only by the nominated coating applicator. Cosmetic repairs to field joints shall be permitted. If significant defects are found the complete field joint shall be remade. The Contractor shall ensure that the field joint coating is flush with adjacent, shop-applied coatings and is within the relevant tolerances. Application of Sheet to Clamps and Guides The clamp and guide surfaces shall be blast cleaned as specified in 5.3. The application of primer and bonding agent to the blast cleaned surface shall be as specified in 5.6. An additional bonding layer of building cement shall be applied to the bonding agent. This shall be checked for tackiness by applying cement to two pieces of rubber and placing together the cemented sides. Upon removal, tackiness shall be evident.

5.8.6

5.9 5.9.1

5.9.2

5.9.3

5.9.4

5.9.5

5.9.6

5.9.7

5.10 5.10.1 5.10.2

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 12

5.10.3

The premoulded sheet, with longitudinal ribs for riser guides, and the plane sheet or blocks for riser clamps, shall be applied to the prepared surface (see also 5.10.4). A shaped mandrel shall be used to hold the sheet in place and maintain compression during curing. A 2 mm thick uncured backing sheet shall be placed between the cured elastomer and the prepared surface in order to effect a chemical bond between the lining and the clamp or guide surface. Care shall be taken to eliminate air entrapment. Vulcanisation shall take place as specified in 5.7.7. Where clamps and guides are designed as split assemblies to be bolted together, their linings shall have an entrance guide along the longitudinal edges to aid fit-up. This can be accomplished by either a stepback, or a chamfer, or in the case of ribbed lining by the removal of the first rib. Application of Copper-Nickel Sleeves Where the coated riser pipe passes through a riser guide, a 3 mm thick copper-nickel sleeve shall be bonded onto the outside of the polychloroprene coating. The sleeve shall extend a distance of 250 mm either side of the riser guide, unless otherwise shown on the contract drawings. The vulcanised coating and the copper-nickel sleeve shall terminate as shown in Figure 1. There shall be no circumferential seam joints in the sleeves and there shall be a 2 to 5 mm gap between the longitudinal edges. Surface preparation of the inner surface of the sleeve shall be as detailed in 5.3, with the exception that the abrasive medium for blasting shall be either iron-free aluminium oxide or a non-ferrous grit. All sharp edges shall be ground smooth prior to blast cleaning. The copper-nickel sleeves shall be formed round the uncured coating and wrapped with nylon tape (in the same manner as for the coating) prior to vulcanisation. Care shall be taken during bonding to ensure that air entrapment is eliminated and during tape wrapping to ensure that the sleeve remains parallel to the pipe surface. After vulcanisation the tape wrap shall be removed and the sleeve shall be visually inspected to check that there is a good sleeve-to-coating bond and that there is no distortion of the sleeve.

5.10.4

5.10.5 5.10.6

5.11 5.11.1

5.11.2

5.11.3

5.11.4

5.11.5

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 13

6.

TESTING OF ELASTOMER PROPERTIES 6.1 Compound Material Control The following tests shall be performed by the manufacturer of the polychloroprene coating. The tests shall use rubber samples taken from each production batch of the compounded material. A production batch is defined as one loading capacity of the internal mixer used for preparing the mixed rubber prior to forming strip or sheet. Where applicable the tests shall be in accordance with BS 903, as detailed in Table 1. (a) Rheological Properties A sample from each production batch shall be tested in an oscillating disc rheometer in accordance with ASTM D2084 at a temperature and oscillation specified in advance to BP by the Contractor. A plot of torque versus time shall be recorded and every batch compared for variability against a standard (a copy of which shall accompany the contractor's proposal). The use of the Mooney viscometer in accordance with ASTM D1646 is an acceptable alternative. Any deviation from the standard shall be grounds for rejection of the batch. (b) Cure and Hardness One sample from every production batch shall be cured in a press, the duration and the temperature being specified by the rubber manufacturer. This temperature and duration shall produce an equivalent material to that of the finished rubber coating. After curing and conditioning, the Shore 'A' hardness of the samples shall be determined. This shall be within the limits specified in Table 1. Any exception shall be grounds for rejection of the batch by BP. (c) Specific Gravity The specific gravity shall be determined from a sample taken from every batch. The values shall not vary more than + or 2% from the stated value. (d) Tensile Strength and Elongation at Break These tests shall be performed on a certified tensile testing machine. Samples, taken from the first and then every tenth production batch and cured under the conditions given by (b), shall be loaded in tension until failure. Applied load and strain shall be recorded and the 'elongation at break' and 'tensile strength' data presented. The minimum results shall meet the requirements specified in Table 1 for each of the tests. Failure

6.1.1

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 14

to comply within the specified range shall be grounds for rejection by BP. (e) Tear Strength These tests shall be performed in a certified testing machine with test pieces in accordance with BS903. Samples shall be taken from the first and then every tenth production batch for test purposes. Failure to comply within the specified range shall be grounds for rejection by BP. (f) Thermal Conductivity When required, one sample shall be taken from one in twenty batches for testing. The results shall meet the minimum requirements specified for the test. Failure to comply with the specified maximum figure shall be grounds for rejection by BP. 6.2 6.2.1 Testing of Vulcanised Rubber Coating The following tests shall be performed by the Contractor in his factory, prior to delivery. BP may appoint a specialist coating inspector to monitor the testing. This however, in no way reduces the responsibility of the Contractor to carry out his own inspection and to make reports to BP. (a) Visual Inspection Every coated component shall be inspected for surface imperfections, lack of bond at joints and ends, blisters, delaminations, cuts, indentations and other apparent irregularities. Any visually detected flaws shall be clearly marked with yellow waterproof crayon and brought to the attention of BP. Failure to satisfy BP as to the integrity of the coating shall be grounds for rejection. (b) Sounding Every coated component shall be sounded over its entire area with a 1 kg hammer or steel straight edge of similar mass. The hammer or straight edge shall be hand held and impacted onto the rubber coated surface through a vertical height of at least 0.5 m with the minimum of additional acceleration. Any marked difference in audible pitch shall be noted and the area marked with yellow waterproof crayon. This method may be supplemented by an ultrasonic test to verify the extent of any fault detected.

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 15

(c)

Adhesion Test Around the circumference of every coated component, two cuts shall be made through to the metal at each end of the pipe coating to form coating strips of 25 mm width. Where cut-outs are made in the coating for anode fixings etc., an adhesive test shall be carried out at this point instead of at one of the ends. Each 25 mm portion shall then be cut transversely through to the metal so that steel grips can be placed on one side of the transverse cut and connected to a spring balance capable of measuring to 100kgf. Each strip of coating shall then be torn, at an angle of 45 degrees, from the pipe around its complete circumference so that the adhesion force can be measured. The removal of the strip shall be entirely due to cohesive tearing of the rubber material. The metal shall remain 100% covered by rubber and the minimum adhesion value of 12 N/mm (31kgf for 25 mm width) shall be achieved. The presence of bare metal, or a lower adhesion value, shall be considered to be due to bond failure and shall result in rejection of that complete pipe section by BP.

(d)

Hardness Test Four equally spaced diametrically opposed pairs of hardness measurements shall be made on every coated component. Results shall be quoted as Shore hardness on the A scale in degrees. (International Rubber Hardness Degrees shall be considered equivalent to Shore 'A' Degrees hardness). These shall meet the requirements specified in Table 1. Failure to comply within the specified limits shall be grounds for rejection by BP.

(e)

Electronic Spark Test Every coated component shall be electronically spark tested over its entire surface area in order to detect faults due to holidays and similar defects. The test equipment shall produce a high frequency high voltage spark discharge employing a brush electrode, except for any seam or joints which shall be tested using a pointed or tipped electrode. The voltage to be employed shall be 2000 V per mm of coat thickness. Any failure during holiday detection shall result in quarantine of the component pending a decision by BP on whether to repair the coating or strip the component for recoating.

(f)

Thickness Measurement

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 16

The coating thickness measurement device shall be approved by BP and shall be used to determine the coating thickness on every coated component. Four equally spaced sets of four measurements shall be taken in four places around the periphery of the component. Any variation below the minimum specified thickness shall be grounds for rejection by BP pending a decision on further action to be taken. (g) Tolerances The thickness of the polychloroprene coating on risers shall be 12 mm, +2 mm, -2 mm unless otherwise specified. The thickness of the ribbed polychloroprene coating for lined guides or clamps shall be +2 mm, -1 mm of the nominal dimension unless otherwise shown on the contract drawings. The external diameterical tolerances for copper-nickel lined areas shall be +2 mm, -2 mm, of the nominal dimensions, unless otherwise shown on the contract drawings.

7.

COATING REPAIRS 7.1 7.1.1 Allowable Defects Defects due to disbondment and porosity only which are 4000 mm2 or less in area and are not within 75 mm from the end of the coating shall not be cause for rejection provided that for:(a) Pipes up to NPS 8 (DN 200) and 10 m or more in coated length there is a maximum of four defects per pipe length coated. Pipes greater than NPS 8 (DN 200) and 10 m or more in coated length there is a maximum of six defects per pipe length coated. Pipes with less than 10 m of coated length shall be permitted a lesser number of defects in proportion to the allowances given in (a) and (b). Bends and fittings of any size shall be permitted a maximum number of defects in proportion to the area of coating compared to the area and allowance permitted in (a).

(b)

(c)

(d)

7.1.2

Defects detected in excess of the numbers stipulated in 7.1.1 may be subject to repairs as specified herein if approved by BP.

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 17

7.2 7.2.1

Repairs When coated pipes, clamps or guides are rejected due to defects such as disbondment, delamination, cuts, indentations, blisters, holidays etc. it may be possible to make repairs to the coating rather than complete stripping and recoating. Where mechanical damage is caused subsequent to delivery of pipe, onsite hand-build repairs may be carried out to reinstate the coating. If the extent of damage is such that complete stripping and recoating is required, this shall be carried out at the contractor's manufacturing facility. All repair procedures shall follow the requirements of this specification. In addition, the procedures shall comply with the following extra requirements:(a) Where damage or disbondment has occurred which is at the steel interface, a complete circumferential band of coating material encompassing the whole of the faulty area shall be removed. For hand building repairs a sheet of maximum thickness 6 mm shall be used to cover the repair area. Greater thickness shall be built up in more than one layer. The area to be repaired shall be cleaned, blast cleaned, primed and coated with bonding agents as detailed in 5.3 and 5.6. The repaired area plus the sound coating shall be totally wrapped in the case of pipes, or placed under a uniform pressure in the case of clamps and guides, and then cured by using either a steam pressure autoclave or electrically heated tapes. All materials used shall comply with the requirement of Table 1. Where surface defect repairs are required the following procedure shall be utilised. The damaged area shall be buffed and cleaned of residual dust. This shall be followed by the application of an interply bonding agent and hand building of uncured compound. Finally, the area shall be tape wrapped and cured.

7.2.2

7.2.3

(b)

(c)

(d)

(e) (f)

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 18

8.

HANDLING AND STORAGE 8.1 All coated pipe, lined guides and clamps shall be adequately protected during handling, storage and transport in order to ensure freedom from damage and contamination. All handling shall employ only nylon webbing straps or slings. All rail cars, trucks and vessels shall be cleaned of loose material and debris which may damage the coated components during transit.

8.2

9.

DOCUMENTATION 9.1 The Contractor shall submit to BP certified copies of the results of all tests and repairs carried out. A copy of the test results obtained to confirm the properties of the rubber sheets, see section 5.4, and those tests required by section 6 shall be given to BP.

9.2

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 19

TEST METHOD PHYSICAL PROPERTY VALUE

Cured, Unaged Hardness (Shore 'A')* Ozone Resistance (1)* Tear Strength* Tensile Strength* Elongation at Break* Compression Set (2)* Abrasion Resistance Adhesion Strength Specific Gravity Thermal Conductivity Cathodic Disbondment BS 903 BS 903 BS 903 BS 903 BS 903 BS 903 DIN 53516 BS 903 BS 903 BS 874 See Appendix C A26 A43 or ASTM D149 A3 A2 A2 A6 A21 A1 65 5 degrees No cracks 40N/mm min 14N/mm2 min 350% min 25% max 225cc max 12N/mm min 1.47 +0.03 0.26 W/mK max 8 mm max

Cured, Aged (3) Parameter marked Volume Swell BS 903 Thermal BS 874 Conductivity

* above, plus: A16 2.5% max 0.30 W/mK max

(1) (2) (3)

Property determined after 70 hours at 40C in 50 pphm ozone and 20% strain Property determined after 24 hours at 70C and 25% strain Aged in substitute seawater, prepared in accordance with ASTM D1141, for 21 days at 70C.

TABLE 1 PHYSICAL PROPERTIES OF ELASTOMER COATING MATERIAL

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 20

FIGURE 1 (PAGE 1 OF 2) POLYCHLOROPRENE (NEOPRENE) COATING OF RISERS, GUIDES AND SUPPORTS

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 21

FIGURE 1 (PAGE 2 OF 2) POLYCHLOROPRENE (NEOPRENE) COATING OF RISERS, GUIDES AND SUPPORTS

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 22

APPENDIX A DEFINITIONS AND ABBREVIATIONS Definitions Standardised definitions may be found in the BP Group RPSEs Introductory Volume. atmospheric zone: dewpoint: the part of an offshore structure above the splash zone. the temperature at which air has reached the saturation point and condensation starts to occur. above -3 m LAT to +12 m LAT or as otherwise defined in the contract document. below -3 m LAT. curing of elastomeric materials under heat and pressure to improve strength and elasticity.

splash zone:

submerged: vulcanising:

Abbreviations Ag/Ag CR ASTM BG DIN DN LAT NACE pphm QC OSHA Silver/silver chloride American Society for Testing and Materials British Gas Deutsche Industrie Normung - German Industrial Standard Nominal Diameter (millimetres) Lowest astronomical tide National Association of Corrosion Engineers Parts per hundred million Quality Control Occupational Safety and Health Administration

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 23

APPENDIX B LIST OF REFERENCED DOCUMENTS A reference invokes the latest published issue or amendment unless stated otherwise. Referenced standards may be replaced by equivalent standards that are internationally or otherwise recognised provided that it can be shown to the satisfaction of BP's professional engineer that they meet or exceed the requirements of the referenced standards. American Standards ASTM D1149 Test method for rubber deterioration - surface ozone cracking in a chamber. Standard specification for substitute ocean water. Standard test method for rubber from natural or synthetic sources viscosity and vulcanisation characteristics. (Mooney Viscometer). Standard test method for rubber property - vulcanisation using oscillating disc cure meter.

ASTM D1141 ASTM D1646

ASTM D2084

NACE RP-02-87

Surface profile measurement of blast cleaned surfaces using replica tapes.

British Standards BS 874 Methods for determining thermal insulating properties, with definitions of thermal insulating terms. Methods of testing vulcanised rubber. Part A.2 Part A.3 Part A.6 Part A.16 Part A.21 Part A.26 Part A.43 Determination of tensile stress-strain properties. Determination of tear strength. Determination of compression set after constant strain. The resistance of vulcanised rubber to liquids. Determination of rubber to metal bond strength. Determination of hardness. Determination of resistance to ozone cracking.

BS 903

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 24

BS 2451 BS 2870 BS 7079-A1

Chilled iron, shot and grit. Specification for rolled copper and copper alloys. Specification for rust grades and preparation grades of uncoated steel substrates and of steel substrates after overall removal of previous coatings.

German Standards DIN 51516 Determination of abrasion resistance.

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 25

APPENDIX C CATHODIC DISBONDMENT TEST Testing of the resistance to cathodic disbondment of the coating shall follow the generalised procedure described below:The resistance to cathodic disbondment shall be determined on a test panel cut from the coated pipe into which a 6 mm diameter holiday has been drilled in the coating exposing the bare metal. The angle at the apex of the drill bit shall be 160 degrees to ensure that a 6 mm diameter holiday is produced with minimal penetration of the substrate. The drill shall be maintained perpendicular to the test panel while making the holiday. The panel shall than be made the cathode in an electrolytic cell, comprising an electrolyte of 3% by weight of sodium chloride dissolved in distilled water and an anode of platinum or similarly inert metallic material. The construction of the cell can best be achieved by adhesively bonding a section of non-metallic pipe, typically 60 mm long and 50 mm bore, to the test panel with the holiday located centrally within the line of the pipe axis. The voltage between the anode and the cathode shall be adjusted so that a potential at the coating holiday of -1.5 volts with respect to a standard calomel electrode is maintained for the duration of the test. The temperature of the test panel and electrolyte shall be maintained at 20C 2C for the duration of the test. The duration of the test shall be 28 days and any loss of fluid through evaporation shall be made up with distilled water. On completion of the test, the extent of disbondment of the coating from the holiday shall be determined by first making a number of radial cuts outward from the holiday of approximately 20 mm in length. Using a sharp knife point at the periphery of the holiday, attempts shall be made to lift the coating from the substrate around the full circumference of the holiday. The resistance to disbondment shall be expressed as the maximum distance over which the coating can be removed, measured radially from the periphery of the holiday.

GS 106-4

POLYCHLOROPRENE COATING OF OFFSHORE RISERS, GUIDES AND SUPPORTS

PAGE 26

You might also like

- Non-shrink precision groutDocument4 pagesNon-shrink precision groutEngr.Mohammed KhaledNo ratings yet

- Design Principles and Criteria Marine Structures ISSC 2006Document79 pagesDesign Principles and Criteria Marine Structures ISSC 2006Nabil Al-KhirdajiNo ratings yet

- NUGROUT HI SPEC cementitious groutDocument2 pagesNUGROUT HI SPEC cementitious groutPaul RuckNo ratings yet

- Analysis of Building Collapse Under Blast LoadsDocument9 pagesAnalysis of Building Collapse Under Blast LoadsIbrahim HadidiNo ratings yet

- Grouting Systems - 620Document6 pagesGrouting Systems - 620arunkumarNo ratings yet

- FIRETEX Passive Fire Protection Brochure PDFDocument6 pagesFIRETEX Passive Fire Protection Brochure PDFPop Andrei IonutNo ratings yet

- 17 Samss 008Document8 pages17 Samss 008Cherukunnon JubuNo ratings yet

- Shrinkage Compensated Cementitious GroutDocument3 pagesShrinkage Compensated Cementitious GroutPramod SinghNo ratings yet

- Lanko Grout 280 Eco BrochureDocument2 pagesLanko Grout 280 Eco BrochureMrgsrzNo ratings yet

- 17 Samss 017Document14 pages17 Samss 017Eagle SpiritNo ratings yet

- Grout CatalogDocument36 pagesGrout CatalogJohneey DeepNo ratings yet

- Oisd STD-226Document76 pagesOisd STD-226rsb72100% (1)

- Structural Design Criteria for Port of Anchorage Modernization ProjectDocument28 pagesStructural Design Criteria for Port of Anchorage Modernization ProjectSai GowthamNo ratings yet

- GIB and ACES Standard Design CriteriaDocument66 pagesGIB and ACES Standard Design CriteriaOluwafemi Samuel AdesanmiNo ratings yet

- Expangrout GP: General Purpose Non-Shrink Cementitious Grout UsesDocument4 pagesExpangrout GP: General Purpose Non-Shrink Cementitious Grout UsesZaid AhmedNo ratings yet

- Field Joint Developments and Compatibility ConsiderationsDocument13 pagesField Joint Developments and Compatibility ConsiderationsabcNo ratings yet

- Cathodic Protection Course BrochureDocument2 pagesCathodic Protection Course BrochurechkzaNo ratings yet

- Esso Chad Project Technical Specification for GroutingDocument10 pagesEsso Chad Project Technical Specification for GroutingFlorin Daniel AnghelNo ratings yet

- Analysis of Blast Loading Effect On High Rise BuildingsDocument7 pagesAnalysis of Blast Loading Effect On High Rise BuildingsAlexander DeckerNo ratings yet

- Advantages of Polypropylene Based CoatingsDocument13 pagesAdvantages of Polypropylene Based CoatingspaimpillyNo ratings yet

- Grouts & AnchorsDocument6 pagesGrouts & Anchorseng_osamahazaymehNo ratings yet

- Blast Resistant Design of Reinforced Concrete WallDocument6 pagesBlast Resistant Design of Reinforced Concrete WallAmin ZuraiqiNo ratings yet

- Fibre Reinforced Concrete PDFDocument79 pagesFibre Reinforced Concrete PDFShaik Asif AliNo ratings yet

- Cathodic ProtectionDocument2 pagesCathodic ProtectionaltamimzNo ratings yet

- An Electrochemical Study of Cathodic Protection of Steel Used For Marine StructuresDocument6 pagesAn Electrochemical Study of Cathodic Protection of Steel Used For Marine StructureshamidNo ratings yet

- 12 Samss 008 PDFDocument4 pages12 Samss 008 PDFErin JohnsonNo ratings yet

- Cathodic Protection Strategies For FPSO's FinalDocument11 pagesCathodic Protection Strategies For FPSO's FinalThaibinh Nguyen100% (1)

- PROJECT STANDARDS AND SPECIFICATIONS Valves and Control Valves Rev01 PDFDocument15 pagesPROJECT STANDARDS AND SPECIFICATIONS Valves and Control Valves Rev01 PDFJohnNo ratings yet

- General Update of The ASCE Report-Design of Blast Resistant Buildings in Petrochemical FacilitiesDocument4 pagesGeneral Update of The ASCE Report-Design of Blast Resistant Buildings in Petrochemical FacilitiesKevin C. Nair100% (1)

- UFC 3-570-06 - Cathodic Protection - (Draft)Document63 pagesUFC 3-570-06 - Cathodic Protection - (Draft)Johnny WalkerNo ratings yet

- Effect of Blast Load On Soft Storey BuildingDocument8 pagesEffect of Blast Load On Soft Storey BuildingEditor IJRITCCNo ratings yet

- RP 4-6 Procedure For The Design of Buildings Subject To Blast LoadingDocument31 pagesRP 4-6 Procedure For The Design of Buildings Subject To Blast Loadingmilecsa100% (1)

- Cement Grout AAADocument4 pagesCement Grout AAAabualamalNo ratings yet

- Reliability-Based Fatigue and Fracture Design Criteria for Welded Offshore StructuresDocument12 pagesReliability-Based Fatigue and Fracture Design Criteria for Welded Offshore StructuresMohammadrezaNo ratings yet

- Cathodic Protection of Steel in Concrete Using Magnesium Alloy AnodeDocument7 pagesCathodic Protection of Steel in Concrete Using Magnesium Alloy AnodeFa HedaiatNo ratings yet

- Corrosion Protection Offshore and Sheet PilingDocument12 pagesCorrosion Protection Offshore and Sheet PilingMihajloDjurdjevicNo ratings yet

- Polyurethane Lining and Coating Specification Penstock Welded Joints 20120327Document12 pagesPolyurethane Lining and Coating Specification Penstock Welded Joints 20120327anbilselvamNo ratings yet

- Structural Analysis of Blast Resistant BuildingsDocument6 pagesStructural Analysis of Blast Resistant BuildingsRahmatullah MawlanyNo ratings yet

- Appendix B - Technical Specification For Plain & Reinforced Concrete WorksDocument24 pagesAppendix B - Technical Specification For Plain & Reinforced Concrete WorksPankaj PriyadarshiNo ratings yet

- Plasite 4500 S Pds 10-14 - MarineDocument3 pagesPlasite 4500 S Pds 10-14 - MarineAchraf BoudayaNo ratings yet

- Corrosion Control Design and Construction DocsDocument3 pagesCorrosion Control Design and Construction DocsNathanNo ratings yet

- Protection of Structural Steel in Hydrocarbon FiresDocument7 pagesProtection of Structural Steel in Hydrocarbon FiresGansh100% (1)

- Cementitious Mortars and Grouts: A Technical OverviewDocument4 pagesCementitious Mortars and Grouts: A Technical OverviewebetaniaNo ratings yet

- Control ValvesDocument18 pagesControl Valvesnathan1979No ratings yet

- Flo-Grout BP800Document26 pagesFlo-Grout BP800qasim078100% (1)

- Cathodic Protection of Buried StructuresDocument22 pagesCathodic Protection of Buried StructuresPhilip OjugohNo ratings yet

- CPM1100 Fundamentals of Cathodic Protection PDFDocument29 pagesCPM1100 Fundamentals of Cathodic Protection PDFmahmoud ahmedNo ratings yet

- CSE 202.04 Inspection of Concrete StructuresDocument67 pagesCSE 202.04 Inspection of Concrete StructuresJellyn BaseNo ratings yet

- Steel Design Standards and MethodsDocument21 pagesSteel Design Standards and MethodsMike JamesNo ratings yet

- Norsok Standard Structural DesignDocument19 pagesNorsok Standard Structural Designsamprof4vwNo ratings yet

- Attachment #03 SP0169-2013 Standard Practice Control of External Corrosion On Underground or Submerged Mettalic Piping SystemsDocument3 pagesAttachment #03 SP0169-2013 Standard Practice Control of External Corrosion On Underground or Submerged Mettalic Piping SystemsArun Sudarshan100% (1)

- CSE 202.01 Materials and Their Impact On Concrete FailuresDocument63 pagesCSE 202.01 Materials and Their Impact On Concrete FailuresJellyn BaseNo ratings yet

- Aa 036531 001Document1 pageAa 036531 001narutothunderjet2160% (1)

- Design of Welded Connections: Submitted To Prof. Berlanty Iskander byDocument17 pagesDesign of Welded Connections: Submitted To Prof. Berlanty Iskander byاحمد حمديNo ratings yet

- NES 170 Requirements For EPDM Rubber Circular and 'D' Section Marine Fenders Category 3Document46 pagesNES 170 Requirements For EPDM Rubber Circular and 'D' Section Marine Fenders Category 3JEORJE0% (1)

- GS 142-4Document23 pagesGS 142-4Diego100% (1)

- Nes 111Document46 pagesNes 111FredoMari LC100% (2)

- Area Classification To Ip 15Document33 pagesArea Classification To Ip 15Kanakarao Malappareddy100% (4)

- NES 304 Part 2 Shafting Systems and PropulsorsDocument36 pagesNES 304 Part 2 Shafting Systems and PropulsorsJEORJENo ratings yet

- Eaton Aeroquip® Hose Assembly Master CatalogDocument384 pagesEaton Aeroquip® Hose Assembly Master CatalogcarlosolmoNo ratings yet

- OGP Safety Performance of Helicopters in O & G IndustryDocument16 pagesOGP Safety Performance of Helicopters in O & G IndustrydediekosNo ratings yet

- Question Set - Asset IntegrityDocument5 pagesQuestion Set - Asset IntegrityAmal A.No ratings yet

- 291Document60 pages291motaz_omar9651No ratings yet

- OGP Human Factors - SafetyDocument8 pagesOGP Human Factors - SafetydediekosNo ratings yet

- OGP Safety Performance of Helicopters in O & G IndustryDocument16 pagesOGP Safety Performance of Helicopters in O & G IndustrydediekosNo ratings yet

- Floating Roof TanksDocument123 pagesFloating Roof TanksSalman BhattiNo ratings yet

- OGP Health Performance IndicatorsDocument20 pagesOGP Health Performance IndicatorsdediekosNo ratings yet

- Insulating KitsDocument4 pagesInsulating KitsdediekosNo ratings yet

- OGP Asset Integrity - The Key To Managing Major Incident RisksDocument20 pagesOGP Asset Integrity - The Key To Managing Major Incident Risksdediekos100% (1)

- OGP Hra RoadmapDocument2 pagesOGP Hra RoadmapdediekosNo ratings yet

- LD-36 Armstrong Flange ConnectionDocument1 pageLD-36 Armstrong Flange ConnectiondediekosNo ratings yet

- Fire HazardsDocument16 pagesFire HazardsdediekosNo ratings yet

- Diving O&g411Document52 pagesDiving O&g411phsemNo ratings yet

- Spiral Wounds Gasket Dimension ASME B16.20Document1 pageSpiral Wounds Gasket Dimension ASME B16.20dediekosNo ratings yet

- D 200032 X 012Document6 pagesD 200032 X 012dediekosNo ratings yet

- Orifice FlangesDocument4 pagesOrifice FlangesdediekosNo ratings yet

- Pneumatic Liquid Pumps Performance ReliabilityDocument24 pagesPneumatic Liquid Pumps Performance ReliabilityCarl Moritz50% (2)

- New Sylabus Training TOPDocument22 pagesNew Sylabus Training TOPdediekosNo ratings yet

- PCV Fisher 310-ADocument20 pagesPCV Fisher 310-Adediekos100% (1)

- EZ Fisher Data SheetDocument24 pagesEZ Fisher Data SheetdediekosNo ratings yet

- Eaton Swivel JointDocument1 pageEaton Swivel JointdediekosNo ratings yet

- PB154 2nd Gen CH Service 8-1999Document44 pagesPB154 2nd Gen CH Service 8-1999dediekos100% (1)

- ED Fisher Data SheetDocument40 pagesED Fisher Data SheetdediekosNo ratings yet

- Cat12 s2Document38 pagesCat12 s2dediekosNo ratings yet

- StrainersCatalogue 2010 SureFlowEquipmentInc YStrainersDocument16 pagesStrainersCatalogue 2010 SureFlowEquipmentInc YStrainersdediekosNo ratings yet

- Oil and Gas Training Course Catalog 2014Document230 pagesOil and Gas Training Course Catalog 2014dediekosNo ratings yet

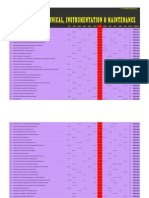

- 01-Engineering, Technical, Instrumentation & MaintenanceDocument3 pages01-Engineering, Technical, Instrumentation & MaintenancedediekosNo ratings yet

- Lenovo - k900 - Dissambley 2013Document18 pagesLenovo - k900 - Dissambley 2013Ravi VermaNo ratings yet

- Rhinofitt Bolt Stud Dimensions For Ansi FlangesDocument1 pageRhinofitt Bolt Stud Dimensions For Ansi Flangesdediekos100% (2)

- Rockwell Hardness Tester GuideDocument16 pagesRockwell Hardness Tester GuideitiseasyNo ratings yet

- Terastandard - Bsi Bs en 6811 597 1514626330Document24 pagesTerastandard - Bsi Bs en 6811 597 1514626330soheila ghaderiNo ratings yet

- 4140 HTDocument2 pages4140 HTwillys8No ratings yet

- HARDNESS TEST METHODSDocument13 pagesHARDNESS TEST METHODShaizum_adamNo ratings yet

- Theories Behind The Origin of The UniverseDocument25 pagesTheories Behind The Origin of The UniverseslayNo ratings yet

- Recycling Aluminum Chips Through Hot Backward ExtrusionDocument15 pagesRecycling Aluminum Chips Through Hot Backward ExtrusionHARI KRISHNAN GNo ratings yet

- AASTU - Rock Engineering CH-2 (MnEg 601) 2019Document91 pagesAASTU - Rock Engineering CH-2 (MnEg 601) 2019not nowNo ratings yet

- ASTM 128 Grade (110mn13) PDFDocument11 pagesASTM 128 Grade (110mn13) PDFbkNo ratings yet

- Alloy Steel Incl Ball Bearing MTD16 (13325) W - 07122018Document7 pagesAlloy Steel Incl Ball Bearing MTD16 (13325) W - 07122018vipin51No ratings yet

- STEEL HARDNESS GUIDEDocument3 pagesSTEEL HARDNESS GUIDEbalaji_jayadeva9546No ratings yet

- LeHTN PDFDocument220 pagesLeHTN PDFjasimabdNo ratings yet

- Surface Severe Plastic Deformation of AISI 304 Via Conventional Shotpeening, Severe Shot Peening and RepeeningDocument7 pagesSurface Severe Plastic Deformation of AISI 304 Via Conventional Shotpeening, Severe Shot Peening and RepeeningjrdelsilvaNo ratings yet

- Remanufacturing of Nodular Cast Iron Crankshaft With Plasma CladdingDocument9 pagesRemanufacturing of Nodular Cast Iron Crankshaft With Plasma CladdingSujay NahaldeNo ratings yet

- 3443 IsDocument17 pages3443 IsRakesh SrivastavaNo ratings yet

- Alloy CuCr1ZrDocument53 pagesAlloy CuCr1ZrPrashant PuriNo ratings yet

- ASSESSMENT Q1 Week 1&2Document14 pagesASSESSMENT Q1 Week 1&2MYLEEN P. GONZALESNo ratings yet

- ASTM D5873 - 14 Standard Test Method For Determination of Rock Hardness by Rebound Hammer MethodDocument3 pagesASTM D5873 - 14 Standard Test Method For Determination of Rock Hardness by Rebound Hammer MethodmakhsmyNo ratings yet

- Gearless Transmission - 2Document42 pagesGearless Transmission - 2Tanvi KhuranaNo ratings yet

- Technical Data - LUPOLEN 5261 ZDocument3 pagesTechnical Data - LUPOLEN 5261 ZCristhian Huanqui TapiaNo ratings yet

- Study On Mechanical Properties of Polyurea Coating With Various Process ParametersDocument9 pagesStudy On Mechanical Properties of Polyurea Coating With Various Process ParameterseiearjunNo ratings yet

- Iso 14577 1 2002 FR en PDFDocument11 pagesIso 14577 1 2002 FR en PDFPaulo Jorge100% (1)

- C864 PDFDocument3 pagesC864 PDFĐường Nguyễn ThừaNo ratings yet

- Liquid Impingement Erosion Using Rotating Apparatus: Standard Test Method ForDocument19 pagesLiquid Impingement Erosion Using Rotating Apparatus: Standard Test Method ForlufabaoNo ratings yet

- Astm C868-85 (R95)Document4 pagesAstm C868-85 (R95)Ian HsuNo ratings yet

- Mos Lab Manul by Abhidhesh YadavDocument45 pagesMos Lab Manul by Abhidhesh YadavabhiNo ratings yet

- Tribological Properties of Hot Forged Al2024-Tib2 In-Situ CompositeDocument7 pagesTribological Properties of Hot Forged Al2024-Tib2 In-Situ CompositeVivekananda SubramaniNo ratings yet

- Science Exam Questions on Properties, Changes and Waste ManagementDocument9 pagesScience Exam Questions on Properties, Changes and Waste ManagementRodel OrtegaNo ratings yet

- Hardness TestingDocument6 pagesHardness TestingRakesh RanjanNo ratings yet

- Jis 1196Document19 pagesJis 1196VISHAL kUMARNo ratings yet