Professional Documents

Culture Documents

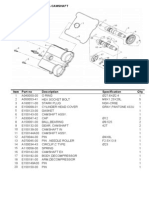

Air Compressors

Uploaded by

herobpo13373Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Compressors

Uploaded by

herobpo13373Copyright:

Available Formats

Air Compressors

Graph of Pressure against volume in a reciprocating compressor

Volumetric efficiency Vh = Actual suction volume Vx/ Theoretical suction volume Vs For greater efficiency air compression should be isothermal as this requires the minimum work input. In practice Isothermal compression is not possible, an ideal Isothermal cycle requires sufficient time to allow all the required heat to be transferred out of the cylinder, practicality dictates that the piston must have a relatively high speed to give a reasonable output, Cylinder cooling on a single stage compressor gives better efficiency but there is a limitation in the surface area to cylinder volume that can be used for cooling effect, but multistage compressors with an efficient extended surface interstage cooler gives cycle improved compression efficiency better approaching that of the isothermal. In theory the greater the number of stages the closer the curve will approach the ideal isothermal compression curve, however there is an increase in cost, complexity, and the law of diminishing returns limit the number. Compression in stages has the following advantages; 1. The compression ratio at each stage is lower and so the final temperature is lower. This reduces problems with lubrication 2. . The machine is smaller and better balanced 3. water can be drained off at each stage 4. Compression better approaches the ideal isothermal It is important that the compressor clearance volume is kept small as possible in order to improve overall volumetric efficiency as the air trapped in this space must expand to below suction pressure before new air can enter, this is an effective loss of stroke. clearance is required in order to prevent the piston striking the cylinder cover when starting or stopping off load. !he clearance volume is sometimes referred to as the "#ump Clearance".

Crankcase lubrication

$ubrication of the crankcase in a compressor does not pose any specific problems and normally consist of splash lubrication with pressurised oil being fed to shell bearings. %here drip cylinder lubrication is used, this should be kept to a minimum conducive with liner wear. standard mineral oil similar to that used in the main engine may be used, although due to carbon deposits, higher quality oils are generally used with the most effective being specifically designed synthetics which have allow a considerable reduction in maintenance but are costly. &ineral oils contain a blend of lighter elements such as paraffin"s, and heavier elements such as asphaltenes. 'uring compression the lighter elements are vaporised leaving the heavy ends, these coat the piston rings and discharge valves in combination with oxidised oil deposits. !hese deposits also coat passage ways and coolers resulting in higher interstage air temperatures. 'eposits on discharge valves cause them to become sticky and leak resulting in hot air being drawn back into the cylinder for recompression. !his increases the temperature and hence causes greater oxidation and deposits, and so the condition deteriorates with increasing rapidity. !emperature can become very high, this may result in oily deposits at the discharge valves carbonising. (ventually this carbon could glow red and cause detonation. It is more likely, however, that oily deposits will be carried over to the air receiver and air start manifold to be ignited by blowpast at the cylinder air start valve. 'eposits at piston rings cause leakage allowing oil to enter the cylinder from the crankcase thus increasing the danger it is essential that crankcase lubrication be kept to a minimum compatible with an acceptable wear rate. )egular maintenance will minimise oily deposits build up and hence the risk of explosion

Materials and design of a reciprocating compressor

!he compressor casing, cylinder covers and piston rings are generally of cast iron. *istons may be of cast iron, steel of aluminium. luminium being the preferred material for use on the $* piston due to its larger diameter. +alves are usually made so that parts can be interchanged between the suction and discharge valves. ,eats are of mild steel with small diameter air passages to prevent the fragments of broken valve plate from entering the cylinder. +alve plates are of vanadium steel heat treated and ground to provided the required hardness and surface finish. ,prings should be arranged such that they lift and seat squarely. -neven spring force or deposits on the seat cause valves to bend resulting in fatigue cracking.

For compressors designed for starting air requirements a water .acket relief valve is fitted.

Rotary Compressor

!he rotary compressor may be of the impeller type similar to that used in the turbocharger , scroll, twin rotating lobes or of the sliding vane type similar to the one shown above. In practice there would be several more vanes than shown. )otary compressors are capable of handling large quantities of low pressure air much more efficiently than a reciprocating compressor. In order to produce increased pressures it is possible to stage rotary compressors but leakage problems increase at higher pressures as well as stress on the vanes.

!he sliding vane compressor consists of a slotted rotor with its axis offset from that of the cylindrical casing. +anes fit in the slots and have contact with the casing /n the suction side the space contained between the casing, the rotor and an ad.acent pair of vanes is gradually increasing allowing air to be drawn in. /n the compression side this same space is gradually reduced causing the pressure increase. %hen the leading vane uncovers the discharge port air will flow to outlet. $arger compressors of this type are water0cooled, smaller compressors tend to be air cooled. !he main problems related with sliding vane compressors concern wear at the vane tips and sealing of the ends

Rotary/reciprocating Compressor

)otary compressors in general do not require internal lubrication but they are not suitable alone for providing air at a pressure for starting duties. !hey can, however, be linked to reciprocating stages to produce a hybrid compressor. !he compressor is lighter, more compact and better balanced than an equivalent all reciprocating unit. In basic terms the rotary first stage supplies air to the reciprocating second and subsequent stages. ll stages being driven by the same shaft

Safety Valve

Materials

Cast iron0Casing, $iners, *istons1 the $* piston is sometimes made from an aluminium alloy, Cylinder covers Steel0 Crankshaft, Conrods, *istons, +alve seats Vanadium Steel0 +alve plates

Starting air compressor circuit

,tarting and stopping sequence is ad.ustable, the magnetic valves are open when the compressor is stopped so any residual pressure is blown off. /n starting the magnetic valve are sometimes delayed to close so as to allow the compressor motor to reach full speed before the compressor is loaded up. !he non0return valves prevent 2* air leaking back from the receiver on which the filling is also of the non return type.

Calculation of re uired cylinder compression for a multistage reciprocating compressor

r ) for r 3 )456 for 3 3 a stage compression two pressure pressure ratio ratio stage

r 3 )457

three

stage

for example, a 7 stage compressor requiring a final pressure of 89bar would have the following interstage pressures 4st stage 4bar compressed to 9bar 6nd stage 9bar compressed to 48bar 7rd stage 48bar compressed to 89bar It would appear that most of the work is being carried out in the final stage, this is untrue as with the increase in pressure is a complimentary reduction in volume, if the temperature conditions remain the same then work will be equally divided between the stages. #y reducing the suction pressure, the cylinder is required to do more work on the air before the discharge valve opens. !his means that the air will be delivered at a higher pressure. !he higher temperature can lead to problems with the cylinder lubrication as well as a drop in efficiency as well as carbonising of the oil and increased deposits on the valves and piston rings and interstage passages. In the extreme it can lead to sei:ure and possible diesel detonation of the oil laden air. !he reduction in pressure at the suction can be due to a partially blocked suction filter or partially choked suction valve. !he lower pressure conditions in the cylinder at the start of compression can cause oil laden air to be drawn from the crankcase up the liner. !his oil can lead to increased deposits in the compressor as well as further downstream in the distribution system 1*4.+4;5 !4 3 1*6. +6;5!6 and

1*45*6;.1!65!4; 3 1+65+4; *4.+4g 3 *6.+6g and From these we get; 1g 04;5g !6 3 1*65*4; g 3 4.9 and if we take for and example *4 3 <.9 bar *6 3 4 bar *f 3 = bar !initial 3 7<< > we end with final temperatures for the two compression"s of !43 84? > and !6 3 9?= > from the graph it can be clearly seen that losses due to the bump clearance has increased and the period of constant pressure delivery has been reduced. *45*6 3 +6g5+4g !4.

Coolers

Plain Tube -easy to clean -very effective due to large surface area of large number small diameter tubes -plugging of failed tube allos cooler to continue in service with little loss in efficiency -must allow for thermal expansion by having one tube plate floating 'U' tube -suitable for higher pressures than plain tube -self compensating for thermal expansion -efficent due to large nomber small diameter tubes -failed tubes may be plugged -more expensive than plain tube and diificult to clean Coil tube -self compensating for expansion -suitable for high pressures -difficult to clean -inefficicent due to large tube diameter - not easy to plug -expensive

You might also like

- Importance of Uniform Air Gap in MotorsDocument1 pageImportance of Uniform Air Gap in Motorsherobpo13373No ratings yet

- Air Coolers: Air Cooler Grid Type Water SeparatorDocument1 pageAir Coolers: Air Cooler Grid Type Water Separatorherobpo13373No ratings yet

- Air ConditioningDocument4 pagesAir Conditioningherobpo13373No ratings yet

- AC SwitchboardsDocument2 pagesAC Switchboardsherobpo13373No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Motor S6S Misutbushit PDFDocument170 pagesMotor S6S Misutbushit PDFArturo Rengifo85% (13)

- PAS WP121L Marine ET - en - GB - 1802Document82 pagesPAS WP121L Marine ET - en - GB - 1802jarekNo ratings yet

- Home Lite Blower Parts ListDocument15 pagesHome Lite Blower Parts ListtackrightNo ratings yet

- Report of Inspection, Testing & Maintenance: of Fire Pump AssembliesDocument6 pagesReport of Inspection, Testing & Maintenance: of Fire Pump AssembliesMatel Franklin AnastaNo ratings yet

- MH114 Air Compressor Manual - Samundra Institute of Air Compressor Manual Matsubara, Vertical 2-StageDocument21 pagesMH114 Air Compressor Manual - Samundra Institute of Air Compressor Manual Matsubara, Vertical 2-StagekelvinNo ratings yet

- Volvo Tad1250 Electric ManualDocument235 pagesVolvo Tad1250 Electric ManualMouloud DerrahiNo ratings yet

- SIS 2.0 Low PowerDocument18 pagesSIS 2.0 Low PowerPETER ADAMNo ratings yet

- PCV Unit 4Document5 pagesPCV Unit 4Abhishek SainiNo ratings yet

- TM 5-3014 Case Si Airborne Tractor With Hough Loader Bucket 1944Document313 pagesTM 5-3014 Case Si Airborne Tractor With Hough Loader Bucket 1944Advocate100% (3)

- Briggs Stratton 1226070210e1Document29 pagesBriggs Stratton 1226070210e1davidNo ratings yet

- SSP376+5 2+Litre+V10+FSI+EngineDocument32 pagesSSP376+5 2+Litre+V10+FSI+EnginePaul Bridges100% (3)

- Air Compressor Damage: 1. TypeDocument2 pagesAir Compressor Damage: 1. TypeRani NoumanNo ratings yet

- KEEWAY 50cc Models: Scooter Service ManualDocument64 pagesKEEWAY 50cc Models: Scooter Service ManualMert AğcaoğluNo ratings yet

- Pra Ukp 1Document35 pagesPra Ukp 1Fauzan FatihNo ratings yet

- Shinddaiwa EB8510 Blower Llustrated Parts ListDocument18 pagesShinddaiwa EB8510 Blower Llustrated Parts ListmsrappNo ratings yet

- Special Service Tools for Lycoming Piston EnginesDocument87 pagesSpecial Service Tools for Lycoming Piston EnginesPatrick Van DammeNo ratings yet

- PM Checklist ReportDocument3 pagesPM Checklist ReportSteven PanyalNo ratings yet

- Assembly and Part Drawing: Water-Cooled Diesel EngineDocument2 pagesAssembly and Part Drawing: Water-Cooled Diesel EngineАлександр ЩеблыкинNo ratings yet

- Buku RX KingDocument7 pagesBuku RX Kingobenk techno100% (2)

- Centro Matic PDFDocument60 pagesCentro Matic PDFparag7676100% (3)

- 8V & 10V QL2 WKSP ManualDocument283 pages8V & 10V QL2 WKSP ManualRicky BurtonshawNo ratings yet

- 4na - Application - Flypartsguy - Com - 5 2019Document23 pages4na - Application - Flypartsguy - Com - 5 2019Kurd SkorvskiNo ratings yet

- Dinli 700 Parts BookDocument45 pagesDinli 700 Parts BookNeacsu Eugen0% (1)

- NAC 250cc Service Manual-English EditionDocument55 pagesNAC 250cc Service Manual-English EditionFabian EtcheniqueNo ratings yet

- Doosan Compressor HP375WJD, XP375WJD and P425WJDDocument126 pagesDoosan Compressor HP375WJD, XP375WJD and P425WJDJonh Dayrus Ventura AlvarezNo ratings yet

- Reciprocating Engine TS TipsDocument5 pagesReciprocating Engine TS TipsEstevamNo ratings yet

- Small Engine: A Step-By-Step Guide To Maintaining Your Small EngineDocument8 pagesSmall Engine: A Step-By-Step Guide To Maintaining Your Small EngineBez ImenaNo ratings yet

- Mercedes Sangyong Section+1A2++M161+Engine PDFDocument254 pagesMercedes Sangyong Section+1A2++M161+Engine PDFjonasNo ratings yet

- Vespa ET4 50 Service Manual Manuale Officina (ENG)Document186 pagesVespa ET4 50 Service Manual Manuale Officina (ENG)Fabrizio Barbato50% (2)

- S35me-B9 5Document348 pagesS35me-B9 5Andre MarthenNo ratings yet