Professional Documents

Culture Documents

1 s2.0 S0894177714000727 Main

Uploaded by

hsemargOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 s2.0 S0894177714000727 Main

Uploaded by

hsemargCopyright:

Available Formats

Experimental Thermal and Fluid Science 55 (2014) 210220

Contents lists available at ScienceDirect

Experimental Thermal and Fluid Science

journal homepage: www.elsevier.com/locate/etfs

Mixed-surfactant additives for enhancement of air-atomized spray cooling of a hot steel plate

Satya V. Ravikumar a, Jay M. Jha a, Ishita Sarkar a, Surjya K. Pal b, Sudipto Chakraborty a,

a b

Department of Chemical Engineering, IIT Kharagpur, Kharagpur 721302, India Department of Mechanical Engineering, IIT Kharagpur, Kharagpur 721302, India

a r t i c l e

i n f o

a b s t r a c t

The current study covers the cooling enhancement of a hot stainless steel plate using mixtures of ionic and nonionic surfactant additives in air-atomized water spray. The surfactant when dissolved in water, exhibits surface activity to inuence the atomization process as well as solidliquid contact by forming a monolayer at airwater interface. The properties of monolayer formed by mixed-surfactant systems depend on the interactions between the surfactants such that the heat transfer rate differs from that of the surface. In this study, sodium dodecyl sulfate (an anionic surfactant), cetrimonium bromide (a cationic surfactant), and polysorbate 20 (Tween 20, a nonionic surfactant) have been used. For detailed analysis on heat transfer performance of mixed-surfactants, the optimum concentration levels of the three surfactants have been considered from the authors earlier work. A test plate of AISI 304 designated steel of surface area 100 mm 100 mm and a thickness of 6 mm has been employed with three subsurface thermocouples to collect the transient temperature data during cooling from an initial surface temperature of 900 C. A commercial inverse heat conduction software, INTEMP has been used to estimate the surface heat ux and temperatures such that the cooling rates can be calculated for all the experiments. The results are analyzed to see the effect of mixed-surfactants on cooling performance of the hot plate, which reveal that the mixtures of nonionic and ionic surfactants give higher heat transfer enhancement than those of the individual surfactants in water. However, catanionic surfactant mixture diminishes the heat transfer ability of pure water. Overall, a maximum cooling rate of 240 C/s and heat transfer co-efcient of 20,000 W/m2 C can be achieved from this study which is very important for run-out table cooling of a Hot Strip Mill in steel industry. 2014 Elsevier Inc. All rights reserved.

Article history: Received 9 November 2013 Received in revised form 22 February 2014 Accepted 12 March 2014 Available online 22 March 2014 Keywords: Air-atomized spray cooling Mixed-surfactant system Transition boiling Heat transfer enhancement Ultrafast cooling

1. Introduction Spray cooling is an efcient heat transfer technique for high heat ux applications. It is widely used in electronic chips [1], space crafts [2], nuclear fuel rods [3], combustion technology [4], and metallurgical processes [5]. There are other liquid cooling technologies like immersion cooling or jet impingement cooling, but they cannot provide satisfactory heat uxes due to the lm boiling phenomena. While cooling an extremely high temperature surface (above the Leidenfrost temperature), a thin layer of vapour develops in between the solid surface and liquid coolant which results in lm boiling [6]. As cooling proceeds, lm boiling and nucleate boiling co-exist because of unstable vapour layer, which is called transition boiling. Thereafter, the heat transfer phenomenon enters into complete nucleate boiling and nally the single phase convection occurs at low temperatures.

Corresponding author. Tel.: +91 3222 283942 (O).

E-mail address: sc@che.iitkgp.ernet.in (S. Chakraborty). http://dx.doi.org/10.1016/j.expthermusci.2014.03.007 0894-1777/ 2014 Elsevier Inc. All rights reserved.

In the steel industry, heat transfer rate at run-out table (ROT) during hot rolling process determines the metallurgical microstructure responsible for a specied mechanical properties [7]. However, this thermo-metallurgical transformations in steels occur at temperature above the Leidenfrost point which may fall under lm boiling heat transfer mechanism depending upon the cooling system used. The major phase transformation of steel occurs between a nish rolling temperature (FRT) of 900 C and a coiling temperature (CT) of 600 C [8,9]. The cooling intensity between the said temperature ranges governs the phase microstructure and corresponding mechanical properties for an intended application. In general, cooling operation at the ROT is carried out in steel industries by means of laminar jets using pure water as coolant media. However, many earlier studies on jet impingement cooling pointed out that the heat transfer on the quench surface is different at the stagnant zone and its surrounding radial ow zones [1012]. In contrast to the non-uniform cooling by jet impingements, spray cooling would be of greater relevance since it is characterized by high and uniform heat uxes. In the environmental and economical

S.V. Ravikumar et al. / Experimental Thermal and Fluid Science 55 (2014) 210220

211

constraints of steel industry, signicant reduction of coolant consumption can be possible by using spray cooling. In ordinary spraying technique where higher water ow rate is used, the chance of lm boiling is more due to the fact that the water droplets with insufcient momentum can easily oat on the vapour layer formed over the hot surface and initiate liquid lms [13]. While, in case of air-atomized spray cooling, compressed air is used to atomize the water into ner droplets and these droplets are sprayed on the hot surface with higher momentum [14,15]. Here, the ner droplets of water with higher momentum touch the hot surface, get deformed increasing the contact area, then the conduction heat transfer takes place through the contact area (common interface) raising the water temperature inside the droplet and it starts evaporating. The lower droplet sizes facilitate higher heat transfer rates [16]. When the droplets get partially evaporated and generate bubbles, they are then swept away from the hot surface by the high velocity superposed air ow. Hence, the formation of stable vapour lm is prevented [9] as there is no occurrence of water pool on the hot surface unlike the immersion cooling or jet impingement or single phase spray cooling. It is found form the earlier studies of authors that this is an effective process for ultrafast cooling of hot steel plate which is an advanced heat treatment technique recently developing for ROT cooling in steel industries [9,17] which is an advanced heat treatment technique recently developing for application into ROT cooling in steel industries [1820]. Several authors have worked on different cooling methods and techniques to achieve ultrafast cooling for generating required metallurgical phase microstructures and mechanical properties in steels [19,21]. It can be concluded from their studies that ultrafast cooling avoids the transition boiling and quickly initiates the bubble nucleation; therefore, the major heat is transferred from the surface by nucleate boiling heat transfer. Moreover, ultrafast cooling provides uniform temperature distribution from the surface. The achieved cooling rate is said to be in ultrafast cooling when the product of the thickness of plate in mm and the cooling rate in C/s is preferably greater than 800 [11]. Recent developments in spray cooling technologies have received considerable attention by altering the physical properties of coolant to achieve optimum cooling intensities. Mohapatra et al. [22] studied the air-atomized spray cooling with surfactant added water to enhance the heat transfer rate from a hot stainless steel surface of 6 mm thickness at an initial surface temperature of 900 C. They have concluded that addition of surfactant increases the cooling rate of steel plate due to decrease in surface tension resulting in higher solidliquid contact leading to quick bubble nucleation. Moreover, atomization process is affected by the high surface activity of the surfactant resulting in smaller droplets which evaporates faster. The type of surfactant used is sodium dodecyl sulfate (SDS), which is an anionic surfactant. The study has been conducted at different concentrations of the surfactant and it reveals that the heat transfer rate increases up to an optimal surfactant concentration (600 ppm) and thereafter decreases. This is due to high foamability of surfactant at higher surfactant concentration levels which obstructs the motion of wetting front on the hot surface resulting in lower heat transfer. The maximum ultrafast cooling rate of 160 C/s is achieved using surfactant added water, which is 60% higher than the cooling performance of pure water in the air-atomized spray. The authors have previously explored the effect of adding three different types of surfactants to the air atomized spray [23]. It has been found that the cationic and nonionic surfactants show better cooling efciencies when a hot steel plate with an initial surface temperature of 900 C is being cooled at a xed air and water ow rate. The heat transfer rate in the transition boiling regime has been enhanced by dissolved surfactants as the molecules of surfactants puncture the vapour layer apart and settle over the hot

surface and promote rapid nucleation of bubbles preventing the formation of a stable vapour layer on the hot surface that leads to higher heat exchange capacity. It results in a quick shift from transition to nucleate boiling with the occurrence of higher critical heat ux. The effect of spray inclination during air atomized spray cooling of a hot steel plate using pure water and anionic surfactant SDS as coolants has also been studied to enhance the heat transfer performance of steel plate [17]. Previous studies also reveal the enhancement of heat transfer rate using surfactant because of its higher surface activity leading to an increase in surface contact, spreadability and evaporation rate of coolant [2428]. In addition, the cavitation theory [29,30] proposes that the surface tension is responsible for easier atomization of spray into ner droplets. The smaller the size of droplets, the faster they can evaporate from the surface [31]. Moreover, increase in vapour nucleation rate by decrease in surface tension [32,33] enhances heat transfer rate in both nucleate boiling and transition boiling regimes. Overall, the existing literature reveals that surfactant water has better cooling performances than pure water. In many industrial and practical applications, a mixture of surfactants is widely used because of its higher performance on nal applications than that of a single surfactant [3436]. These binary surfactant mixtures are of anionic and cationic, cationic and nonionic, and nonionic and anionic surfactants respectively. The combination of mixed-surfactants can present synergic properties [37,38]. The major advantages with surfactant mixtures are: (1) the properties attained by the surfactant mixtures are better than those obtained by individual surfactants; (2) the concentration of mixed-surfactant needed for a required surface tension is lower than that of each individual surfactant concentration; (3) nally, the CMC of a mixture of any two surfactants is less than that of the individual surfactants. Stocco et al. [39] used myristic acid (anionic surfactant) to cetrimonium bromide (cationic surfactant) to increase the foam stability of cationic surfactant. The bubble coalescence time of ionic surfactants (SDS and CTAB) is decreased by the addition of nonionic surfactant (Tween 20), as reported by Suryanarayana and Ghosh [38]. In any binary mixed-surfactant system (SDSCTAB, SDSTween 20, CTABTween 20) [40], at a particular concentration of single surfactant the surface tension value alters with increasing concentration of the other surfactant. On basis of the surfactant enhanced heat transfer literature, spreadability of coolant is also one reason for high heat removal rate from the test surface [41]. Rosen and Liu [42] used the mixtures of anionic and cationic surfactant for getting enhanced spreadability on polyethylene surface. The superspreading of aqueous mixtures of different surfactants on a solid surface has been found by Stoebe et al. [43]. Although the signicance of surfactant on heat transfer enhancement has been found in the literature, no work has been reported on the heat transfer performances of aqueous binary surfactant mixtures. Moreover, only few works have been reported on the cooling of a solid surface kept at high temperature (above 900 C). Hence the current study focuses on the air-atomized water spray cooling with dissolved binary surfactant mixtures in pure water to cool a hot steel plate. The plate used in the current study is a stainless steel of grade AISI 304 with dimensions 100 mm 100 mm 6 mm. The cooling starts at the initial plate temperature of 900 C, which is observed in ROT cooling in a Hot Strip Mill of a steel plant. The binary surfactant mixtures used are SDSCTAB, CTABTween 20 and SDSTween 20.

2. Experimental conguration The experimental set-up for air-atomized spray cooling is shown in Fig. 1, which consists of test plate holder with air-atomized spray nozzle arrangement on top, the liquid coolant ow loop

212

S.V. Ravikumar et al. / Experimental Thermal and Fluid Science 55 (2014) 210220

Fig. 1. Schematic diagram of air-atomized spray cooling.

and the air ow loop. A stainless steel plate of AISI 304 grade has been used in the experiments and the dimensions are 6 mm thickness and surface area of 100 mm 100 mm. A full cone internal mixing air-atomized spray nozzle (Model No: 170.801, Lechler Inc., Germany) has been used in this study. The experiments have been conducted from a xed nozzle-to-plate distance of 60 mm and at xed ow rate of air and liquid viz. 10 lpm and 30 Normal m3/h respectively. The experimental procedure used is same as reported earlier [23] and the working uids used in this study are binary mixtures of different surfactant additives in pure water. In each experiment, the steel plate has been heated to a temperature of above 900 C in an electrically heated mufe furnace. Three subsurface K-type thermocouples have been used for recording transient temperature data during the experiments. The real time data during cooling have been collected with the help of a data acquisition system (NIcDAQ-9174 with NI 9211 card) having a sampling frequency of 10 Hz. The optimum concentrations of the three surfactants for using them as effective coolants is based on the earlier study [23]. These optimum solutions are 600 ppm SDS, 240 ppm CTAB and 56 ppm Tween 20 respectively. By using these solutions in the proportion of 25%, 50% and 75%, the mixture of binary solutions have been prepared. Hence, in this binary mixed-surfactant system (SDS CTAB, SDSTween 20, CTABTween 20), 0% and 100% solution corresponds to the volume percentage of any single surfactant at their optimum concentration as mentioned above. For example, 25:75 vol% SDS:CTAB binary mixture means that 25% (by volume)

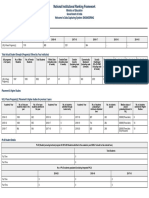

Table 1 Design of experiments for mixed-surfactant system. Serial no. 1 2 3 Binary mixtures of surfactant systems Anionic (SDS) + cationic (CTAB) Anionic (SDS) + nonionic (Tween 20) Cationic (CTAB) + nonionic (Tween 20) Volume percentage 0, 25, 50, 75, and, 100

of 600 ppm SDS in aqueous solution was added with 75% (by volume) of 240 ppm CTAB in aqueous solution to prepare the said binary mixture. The design of experiments has been shown in Table 1.

3. Inverse heat conduction analysis In this study, the measured temporal variation of internal temperatures of the specimen by thermocouples is used to determine the unknown heat ux boundary conditions on the cooling surface. To estimate the heat ux and temperature distribution along the quench surface, an inverse heat conduction analysis is conducted in commercial inverse heat conduction software INTEMP using varying thermal properties of material. It has been successfully applied by the scientic community for the solutions of the inverse heat conduction problems based on the measured thermocouple data [9,11,15,44]. The L-curve analysis has been applied for smoothing the data, which is constructed by a number of executions of INTEMP in a range of smoothing parameters. Each output le gives the one ux data and error data. The ux data (Y-axis) versus error data (X-axis) is than plotted which forms L-curve. The corner value in the L-curve gives the optimal smoothing parameters. The detailed methodology of model and computations have been described by Trujillo and Busby [45,46] who developed the INTEMP software. The analysis, procedure and limitations have also been outlined in the authors earlier work [23]. In the current experimental analysis, a 2D planar model with a length of 100 mm and a thickness of 6 mm is employed to model the heat transfer phenomena of AISI 304 stainless steel plate. As anticipated by Zumbrunnen [47] different zones have been identied on the quenching surface of which the maximum heat removal occurs in the single phase forced convection zone followed by the nucleate/transition boiling zone. Based on this, the test surface has been divided into three heat ux zones. It contains one direct impact zone and two radial ow zones based on their thermocouple

S.V. Ravikumar et al. / Experimental Thermal and Fluid Science 55 (2014) 210220

213

location away from the stagnant point, which are previously summarized by the present authors [23]. 4. Measurement uncertainty In order to maximize the accuracy of the research outcome, efforts have been made to minimize the uncertainties in the experimental and computational results. An uncertainty methodology by ASME test code PTC 19.8-1983 has been used in the current study [59]. The rst major source of error arises from fault in the measuring instrument which is known as bias. Another type of error comes into play due to lack of preciseness in denition of measured quantity and this is known as random or precision error. In this study, the measured quantities are temperature by thermocouples and physical properties of coolants by calibrated instruments. The calculated quantities are surface heat ux and surface temperatures. The K-type thermocouples which are used to record the temperature during experiments lead to uncertainties in the results. The bias in temperature measurement is 2.8 C with zero precision. A data acquisition system (NI-9211, manufactured by National Instruments Co., USA) is used in this study for the temperature recording. The offset in the temperature measurement and the sensitivity is +0.7 C and <0.07 C respectively, as reported by the manufacturer. Temperature recorded by the data card may also contain errors due to lag in the thermocouple wire. An effort has been made to restrict this uncertainty due to thermocouple wire within 2 C by using a specially calibrated thermocouple wire for recording the instantaneous readings measured by the thermocouple. The uncertainty due to lack of contact between the thermocouple tip and the plate has been avoided by using a highly conductive material in thermocouple holes to ll the isolated air gaps. The errors in the thermo-physical properties of coolants such as surface tension, contact angle and viscosity are 0.4%, 0.2% and 2.1%, respectively which arise from calibrated instruments. The surface temperature and surface heat ux are calculated by an inverse heat conduction analysis software called INTEMP. It eliminates the noise present in the boundary values by optimal smoothing parameter using L-curve methodology which reports the uncertainties in the output values. Based on the value of optimal smoothing parameter, the precision error in surface heat ux estimation is 2.4%. To ensure the reproducibility of the results, each experiment has been repeated thrice. The standard deviation in cooling rate estimation has been found to be 1.91%. In this study, the calculated surface temperatures by INTEMP has also been veried using infrared thermal measurement technique on natural cooling experiment. The error between the calculated surface temperature by INTEMP and measured surface temperature by infrared thermograph is found to be within 3%. 5. Results and discussion Before performing the spray cooling experiments, all the coolants were characterized by measuring physical properties of coolants to understand the mechanism for heat transfer enhancement. The properties measured are surface tension, viscosity and contact angle. The surface tension of the coolant was measured using Tensiometer [Krss (Germany), model: K100] which is based on the Wilhelmy plate method. The detailed measuring procedure is available in the literature [48]. From the Young equation [49], surface tension is responsible for wetting ability of solid surface by depends upon on its contact angle with the coolant used. Therefore, in this study the contact angle of the surface is measured using Goniometer [Rame-Hart instrument (USA), model: 190-F2). Finally, the zero-shear viscosities of the coolants are measured using viscometer [Brookeld Viscometer (USA), model: DV2T]. All the

measurements have been repeated thrice and the average value has been taken for better accuracy of the experiment. 5.1. Physical property measurements of the surfactants 5.1.1. Surface tension and contact angle The change in surface tension and subsequent contact angle in different binary mixtures of surfactant has been shown in Fig. 2 of

Fig. 2. Variation of surface tension and contact angles with (a) SDSCTAB binary surfactant mixture, (b) CTABTween 20 binary surfactant mixture and (c) SDS Tween 20 binary surfactant mixture.

214

S.V. Ravikumar et al. / Experimental Thermal and Fluid Science 55 (2014) 210220

which, Fig. 2a is for SDS (anionic)CTAB (cationic) binary surfactant mixture, Fig. 2b is for CTAB (cationic)Tween 20 (nonionic) and Fig. 2c for SDS (anionic)Tween 20 (nonionic) surfactant systems. For these systems, primary X-axis in Fig. 2 shows the percentage amount of primary surfactant in binary mixture and the corresponding percentage of second surfactant is shown in secondary X-axis. In the anioniccationic binary system, the surfactants consist of oppositely charged ions [50] which leads to the risk of emulsion precipitation [51]. Due to this the surface activity property will diminish which results in increase in solidliquid contact angle also. From the Fig. 2a, catanionic binary mixture of 25:75 vol% SDS:CTAB shows appreciable surface activity compared to those of the single surfactant used as additive. The reason for this result is that synergic property exists at these compositions of catanionic surfactants. Synergism is nothing but properties attainable by a mixture of surfactants which are better than those of individual surfactant themselves. Increase in SDS volume percentage beyond 25% in the mixture makes the surface tension and contact angle higher than that of individual surfactant amount of CTAB (100%). This is due to the fact that oppositely charged ions in catanionic surfactant mixture initiates the precipitations which make surfactants ineffective in solutions. The surface tension attained by individual surfactants such as 100% SDS and 100% CTAB are 52.2 mN/m and 41.88 mN/m, respectively. Whereas, binary mixture of 25% SDSCTAB can attain a surface tension value of 38.9 mN/m, which is 34.19% and 7.67% less than that of pure SDS and pure CTAB, respectively. As shown in Fig. 2b, the binary mixtures of cationic and nonionic surfactants show higher performance in decreasing surface tension compared to that of their individual surfactant concentrations. The higher percentages of nonionic surfactant Tween 20 (75%) and lower percentages of cationic surfactant CTAB (25%) in the binary mixture shows optimum values of surface tension and contact angle in the solutions. The surface tension at this optimum cationic (CTAB)nonionic (Tween 20) binary mixture is 19.3% and 10.5% less than that of pure CTAB and Tween 20 of individual surfactant solutions. Similarly, Fig. 2c shows that in anionic and nonionic binary system the surface tension and contact angle decrease appreciably compared to that at 100% concentrations of two individual surfactant values. Moreover, at higher percentages of nonionic surfactant i.e., 75% Tween 20 and 25% SDS, the fall in surface tension and contact angles are more appreciable. The surface tension property at any composition of this binary mixture is lesser than that of their individual surfactant values. The reason for this result is that synergism continues for entire composition of this binary mixture and this property is higher at 75% Tween 20 and 25% SDS binary system. The surface tension value at this binary mixture is 66.24% and 23.54% lesser than that of the values of pure SDS and Tween 20, respectively. By comparing the results of all the three binary mixtures reported in Fig. 2, the surface tension results of anionicnonionic surfactant is the most appreciable. The surface tension value at optimum binary mixture of anionicnonionic surfactant shows higher activity i.e., 23.89% and 11.78% less than that of anionic-cationic and cationicnonionic surfactants, respectively. Since lower surface tension results in lower solidliquid contact angle, this leads to higher spreadability with higher wettability of surfactant mixtures on the surface.

Fig. 3. Variation of viscosity with (a) SDSCTAB binary surfactant mixture, (b) CTABTween 20 binary surfactant mixture and (c) SDSTween 20 binary surfactant mixture.

5.1.2. Viscosity of surfactant solutions The effect of different binary mixtures of anioniccationic surfactant, (b) cationicnonionic surfactant, (c) anionicnonionic surfactant on viscosity of the resulting mixture is shown in

Fig. 3ac, respectively. It can be seen that SDSCTAB binary mixture shows greater increase in viscosity of solution due to the formation of precipitate emulsion by oppositely charged ions. For CTABTween 20 and SDSTween 20 binary mixtures also, the viscosity slightly increases, which is due to the higher viscosity of secondary surfactant (SDS or CTAB) in the binary mixture [23].

S.V. Ravikumar et al. / Experimental Thermal and Fluid Science 55 (2014) 210220

215

5.2. Air-atomized spray cooling Before conducting the experiments with mixed-surfactant additives, the cooling study with pure water as coolant has been undertaken as a base case to relate the expected improved cooling capabilities of the additives. As discussed earlier in Section 3, in all the experiments, the measured internal temperature data obtained by the thermocouples has been used to calculate the corresponding surface temperature and surface heat ux variations using inverse heat conduction solver. One of such result is presented in Fig. 4 as a representative case, wherein Fig. 4a shows the measured internal temperature histories and Fig. 4b depicts the corresponding surface temperature and heat ux histories on the quenching surface. The coolant used for the current experiment is pure water. It can be seen that the curves in Fig. 4a represent the temperature histories at thermocouple location from 1 to 3, in which location 2 is the direct spray impact zone and location 3 is nearer to location 2 than location 1. Therefore, the cooling occurs rst at location 2 and then at location 3 and location 1 respectively. The delay in cooling at the horizontal ow zones are mainly because wetting front takes some time to reach the surface away from the stagnant point due to ow retardation effect. It is observed from Fig. 4b, the surface temperature proles which follow the same trend as the internal temperature curves but at the same time, it is observed that surface is cooled about 4 s earlier than the corresponding internal positions. This is because heat transfer rate at the surface of the plate is faster than that at the internal positions as direct contact of the spray takes place with the surface. The corresponding variations in surface heat ux with cooling time

at different positions on the surface of the plate have also been shown in Fig. 4b. It is observed from the gure that at all the three locations the surface heat ux increases with increasing cooling time up to certain value known as critical heat ux due to the onset of transition boiling heat transfer and thereafter decreases at the nucleate boiling regime. Heat transfer is different in different zones like direct impact zone and horizontal ow zones which is well in agreement with the study of Zumbrunnen [47]. The maximum value of critical heat ux is found at location 2 which corresponds to the direct impingement zone and it decreases with locations away from the stagnation point. The reason behind this phenomenon is mainly the spatial variation in spray mass ux over the surface. Moreover, there is a delay in wetting of regions located away from the direct spray impingement zone. The boiling curve that is a plot between surface heat ux and corresponding surface temperature during cooling with pure water coolant is shown in Fig. 5, which is at stagnant zone. It can be seen that two different changeovers exist, in which one occurs at 380 C and another at 130 C. At surface temperature between 920 C and 380 C, the surface heat ux increases with decreasing surface temperature as a result of transition boiling. In this regime, due to intermittent contact between the coolant and solid surface the lm boiling and nucleate boiling will co-exist which makes the vapour layer unstable by rapid nucleation of bubbles resulting in increase in heat ux gradually to a maximum value. This phenomenon is also known as spray evaporative cooling where the maximum heat ux value in the boiling curve is known as the critical heat ux (CHF). It can be considered as transition point between transition and nucleate boiling. In the nucleate boiling where surface heat ux decreases with the decrease in surface temperature between 380 C and 130 C vigorous bubble nucleation bubbles occurs which grow in sizes resulting in formation of liquid lms over the quench surface. As the surface temperature further decreases below 130 C, a continuous liquid lm formed by the spray coalescence, as a result, no bubble can form and therefore the heat transfer takes place by single phase forced convection mode where the surface heat ux decreases. These boiling heat transfer transitions are well in agreement with the study of Jia and Qiu [52], Hall et al. [53] and Chester et al. [54] who also observed similar behaviour. It is to be noted that no stable lm boiling regime has been found on the test surface during cooling as stable vapour blanket could not be formed since the superposed air swept away the vapour and partially evaporated droplets. Therefore, the present study operates under transition and nucleates boiling regimes only which is the greatest advantage of air-atomized spray cooling. Similar trends of the cooling results are found in the experimental runs

Fig. 4. (a) Measured internal temperature histories by thermocouples. (b) Calculated surface temperature and heat ux histories by INTEMP.

Fig. 5. Boiling curve at the stagnant zone of the plate from an experiment with pure water coolant.

216

S.V. Ravikumar et al. / Experimental Thermal and Fluid Science 55 (2014) 210220

where aqueous mixed-surfactant additives were used as coolants and are discussed in the subsequent sections. 5.2.1. Binary mixture of anionic and cationic surfactants The rst binary system used in our study is a mixture of 600 ppm aqueous solution of SDS (anionic) and 240 ppm aqueous solution of CTAB (cationic). The binary compositions taken are 0:100 vol% SDS:CTAB, 25:75 vol% SDS:CTAB, 50:50 vol% SDS:CTAB, 75:25 vol% SDS:CTAB, and 100:0 vol% SDS:CTAB as discussed earlier. Fig. 6a shows the effect of proportion of SDSCTAB binary surfactant mixture on the boiling curve. The temperature region between 900 and 200 C is particularly taken to analyze the experimental results, which covers the transition and nucleate boiling heat transfer regimes. It can be seen that all the curves in the gure are qualitatively same but vary quantitatively due to the use of different percentage of surfactant mixtures in the coolant. In all the cases, the heat ux increases with decreasing surface temperature due to the onset of transition boiling and reaches a maximum value known as critical heat ux which is the limiting point of transition boiling. Thereafter; it decreases with decrease in surface temperature which marks the nucleate boiling heat transfer regime. The boiling curves of SDSCTAB binary mixtures shows that the heat transfer rate in transition and nucleate boiling are high for 0:100 vol% SDS:CTAB and 100:0 vol% SDS:CTAB. The heat transfer rate, however, decreases in case of their binary mixtures. This occurs mostly due to the formation of emulsions. The surface heat uxes achieved with the binary mixtures are all lower than that obtained with pure surfactant solutions (0:100 vol% SDS:CTAB and 100:0 vol% SDS:CTAB). The reason is that the suppression of surface tension by using these mixtures are not so effective (see Fig. 2a) and moreover it initiates emulsion precipitation which causes the increase in viscosity of coolant (see Fig. 2b). Increase in viscosity makes the atomization and evaporation of droplets difcult. However, the binary mixture of 25:75 vol% SDS:CTAB shows better performance than that of other combinations, which is due to signicant decrease in surface tension at this mixed-surfactant concentration. As explained in the authors earlier study [23], in surfactant enhanced transition boiling, due to lower vapour thickness in case of smaller droplet sizes facilitated by decrease in surface tension makes faster intermittent contact with hot surface with a higher bubble nucleation rate. Then the bubbles coalescence and grow in sizes in surfactant added water. Moreover, the surfactant molecules puncture the vapour layer due to difference in their boiling point with pure water and allow the droplets to touch the hot plate. The smaller droplets can easily go through the ruptures

Fig. 6b. Variation in cooling rate with aqueous SDSCTAB binary surfactant mixture.

formed by surfactant molecules and as a result higher evaporation rate occurs. In this study, for application into ROT cooling of steel processing industries, the cooling rate is calculated between 900 and 600 C because the phase transformations in steels occur in this temperature range. Fig. 6b shows the variation in cooling rate with aqueous SDSCTAB binary surfactant mixture. The maximum cooling rate obtained with this binary mixture is 176 C/s (at 25:75 vol% SDS:CTAB) while the maximum rates obtained with 0:100 vol% SDS:CTAB and 100:0 vol% SDS:CTAB are even higher. In SDSCTAB mixture, the positive and negatively charged ions equally cancel out resulting in micro emulsion which obstructs the coolant ow and evaporation becomes difcult. This also leads to increase in viscosity of coolant results in formation of lms on the surface. Hence, this binary mixture of anioniccationic surfactant is not recommended for use.

Fig. 6a. Effect of SDSCTAB binary surfactant mixture on boiling curve.

5.2.2. Binary mixture of cationic and nonionic surfactants The second binary system used in this study is a mixture of 240 ppm aqueous solution of CTAB (cationic) and 56 ppm aqueous solution of Tween 20 (nonionic). The binary compositions are 0:100 vol% CTAB:Tween 20, 25:75 vol% CTAB:Tween 20, 50:50 vol% CTAB:Tween 20, 75:25 vol% CTAB:Tween 20, and 100:0 vol% CTAB:Tween 20 as discussed earlier. The effect of CTABTween 20 binary surfactant mixture on the boiling curve is shown in Fig. 7a. In all the cases, the boiling curve follows the same trend. The surface heat ux increases in the transition boiling regime reaching a critical heat ux and then decreases in the nucleate boiling regime. It can be seen that the heat transfer rate in transition and nucleate boiling is the highest for 25:75 vol% CTAB:Tween 20 binary solution and it decreases with increasing concentration of CTAB in the binary mixture. The highest critical heat ux value has also been observed at the 25:75 vol% CTAB:Tween 20 binary solution. The reason for the highest heat transfer rate with this binary mixture is due to the lower surface tension (see Fig. 2b) and it increases with increasing concentration of CTAB in the binary surfactant mixture. Fig. 7b shows a marginal variation of cooling rate with CTAB Tween 20 binary surfactant mixtures. The highest cooling rate achieved with 25:75 vol% CTAB:Tween 20 solution is 225 C/s whereas that of pure CTAB at optimum concentration (240 ppm) is 207 C/s and that of pure Tween 20 at optimum concentration (56 ppm) is 215 C/s. Hence, the cooling rate obtained with any binary mixture of CTAB and Tween 20 is slightly higher than that

S.V. Ravikumar et al. / Experimental Thermal and Fluid Science 55 (2014) 210220

217

be said that coolant of low surface tension along with low viscosity is most suitable for higher performance as an effective coolant. Fig. 8b shows the cooling rates of SDS and Tween 20 and their binary mixtures. The highest cooling rate obtained is 240 C/s whereas that achieved by pure SDS is 187 C/s and that by Tween 20 is 215 C/s. Hence, the cooling rate obtained by binary mixtures of SDS and Tween 20 is much higher than that obtained by the pure surfactant solutions. The resultant enhancement in cooling rate by this mixed-surfactant system is in the range of 1222%. 5.3. Comparative study on mixed-surfactant systems The comparative study on heat transfer performances of optimum surfactant fractions for the three different binary surfactant mixtures described earlier has been presented in Fig. 9. From the estimated values of surface heat ux and surface temperatures (Fig. 9a), the heat transfer co-efcient with respect to surface temperature has been calculated and reported in Fig. 9b. The cooling performance of pure water is also presented along with to understand the enhanced performance provided by the surfactant mixtures. The optimum combinations of the mixed-surfactant solutions are 25:75 vol% SDS:CTAB, 25:75 vol% CTAB:Tween 20 and 25:75 vol% SDS:Tween 20. The surface tension values obtained by these three mixtures are 38.9 mN/m, 35.1 mN/m and 31.4 mN/ m, respectively, while the viscosity values are found to be 1.34 mPa s, 0.52 mPa s and 0.72 mPa.s, respectively. It can be seen

Fig. 7a. Effect of CTABTween 20 binary surfactant mixture on boiling curve.

Fig. 7b. Variation in cooling rate with CTABTween 20 binary surfactant mixture.

of pure surfactant solutions while the enhancement is in the range of 58%. 5.2.3. Binary mixture of anionic and nonionic surfactants The third and nal binary system which is used in our study is 600 ppm aqueous solution of SDS (anionic) and 56 ppm aqueous solution of Tween 20 (nonionic). The binary compositions prepared are 0:100 vol% SDS:Tween 20, 25:75 vol% SDS:Tween 20, 50:50 vol% SDS:Tween 20, 75:25 vol% SDS:Tween 20, and 100:0 vol% SDS:Tween 20, as in the previous cases. Fig. 8a shows the boiling curves of SDS and Tween 20 and their binary mixtures. The boiling curves show the same trend where the heat ux increases in the transition boiling regime. Thereafter it reaches a critical heat ux and decreases in the nucleate boiling regime. The heat transfer rate in transition and nucleate boiling is the highest with 25:75 vol% SDS:Tween 20 solutions and also a very high critical heat ux of 3.98 MW/m2 has been obtained. Increase in SDS concentration in the binary mixture makes the heat transfer rate lower. All the binary mixtures have higher heat ux than that of their pure surfactant solutions. The higher heat transfer rate with SDSTween 20 binary surfactant mixture is due to very low surface tension values as evident in Fig. 2c and it increases with the increase in SDS fraction. On the other hand, pure Tween 20 shows very less viscosity and it increases with increase in SDS fraction in the binary surfactant mixture. Therefore, it can

Fig. 8a. Effect of SDSTween 20 binary surfactant mixture on boiling curve.

Fig. 8b. Variation in cooling rate with SDSTween 20 binary surfactant mixture.

218

S.V. Ravikumar et al. / Experimental Thermal and Fluid Science 55 (2014) 210220

Fig. 9. Variation in (a) surface heat ux and (b) heat transfer co-efcient with surface temperature at an optimum concentration of the binary surfactant mixtures.

from Fig. 9 that SDSTween 20 binary surfactant mixture shows the best performance in transition and nucleate boiling with highest critical heat ux and heat transfer coefcients. This is due to very low surface tension obtained by this mixture which makes the droplets ner in size when it is injected from the nozzle. This low surface tension is also responsible for a higher contact area when the droplet hits the solid surface due to the lower contact angle. Smaller droplets with higher contact area can quickly evaporate from the surface resulting in a vapour blanket of lower thickness. This has also been observed by Biance et al. [55], who found that the vapour layer formed by the impingement of droplet on the hot surface is proportional to its initial diameter. Lesser vapour thickness can easily be punctured by the surfactant molecules and allows faster intermittent contact of spray droplets. Consequently, nucleation and accumulation of small vapour bubbles take place to form slugs that maximize the droplet evaporation rate which in turn causes an increase in transition boiling heat transfer. The result is in agreement with the observations by Crafton and Black [56], who found that the evaporation rates of thinner and broader droplets are higher on the metal surface. As observed from authors earlier work [23] the best coolants are CTAB and Tween 20 but coming to the case of those mixed-surfactants their binary mixtures did not give best performance. It can also be seen from the authors earlier study that SDS alone shows low cooling performance due to the effect of viscosity and higher surface tension and higher foamability characteristics. But when it is mixed with Tween 20, it shows higher performance and it decreases with increase in SDS concentration. The synergetic properties of Tween 20 with SDS is higher than CTAB. Therefore, SDS Tween 20 case shows higher performance than CTABTween 20. On the other hand, it is to be noted that the viscosity of SDS Tween 20 binary surfactant mixture is slightly higher than that of the value of CTABTween 20 binary surfactant mixture. This does not mean that increase in viscosity accelerates the cooling rates. At this state it is crucially important to explain why heat transfer rate is higher in the case of SDSTween 20 than that of

Fig. 10. Progression of wetting front on the hot surface during working with binary mixtures of (a) pure water, (b) SDSCTAB, (c) CTABTween 20 and (d) SDSTween 20.

S.V. Ravikumar et al. / Experimental Thermal and Fluid Science 55 (2014) 210220 Table 2 Maximum achieved cooling rate and critical heat ux values of different binary surfactant mixtures. Serial no. 1 2 3 4 Surfactant system Pure water 25:75 vol% SDS:CTAB 25:75 vol% CTAB:Tween 20 25:75 vol% SDS:Tween 20 Cooling rate (C) 167 176 224 240 Critical heat ux (MW/m2) 2.74 2.97 3.52 3.98

219

CTABTween 20 binary mixture. Both the aqueous binary solution shows the lesser viscosity than that of pure water. Obviously, coolant of lower viscosity is favourable for higher cooling intensities. Then, what is the dominant factor in case of SDSTween 20 mixture? It can be seen from Fig. 2b and c, the surface tension of SDSTween 20 appears to be 10.4% lesser than that of CTABTween 20, therefore the cooling rate is greater in the case of SDSTween 20. This means that decrease in surface tension is certainly the dominant factor to intensify the cooling rate, as discussed earlier. Since the surface tension is the governing parameter for vapour lm wave length of instability [57] due to droplets of higher contact area and higher number density of bubble nucleation sites, the heat transfer rate in the transition boiling is greatly enhanced by a decrease in surface tension. Finally, it can be concluded that surface tension is the major inuencing parameter for higher heat transfer than viscosity. The photographs of the propagation of wetting front on the hot surface during cooling with different optimum binary mixtures of surfactant solutions are shown in Fig. 10. It is evident from the gure that the movement of wetting front (dark region) is faster in case of 25:75 vol% SDS:Tween 20 solution than that of 25:75 vol% CTAB:Tween 20 and 25:75 vol% SDS:CTAB respectively, which conveys that higher heat transfer is responsible for higher wetting front velocity, which all are faster than that of pure water spreading rate. This is well in agreement with the study of Abdalrahman et al. [58] that the speed of wetting front is responsible for the higher quench ability of the hot surface. Finally, the effects of binary mixtures on the cooling rate and critical heat ux is shown in Table 2. The cooling rate of SDS Tween 20 binary surfactant is 240 C/s which is 7 percent higher than the next higher value (224 C/s) by CTABTween 20 and compared to pure water (167 C/s) performance these are 43% and 34% higher respectively. Overall, the maximum cooling rates achieved by SDSTween 20 and CTABTween 20 are in the higher range of an ultrafast cooling process.

The experimental nding reveals that binary mixtures SDS Tween 20 and CTABTween 20 show enhanced performances in surface cooling rate than that of their pure surfactant solutions used as coolant. Among the three mixed-surfactant systems, SDSTween 20 shows the higher cooling capability of the hot steel plate due to its high surface activity than that of CTABTween 20 and CTABTween 20 surfactant systems. The coolant of higher surface activity (low surface tension) makes the droplets ner when the process of atomization in the nozzle. Low surface tension is also responsible for a higher wettability when the droplet hits the solid surface due to the lower contact angle. Therefore, smaller droplets with higher contact area can quickly evaporate from the surface resulting in a vapour blanket of lower thickness which in turn causes an increase in transition boiling heat transfer. The binary surfactant mixtures of SDSCTAB not at all recommended for using it as coolant because of the oppositely charged ions in anionic and cationic surfactants causes risk of emulsion precipitation, which makes the evaporation difcult. The optimum fraction for the higher cooling rates in the CTABTween 20 and SDSTween 20 systems are 25:75 vol% and 25:75 vol%, respectively. In these systems, the heat transfer decreases with increase in the fraction of ionic surfactant (CTAB or SDS). The maximum cooling rates obtained with SDSCTAB mixture (25:75% by volume) is 176 C/s, that with CTABTween 20 mixture (25:75% by volume) is 224 C/ s and that with SDSTween 20 mixture (25:75% by volume) is 240 C/s. The critical heat uxes achieved in these cases are 2.97 MW/m2, 3.52 MW/m2 and 3.98 MW/m2 respectively which are higher than those attained by pure water. The CTABTween 20 and SDSTween 20 mixtures only shows higher performances than that of pure surfactants. Overall, a maximum heat transfer co-efcient of 20,000 W/m2 C has been achieved in air-atomized spray cooling, which is very high value than that obtained from any conventional spray cooling. Hence, the mixed-surfactant systems are suitable for heat transfer enhancements with the binary mixture of anionic and nonionic surfactant (SDS and Tween 20) being the best one. A wide range of ultrafast cooling rates from 167 C/s (for pure water) to 240 C/s (for 25:75 vol% SDS:Tween 20 mixture) have been achieved in the current study. Different cooling rates in the ROT of a hot strip mill lead to formation of different microstructures which are suitable for varied applications. Different surfactant mixtures can thus be used to attain different cooling rates to obtain the steels of specic applications.

References

[1] J.S. Coursey, J. Kim, K.T. Kiger, Spray cooling of high aspect ratio open microchannels, J. Heat Transf. 129 (2007) 10521059. [2] K.I. Yoshida, Y. Abe, T. Oka, Y.H. Mori, A. Nagashima, Spray cooling under reduced gravity condition, J. Heat Transf. 123 (2001) 309318. [3] M.E. Sawan, M.W. Carbon, A review of spray-cooling and bottom-ooding work for LWR cores, Nucl. Eng. Des. 32 (1975) 191207. [4] Q. Wang, P. Liu, S. Xu, B. Wang, T. Wang, A parametric study to design an effective spray cooling deployment in an entrained-ow coal gasier, in: 25th Annual International Pittsburgh Coal Conf., PCCProceedings, CSREA Press, Bogart, GA USA, 2008, pp. 22582268. [5] M. Raudensky, J. Horsky, A.A. Tseng, C.-I. Weng, Heat transfer evaluation of impingement cooling in hot rolling of shaped steels, Steel Res. 65 (1994) 375 381. [6] J.D. Bernardin, I. Mudawar, Film boiling heat transfer of droplet streams and sprays, Int. J. Heat Mass Transf. 40 (1997) 25792593. [7] S.D. Cox, S.J. Hardy, D.J. Parker, Inuence of runout table operation setup on hot strip quality, subject to initial strip condition: heat transfer issues, Ironmak. Steelmak. 28 (2001) 363372. [8] S.V. Ravikumar, J.M. Jha, S.S. Mohapatra, S.K. Pal, S. Chakraborty, Inuence of ultrafast cooling on microstructure and mechanical properties of steel, Steel Res. Int. 84 (2013) 11571170. [9] S.S. Mohapatra, S.V. Ravikumar, S.K. Pal, S. Chakraborty, Ultra fast cooling of a hot steel plate by using high mass ux air atomized spray, Steel Res. Int. 84 (2013) 229236.

6. Conclusions The heat transfer characteristics of different binary mixed-surfactant systems in air-atomized spray cooling have been studied in the present work. Aqueous solutions of 600 ppm anionic surfactant (i.e., SDS), 240 ppm cationic surfactant (i.e., CTAB) and 56 ppm nonionic surfactant (i.e., Tween 20) have been used in these studies. The mixed-surfactant systems considered are SDSCTAB, CTABTween 20 and SDSTween 20. From these, the binary mixtures prepared in the proportion of 0:100 vol%, 25:75 vol%, 50:50 vol%, 75:25 vol%, and 100:0 vol% respectively. The cooling capability of pure water has also been tested to understand the enhanced performance provided by the surfactant mixtures. An AISI 304 grade stainless steel plate of initial temperature >900 C has been chosen for spray cooling experimentation. The novelty of the work lies in the fact that these mixed-surfactant systems (SDSCTAB, CTABTween 20 and SDSTween 20) have been used in a high temperature heat transfer application.

220

S.V. Ravikumar et al. / Experimental Thermal and Fluid Science 55 (2014) 210220 [34] G. Kume, M. Gallotti, G. Nunes, Review on anionic/cationic surfactant mixtures, J. Surfactants Deterg. 11 (2008) 111. [35] P. Kang, H. Xu, C. Song, Properties of binary surfactant system of alkyl polyglycosides and a-sulphonated fatty acid methyl ester, Tenside, Surfactants, Deterg. 50 (2013) 192198. [36] T. Bramer, N. Dew, K. Edsman, Pharmaceutical applications for catanionic mixtures, J. Pharm. Pharmacol. 59 (2007) 13191334. [37] M.J. Rosen, X.Y. Hua, Synergism in binary mixtures of surfactants: II. Some experimental data, J. Am. Oil Chem. Soc. 59 (1982) 582585. [38] G. Suryanarayana, P. Ghosh, Adsorption and coalescence in mixed-surfactant systems: airwater interface, Ind. Eng. Chem. Res. 49 (2010) 17111724. [39] A. Stocco, D. Carriere, M. Cottat, D. Langevin, Interfacial behavior of catanionic surfactants, Langmuir 26 (2010) 1066310669. [40] N. Jadidi, B. Adib, F.B. Malihi, Synergism and performance optimization in liquid detergents containing binary mixtures of anionicnonionic, and anionic-cationic surfactants, J. Surfact. Deterg. 16 (2013) 115121. [41] G. Karapetsas, R.V. Craster, O.K. Matar, On surfactant-enhanced spreading and superspreading of liquid drops on solid surfaces, J. Fluid Mech. 670 (2011) 5 37. [42] M.J. Rosen, H. Liu, Mechanism of the enhanced spreading of some mixtures of anionic and cationic hydrocarbon chain surfactants on a highly hydrophobic polyethylene surface, J. Surfact. Deterg. 8 (2005) 157163. [43] T. Stoebe, Z. Lin, R.M. Hill, M.D. Ward, H.T. Davis, Surfactant-enhanced spreading, Langmuir 12 (1996) 337344. [44] H. Leocadio, J.C. Passos, D.C.F.S. A, Heat transfer behaviour of a high temperature steel plate cooled by a sub-cooled impinging circular water jet, in: 7th ECI International Conference on Boiling Heat Transfer, Florianopolis, Brazil, 2009, pp. 37. [45] D.M. Trujillo, H.R. Busby, Optimal regularization of the inverse-heat conduction problem using the L-curve, Int. J. Numer. Meth. Heat Fluid Flow 4 (1994) 447452. [46] D.M. Trujillo, H.R. Busby, Practical Inverse Analysis in Engineering, CRC Press, 1997. p. 235. [47] D.A. Zumbrunnen, Method and apparatus for measuring heat transfer distributions on moving and stationary plates cooled by a planar liquid jet, Exp. Thermal Fluid Sci. 3 (1990) 202213. [48] J. Drelich, C. Fang, C.L. White, Measurement of interfacial tension in uiduid systems, in: A. Hubbard (Ed.), Encyclopedia of Surface and Colloid Science, Marcel Dekker Inc., 2002, pp. 31523166. [49] T. Young, An essay on the cohesion of uids, Philos. Trans. R. Soc. Lond., A 95 (1805) 6587. [50] Y. Wang, C.M. Pereira, E.F. Marques, R.O. Brito, E.S. Ferreira, F. Silva, Catanionic surfactant lms at the airwater interface, Thin Solid Films 515 (2006) 2031 2037. [51] B. Jnsson, P. Jokela, A. Khan, B. Lindman, A. Sadaghiani, Catanionic surfactants: phase behavior and microemulsions, Langmuir 7 (1991) 889 895. [52] W. Jia, H.H. Qiu, Experimental investigation of droplet dynamics and heat transfer in spray cooling, Exp. Therm. Fluid Sci. 27 (2003) 829838. [53] D.E. Hall, F.P. Incropera, R. Viskanta, Jet impingement boiling from a circular free-surface jet during quenching: Part 1-Single-phase jet, J. Heat Transf. 123 (2001) 901910. [54] N.L. Chester, M.A. Wells, V. Prodanovic, Effect of inclination angle and ow rate on the heat transfer during bottom jet cooling of a steel plate, J. Heat Transf. 134 (2012) 122201122209. [55] A.L. Biance, C. Clanet, D. Qur, Leidenfrost drops, Phys. Fluids 15 (2003) 1632 1637. [56] E.F. Crafton, W.Z. Black, Heat transfer and evaporation rates of small liquid droplets on heated horizontal surfaces, Int. J. Heat Mass Transf. 47 (2004) 11871200. [57] N. Zuber, Hydrodynamic aspects of boiling heat transfer, in, University of California, California, 1959. p. 196. [58] K.H.M. Abdalrahman, U. Alam, E. Specht, Wetting front tracking during metal quenching using array of jets, ASME Conf. Proc. 2010 (2010) 475484. [59] R.B. Abernethy, R.P. Benedict, R.B. Dowdell, ASME measurement uncertainty, J. Fluids Eng. 107 (1985) 161164.

[10] N. Karwa, T. Gambaryan-Roisman, P. Stephan, C. Tropea, Experimental investigation of circular free-surface jet impingement quenching: transient hydrodynamics and heat transfer, Exp. Therm. Fluid Sci. 35 (2011) 14351443. [11] S.S. Mohapatra, S.V. Ravikumar, A. Verma, S.K. Pal, S. Chakraborty, Experimental investigation of effect of a surfactant to increase cooling of hot steel plates by a water jet, J. Heat Transf. 135 (2013) 032101032107. [12] B.W. Webb, C.F. Ma, Single-phase liquid jet impingement heat transfer, in: P.H. James, F.I. Thomas (Eds.), Advances in Heat Transfer, Elsevier, 1995, pp. 105 217. [13] U. Alam, J. Krol, E. Specht, J. Schmidt, Enhancement and local regulation of metal quenching using atomized sprays, J. ASTM Int. 5 (2008) 110. [14] F. Puschmann, E. Specht, Transient measurement of heat transfer in metal quenching with atomized sprays, Exp. Therm. Fluid Sci. 28 (2004) 607615. [15] M. De Oliveira, J. Ward, D.R. Garwood, R.A. Wallis, Quenching of aerospace forgings from high temperatures using air-assisted, atomized water sprays, J. Mater. Eng. Perform. 11 (2002) 8085. [16] K.A. Estes, I. Mudawar, Correlation of sauter mean diameter and critical heat ux for spray cooling of small surfaces, Int. J. Heat Mass Transf. 38 (1995) 29852996. [17] S. Ravikumar, J. Jha, S. Mohapatra, A. Sinha, S. Pal, S. Chakraborty, Experimental study of the effect of spray inclination on ultrafast cooling of a hot steel plate, Heat Mass Transf. 49 (2013) 15091522. [18] E.Y. Liu, L.G. Peng, Y. Guo, Z.D. Wang, D.H. Zhang, G.D. Wang, Advanced run-out table cooling technology based on ultra fast cooling and laminar cooling in hot strip mill, J. Cent. S. Univ. Technol. (English Ed.) 19 (2012) 13411345. [19] Y.k. Sun, D. Wu, Effect of ultra-fast cooling on microstructure of large section bars of bearing steel, J. Iron. Steel Res. Int. 16 (2009). 61-65,80. [20] J.C. Herman, Impact of new rolling and cooling technologies on thermomechanically processed steels, Ironmak. Steelmak. 28 (2001) 159163. [21] Y. Tian, S. Tang, B. Wang, Z. Wang, G. Wang, Development and industrial application of ultra-fast cooling technology, Sci. China Technol. Sci. 55 (2012) 15661571. [22] S.S. Mohapatra, S.V. Ravikumar, S. Andhare, S. Chakraborty, S.K. Pal, Experimental study and optimization of air atomized spray with surfactant added water to produce high cooling rate, J. Enhanc. Heat Transf. 19 (2012) 397408. [23] S.V. Ravikumar, J.M. Jha, I. Sarkar, S.S. Mohapatra, S.K. Pal, S. Chakraborty, Achievement of ultrafast cooling rate in a hot steel plate by air-atomized spray with different surfactant additives, Exp. Therm. Fluid Sci. 50 (2013) 7989. [24] S. Chandra, M. Di Marzo, Y.M. Qiao, P. Tartarini, Effect of liquidsolid contact angle on droplet evaporation, Fire Saf. J. 27 (1996) 141158. [25] S.C. Tinker, M. di Marzo, P. Tartarini, S. Chandra, Y.M. Quiao, Dropwise evaporative cooling: effect of dissolved gases and surfactants, in: D.P. Lund, E.A. Angell (Eds.), International Conference on Fire Research and Engineering, Boston, 1995, pp. 9196. [26] Y.M. Qiao, S. Chandra, Experiments on adding a surfactant to water drops boiling on a hot surface, Proc. R. Soc. Lond., A 453 (1997) 673689. [27] Y.M. Qiao, S. Chandra, Spray cooling enhancement by addition of a surfactant, J. Heat Transf. 120 (1998) 9298. [28] L. Cheng, D. Mewes, A. Luke, Boiling phenomena with surfactants and polymeric additives: a state-of-the-art review, Int. J. Heat Mass Transf. 50 (2007) 27442771. [29] J.W. Westwater, in: Thomas B. Drew, John W. Hoopes, Jr., Theodore Vermeulen (Eds.), Advances in Chemical Engineering, vol. 6, Academic Press, New York, 1966, p. 455 ($17.50, AIChE J. 13 (1967) 827828). [30] W. Cheng, B. Xie, F. Han, H. Chen, An experimental investigation of heat transfer enhancement by addition of high-alcohol surfactant (HAS) and dissolving salt additive (DSA) in spray cooling, Exp. Thermal Fluid Sci. 45 (2013) 198202. [31] P. Bhattacharya, A.N. Samanta, S. Chakraborty, Spray evaporative cooling to achieve ultra fast cooling in runout table, Int. J. Thermal Sci. 48 (2009) 1741 1747. [32] V. Wasekar, Heat transfer in nucleate pool boiling of aqueous SDS and triton X100 solutions, Heat Mass Transf. 45 (2009) 14091414. [33] V.M. Wasekar, R.M. Manglik, Pool boiling heat transfer in aqueous solutions of an anionic surfactant, J. Heat Transf. 122 (2000) 708715.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Institute Name: RGUKT-RK Valley (IR-E-C-45102)Document7 pagesInstitute Name: RGUKT-RK Valley (IR-E-C-45102)hsemargNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ARCH NIRF FrameworkDocument63 pagesARCH NIRF FrameworkhsemargNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- RGUKT Audio QuoteDocument1 pageRGUKT Audio QuotehsemargNo ratings yet

- Answer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NameDocument1 pageAnswer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NamehsemargNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Slip CastingDocument10 pagesSlip CastinghsemargNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Mse314 315 316Document390 pagesMse314 315 316hsemargNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Lecture 1423455076Document199 pagesLecture 1423455076hsemargNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- © 1890 Nature Publishing GroupDocument4 pages© 1890 Nature Publishing GrouphsemargNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Foundry Technology PatternsDocument36 pagesFoundry Technology PatternshsemargNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Liberty Ships Brittle Fracture (Final)Document5 pagesLiberty Ships Brittle Fracture (Final)hsemargNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- ADBCYears 01Document1 pageADBCYears 01hsemargNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Key Role of Impurities in Ancient Damascus Steel BladesDocument13 pagesThe Key Role of Impurities in Ancient Damascus Steel BladeshsemargNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Gabby Resume1Document3 pagesGabby Resume1Kidradj GeronNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- CDKR Web v0.2rcDocument3 pagesCDKR Web v0.2rcAGUSTIN SEVERINONo ratings yet

- Computer First Term Q1 Fill in The Blanks by Choosing The Correct Options (10x1 10)Document5 pagesComputer First Term Q1 Fill in The Blanks by Choosing The Correct Options (10x1 10)Tanya HemnaniNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Google App EngineDocument5 pagesGoogle App EngineDinesh MudirajNo ratings yet

- ST JohnDocument20 pagesST JohnNa PeaceNo ratings yet

- On CatiaDocument42 pagesOn Catiahimanshuvermac3053100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Unit 2Document97 pagesUnit 2MOHAN RuttalaNo ratings yet

- Internship ReportDocument46 pagesInternship ReportBilal Ahmad100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Expectation Vs Reality: Job Order and Contract of ServiceDocument10 pagesExpectation Vs Reality: Job Order and Contract of ServiceMikee Louise MirasolNo ratings yet

- Process States in Operating SystemDocument4 pagesProcess States in Operating SystemKushal Roy ChowdhuryNo ratings yet

- ARUP Project UpdateDocument5 pagesARUP Project UpdateMark Erwin SalduaNo ratings yet

- 1SXP210003C0201Document122 pages1SXP210003C0201Ferenc SzabóNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- EnerconDocument7 pagesEnerconAlex MarquezNo ratings yet

- Aitt Feb 2017 TH Sem IIIDocument6 pagesAitt Feb 2017 TH Sem IIIMadhu KumarNo ratings yet

- BSCSE at UIUDocument110 pagesBSCSE at UIUshamir mahmudNo ratings yet

- CV Ovais MushtaqDocument4 pagesCV Ovais MushtaqiftiniaziNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Loading N Unloading of Tanker PDFDocument36 pagesLoading N Unloading of Tanker PDFKirtishbose ChowdhuryNo ratings yet

- SEERS Medical ST3566 ManualDocument24 pagesSEERS Medical ST3566 ManualAlexandra JanicNo ratings yet

- Reference Template For Feasibility Study of PLTS (English)Document4 pagesReference Template For Feasibility Study of PLTS (English)Herikson TambunanNo ratings yet

- Topic 4: Mental AccountingDocument13 pagesTopic 4: Mental AccountingHimanshi AryaNo ratings yet

- Chapter 5Document3 pagesChapter 5Showki WaniNo ratings yet

- PLT Lecture NotesDocument5 pagesPLT Lecture NotesRamzi AbdochNo ratings yet

- Resume Jameel 22Document3 pagesResume Jameel 22sandeep sandyNo ratings yet

- 2021S-EPM 1163 - Day-11-Unit-8 ProcMgmt-AODADocument13 pages2021S-EPM 1163 - Day-11-Unit-8 ProcMgmt-AODAehsan ershadNo ratings yet

- Job Description For QAQC EngineerDocument2 pagesJob Description For QAQC EngineerSafriza ZaidiNo ratings yet

- 6 V 6 PlexiDocument8 pages6 V 6 PlexiFlyinGaitNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fake PDFDocument2 pagesFake PDFJessicaNo ratings yet

- Methodical Pointing For Work of Students On Practical EmploymentDocument32 pagesMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavNo ratings yet

- 450i User ManualDocument54 pages450i User ManualThượng Lê Văn0% (2)

- XgxyDocument22 pagesXgxyLïkïth RäjNo ratings yet