Professional Documents

Culture Documents

Multivariable Modelling For The Cathodic Quality

Uploaded by

Santiago Bejarano AlfaroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multivariable Modelling For The Cathodic Quality

Uploaded by

Santiago Bejarano AlfaroCopyright:

Available Formats

Multivariable Modelling for the Cathodic Quality

Compaa Minera Doa Ins de Collahuasi SCM Gerencia Lixiviacin

Multivariable Modelling for the Cathodic Quality

G. vila; F. Romero; R. Fester (CMDIC) & L. Yacher (CONTAC Ing. Ltda.)

Multivariable Modelling for the Cathodic Quality

Collahuasi Location

Chilean Altiplane (First Region). Mean height of operations: 4,400 m.a.s.l. 230 Km SE of Iquique. Patache Port 60 Km S of Iquique.

Multivariable Modelling for the Cathodic Quality

Oxide Plant Data

� � � Process design for 50,000 [Ton/y] of Cathodes High Grade, leaching Oxides ores. Cathodes production started on July 1998. LME Grade A Certification. Process: Primary Crusher (1) Secondary Crusher (1) & Tertiary Crushers (4) Agglomeration Drums (2) Static Heaps (main pad: 550[m]x1,950[m]) with Coveyor Belts Train and Radial Stacker Two Leaching Cycles (ILS & Raffinate) SX (1 train for 1,000 [m3/h]) : 2E+1W+2S EW : 188 cells (60 SS cathodes+61 Pb anodes per cell), Kidd Process, 36 [KA].

Actual production data (average): Ore to Heaps : 6,500,000 [Ton/year], 18,000 [Ton/d]. Ore : oxide & mixed ores; grade CuT 1.28 [%]. Leaching recovery : 75 [%] PLS : Cu = 8.0 [gpl], Mn = 12.0 [gpl] SX : extraction efficiency 94 [%] EW : current efficiency 95 [%], current density 290 [A/m2] Cathodes production : 62,000 [Ton/y]

Multivariable Modelling for the Cathodic Quality

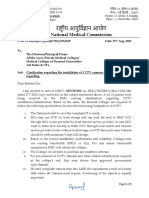

Introduction. � Historically Collahuasi have had excellent quality records: ~ 96% Grade A LME. � Grade A LME : S 15 [ppm] & Pb 5 [ppm]. � Since 2004 an increase of Sulphur (S) in cathodes has affected quality. Pb O.K. � Production/Quality trade-off since 2004 because high copper price.

Out of Specification (S>15, Pb>5) 0,2% 2,4% 9,0%

Grade A LME

Refinery Rejection

2003 2004 2005

97,5% 94,8% 90,0%

2,3% 2,8% 1,0%

On 2005 it was decided to develop an study using an multivariable analysis approach to give clarity on cathodic quality. The SCAN (Contac Ing. Ltda.) software was used.

Multivariable Modelling for the Cathodic Quality

Methodology. SCAN software (off-line version) was used with the following methods:

� � VFA (Variability Factors Analysis) PLS (Partial Least Squares).

Operational data since Jan-2003 to Dec-2005.

Year 2003 was identified as the desired pattern (best quality, production and stability).

VFA analysis defined the pattern model (2003) allowing to compare 2004 and 2005 operation against this model. Variables that most explain the operational drift those years were identified. Sulphuric acid in electrolyte has remain almost constant (~200 [gpl]) during the period, so does not implies the increase of S in cathodes. Using PLS method it was developed a predictive model of Sulphur (S) content in cathodes as function of Cu in outcoming (poor) electrolyte, flow and temperature of incoming electrolyte to cells and current.

Multivariable Modelling for the Cathodic Quality

VFA analysis.

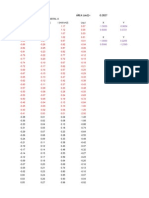

Process variables (21) for the analysis.

CLAVE Fe+2 EEC (gpl) Mn+2 EEC (ppm) T EEC (C) Q SN (m3/hr) Co ER (ppm) Mg ER (ppm) Al ER (gpl) SiO2 ER (ppm) SL. SUS ER (ppm) Cu EP (gpl) AC EP (gpl) Corriente promedio por celda (A) Adicin de Goma Guar (Kg) Adicin Sulfato de Cobalto (Kg) Adicin Sulf_ Ferroso (Kg) Descarte Electrolito (m3/hr) Peso Promedio Ctodos Da (Kg) Cu en Cmara de Lavado (gpl) Temp. cmara lavado (C) PESO BORRA DIARIO (Kg) Guar (gr/ton) VARIABLE Fe+2 en el electrolito entrante a celda (gpl) Mn+2 electrolito entrante a celda (ppm) Temperatura electrolito entrante a celda (C) Caudal electrolito por sector de nave EW (m3/hr) Co+2 electrolito rico (ppm) Mg+2 electrolito rico (ppm) Al electrolito rico (gpl) SiO2 electrolito rico (ppm) Slidos en suspensin electrolito rico (ppm) Cu+2 electrolito pobre (gpl) cido electrolito pobre (gpl) Corriente promedio por celda (A) Adicin de Goma Guar diaria (Kg) Adicin Sulfato de Cobalto diaria (Kg) Adicin Sulfato Ferroso diario (Kg) Caudal de Descarte electrolito (m3/hr) Peso Promedio Ctodos Da (Kg) Cu en Cmara de Lavado (gpl) Temperatura cmara lavado (C) Peso de borra diario (Kg) Adicin Goma Guar por tonelada diaria de ctodos cosechados (gr/ton)

Multivariable Modelling for the Cathodic Quality

VFA analysis. Objective: to reduce the number of variables that explain the process, generating a few variability factors (VF) that explain a high percentage (>70%) of whole process variability.

VARIABILIDAD EXPLICADA

80 70 60 50 40 30 20 10 0 1 2 3 4 5 6 7 8 9 10 11

%VARIABILIDAD EXPLICADA

N VF's

The VFA analysis of 21 variables concludes with 11 VF that explain more than 70% of whole process variability of 2003.

Multivariable Modelling for the Cathodic Quality

VFA analysis. PATTERN MODEL 2003 AND OPERATION MAP 2003

SCORE PLOT 2003

GLOBAL HOTELLING INDEX 2003

Score plots diagrams allow to supervise the 21 process variables jointly. The two first VF (VF1 and VF2) explain 33% of whole process variability.

The Global Hotelling Index measures the degree of belonging for the operational data set to the pattern model defined, establishing a maximum statistical limit 1.

Multivariable Modelling for the Cathodic Quality

VFA analysis. PATTERN MODEL 2003 AND OPERATION MAP 2004

SCORE PLOT 2004 Variable Current in cells Cu+2 poor electrolyte Incoming electrolyte temp. Difference % (*) 328% 275% 227%

GLOBAL HOTELLING INDEX 2003-2004 Effect of decreasing current in cells Effect of gradual increase in electrolyte temperature

(*): (<Hotelling of variable in 2004> - <Hotelling of variable in 2003>)/<Hotelling of variable in 2003>

Multivariable Modelling for the Cathodic Quality

VFA analysis. PATTERN MODEL 2003 AND OPERATION MAP 2005

SCORE PLOT 2005 Variable Incoming electrolyte temp. Current in cells Cu+2 poor electrolyte Difference % (*) 438% 252% 227%

GLOBAL HOTELLING INDEX 2003-2005

Effect of gradual increase in electrolyte temperature

(*): (<Hotelling of variable in 2005> - <Hotelling of variable in 2003>)/<Hotelling of variable in 2003>

Multivariable Modelling for the Cathodic Quality

VFA analysis.

Effect of gradual increase in incoming electrolyte temperature (TEEC)

Multivariable Modelling for the Cathodic Quality

PLS analysis. Objective: to generate a predictive model of output variable as a function of many input variables. By definition the model explains a short-term relationship between the variables. To predict the sulphur (S) content in cathodes the following input variables were chosen:

CLAVE T EEC (C) Q EEC (m3/hr) Cu EP (gpl) I (A) VARIABLE Temperatura electrolito entrante a celda (C) Caudal electrolito entrante a celdas por sector de nave EW (m3/hr) Cu+2 electrolito pobre (gpl) Corriente promedio por celda (A)

For comparison purposes two PLS models of S in cathodes were generated: S2003(ppm) = f TEEC, QEEC, Cu+2EP, I , normal operation S2005(ppm) = f TEEC, QEEC, Cu+2EP, I , high sulphur in cathodes operation

Multivariable Modelling for the Cathodic Quality

PLS analysis. 2003 PLS model for cathodic quality (sulphur content in cathodes):

S ( ppm ) = 0 ,1 T EEC 0 ,2 Q 0 ,2 Cu + 2 + 2 ,7 10 4 I EP EEC + 253

Scaled regression coefficient for each input variable in 2003 PLS model of S

Multivariable Modelling for the Cathodic Quality

PLS analysis. 2005 PLS model for cathodic quality (sulphur content in cathodes):

S ( ppm ) = T EEC 0 .2 Q EEC 0 ,1 Cu + 2 + 5 . 4 10 4 I EP + 365

More stable operation in January-May period, for modelling purposes.

Scaled regression coefficient for each input variable in 2005 PLS model of S

Multivariable Modelling for the Cathodic Quality

Conclusions. � The VFA pattern model for 2003 operation was a good pattern model to represent a normal operation of EW tankhouse. � It can be clearly seen the operational drift of 2004 and 2005 in the score plots compared with the operation in 2003. The evolution of Global Hotelling Index in 2003-2005 period also reflects this behavior. � According to VFA analysis the variables that mainly explain the 2004 operational drift were current in cells (I) and Cu+2 poor electrolyte (Cu+2EP) because its high variability. The third variable was the incoming electrolyte temperature (TEEC). The SX-EW process was disturbed because of major changes in Heaps Leaching process. � Also with the VFA analysis extended to 2005, the variable that becomes more relevant to explain the 2005 operational drift was the incoming electrolyte temperature (TEEC). This variable increased gradually since 2004.

Multivariable Modelling for the Cathodic Quality

Conclusions. � The PLS analysis for 2005 (January-May) also demonstrates the great influence of TEEC over sulphur content in cathodes. It is known that in the short-term temperature favors the transport phenomena, so it was necessary to study the external agents that difficult them. � Considering a long-term analysis, the gradual increase in TEEC also increased the sulphur content in cathodes S (decreasing the quality). This apparent contradiction in the effect of TEEC over S can be solved by the following hypothesis:

�The external agent that difficult transport phenomena is the reagent (Guar Gum) that is used to improve the Cu crystal deposit over the cathode, but in presence of higher temperatures than specification for the reagent. �Guar Gum in presence of higher temperatures rapidly decreases its mean life, generating degraded by-products in the electrolyte. It is not possible to measure the amount of degraded Guar Gum in the electrolyte. �Those degraded by-products generates an irregular Cu deposit over the cathodes body, promoting the occlusion of electrolyte (and hence sulphur) inside cathodes structure. �Electrolyte bleeding in tankhouse can be used to decrease the amount of degraded Guar Gum and hence to improve cathodic quality in terms of sulphur.

You might also like

- Roster MLLDocument13 pagesRoster MLLSantiago Bejarano AlfaroNo ratings yet

- Mineral ADocument5 pagesMineral ASantiago Bejarano AlfaroNo ratings yet

- Aspectos Electroquímicos en Los Procesos HidrometalúrgicosDocument38 pagesAspectos Electroquímicos en Los Procesos HidrometalúrgicosSantiago Bejarano AlfaroNo ratings yet

- ReadmeDocument11 pagesReadmeBlack Vs WhiteNo ratings yet

- Intel (R) Turbo Boost ReleaseNotes 1002Document9 pagesIntel (R) Turbo Boost ReleaseNotes 1002Santiago Bejarano AlfaroNo ratings yet

- A LalalalalalalaDocument1 pageA LalalalalalalaSantiago Bejarano AlfaroNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- TV Antenna Tower CollapseDocument4 pagesTV Antenna Tower CollapseImdaad ChuubbNo ratings yet

- The Fluency Course Teacher Instructions PDFDocument9 pagesThe Fluency Course Teacher Instructions PDFGabriel da RochaNo ratings yet

- Growing Onion Management and Water NeedsDocument25 pagesGrowing Onion Management and Water NeedsKATE NAVAJANo ratings yet

- CCTV Guidelines - Commission Letter Dated 27.08.2022Document2 pagesCCTV Guidelines - Commission Letter Dated 27.08.2022Sumeet TripathiNo ratings yet

- Unit: 1: Newton's Laws of Motion & Principle of Transmissibility of ForceDocument5 pagesUnit: 1: Newton's Laws of Motion & Principle of Transmissibility of ForceKunal SinghNo ratings yet

- Credit Risk ManagementDocument64 pagesCredit Risk Managementcherry_nu100% (12)

- Eu Clinical TrialDocument4 pagesEu Clinical TrialAquaNo ratings yet

- Hansen Aise Im Ch12Document66 pagesHansen Aise Im Ch12Rizki19maretNo ratings yet

- Hailey College of Commerce University of PunjabDocument12 pagesHailey College of Commerce University of PunjabFaryal MunirNo ratings yet

- PBPO008E FrontmatterDocument13 pagesPBPO008E FrontmatterParameswararao Billa67% (3)

- 3 A Sanitary Standards Quick Reference GuideDocument98 pages3 A Sanitary Standards Quick Reference GuideLorettaMayNo ratings yet

- Wits Appraisalnof Jaw Disharmony by JOHNSONDocument20 pagesWits Appraisalnof Jaw Disharmony by JOHNSONDrKamran MominNo ratings yet

- Ezpdf Reader 1 9 8 1Document1 pageEzpdf Reader 1 9 8 1AnthonyNo ratings yet

- Polyembryony &its ImportanceDocument17 pagesPolyembryony &its ImportanceSURIYA PRAKASH GNo ratings yet

- Brachiocephalic Artery: AnteriorDocument37 pagesBrachiocephalic Artery: AnteriorFarah FarahNo ratings yet

- Ladies Code I'm Fine Thank YouDocument2 pagesLadies Code I'm Fine Thank YoubobbybiswaggerNo ratings yet

- Manuscript PDFDocument50 pagesManuscript PDFMartina Mae Benig GinoNo ratings yet

- What Is Terrorism NotesDocument3 pagesWhat Is Terrorism NotesSyed Ali HaiderNo ratings yet

- Things You Can Do at Burnham ParkDocument2 pagesThings You Can Do at Burnham ParkBcpo TeuNo ratings yet

- Abacus 1 PDFDocument13 pagesAbacus 1 PDFAli ChababNo ratings yet

- Your Bentley Bentayga V8: PresentingDocument9 pagesYour Bentley Bentayga V8: PresentingThomas SeiferthNo ratings yet

- 100 IdeasDocument21 pages100 IdeasNo ID100% (1)

- MFD16I003 FinalDocument16 pagesMFD16I003 FinalAditya KumarNo ratings yet

- Tugas Inggris Text - Kelas 9Document27 pagesTugas Inggris Text - Kelas 9salviane.theandra.jNo ratings yet

- Knitting in Satellite AntennaDocument4 pagesKnitting in Satellite AntennaBhaswati PandaNo ratings yet

- El TontoDocument92 pagesEl TontoRobertNo ratings yet

- Ajsl DecisionMakingModel4RoRoDocument11 pagesAjsl DecisionMakingModel4RoRolesta putriNo ratings yet

- A Sample Script For Public SpeakingDocument2 pagesA Sample Script For Public Speakingalmasodi100% (2)

- 5070 s17 QP 22 PDFDocument20 pages5070 s17 QP 22 PDFMustafa WaqarNo ratings yet

- Cutler Hammer Dry Type TransformerDocument220 pagesCutler Hammer Dry Type TransformernprajanNo ratings yet